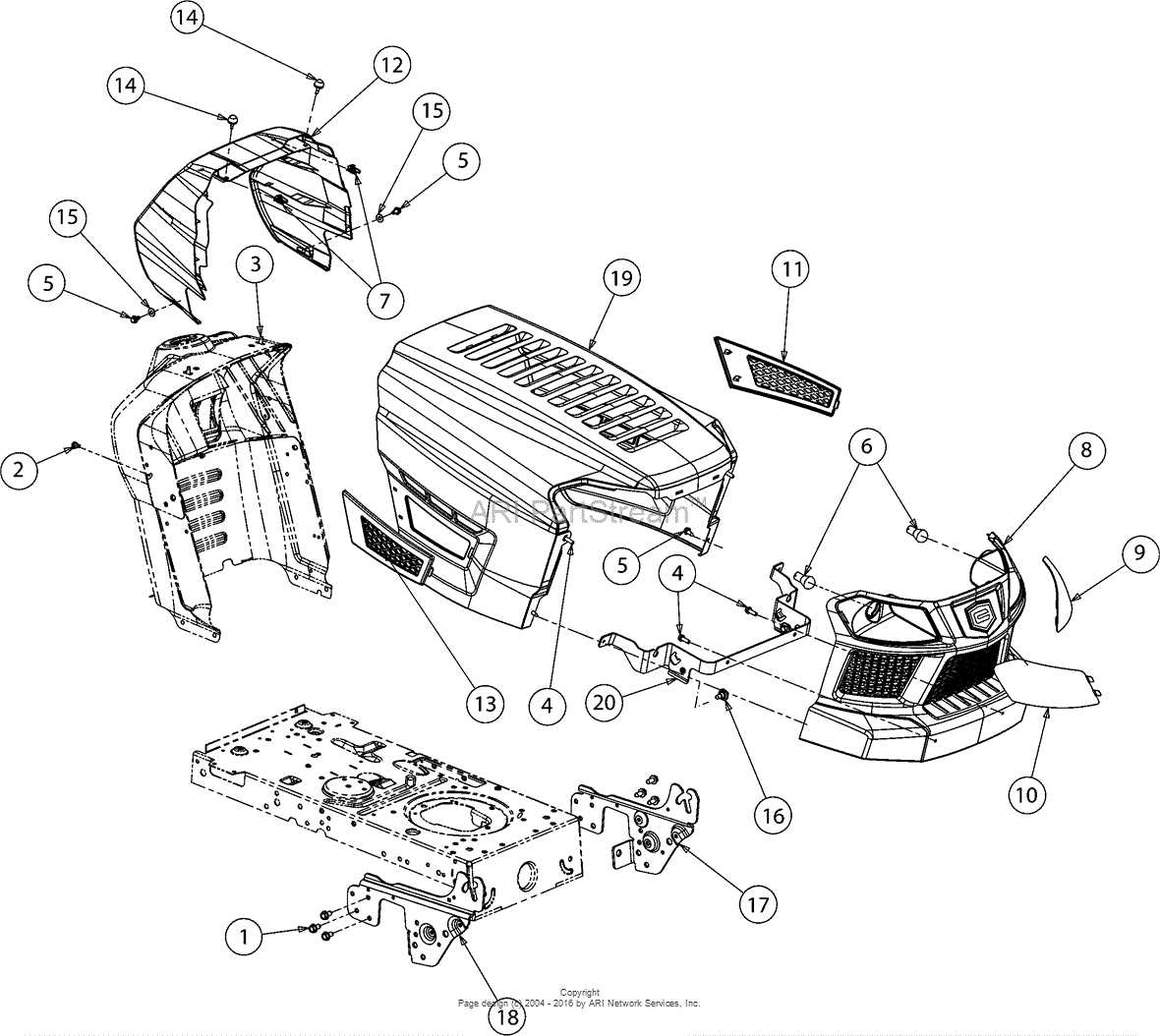

Engine Layout and Key Elements

The internal structure of the engine is organized to ensure efficient power generation and smooth operation. Each component plays a crucial role in maintaining performance and reliability, with an emphasis on optimal energy conversion and durability. Understanding the core elements of the system is essential for regular maintenance and troubleshooting.

Main Components

- Combustion Chamber: This is where the fuel mixture is ignited, producing the power that drives the machine.

- Pistons and Cylinders: These work in tandem to convert the energy from combustion into mechanical movement.

- Crankshaft: Transfers the pistons’ motion into rotational energy, which powers the machine.

- Valves: Control the flow of air and fuel into the chamber and the release of exhaust gases.

Supporting Systems

- Cooling System: Regulates the engine’s temperature to prevent overheating, using air or liquid as a cooling agent.

- Fuel System: Ensures a steady and efficient delivery of fuel to the combustion chamber for consistent power output.

- Ignition System: Sparks the fuel-air mixture to initiate combustion, essential for the engine’s startup and operation.

Understanding the Motor and Connections

The motor plays a central role in powering the machine, converting energy into motion through a complex arrangement of components and wiring. Understanding its structure and how various parts interact helps ensure efficient operation and maintenance. It’s important to familiarize yourself with the connections, as they provide the necessary flow of electricity and ensure the system functions smoothly.

Core Elements of the Motor

The heart of the motor consists of several key elements designed to work together harmoniously. The rotor and stator generate the electromagnetic forces that drive the unit, while the wiring connects these elements to the power source. Each connection is crucial for maintaining stability and avoiding potential issues during operation.

Electrical Connections and Wiring

Wiring links the

Blade System and Cutting Mechanism

The blade system is crucial for the efficient operation of any lawn maintenance equipment. It is designed to deliver precise cuts, ensuring even grass levels and a well-manicured finish. The cutting mechanism works in harmony with the blade structure, providing the necessary rotation and power to trim vegetation effectively.

Blade Design and Material

The blades are crafted from durable materials that withstand continuous use and resist damage from debris or obstacles. Their design varies based on the required cutting precision, allowing for both fine and coarse trimming. Sharpness and alignment are key factors in maintaining optimal performance.

Cutting Efficiency and Maintenance

Proper maintenance of the blades is essential to retain cutting efficiency. Regular sharpening and inspection of the cutting mechanism help prolong the lifespan of the system

How the Mowing Process Works

The process of cutting grass involves a carefully coordinated system that transforms the power generated by the engine into effective and precise lawn maintenance. This mechanism relies on various components working together to achieve a clean and uniform cut, ensuring that the surface is both visually appealing and healthy.

At the heart of this operation lies the cutting mechanism, which typically consists of rotating blades that slice through the grass with speed and efficiency. As the machine moves forward, these sharp edges engage with the grass, trimming it to the desired height. The design of the blades plays a crucial role in determining the quality of the cut, as well as the speed at which the task can be accomplished.

Grass height adjustment is another essential feature, allowing users to customize the cutting height according to their specific needs. This adaptability ensures that different types of grass can be maintained optimally, promoting healthy growth and preventing damage to the lawn.

Additionally, the propulsion system contributes to the overall efficiency of the mowing task. Whether powered by gas or electricity, the engine provides the necessary force to maneuver the device across various terrains, making it versatile for different lawn sizes and conditions.

In summary, the combination of sharp blades, height adjustment features, and a reliable propulsion system ensures that the mowing process is not only efficient but also tailored to the needs of the user and the specific conditions of the lawn.

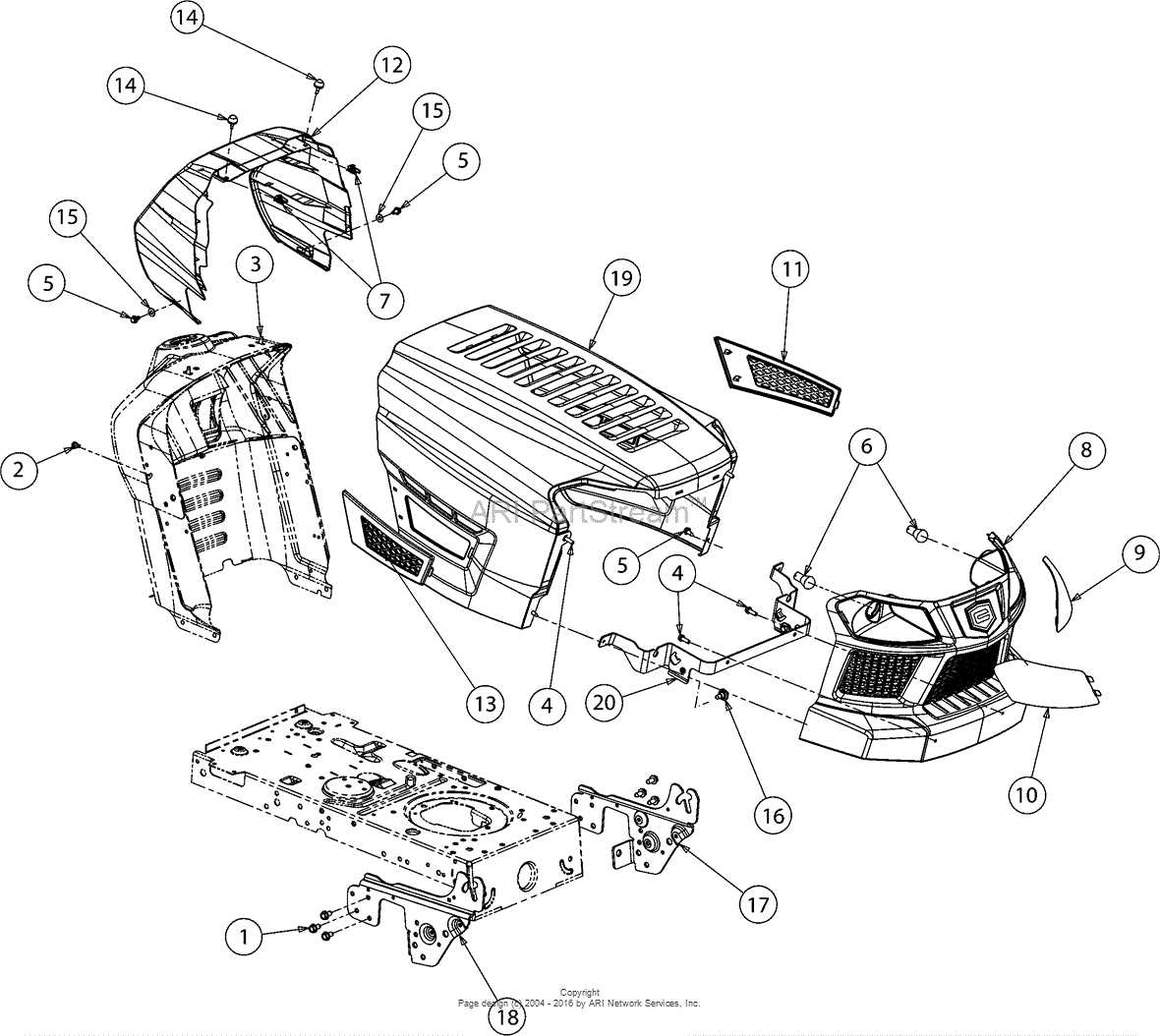

Transmission and Drive Assembly

The transmission and drive assembly plays a crucial role in converting the engine’s power into movement, ensuring smooth operation of the machinery. This complex system consists of various components working in harmony to facilitate efficient energy transfer and performance.

Key elements of the assembly include:

- Gears: These components help regulate speed and torque, allowing for optimized performance across different operational conditions.

- Belts: They connect the engine to the drive mechanism, providing flexibility and reliability in power transmission.

- Sprockets: Essential for transferring rotational force, these parts work closely with chains to maintain effective drive engagement.

- Bearings: They reduce friction and support moving parts, contributing to the overall longevity and efficiency of the system.

Understanding the interplay between these components is vital for maintenance and troubleshooting. Regular inspection and timely replacement of worn parts can prevent larger mechanical failures, ensuring the machine operates at peak performance.

Essential Gears and Movement Control

The intricate mechanisms that govern the functionality of any equipment rely heavily on key components that ensure smooth operation and precision. Among these, gears play a pivotal role in facilitating movement and controlling the device’s performance. Understanding these essential elements is crucial for anyone looking to maintain or enhance their machinery’s efficiency.

Key Components of Movement

At the heart of effective movement control are various types of gears that work in tandem to translate energy into motion. These components vary in size, shape, and function, enabling them to handle different loads and speeds. For instance, gear ratios are critical in determining how power is distributed throughout the system, allowing for either rapid movement or increased torque, depending on the application.

Maintaining Optimal Performance

To ensure that the motion control system operates flawlessly, regular maintenance is essential. This includes checking for wear and tear on the gears, lubricating them appropriately, and replacing any damaged parts promptly. By prioritizing these practices, users can extend the lifespan of their equipment while maintaining optimal functionality.

Electrical Wiring and Ignition System

The electrical circuitry and ignition mechanism play a crucial role in the efficient operation of outdoor power equipment. Understanding these components is essential for ensuring optimal performance and addressing potential issues that may arise during use.

At the heart of the ignition system, various elements work together to generate a spark necessary for engine combustion. This process relies on a series of interconnected wires and components that must function harmoniously. Key components include:

- Ignition coil: Transforms battery voltage into a higher voltage needed for a spark.

- Spark plug: Produces the spark that ignites the air-fuel mixture.

- Flywheel: Contains magnets that interact with the ignition coil to produce voltage.

- Starter solenoid: Engages the starter motor when the ignition switch is activated.

Proper wiring is vital for the reliable operation of these systems. Each wire serves a specific purpose, and any disruption can lead to performance issues. Common wiring components include:

- Connectors: Facilitate secure connections between different electrical components.

- Switches: Control the flow of electricity within the system.

- Fuses: Protect the circuitry by preventing overloads.

- Grounding wires: Ensure safety by directing excess current away from sensitive parts.

Regular inspection and maintenance of the electrical wiring and ignition components can help prevent failures. If issues are detected, troubleshooting should be performed to identify faulty parts or loose connections, ensuring that the equipment operates smoothly and efficiently.

How Power Flows Through the Mower

The efficient operation of a lawn mower relies on a well-coordinated flow of energy throughout its components. Understanding this process is crucial for maintenance and troubleshooting. Energy transfer begins at the engine, where fuel is converted into mechanical power, subsequently propelling various parts of the machine to perform their designated functions.

Power distribution within the mower involves several key elements, each playing a vital role in the overall performance. The main components include the engine, drive system, cutting mechanism, and electrical components. Below is a simplified overview of how energy travels through these systems.

| Component |

Function |

| Engine |

Converts fuel into mechanical energy |

| Transmission |

Transfers power from the engine to the wheels |

| Cutting Deck |

Utilizes blades to cut grass with the power received from the engine |

| Electrical System |

Provides power for starting the engine and operating lights |

Each part of the mower is designed to maximize efficiency, ensuring that energy flows seamlessly from one section to another. Regular maintenance helps keep this energy transfer optimal, allowing for a smooth and effective mowing experience.

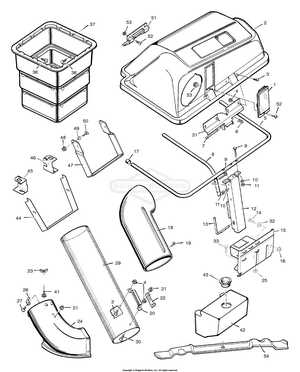

Fuel System and Related Parts

The fuel system plays a crucial role in the efficient operation of small engines, ensuring the proper delivery and atomization of fuel for optimal combustion. Understanding the components involved in this system can aid in maintenance and troubleshooting, enhancing performance and longevity.

Key Components of the Fuel System

This system typically consists of several essential elements, including the fuel tank, lines, filters, and carburetor. Each part works in harmony to store, transport, and mix fuel with air, facilitating the engine’s power generation process. Regular inspection and cleaning of these components are vital to prevent clogs and ensure smooth operation.

Maintenance Tips

To maintain an efficient fuel system, it is advisable to replace filters regularly and check for any leaks in the lines. Additionally, using fresh fuel and following the manufacturer’s recommendations for storage can significantly reduce the risk of fuel-related issues. Proper care ensures that the engine runs smoothly and efficiently, minimizing the likelihood of performance degradation.

Components Involved in Fuel Supply

The efficient operation of any internal combustion engine relies heavily on the intricate system responsible for delivering fuel. This network is composed of various elements that work together to ensure a consistent and reliable flow of fuel to the engine. Each component plays a crucial role in maintaining optimal performance and preventing potential issues that could arise from fuel delivery interruptions.

One of the primary elements is the fuel tank, which stores the fuel until it is needed by the engine. The tank must be properly sealed to prevent leaks and evaporation, ensuring that the fuel remains available. Attached to the tank is the fuel pump, which actively transfers the fuel to the engine. Depending on the design, the pump may operate mechanically or electronically, but its primary function is to maintain the necessary pressure for effective fuel delivery.

Once the fuel is pumped, it passes through filters designed to trap contaminants and impurities. These filters are essential for protecting the engine from damage caused by foreign particles. After filtration, the clean fuel travels through lines to the carburetor or fuel injectors, where it is mixed with air before entering the combustion chamber. This precise mixing is vital for efficient combustion and overall engine performance.

In summary, the components involved in fuel delivery form a complex yet essential network that supports the engine’s functionality. Understanding how these parts interact and contribute to the overall system can help in maintaining and troubleshooting engine performance issues.