In the realm of machinery maintenance and repair, visual representations play a crucial role in comprehending the intricate arrangements of individual elements. Such illustrations serve as valuable guides, facilitating the identification and organization of various components within a specific device. By delving into these visual resources, users can enhance their understanding of how each piece interacts within the larger system.

Effective navigation through these representations allows for more efficient troubleshooting and part replacement. Enthusiasts and technicians alike benefit from having access to detailed layouts, which simplify the process of locating essential elements. As users become familiar with these structures, they can approach repairs with greater confidence and precision.

Ultimately, the clarity offered by these visual aids not only supports successful repairs but also fosters a deeper appreciation for the engineering behind the device. Whether for hobbyists or professionals, exploring these detailed illustrations can elevate one’s skills and knowledge in mechanical maintenance.

Overview of Craftsman T3200 Components

This section provides a comprehensive look at the various elements that make up a specific garden machinery model. Understanding these components is essential for effective maintenance and repair, ensuring optimal performance and longevity.

Key elements include:

- Engine: The heart of the machine, responsible for providing power.

- Transmission: This component facilitates the transfer of power from the engine to the wheels.

- Deck: The base structure that houses the cutting mechanism, crucial for achieving a clean cut.

- Wheels: Essential for mobility, these parts allow for maneuverability across different terrains.

- Controls: The interface used to operate the machine, including steering and speed adjustments.

Each of these components plays a vital role in the functionality and efficiency of the equipment. Familiarity with their locations and functions can enhance user experience and streamline repair processes.

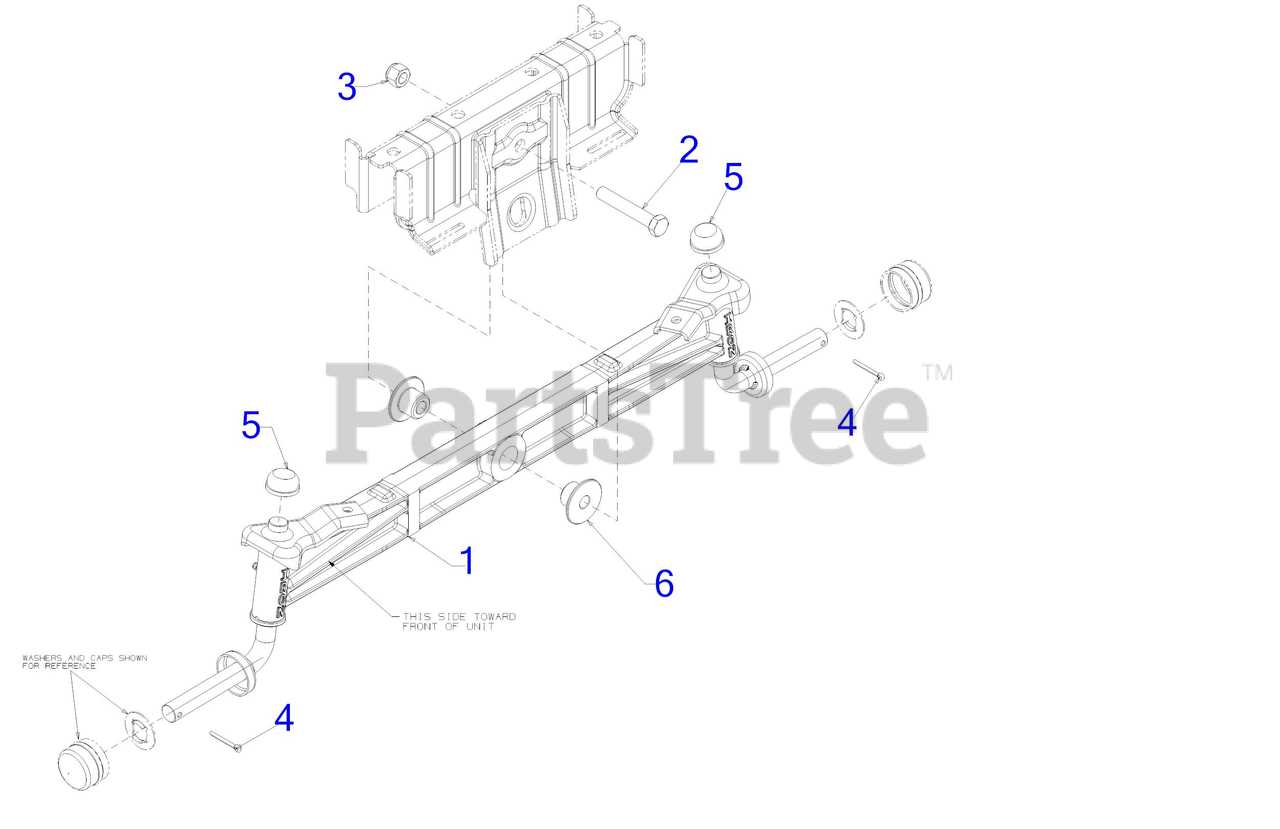

Identifying Key Assembly Parts

Understanding the essential components of a machine’s structure is crucial for effective maintenance and repair. By recognizing the various elements within the assembly, users can enhance their ability to troubleshoot issues and perform necessary upgrades. This section aims to outline the primary components that contribute to the overall functionality.

Primary Components Overview

The assembly consists of several integral units that work together seamlessly. Key elements include the engine block, drive system, and control mechanisms. Each part plays a vital role in ensuring the smooth operation of the equipment. Recognizing these components allows for more efficient diagnostics and repairs.

Benefits of Familiarity

Being knowledgeable about the critical assembly units not only aids in troubleshooting but also empowers users to undertake preventive maintenance. Understanding how these components interact can significantly reduce downtime and improve the longevity of the machinery. Investing time in familiarization with the assembly structure is invaluable for any user.

Functionality of Major Elements

This section explores the essential components of a mechanical system, detailing their roles and interconnections. Understanding how each part contributes to the overall operation is crucial for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Engine | Powers the system, converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, allowing for speed and torque adjustments. |

| Chassis | Supports all components and provides stability during operation. |

| Control System | Facilitates user interaction, enabling adjustments and monitoring of performance. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Cooling System | Regulates temperature to prevent overheating and maintain optimal performance. |

Maintenance Tips for Optimal Performance

To ensure your equipment operates at its best, regular upkeep is essential. Implementing a systematic maintenance routine can significantly enhance functionality and longevity.

- Regular Cleaning: Keep all surfaces free from debris and dirt to prevent blockages and wear.

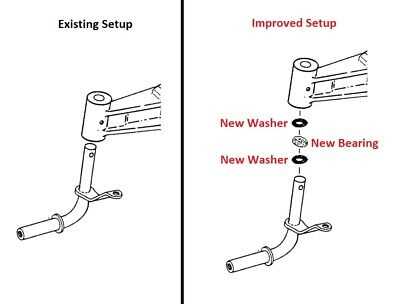

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent rust.

- Inspection: Frequently check components for signs of damage or wear and replace any faulty parts promptly.

By adhering to these guidelines, you can maximize efficiency and ensure reliable performance throughout its use.

Understanding the Wiring Layout

A comprehensive grasp of the electrical connections within a machine is crucial for effective troubleshooting and maintenance. This section delves into the intricate arrangement of wires and their respective functions, providing insights into how the various components interact with one another. By familiarizing yourself with this configuration, you can enhance your understanding of the overall system’s operation.

Key Components and Their Functions

The wiring framework consists of several vital elements, each serving a specific role. Power sources, switches, and connectors are essential for ensuring that energy flows smoothly throughout the unit. Recognizing the purpose of each component helps in diagnosing issues and performing repairs efficiently.

Common Wiring Issues

Various complications may arise within the wiring system, including loose connections, frayed wires, and short circuits. Identifying these problems early can prevent further damage and maintain optimal performance. Regular inspections and a clear understanding of the wiring layout are key to preserving the functionality of the equipment.

Exploring Engine Specifications

This section delves into the key attributes and functionalities of a specific type of motor utilized in various outdoor machinery. Understanding these specifications is crucial for maintenance, performance enhancement, and ensuring optimal operation.

Key components that define the engine’s performance include:

- Displacement: Refers to the total volume of all cylinders.

- Power Output: The amount of power produced, usually measured in horsepower.

- Torque: Indicates the rotational force the engine generates.

- Fuel Type: Specifies the kind of fuel required for operation.

Additional factors to consider are:

- Cooling System: Determines how heat is managed during operation.

- Lubrication: Essential for minimizing wear and ensuring longevity.

- Starting Mechanism: Can influence ease of use and reliability.

By familiarizing oneself with these specifications, users can better understand how to care for and optimize their equipment.

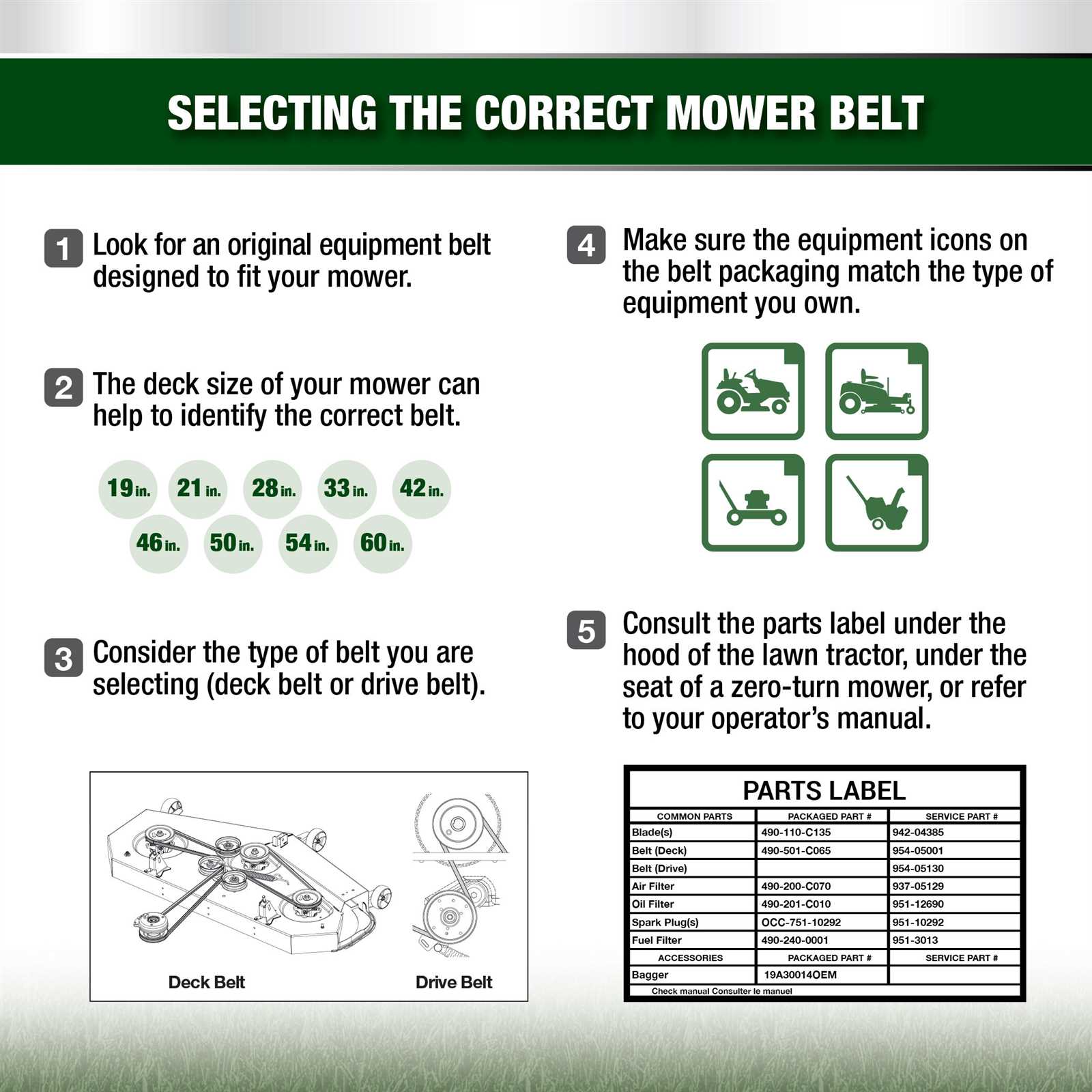

Parts Compatibility and Substitutes

Understanding the interchangeability of components is essential for maintaining optimal performance in various machinery. When original components are unavailable, identifying suitable alternatives can ensure continued functionality without compromising quality.

When considering replacements, take into account the following factors:

- Specifications: Ensure that the dimensions and operational parameters match the requirements of your equipment.

- Manufacturer Recommendations: Always consult guidance from manufacturers to find compatible options.

- Material Quality: Opt for substitutes made from durable materials to avoid premature failure.

Below are potential sources for alternative components:

- Local hardware stores often stock universal replacements.

- Online marketplaces provide a wide range of compatible options.

- Specialty retailers may offer components specifically designed for similar machinery.

By thoroughly researching and selecting appropriate substitutes, you can ensure that your equipment remains functional and reliable.

Common Issues and Solutions

In any mechanical device, users may encounter a variety of challenges that can affect performance and functionality. Understanding these common problems, along with their potential solutions, can enhance the overall experience and ensure efficient operation.

Frequent Challenges

- Engine starting difficulties

- Uneven cutting or poor performance

- Excessive vibrations during operation

- Battery drainage issues

Effective Solutions

- For starting issues, check the fuel supply and ensure the ignition system is functioning correctly.

- To address uneven cutting, inspect the blades for damage or dullness and make necessary adjustments.

- If vibrations are excessive, examine the mounting points and components for wear or misalignment.

- In cases of battery drainage, confirm that the charging system is operational and the connections are secure.

Tools Required for Assembly

When undertaking the assembly of mechanical components, having the right instruments at your disposal is essential for achieving optimal results. A well-equipped workspace can significantly streamline the process, making it more efficient and enjoyable.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for connecting and securing various elements. These instruments allow for precise adjustments and ensure that every component fits snugly, promoting durability and functionality.

Power Tools for Efficiency

Incorporating power tools like drills and impact drivers can expedite the assembly process, especially when dealing with numerous fasteners. These tools provide the necessary torque and speed, reducing manual effort and time spent on each connection.

Safety Precautions During Repair

When engaging in maintenance tasks, prioritizing safety is essential. Ensuring a secure environment can prevent accidents and injuries while working with machinery and tools.

Before beginning any repair work, it’s crucial to wear appropriate personal protective equipment. This includes gloves to shield hands from sharp edges and goggles to protect the eyes from debris. Additionally, ensuring that the workspace is well-lit and organized minimizes the risk of mishaps.

Always disconnect power sources before attempting repairs. This practice safeguards against electrical shocks and accidental startups. Familiarizing oneself with the equipment and its components can also aid in identifying potential hazards.

Moreover, using tools correctly and maintaining them in good condition is vital. Dull or damaged tools can lead to slips and injuries, so regular inspections should be part of the repair routine.

Lastly, keeping a first aid kit nearby is a prudent measure. In case of minor injuries, quick access to medical supplies can make a significant difference in response time and care.