When it comes to maintaining and repairing your machinery, having a clear reference can significantly simplify the process. Visual aids play a crucial role in helping users navigate the complex assembly of various components, ensuring that each part is correctly identified and understood. A comprehensive visual representation allows for efficient troubleshooting and enhances the overall maintenance experience.

In this section, we will explore an insightful reference that details the arrangement and function of individual elements within your device. By breaking down the intricate relationships between various sections, this guide serves as a valuable tool for both novice users and seasoned technicians alike. The clarity provided by such illustrations can greatly reduce the time spent on repairs and upkeep.

Whether you are looking to replace a worn-out section or simply wish to familiarize yourself with your equipment, a well-structured visual reference is indispensable. It not only aids in recognizing specific components but also fosters a deeper understanding of how each part contributes to the overall functionality of the machinery.

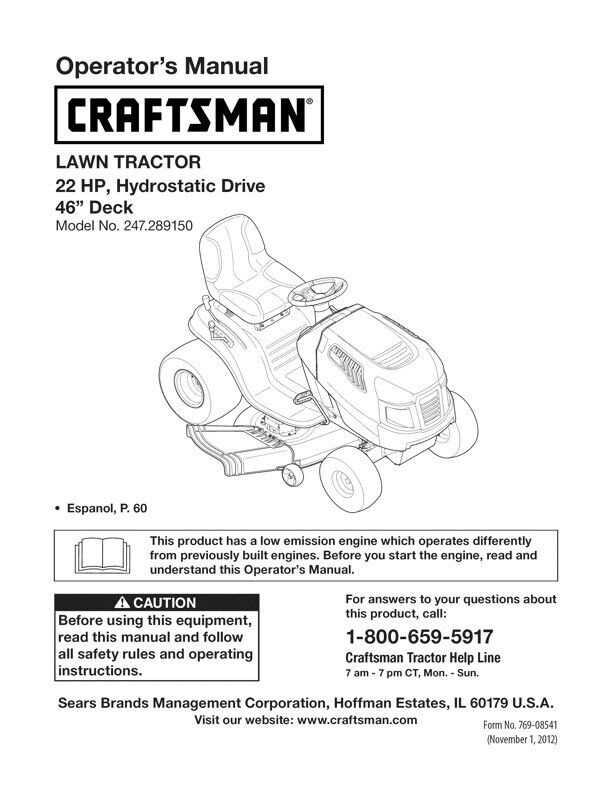

Understanding the Craftsman YS 4500

This section explores the key features and components of a specific lawn care machine, focusing on its design, functionality, and overall utility. By examining the intricacies of this equipment, users can enhance their maintenance practices and improve operational efficiency.

Key Features

- Powerful engine for optimal performance

- Ergonomic design for user comfort

- Advanced cutting technology for precision

- Durable materials ensuring longevity

Maintenance Tips

- Regularly check and replace oil

- Inspect and clean air filters

- Sharpen or replace blades as needed

- Ensure tires are properly inflated

Key Features of the YS 4500

This section highlights the standout characteristics of a popular lawn maintenance tool, emphasizing its innovative design and user-friendly attributes. The focus is on how these features contribute to efficiency and overall performance, making it a preferred choice for many users.

Design and Ergonomics

The equipment is crafted with user comfort in mind. Its ergonomic handles and balanced weight distribution ensure a comfortable grip during extended use. This thoughtful design minimizes fatigue and enhances control, allowing for precise maneuvering in various terrains.

Performance and Versatility

Equipped with a powerful engine, this model delivers robust performance, ensuring that even tough tasks are completed efficiently. The versatility of this tool allows it to adapt to different landscaping needs, making it suitable for both residential and commercial use.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine designed for heavy-duty tasks. |

| Ergonomic Design | Comfortable handles to reduce strain during operation. |

| Versatility | Can tackle various lawn care tasks with ease. |

| Durability | Constructed with high-quality materials for long-lasting use. |

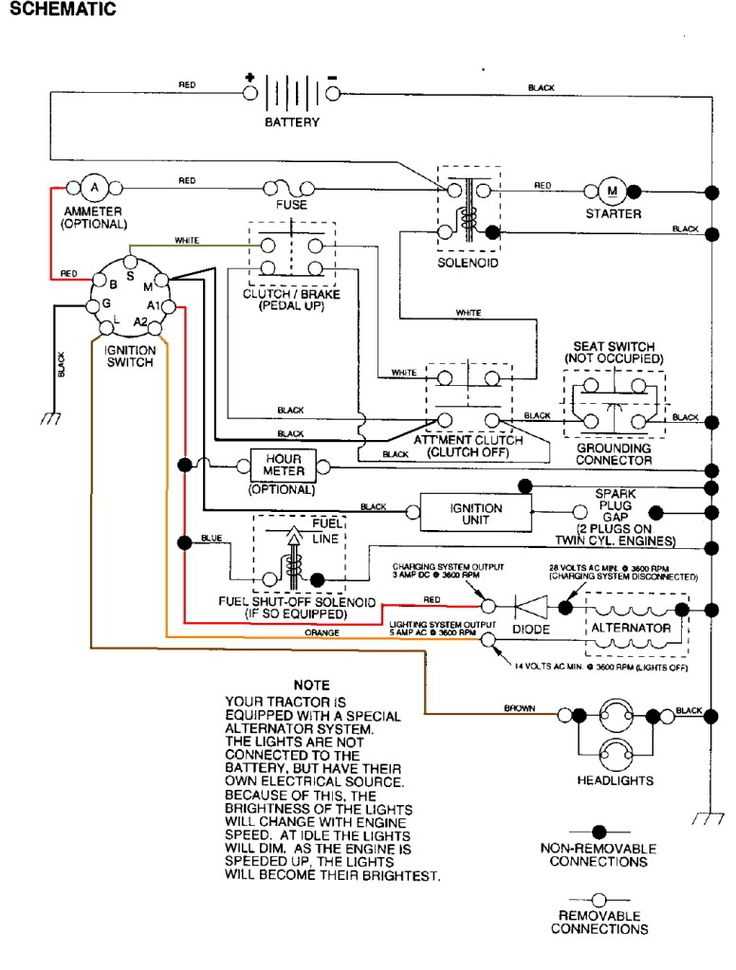

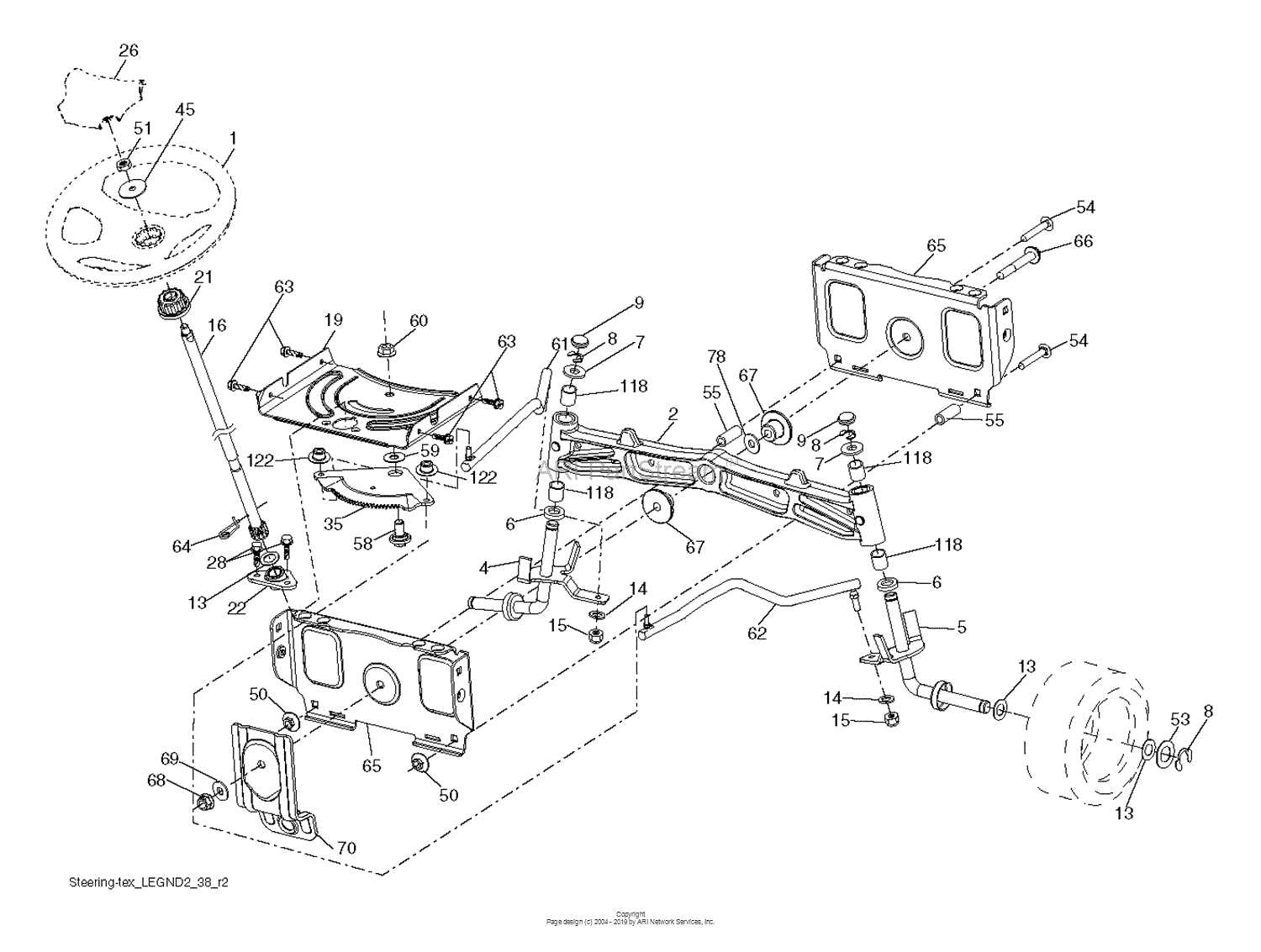

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of complex machinery. They provide users with essential insights into how various elements fit together, ensuring efficient maintenance and repair.

Benefits of Visual Guides

- Enhances comprehension of structure and layout.

- Facilitates identification of individual elements.

- Streamlines the troubleshooting process.

- Improves communication between users and service professionals.

Efficiency in Repair and Maintenance

- Enables quicker access to necessary components.

- Reduces the likelihood of errors during assembly.

- Promotes systematic approaches to problem-solving.

Common Issues with Craftsman Mowers

When operating lawn equipment, users often encounter several recurring problems that can hinder performance and efficiency. Understanding these challenges is essential for effective maintenance and smooth operation.

Engine Performance Problems

One of the most frequent issues involves engine difficulties, which can stem from various factors, including fuel quality, spark plug conditions, and air filter cleanliness. Regular checks can prevent these complications.

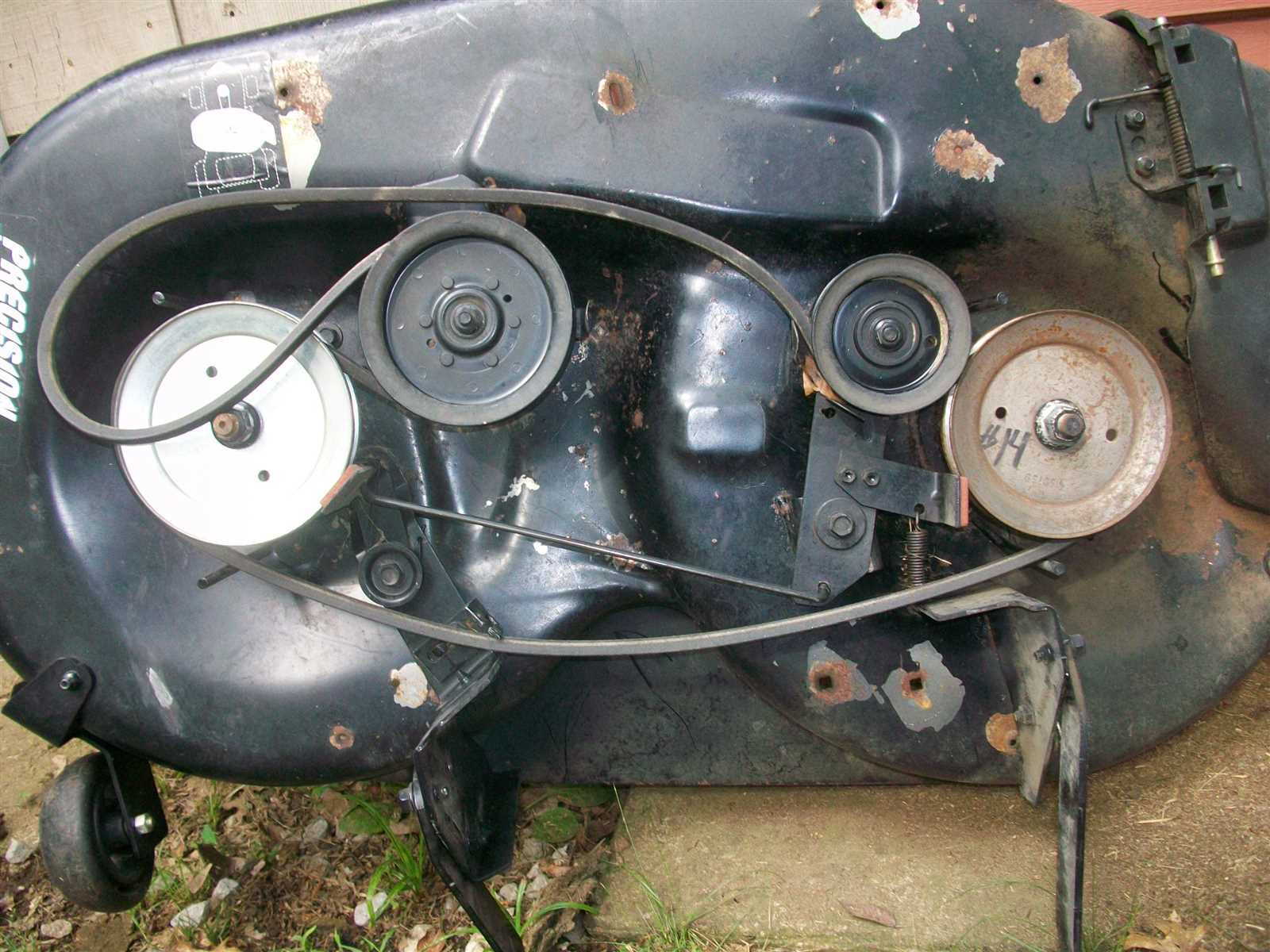

Cutting and Mowing Challenges

Another common concern is related to cutting effectiveness. Dull blades, improper deck height, or uneven terrain can lead to subpar results. Keeping blades sharp and maintaining correct settings is crucial for optimal lawn care.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Empty fuel tank | Refill with fresh fuel |

| Dull cutting | Worn blades | Sharpen or replace blades |

| Uneven cut | Incorrect deck height | Adjust deck settings |

How to Access the Parts Diagram

Finding the visual guide for your equipment’s components is essential for effective maintenance and repair. This resource helps you identify each piece and understand its role, ensuring you can perform tasks efficiently.

Online Resources

Many manufacturers provide comprehensive guides on their official websites. To locate the necessary visuals:

- Visit the official site of the manufacturer.

- Navigate to the support or service section.

- Enter the model number in the search bar.

- Look for a section dedicated to manuals or schematics.

Community Forums and Groups

Online forums and social media groups can be valuable sources of information. Here’s how to utilize them:

- Join relevant groups on platforms like Facebook or Reddit.

- Post inquiries about the visual layout of your specific model.

- Share insights or download resources shared by other members.

Accessing this information can simplify troubleshooting and enhance your understanding of the equipment, ultimately saving you time and effort during repairs.

Essential Tools for Maintenance

Proper upkeep of equipment and machinery relies heavily on having the right tools at hand. These instruments not only facilitate repairs but also enhance the longevity and efficiency of your devices. A well-equipped workspace ensures that tasks can be performed swiftly and effectively, minimizing downtime and improving overall productivity.

Basic Hand Tools

Hand tools are fundamental for any maintenance job. They provide the versatility needed for various tasks, from simple adjustments to complex repairs. Here are some of the must-have hand tools:

| Tool | Function |

|---|---|

| Screwdriver Set | For tightening or loosening screws. |

| Wrench Set | To grip and turn nuts and bolts. |

| Pliers | For gripping, twisting, and cutting wires. |

| Hammer | To drive nails or break apart objects. |

| Utility Knife | For cutting various materials with precision. |

Power Tools

In addition to hand tools, power tools can greatly enhance efficiency during maintenance tasks. They enable users to tackle larger jobs with less physical effort and in a shorter time. Key power tools include:

| Tool | Function |

|---|---|

| Drill | For making holes and driving screws. |

| Saw | To cut through various materials, including wood and metal. |

| Angle Grinder | For grinding, cutting, and polishing surfaces. |

| Impact Driver | For driving screws into tough materials with high torque. |

| Rotary Tool | For precision tasks such as engraving and sanding. |

Identifying Replacement Parts Easily

When it comes to maintaining outdoor equipment, recognizing the right components is essential for efficient repairs and replacements. Understanding how to navigate the various elements of your machine can save time and reduce frustration. By familiarizing yourself with the key features and typical issues associated with your equipment, you can streamline the process of finding what you need.

One effective approach is to consult a detailed schematic that outlines each component’s location and function. Such visual aids provide clarity and help you pinpoint which items require attention. Additionally, keeping a record of model specifications and any previous repairs can assist in quickly identifying necessary replacements in the future.

Moreover, engaging with online communities and forums dedicated to equipment maintenance can be invaluable. Enthusiasts often share insights and resources, enhancing your understanding of common problems and solutions. Leveraging these tools will empower you to tackle repairs confidently and efficiently.

Ordering Craftsman Parts Online

In today’s digital age, acquiring components for tools and equipment has never been easier. The convenience of online shopping allows enthusiasts and professionals alike to find the necessary items from the comfort of their homes. With a few clicks, one can navigate through various platforms to locate the specific pieces required for repairs or upgrades.

Finding Reliable Sources

When searching for the right components, it’s essential to choose trustworthy websites that specialize in equipment supplies. Look for platforms with user reviews, detailed product descriptions, and clear return policies. Checking for authorized dealers can also ensure the authenticity of the items purchased.

Ensuring Compatibility

Before placing an order, verify that the selected components are compatible with your equipment. Most online retailers provide tools or guides to help with this process. Double-checking model numbers and specifications can save time and prevent potential issues down the line.

DIY Repair Tips for Beginners

Engaging in home repairs can be an empowering experience, allowing you to save money and learn valuable skills. Whether you’re fixing a tool or tackling a household project, a systematic approach can simplify the process and enhance your confidence.

Understanding Your Tools

Before diving into any repair, familiarize yourself with the necessary tools. Basic instruments like screwdrivers, wrenches, and pliers are essential. Learn their functions and proper handling to ensure safety and effectiveness during your projects.

Step-by-Step Approach

Take your time to analyze the issue at hand. Start by disassembling the object carefully and documenting each step. This methodical approach helps you avoid confusion when reassembling. Always keep safety in mind and consult resources for guidance when needed.

Upgrading Components for Performance

Enhancing the functionality of your equipment can significantly improve its overall efficiency and effectiveness. By focusing on specific elements, you can elevate performance, extend the lifespan of the machinery, and create a more satisfying user experience. This approach not only maximizes output but also ensures that you are getting the most value from your investment.

Identifying Key Areas for Improvement

To begin the enhancement process, it’s crucial to pinpoint which components have the most impact on performance. Look for parts that are commonly subjected to wear and tear, such as engines and transmissions. Upgrading these areas can lead to smoother operation and better responsiveness, making your work more efficient.

Selecting High-Quality Alternatives

Once you have identified the components that require attention, the next step is to select superior alternatives. Investing in high-quality replacements can drastically improve reliability and efficiency. Consider options that are designed for enhanced durability and performance. Doing so will not only enhance current capabilities but also contribute to lower maintenance costs in the long run.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both the individual performing the work and the surrounding environment. By following specific guidelines, one can minimize risks and enhance the efficiency of repair activities. Here are essential precautions to consider.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-lit and organized to avoid accidents and facilitate a clear workflow.

- Disconnect power sources before beginning any repair to prevent electrical shocks or accidental startups.

Taking a moment to assess potential hazards can significantly reduce the likelihood of injuries. Here are some common safety practices to follow:

- Read and understand the manufacturer’s instructions before starting any work.

- Keep tools in good condition and use them as intended.

- Store hazardous materials properly and keep them away from children and pets.

- Maintain a first aid kit readily available in case of emergencies.

By adhering to these guidelines, you can create a safer environment while effectively completing necessary repairs.

Resources for Further Assistance

When seeking additional guidance on maintenance and repairs, there are various valuable sources to explore. These resources can provide insights, detailed instructions, and community support, ensuring you have all the information needed for effective troubleshooting.

Online Forums: Engaging in dedicated discussion platforms allows users to exchange experiences and advice. Here, you can connect with enthusiasts who have faced similar challenges.

Instructional Videos: Video tutorials are incredibly helpful for visual learners. Numerous platforms host content that covers everything from basic upkeep to complex repairs.

Official Manuals: Manufacturer documentation often contains essential guidelines and specifications. Accessing these resources can clarify intricate details about operation and care.

Local Repair Shops: Consulting with professionals in your area can provide hands-on assistance and expertise, ensuring that your machinery is handled with care and knowledge.

Utilizing these resources can ultimately enhance your understanding and efficiency in maintenance tasks.