In the realm of machinery and equipment, having a comprehensive understanding of the various elements that contribute to optimal functionality is essential. Each component plays a crucial role, and knowing how they interconnect enhances not only maintenance practices but also overall performance. This knowledge is invaluable for both enthusiasts and professionals alike.

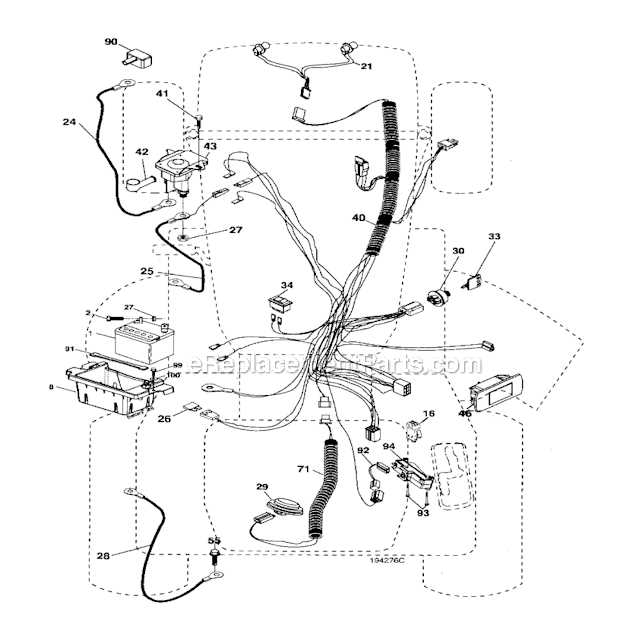

Effective navigation through technical schematics empowers users to diagnose issues swiftly and efficiently. By delving into the intricacies of individual components and their interactions, one can better appreciate the design and engineering behind the equipment. Additionally, recognizing the specific roles of each element aids in ensuring proper repairs and replacements when necessary.

Utilizing visual representations of mechanical assemblies can significantly simplify complex processes. These guides provide clarity, allowing users to visualize how parts fit together and function as a cohesive unit. As a result, familiarity with these resources not only facilitates successful repairs but also enhances the user’s confidence in managing their equipment.

Understanding Craftsman YS4500 Components

This section delves into the various elements that comprise a popular riding mower model, focusing on their functions and significance. Recognizing these components enhances the user’s ability to maintain and troubleshoot the machine effectively.

Key Elements of the Mower

- Engine: The powerhouse responsible for propelling the mower and powering its various features.

- Transmission: This mechanism transmits power from the engine to the wheels, allowing for smooth movement and speed control.

- Deck: The cutting platform where the blades are housed, crucial for achieving an even cut.

- Blades: Sharp instruments designed to slice through grass efficiently, influencing the overall cutting performance.

- Battery: Provides electrical energy to start the engine and power various electrical components.

Additional Components to Consider

- Wheels: Essential for mobility, supporting the weight of the mower and ensuring stability on various terrains.

- Fuel System: Comprises the tank, lines, and filter, responsible for delivering fuel to the engine.

- Steering Mechanism: Allows the operator to navigate and control the mower’s direction.

- Safety Features: Includes mechanisms that prevent operation under unsafe conditions, enhancing user protection.

Overview of Essential Parts

This section provides an insight into the fundamental components that contribute to the efficient operation of the machinery. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity.

Key components include the engine, which powers the entire system, and the transmission, responsible for transferring power to the wheels. Additionally, the chassis serves as the framework that supports all other elements, providing stability and strength. Other notable elements are the electrical system, essential for starting the engine and powering various features, and the deck, which houses the cutting mechanism for effective lawn care.

Familiarity with these crucial components not only aids in identifying potential issues but also enhances the user’s ability to perform necessary repairs or upgrades efficiently. Regular inspection and understanding of each part’s function contribute significantly to maintaining the overall health of the equipment.

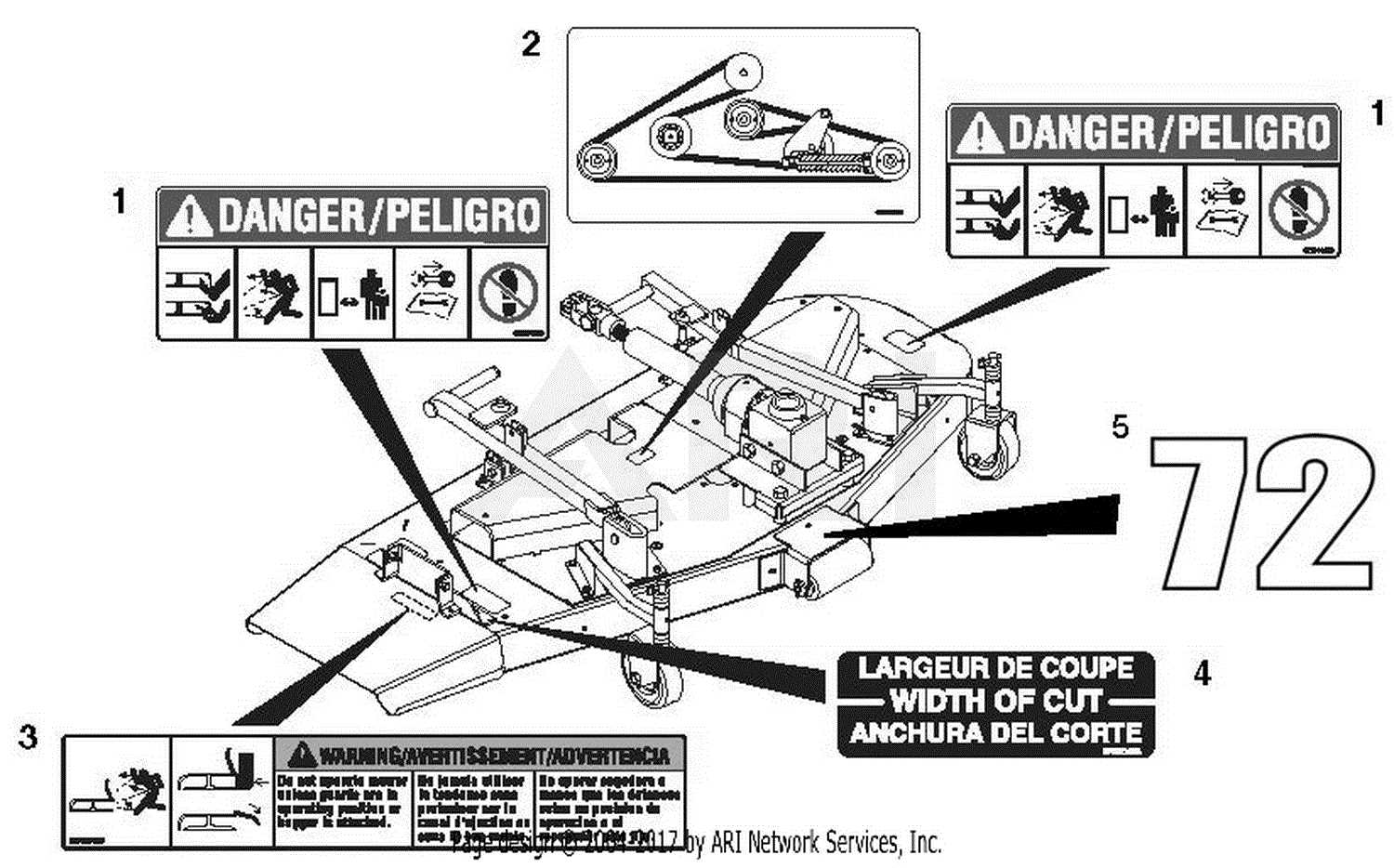

Importance of Accurate Diagrams

Detailed illustrations play a crucial role in ensuring the proper assembly, maintenance, and repair of mechanical systems. They serve as essential guides that help users understand complex structures and components, allowing for efficient troubleshooting and effective communication between technicians.

Having precise visual representations can greatly enhance the following aspects:

- Clarity: Clear illustrations provide a straightforward understanding of the layout and interconnections of various elements.

- Efficiency: Accurate visuals enable quicker identification of components, reducing the time spent on repairs or replacements.

- Safety: Proper representations help prevent incorrect handling of parts, minimizing the risk of accidents during maintenance.

- Documentation: Well-documented visuals serve as valuable references for future repairs and modifications.

In summary, well-crafted visuals are indispensable for anyone involved in the upkeep and enhancement of mechanical systems, ensuring tasks are executed with precision and confidence.

Identifying Common Replacement Components

When maintaining or restoring outdoor equipment, recognizing frequently needed replacement items is crucial for ensuring optimal performance. Understanding the most common components that may require replacement helps users efficiently source and install them, prolonging the lifespan of the machinery.

Below is a table highlighting typical replacement components along with their respective functions and potential signs indicating the need for a replacement:

| Component | Function | Signs of Replacement Need |

|---|---|---|

| Air Filter | Ensures clean air intake for optimal engine performance. | Visible dirt buildup or decreased engine power. |

| Spark Plug | Ignites the air-fuel mixture within the engine cylinder. | Difficulty starting or engine misfires. |

| Blades | Cuts grass and vegetation effectively. | Signs of wear, such as dull edges or nicks. |

| Batteries | Powers the electrical components of the equipment. | Slow cranking or failure to start the machine. |

| Drive Belts | Transfers power from the engine to the wheels. | Squealing noises or visible cracks in the belt. |

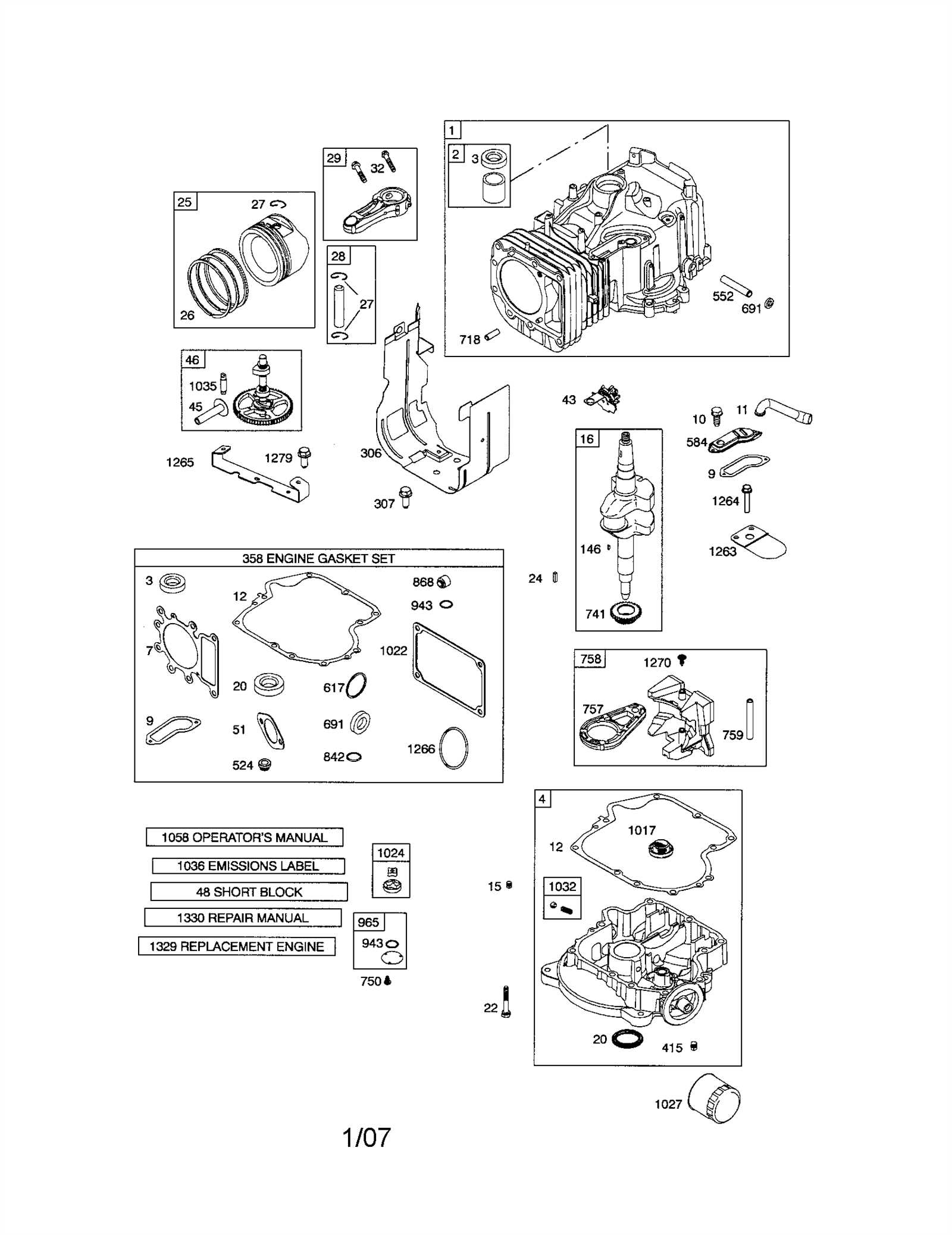

Tips for Using Parts Diagrams

Utilizing visual representations of component layouts can significantly enhance your understanding of machinery and its intricacies. These illustrations serve as invaluable resources, guiding users through the identification and replacement of various elements, thereby facilitating maintenance and repairs.

Understanding the Layout

Familiarizing yourself with the structure of these visuals is crucial. Each section typically indicates the location and function of components, making it easier to locate specific items. Pay attention to any accompanying annotations, as they often provide essential details regarding specifications and compatibility.

Organizing Your Approach

When planning repairs or replacements, consider creating a checklist based on the visual aid. This strategy not only helps in acquiring the necessary components but also ensures that you systematically address each part of the machine. Below is a sample checklist template:

| Component Name | Quantity Needed | Notes |

|---|---|---|

| Component A | 1 | Check compatibility |

| Component B | 2 | Inspect for wear |

| Component C | 1 | Order online |

Maintenance Guidelines for Longevity

Proper upkeep is essential for ensuring the extended life and reliable performance of any mechanical equipment. Regular maintenance not only enhances efficiency but also prevents unforeseen breakdowns and costly repairs.

Here are some key recommendations for effective maintenance:

- Routine Inspections: Conduct regular checks on all components to identify wear and tear.

- Cleaning: Keep all surfaces clean and free from debris to prevent accumulation that can affect performance.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and wear.

- Fluid Levels: Regularly check and maintain the appropriate levels of fluids, including oil and fuel.

- Filter Replacement: Change filters periodically to ensure optimal airflow and engine performance.

Following these practices will significantly contribute to the longevity of your equipment, ensuring it remains in excellent working condition for years to come.

Step-by-Step Assembly Instructions

Assembling your equipment requires careful attention to detail and a clear understanding of the components involved. Following a systematic approach can ensure that each part is correctly positioned and securely fastened, leading to optimal performance.

1. Gather Necessary Tools: Before beginning, collect all the tools needed for assembly. Common items include wrenches, screwdrivers, and pliers.

2. Review the Component List: Familiarize yourself with each element that will be used during assembly. This will help you identify parts and avoid confusion.

3. Begin with the Base: Start by securing the base structure. Ensure that it is level and stable before adding other components.

4. Attach the Frame: Carefully position the frame onto the base. Align the holes and fasten using bolts or screws as per your guide.

5. Install the Engine: Follow the specified instructions to place the engine securely. Pay attention to connections, ensuring that cables are routed correctly.

6. Connect the Drive System: Attach the drive components, making sure they are firmly connected and that no parts are obstructing movement.

7. Finalize with Accessories: Complete the assembly by adding any additional features or accessories. Check that all parts are properly secured and functioning as intended.

8. Conduct a Thorough Inspection: After assembly, inspect the entire unit for any loose fittings or misalignments. This step is crucial for safety and performance.

Common Issues and Solutions

When operating outdoor machinery, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems and their respective solutions can help maintain optimal functionality and extend the lifespan of the equipment. Below are several typical issues and effective remedies.

Starting Difficulties

One prevalent concern is trouble starting the machine. This can stem from several factors, including a drained battery, faulty ignition components, or old fuel. To resolve this issue, check the battery for charge and connections, replace any worn-out ignition parts, and ensure the fuel is fresh and appropriate for the equipment.

Uneven Cutting Performance

Another frequent issue is inconsistent cutting, which can result from dull blades, improper height adjustments, or debris buildup under the cutting deck. To address this, regularly sharpen the blades, adjust the cutting height according to the grass type, and clean the deck thoroughly after each use to prevent clogs and improve performance.

Where to Purchase Parts

When it comes to maintaining your outdoor equipment, finding reliable sources for components is essential. Whether you are looking for original or aftermarket options, there are several avenues to explore that can provide you with the necessary items to keep your machinery running smoothly.

Online Retailers: Numerous e-commerce platforms specialize in outdoor machinery supplies. Websites such as Amazons, eBay, and dedicated tool suppliers often have a wide selection. Ensure to read reviews and check ratings before making a purchase to guarantee quality.

Local Hardware Stores: Many community hardware stores carry essential supplies for outdoor equipment. Visiting these shops not only allows you to inspect items before buying but also gives you the opportunity to seek advice from knowledgeable staff.

Authorized Dealers: Another option is to reach out to authorized dealers. These establishments typically offer genuine components and have a reputation for providing excellent customer service. They can also assist you in identifying the correct components for your model.

Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove. Many of these places offer pre-owned components at a fraction of the cost, making them an attractive choice for cost-conscious individuals.

Comparative Analysis of Similar Models

When examining various lawn care machines, it becomes essential to assess the similarities and differences among different models to identify their unique strengths and weaknesses. This analysis provides insights into performance, features, and overall user satisfaction, helping potential buyers make informed decisions.

Performance Metrics

The performance of these machines can vary significantly based on engine power, cutting width, and maneuverability. For instance, models with higher horsepower typically offer better performance on uneven terrains, while those with wider cutting decks can cover more ground in less time. Evaluating these aspects allows users to select the most suitable option for their specific needs.

Feature Comparison

Another critical factor in this comparison is the range of features offered by each model. Some machines may include advanced cutting technology, enhanced steering mechanisms, or user-friendly controls. By analyzing these features, one can determine which model provides the best combination of functionality and ease of use, ultimately enhancing the mowing experience.

Expert Recommendations for Upgrades

Enhancing the performance and longevity of your outdoor machinery can significantly improve its functionality. Focusing on specific components can lead to better efficiency, increased durability, and an overall enhanced user experience. By implementing thoughtful modifications, users can adapt their equipment to meet evolving needs and tackle various tasks more effectively.

Improving Engine Performance

Upgrading the engine components can lead to notable improvements in power and efficiency. Consider investing in a high-performance air filter or a more efficient carburetor to optimize fuel intake and combustion. Regular maintenance, such as changing the oil and using quality lubricants, also plays a crucial role in maintaining engine health and performance.

Enhancing Cutting Efficiency

For those seeking to improve cutting capabilities, upgrading blades and drive systems is essential. High-quality, sharper blades will ensure cleaner cuts, reducing the workload on the engine. Additionally, exploring options for more advanced drive belts can enhance the transmission of power, resulting in smoother operation and improved handling.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety is of paramount importance. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. This section outlines essential safety measures to follow while performing repairs on mechanical equipment.

Wear Appropriate Personal Protective Equipment

Always equip yourself with the necessary protective gear before beginning any repair work. This includes wearing safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges, and steel-toed boots to safeguard your feet from heavy objects. Additionally, consider using ear protection if operating loud machinery.

Ensure Proper Workspace Conditions

Maintain a clean and organized workspace to facilitate safe repairs. Remove any clutter that may pose tripping hazards and ensure adequate lighting to clearly see the components you are working on. Before starting, double-check that the equipment is powered off and that any energy sources are properly disconnected. Following these steps will help prevent unexpected incidents during your repair process.

Resources for Further Research

For those seeking to deepen their understanding of small engine machinery and its components, a variety of materials and platforms are available. These resources can enhance knowledge about assembly, maintenance, and troubleshooting, providing valuable insights for both novices and experienced users.

Online Resources

- O’Reilly Online Learning – Offers a plethora of books and courses on small engine repair and maintenance.

- YouTube – A vast repository of instructional videos that cover a wide range of topics related to engine maintenance.

- Reddit – Lawn Care Community – A forum where enthusiasts discuss issues, share tips, and provide support for all types of lawn equipment.

Print and Digital Publications

- Amazon – A selection of manuals and guides specifically focused on engine repair and maintenance.

- National Lawn Mower Museum – Provides historical insights and resources related to lawn machinery.

- Mechanic Advisor – A website dedicated to automotive and machinery repair, featuring articles and expert advice.