In the realm of machinery maintenance, comprehending the intricate design of your equipment is essential for optimal performance. Each component plays a vital role, ensuring seamless operation and longevity. A thorough grasp of how these elements interact can significantly enhance your experience with the device.

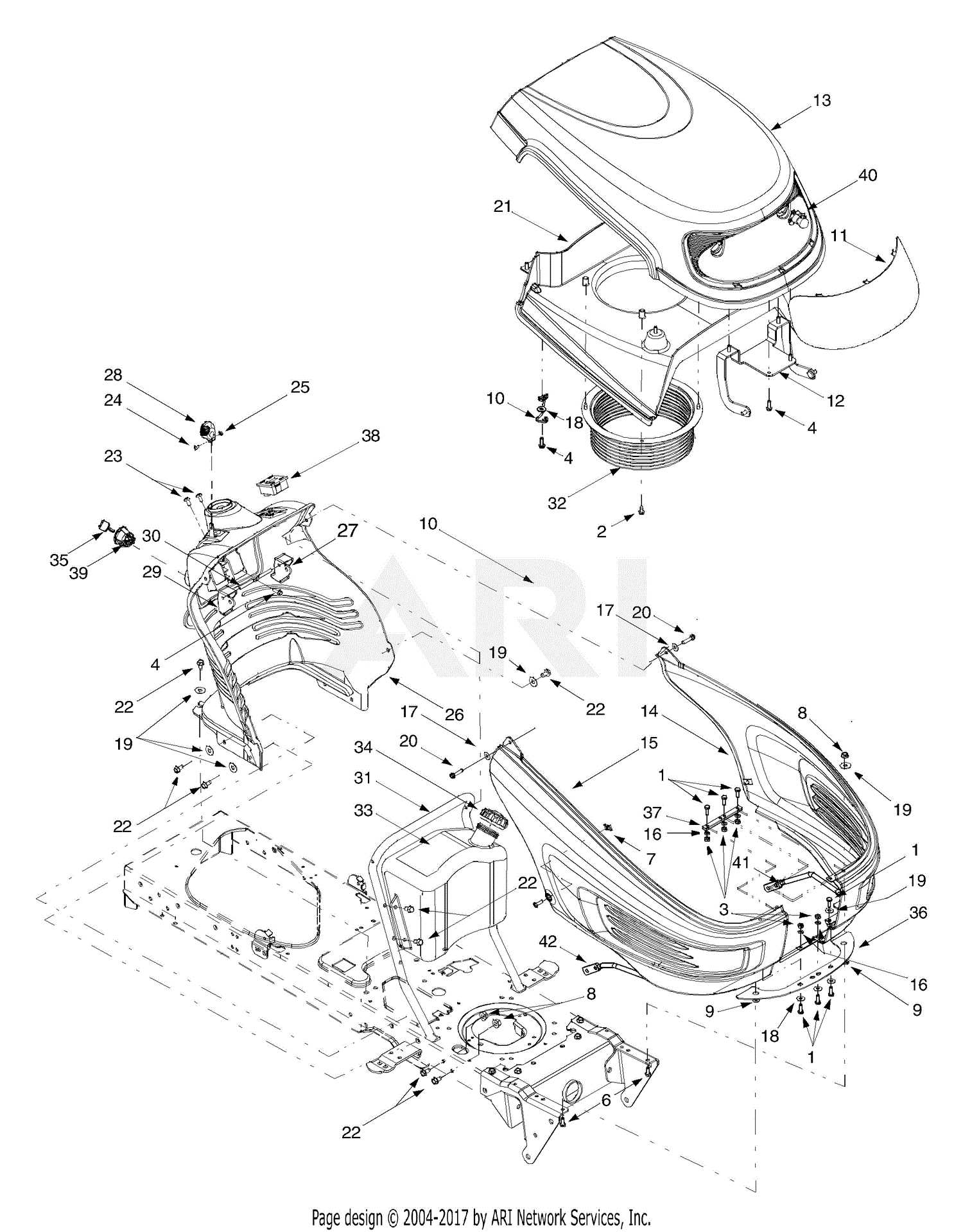

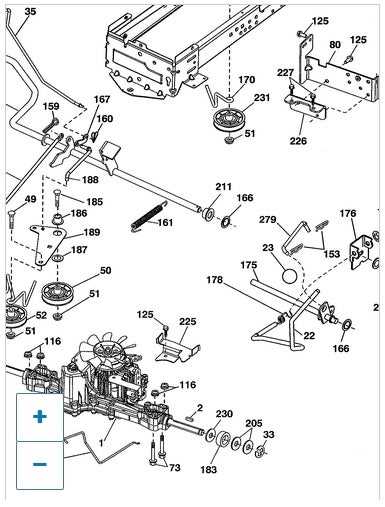

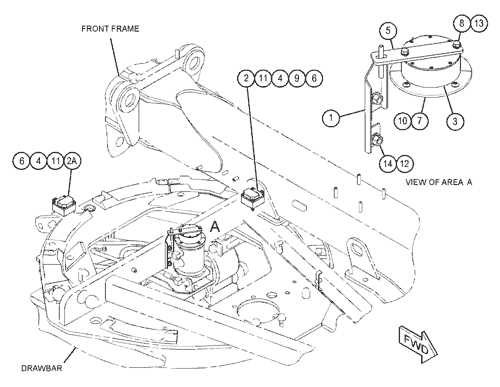

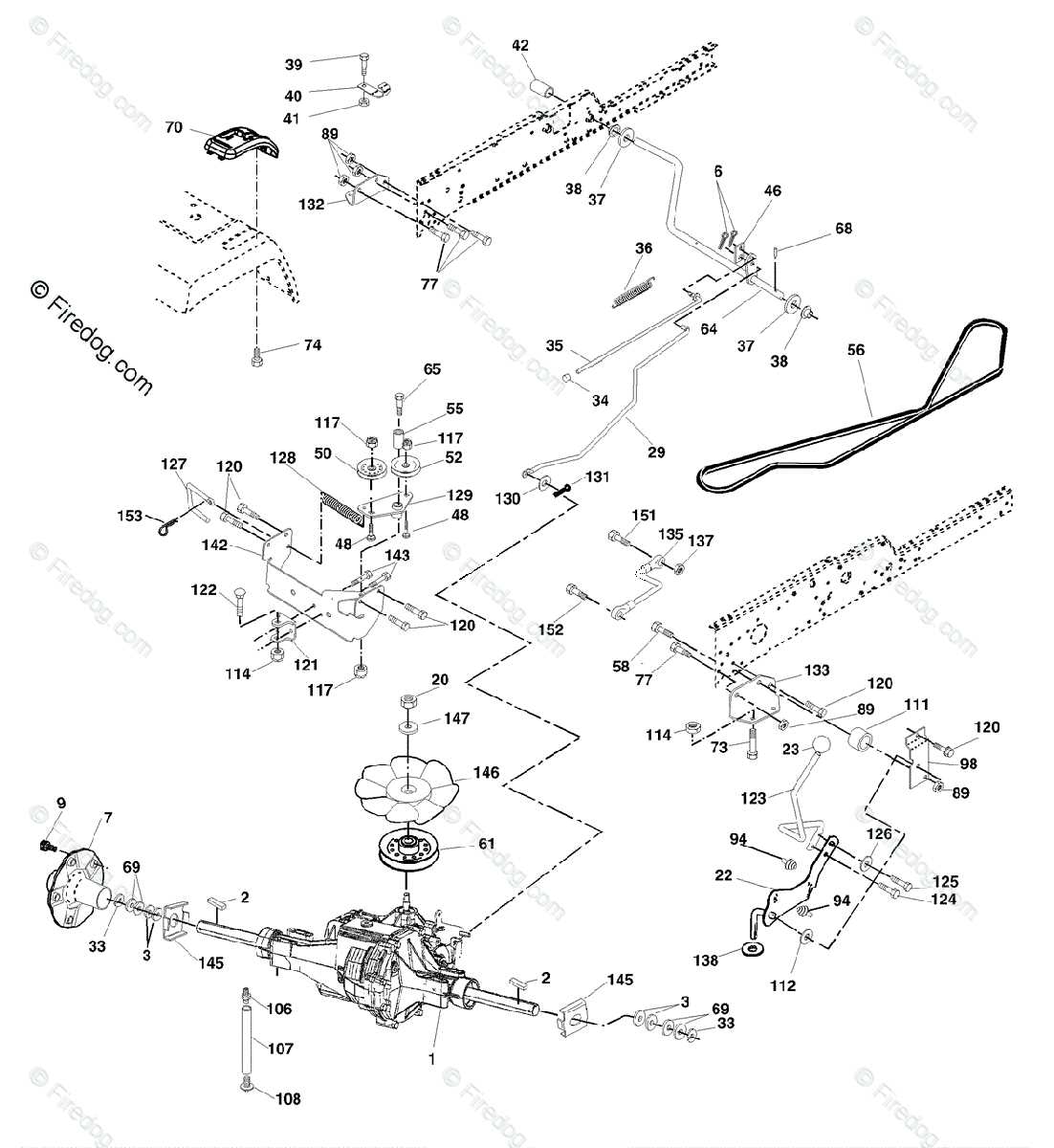

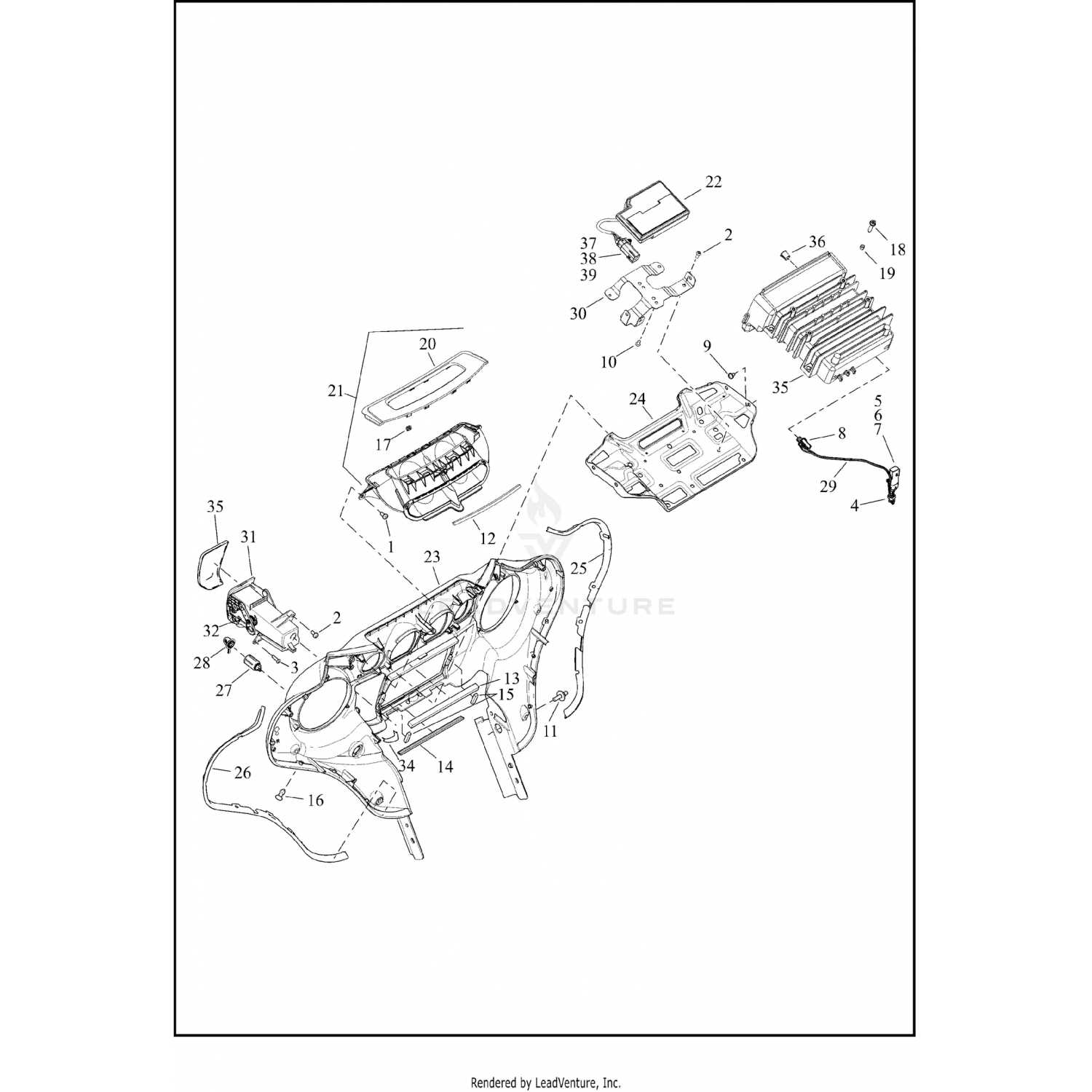

Visual representations serve as invaluable resources, illustrating the relationships between various segments. By examining these detailed layouts, users can easily identify individual pieces, facilitating informed decision-making when it comes to repairs or upgrades. A well-structured overview can demystify the complexity of mechanical assemblies, empowering users to tackle maintenance tasks with confidence.

Exploring the specifics of each element allows for a deeper appreciation of the craftsmanship involved. Recognizing how each part contributes to the overall functionality not only aids in troubleshooting but also fosters a greater understanding of the technology behind the tools we rely on. Armed with this knowledge, users can ensure their devices remain in peak condition for years to come.

Understanding Craftsman YT 3000 Parts

When maintaining and repairing a specific model of outdoor machinery, it’s crucial to familiarize yourself with its various components. A comprehensive grasp of the individual elements contributes significantly to efficient operation and longevity. Each part plays a vital role in the overall functionality, ensuring that the equipment runs smoothly and effectively.

Key Components and Their Functions

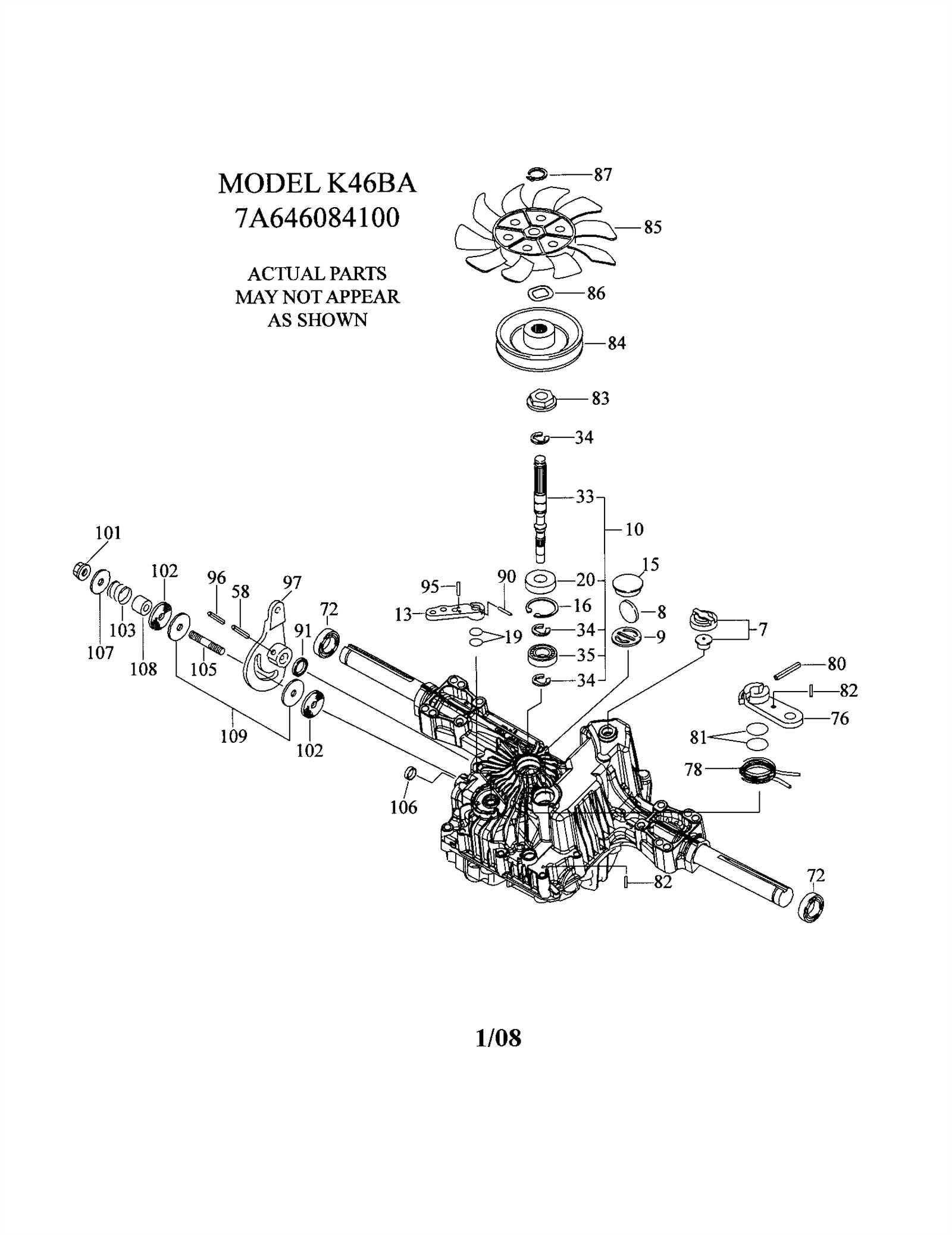

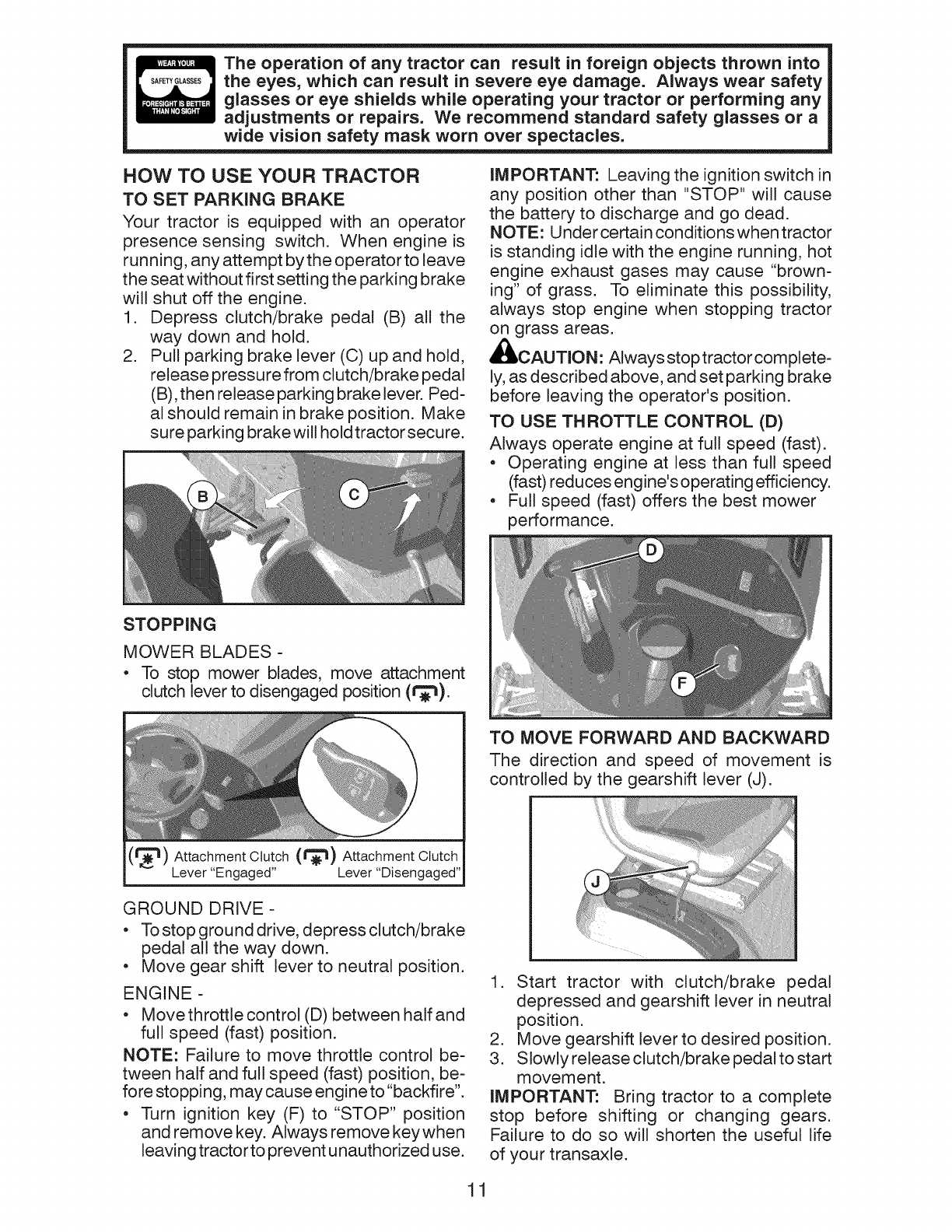

Essential elements include the engine, transmission, and chassis, each serving distinct purposes. The power source drives the machine, while the transmission facilitates the transfer of power to the wheels. Understanding how these parts interact can help troubleshoot issues and perform maintenance tasks more effectively.

Maintenance Tips for Longevity

Regular inspection of these components can prevent major breakdowns. Checking for wear and tear, ensuring proper lubrication, and replacing damaged items promptly are key practices. By taking proactive measures, you can enhance the performance and lifespan of your outdoor equipment.

Overview of the Craftsman YT 3000

This section provides a comprehensive look at a well-regarded lawn care machine known for its reliability and efficiency. Ideal for homeowners, this model excels in both performance and ease of use, making it a popular choice for maintaining outdoor spaces. With a user-friendly design and robust features, it stands out in the market of lawn tractors.

Key Features

The equipment is equipped with several notable characteristics that enhance its functionality. From powerful engines to ergonomic seating, these elements contribute to a smoother mowing experience. Below is a summary of its essential features:

| Feature | Description |

|---|---|

| Engine Power | Equipped with a reliable engine that ensures efficient performance. |

| Cutting Width | A generous cutting width allows for quicker mowing of larger areas. |

| Transmission | Features a smooth transmission system for easy handling. |

| Comfort | Designed with user comfort in mind, providing a pleasant riding experience. |

Maintenance Considerations

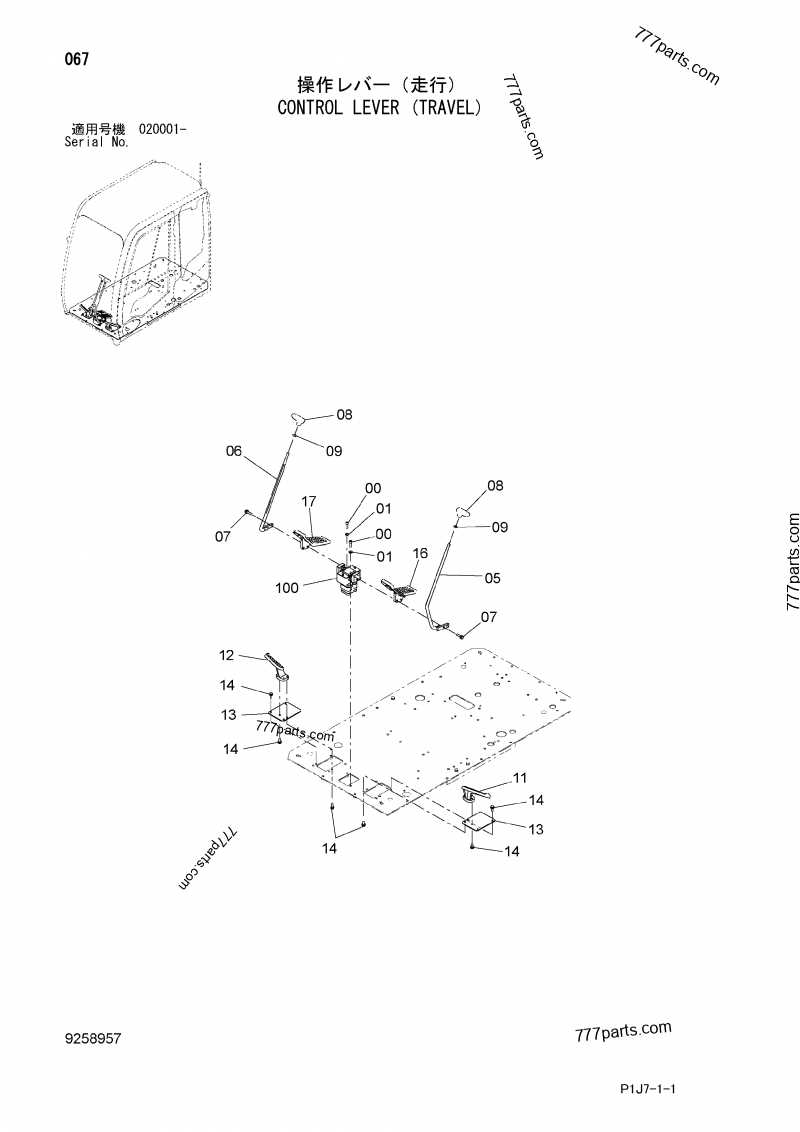

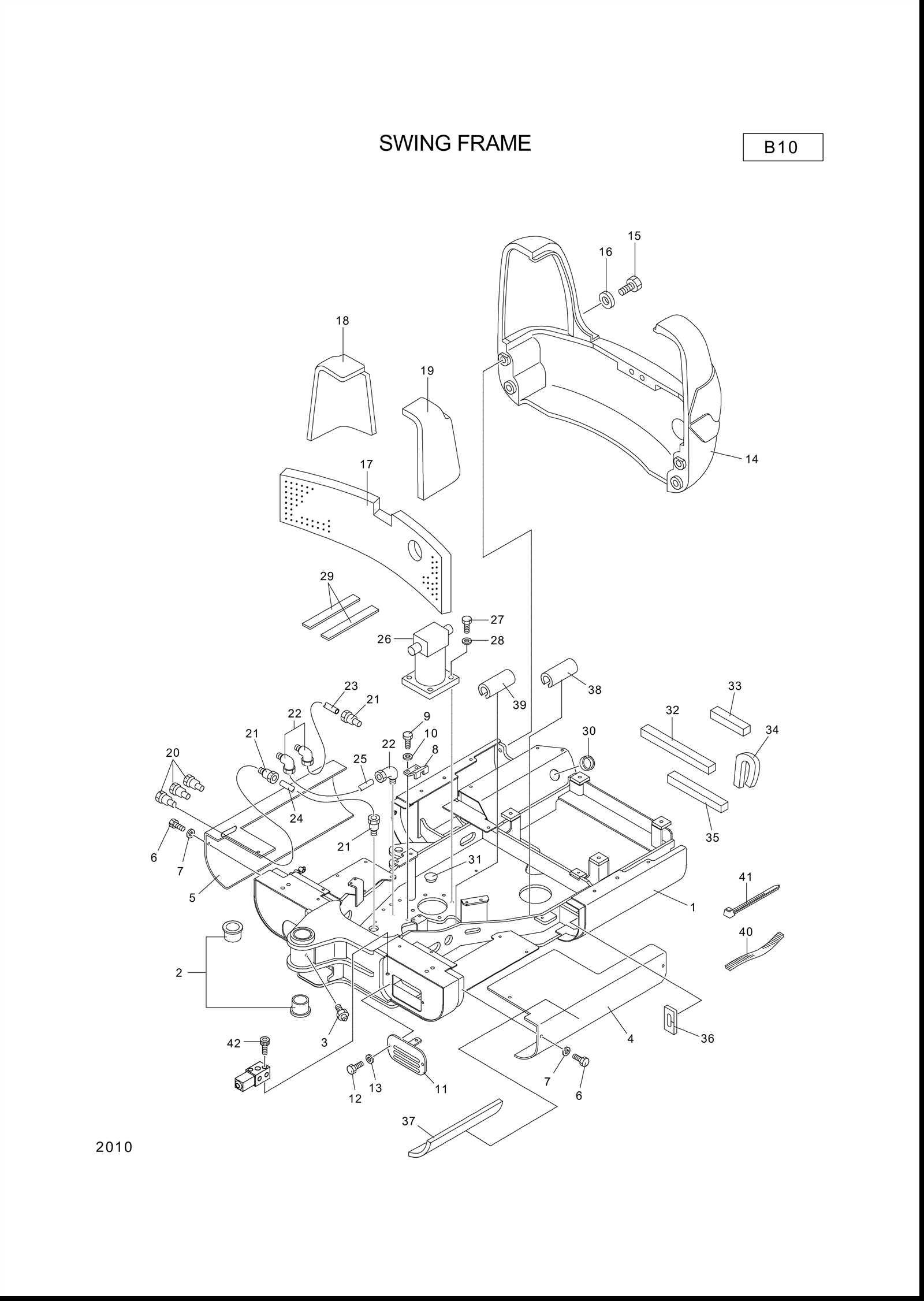

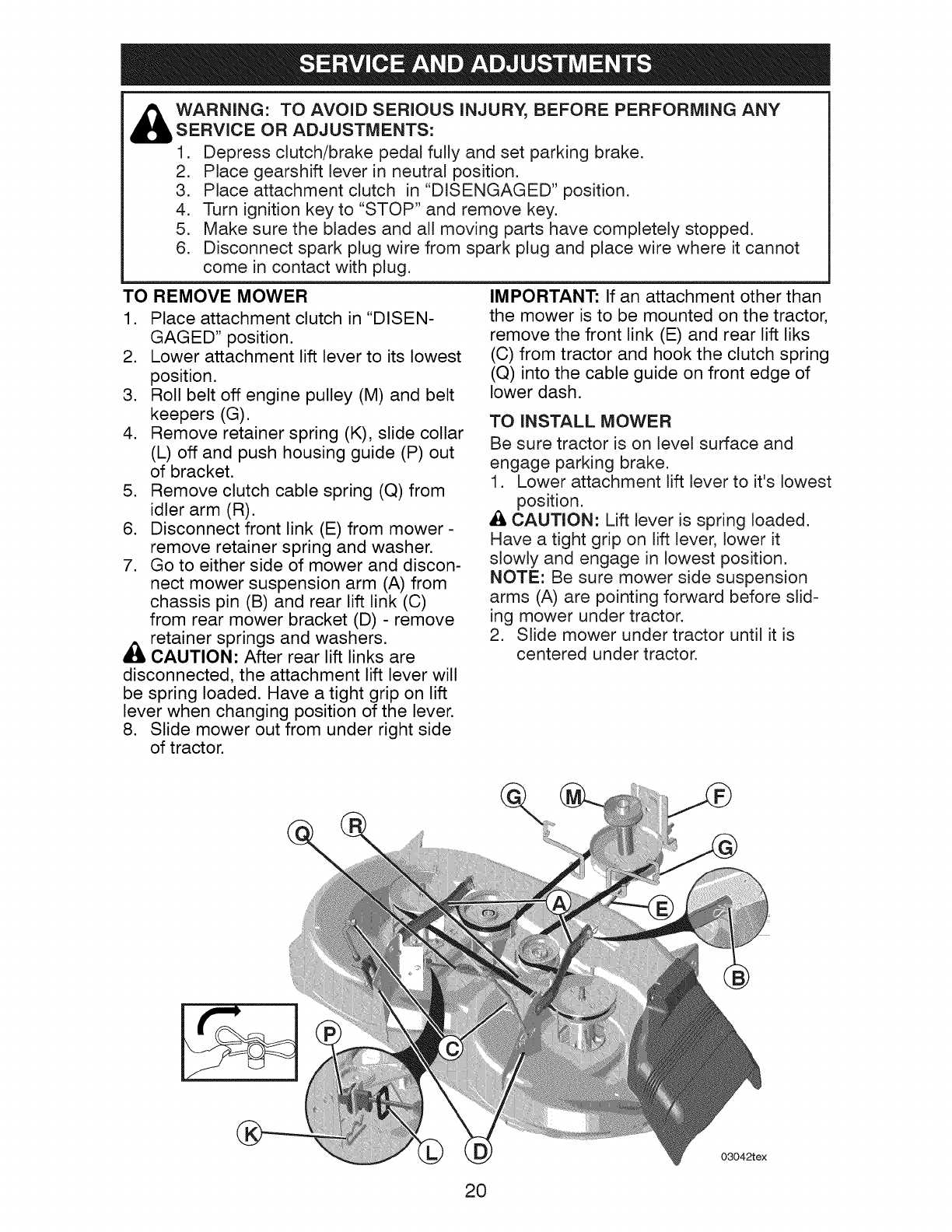

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements not only simplify the process of identifying components but also enhance overall efficiency in managing equipment.

Facilitating Repairs

When faced with a malfunction, having a clear visual guide aids technicians in quickly locating the necessary components. This accessibility is vital for:

- Reducing downtime during repairs

- Ensuring accurate reassembly

- Minimizing the risk of errors

Enhancing Maintenance Practices

Regular upkeep is essential for prolonging the lifespan of equipment. A comprehensive visual reference allows users to:

- Identify wear and tear on specific elements

- Plan maintenance schedules effectively

- Educate less experienced personnel on component locations

Key Components of the YT 3000

Understanding the essential elements of this lawn care equipment is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficient operation and durability, contributing to a seamless user experience.

Engine and Power System

The power unit is the heart of the machine, providing the necessary energy for its various functions. A reliable engine guarantees robust performance, allowing for effective cutting and maneuverability across different terrains. It’s important to pay attention to fuel efficiency and ease of starting to enhance user convenience.

Cutting Mechanism

The cutting assembly is pivotal for achieving a clean and precise lawn finish. This system typically includes blades that can be adjusted for height and sharpness, ensuring adaptability to various grass types and conditions. Regular maintenance of this mechanism is essential to prevent wear and ensure longevity.

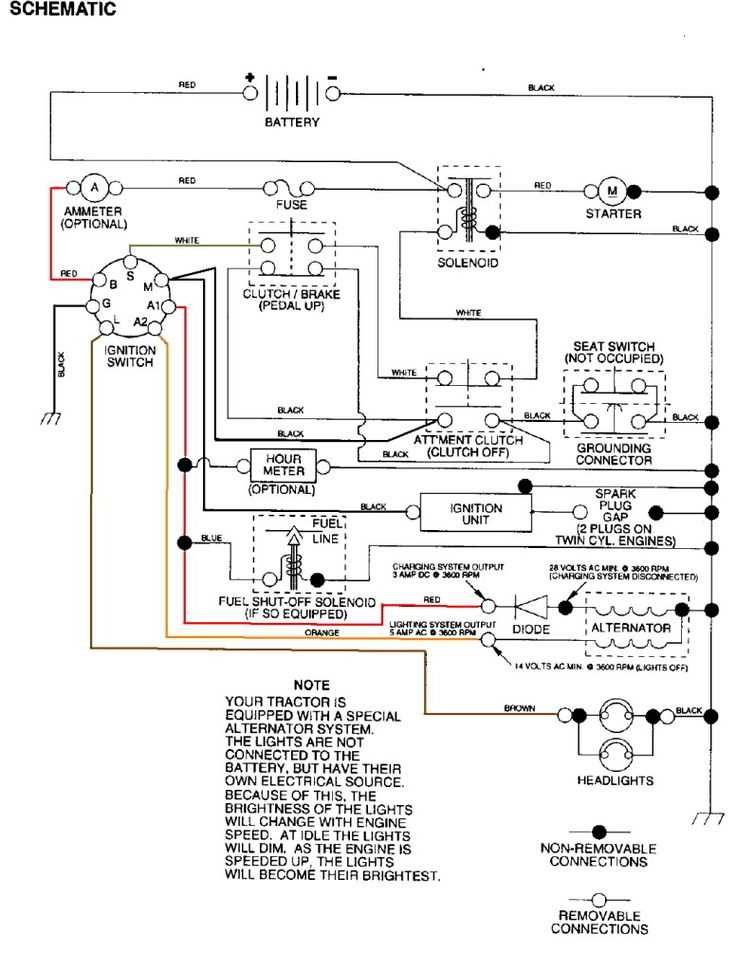

How to Read Parts Diagrams

Understanding schematics is essential for anyone looking to maintain or repair their equipment effectively. These visual representations provide a detailed overview of components, making it easier to identify and locate specific pieces. Familiarity with the layout and symbols used can significantly enhance your repair skills and streamline the process.

Key Elements of a Schematic

When examining a visual representation, pay attention to the following aspects:

| Element | Description |

|---|---|

| Symbols | Icons representing various components, each with a specific meaning. |

| Labels | Text indicating the names or numbers of the components for easy identification. |

| Connections | Lines or arrows showing how parts are linked or interact with each other. |

| Key | A legend that explains the symbols and terminology used in the illustration. |

Steps for Effective Interpretation

To effectively interpret the illustration, follow these steps:

- Start with the key to familiarize yourself with the symbols.

- Identify the major components and their locations.

- Trace the connections to understand how parts interact.

- Note any specific annotations or numbers for detailed guidance.

Common Issues and Solutions

When dealing with machinery, users may encounter various challenges that can affect performance and usability. Understanding these issues and their potential remedies can help maintain efficiency and extend the lifespan of the equipment.

Frequent Problems

- Difficulty Starting: Many users report trouble getting the machine to start, often due to fuel or electrical issues.

- Uneven Operation: Machines may operate inconsistently, leading to subpar results.

- Excessive Noise: Unusual sounds can indicate wear and tear or misalignment of components.

- Overheating: Units may become excessively hot, often due to lack of maintenance or airflow obstruction.

Possible Solutions

- Check Fuel Supply: Ensure the fuel tank is full and that fuel lines are not clogged.

- Inspect Electrical Connections: Tighten any loose wires and replace faulty components.

- Maintain Regular Servicing: Follow a schedule for cleaning and inspecting parts to prevent build-up and ensure proper function.

- Monitor Temperature: Allow the machine to cool down during extended use and clear any vents to facilitate airflow.

Replacement Parts Availability

Access to components for maintenance and repair is essential for ensuring optimal performance and longevity of any equipment. Understanding where to find these items can save time and enhance efficiency. Numerous suppliers offer a wide range of options, catering to various needs and preferences.

Here is a summary of common sources for acquiring replacement components:

| Source | Description |

|---|---|

| Authorized Retailers | These outlets provide genuine components and often have knowledgeable staff for assistance. |

| Online Marketplaces | Websites specializing in equipment sales can offer both new and refurbished items, often at competitive prices. |

| Local Repair Shops | These businesses may stock essential components or can order them on demand, often with quick turnaround times. |

| Manufacturer’s Website | Direct purchases from the producer ensure authenticity and may provide a wider selection of items. |

| Third-Party Suppliers | These companies often provide compatible alternatives, which can be more budget-friendly without sacrificing quality. |

Researching these options will facilitate finding the right components to keep equipment running smoothly and efficiently.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your tools. By adopting a few simple practices, you can keep your machinery in excellent working condition and avoid costly repairs.

Regular Cleaning

Keeping your tools clean is essential. After each use, remove dirt and debris that may accumulate. A soft brush or cloth can help reach difficult areas. Pay special attention to ventilation openings and moving parts, as buildup can lead to overheating and mechanical failure.

Lubrication and Inspection

Frequent lubrication of moving components is crucial for smooth operation. Use appropriate lubricants recommended by the manufacturer to reduce friction and wear. Additionally, perform periodic inspections to identify any signs of wear or damage. Early detection can prevent more significant issues down the line.

By integrating these practices into your routine, you can significantly improve the reliability and longevity of your tools.

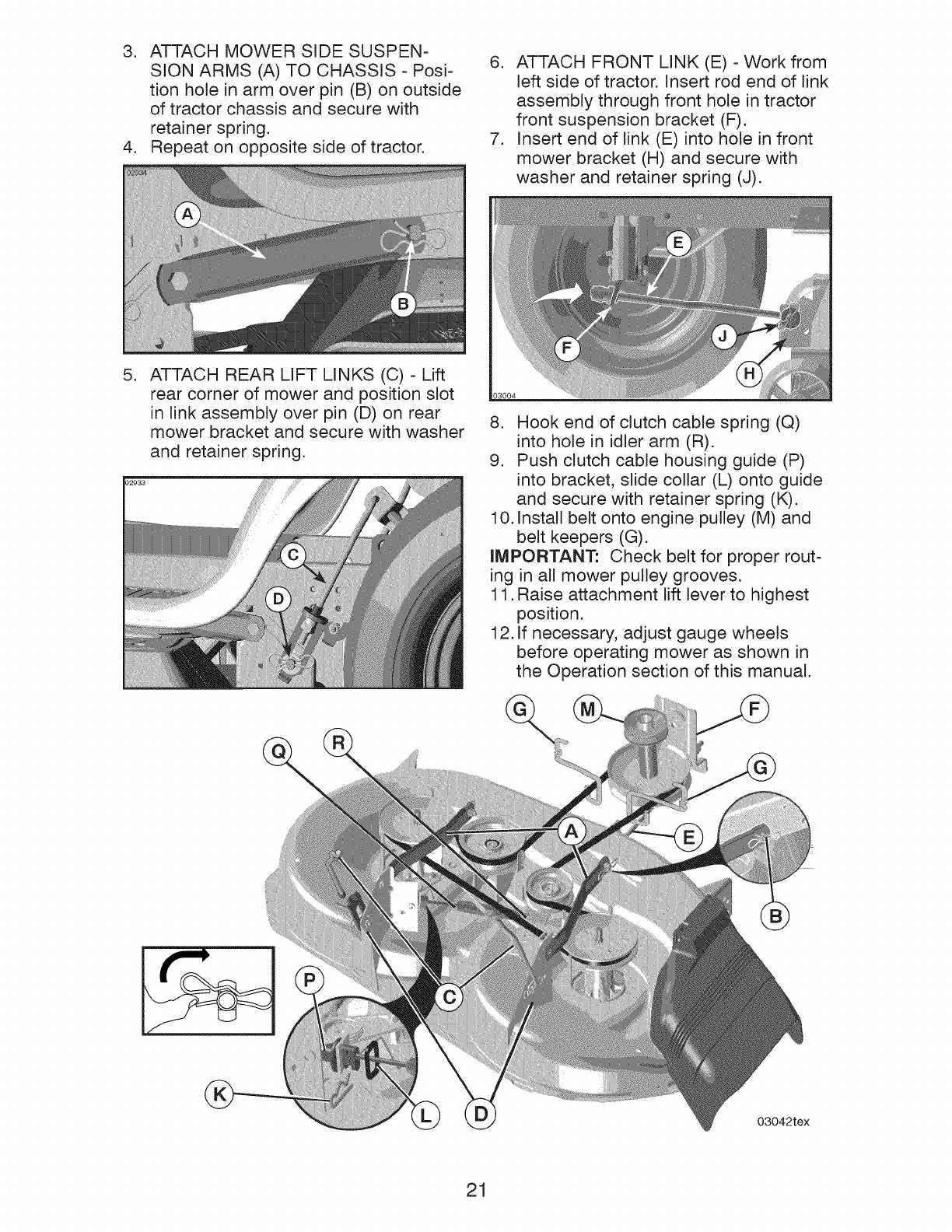

DIY Repairs and Parts Replacement

Engaging in home repairs and component swaps can be a rewarding experience that enhances your understanding of your tools and devices. This section explores practical approaches for tackling common issues, ensuring you can restore functionality effectively and efficiently.

Identifying Issues

The first step in any repair process is to accurately identify the problem. This can save time and resources. Here are some common signs to look for:

- Unusual noises during operation

- Loss of power or efficiency

- Visible damage to external components

- Frequent malfunctions or breakdowns

Replacement Process

Once the issue is diagnosed, the next phase is to proceed with the replacement of the faulty components. Follow these guidelines for a successful outcome:

- Gather necessary tools and materials.

- Consult the user manual or online resources for guidance.

- Carefully disassemble the device, noting the arrangement of parts.

- Replace the defective elements with new or refurbished items.

- Reassemble the unit, ensuring all connections are secure.

- Test the device to verify that the repair was successful.

By following these steps, you can tackle a variety of repairs with confidence, saving time and money while gaining valuable skills in the process.

Tools Needed for Repairs

When it comes to conducting maintenance or fixes on machinery, having the right instruments at hand is essential for a smooth and efficient process. Each repair task may require a unique set of tools tailored to specific components, ensuring that every aspect is addressed accurately.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening or tightening bolts and nuts of various sizes. |

| Screwdriver Set | Essential for inserting or removing screws; available in multiple types, including flathead and Phillips. |

| Pliers | Helpful for gripping, bending, or cutting wires and small components. |

| Socket Set | Facilitates the easy application of torque to nuts and bolts in tight spaces. |

| Multimeter | Used for measuring voltage, current, and resistance to troubleshoot electrical issues. |

| Safety Gear | Includes gloves and goggles to protect against debris and injuries during repairs. |

Equipping yourself with these tools will not only streamline the repair process but also enhance the overall safety and effectiveness of your work. Understanding the function of each instrument allows for a more competent and confident approach to any maintenance task.

Finding the Right Manuals

When it comes to maintaining and repairing your equipment, having the correct documentation is essential. These guides not only provide detailed instructions but also ensure that you can identify and replace components accurately. Accessing the right materials can significantly enhance your understanding of the machinery and improve your troubleshooting skills.

To locate the appropriate manuals, consider the following sources:

- Official Manufacturer Website: Most brands offer downloadable manuals directly on their sites. Look for a support or resources section.

- Online Retailers: Websites that sell tools and machinery often provide links to user guides and manuals for the products they sell.

- Third-Party Websites: There are numerous online platforms dedicated to providing manuals and schematics for various brands and models.

- Community Forums: Engaging with forums can connect you with other users who may share their manuals or insights on where to find them.

Once you find a suitable manual, ensure that it corresponds exactly to your model. This will help you avoid any confusion and ensure accurate repairs and maintenance.

In conclusion, the right documentation is invaluable for anyone looking to maintain their tools effectively. By utilizing these resources, you can empower yourself with the knowledge needed for successful upkeep.

Online Resources for Parts Lookup

Finding components for various equipment can often be a challenge. However, numerous online platforms offer comprehensive resources to assist users in identifying and acquiring the necessary elements for their machines. These tools not only simplify the search process but also ensure that individuals can obtain the correct items for their needs.

Popular Websites

- Manufacturer Websites: Official sites often provide detailed catalogs, schematics, and the ability to order directly.

- Online Retailers: E-commerce platforms frequently have extensive inventories, including user reviews and compatibility information.

- Forums and Community Boards: User-generated content on discussion platforms can offer valuable insights and recommendations for sourcing specific components.

- Repair Guides and Blogs: Many enthusiasts share detailed tutorials and links to where to find necessary replacements.

Utilizing Search Engines

In addition to dedicated websites, utilizing search engines effectively can yield quick results. Consider the following tips:

- Use specific keywords related to the equipment and desired component.

- Include terms like “replacement” or “accessories” to narrow down the search.

- Check for local suppliers that may offer faster shipping options.

By leveraging these online resources, users can navigate the often complex landscape of acquiring components with ease and confidence.

Customer Reviews and Experiences

Feedback from users provides invaluable insights into the performance and reliability of various tools and equipment. By sharing their personal stories and observations, customers contribute to a collective understanding of what to expect, helping potential buyers make informed decisions.

Positive Impressions

Many users have praised the durability and efficiency of their tools. One reviewer highlighted how the equipment exceeded expectations in handling tough tasks, stating, “It performs flawlessly even under heavy use.” Such testimonials emphasize the trust and satisfaction that come from reliable performance.

Challenges Encountered

Conversely, some individuals noted challenges with specific features or maintenance. A customer mentioned, “While the overall design is great, I faced issues with the assembly instructions, which could be clearer.” This feedback underlines the importance of user-friendly guides and support to enhance the overall experience.