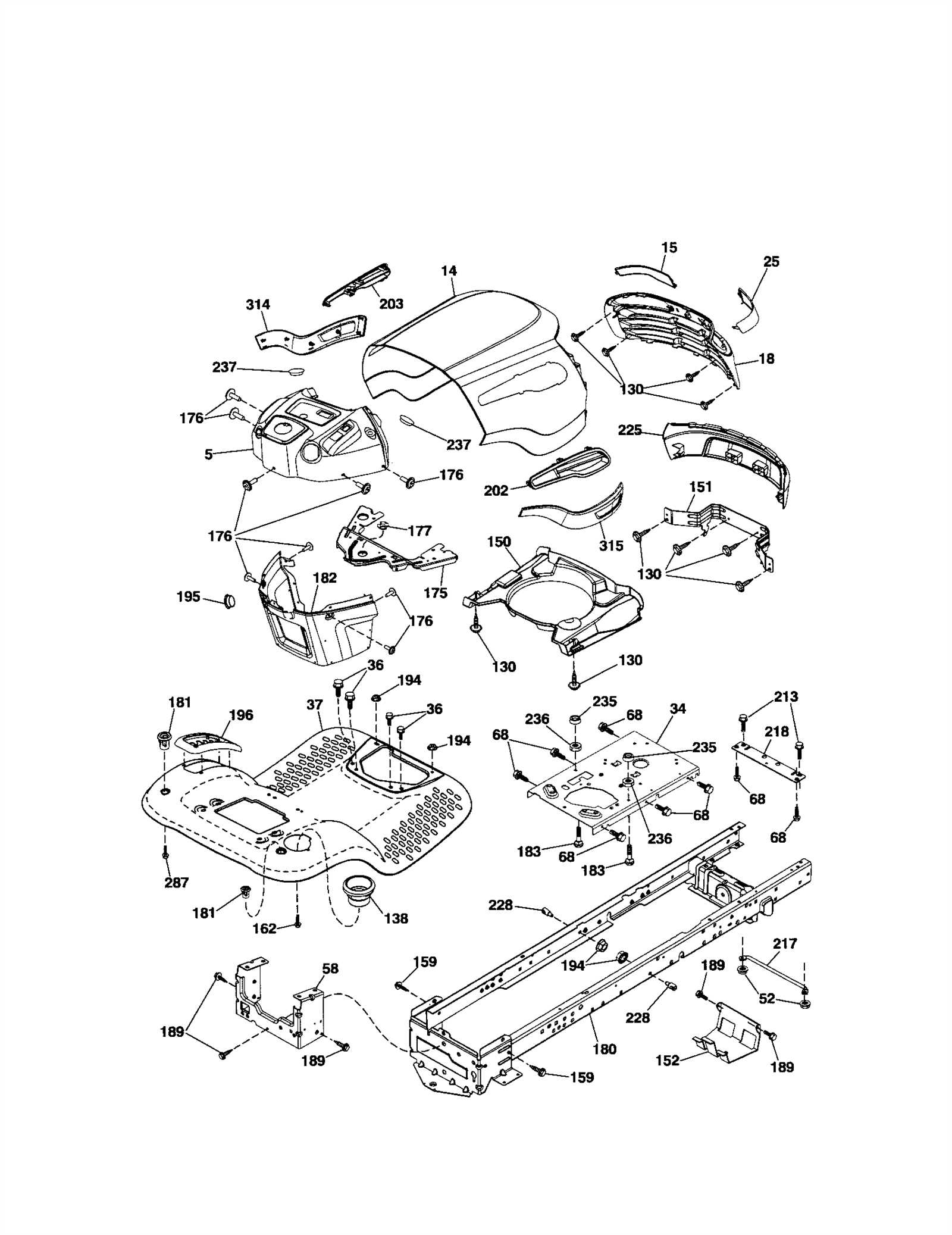

The inner workings of a lawn tractor play a crucial role in its efficiency and functionality. Knowing the arrangement and roles of various elements within the machinery helps users maintain and troubleshoot their equipment effectively. This section focuses on the layout and interaction of key components, offering insights that can enhance your understanding of how everything fits together.

For those looking to enhance their maintenance skills or simply better comprehend the operational aspects of their equipment, visual aids can be incredibly beneficial. By examining the configuration of different parts, users can identify potential issues, ensure proper assembly, and improve the overall longevity of their machine.

In this guide, we will delve into the intricacies of the equipment’s structure. With a detailed overview of essential elements, you will be better equipped to tackle repairs and adjustments with confidence. Whether you are a seasoned operator or a newcomer, familiarizing yourself with these features is a step toward optimal performance and care.

Understanding Craftsman YTS3000 Components

To effectively maintain and operate a lawn tractor, it is essential to grasp the various elements that contribute to its functionality. Each component plays a significant role in ensuring optimal performance and longevity. This section will delve into the key parts of a typical garden machine, highlighting their purposes and interrelations.

Key Elements of the Machine

The fundamental aspects of this equipment include the engine, transmission, and chassis. The engine is the heart of the machinery, providing the necessary power to drive the vehicle and operate the cutting mechanisms. The transmission system facilitates smooth gear shifting, allowing for varied speed control and maneuverability. Meanwhile, the chassis serves as the framework that supports all other components, ensuring stability and durability during operation.

Importance of Regular Maintenance

Understanding these elements not only enhances operation but also emphasizes the need for regular upkeep. Routine inspections and preventive maintenance can prevent potential issues, ensuring that each part functions harmoniously. By familiarizing oneself with these components, users can take proactive steps to prolong the life of their machinery and enhance overall performance.

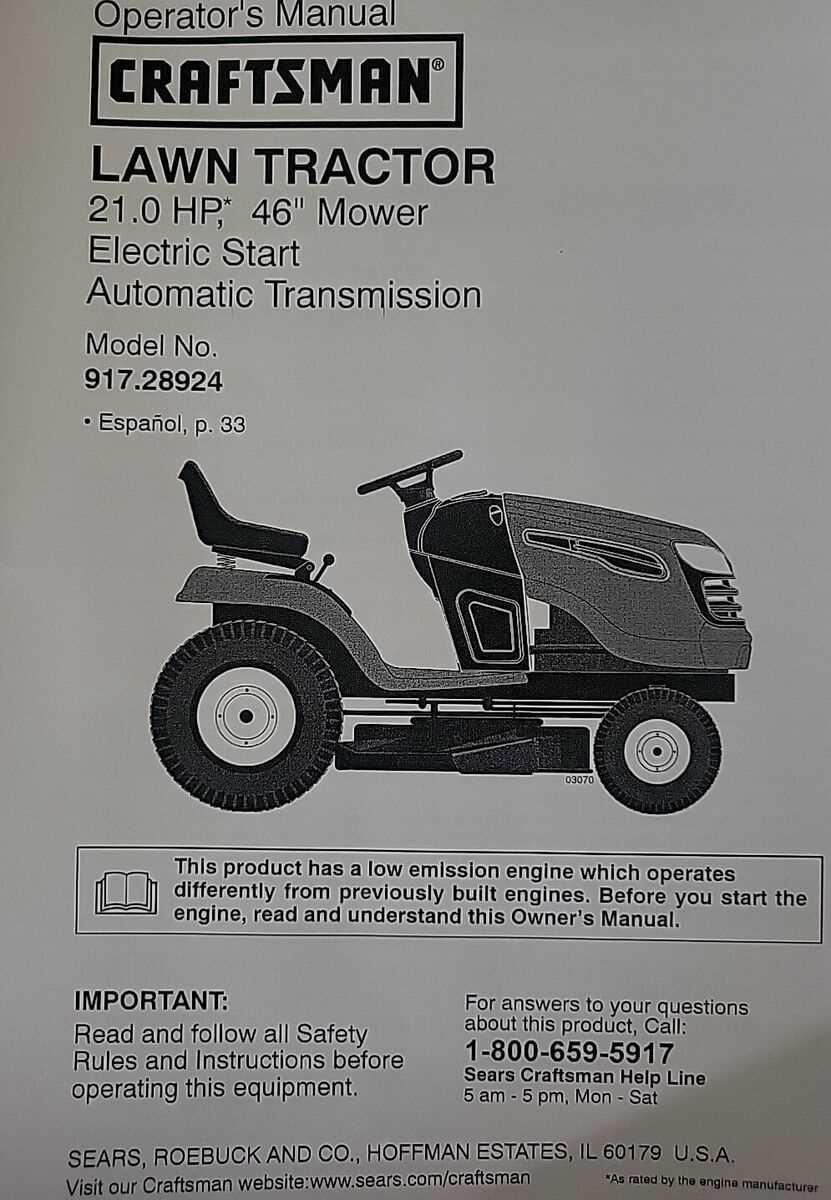

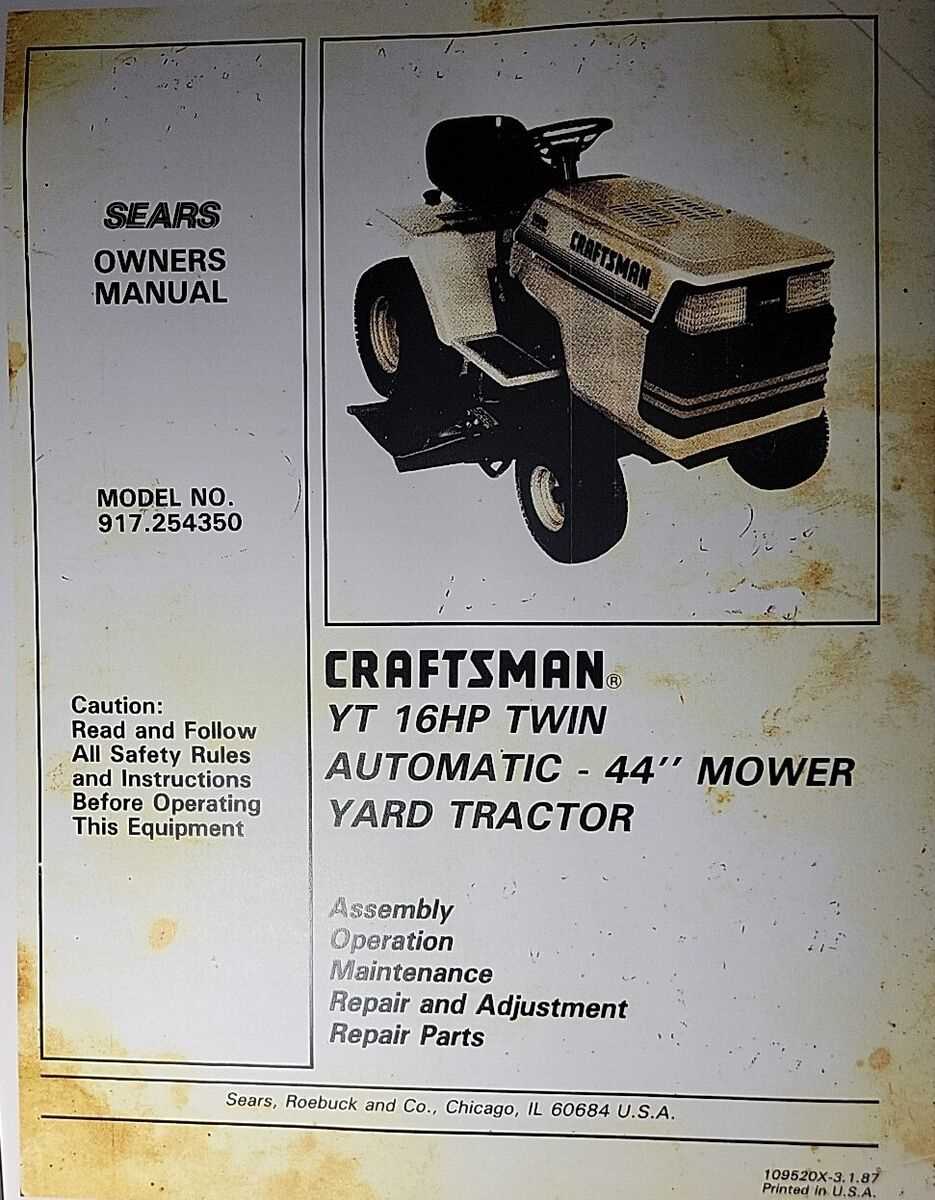

Overview of Craftsman YTS3000 Model

This section provides an insightful examination of a particular lawn care equipment model known for its efficiency and durability. Designed for homeowners seeking reliable performance, this model stands out with its user-friendly features and robust construction, making lawn maintenance a straightforward task.

Key Features

Featuring a powerful engine and an ergonomic design, this equipment ensures a smooth operation and comfortable handling. Its cutting capabilities are enhanced by adjustable settings, allowing users to achieve their desired lawn height with ease. The sturdy build and quality materials contribute to its longevity, making it a valuable investment for gardening enthusiasts.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Four-stroke gasoline engine |

| Cutting Width | 42 inches |

| Transmission | Automatic |

| Weight | Approximately 400 lbs |

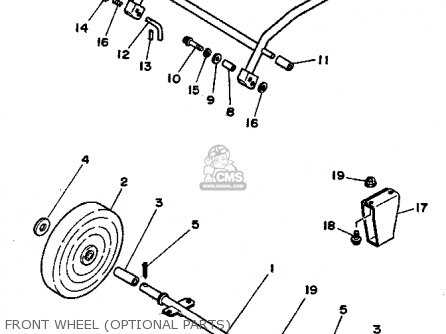

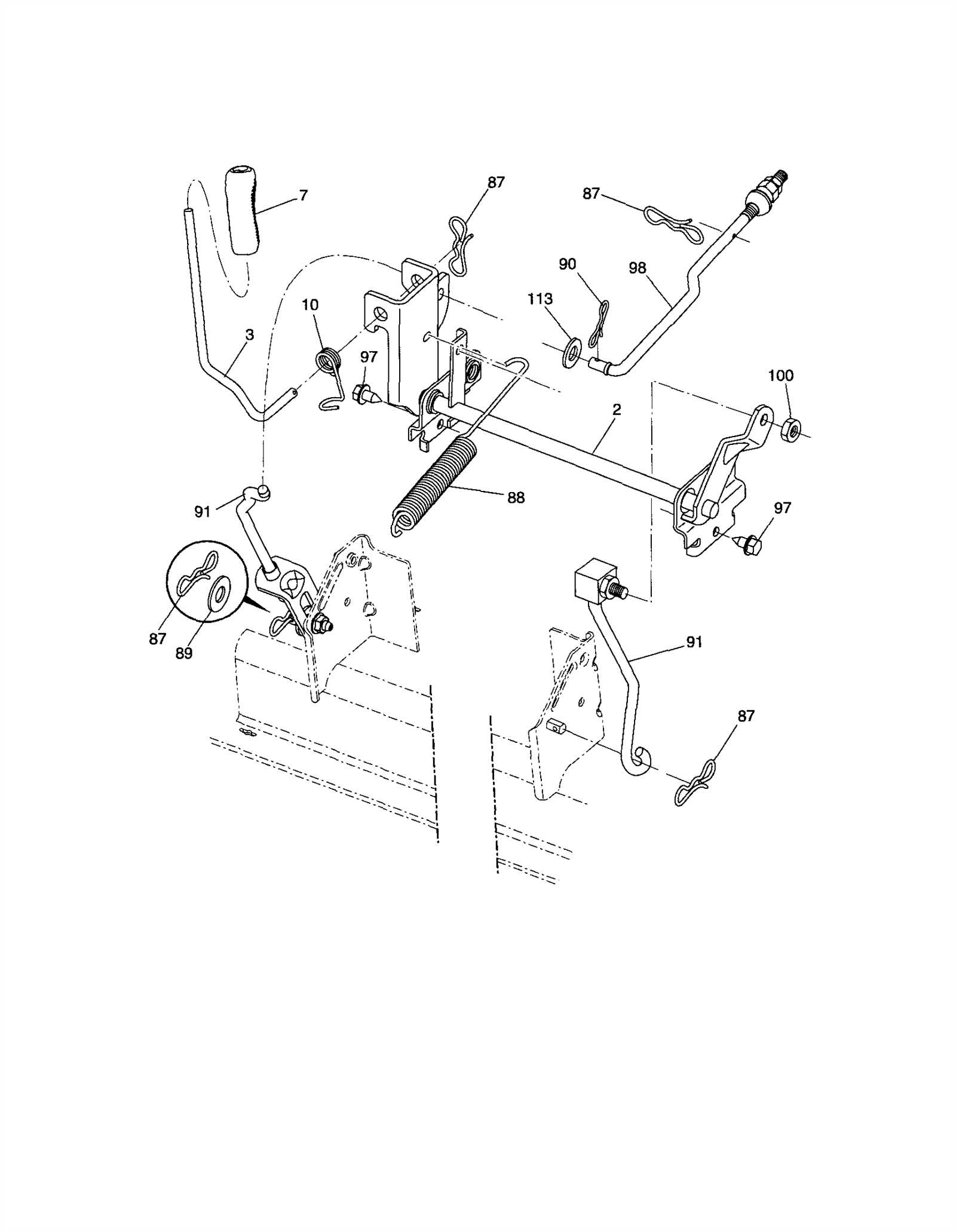

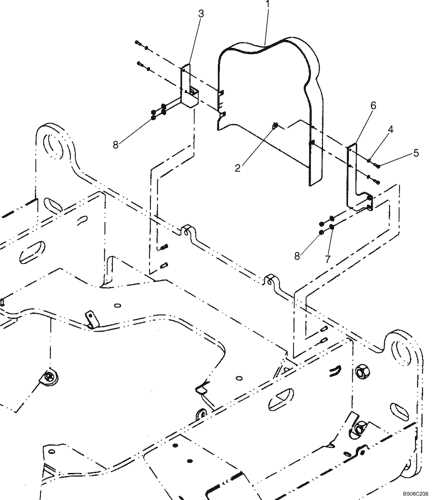

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations that detail each segment not only facilitate a better grasp of the overall structure but also aid in identifying specific elements that may require attention. This knowledge empowers users to approach repairs with confidence, ensuring that they can address issues efficiently and accurately.

One key benefit of utilizing these visual guides is the simplification of complex assembly processes. By clearly outlining the relationship between different pieces, users can follow instructions more easily, reducing the likelihood of errors during reassembly. This is particularly important for intricate machinery, where the incorrect installation of a single component can lead to larger problems down the line.

Moreover, these visual tools serve as invaluable resources during troubleshooting. When a malfunction occurs, having a clear view of each section allows users to pinpoint potential trouble areas quickly. This capability not only saves time but also minimizes the frustration often associated with diagnosing mechanical issues.

In addition, access to these illustrations fosters a greater understanding of the equipment’s functionality. Users become more familiar with how each element contributes to the overall operation, enhancing their ability to optimize performance and implement preventative measures. Consequently, this knowledge can lead to longer-lasting machinery and improved efficiency.

Identifying Key Parts and Functions

Understanding the essential components of a machine is crucial for effective operation and maintenance. Each element plays a significant role in ensuring the overall functionality and efficiency of the equipment. By familiarizing oneself with these elements, users can troubleshoot issues and perform necessary repairs with confidence.

Main Components

The primary elements include the engine, transmission, and chassis. The engine is responsible for generating power, while the transmission facilitates the transfer of that power to the wheels. The chassis serves as the foundation, providing support and stability to the entire structure.

Additional Features

Other noteworthy elements include the steering system and braking mechanisms. The steering system allows for directional control, enhancing maneuverability. Meanwhile, the braking mechanisms ensure safety by enabling quick and reliable stopping. Recognizing these features helps users appreciate the intricacies of their machinery.

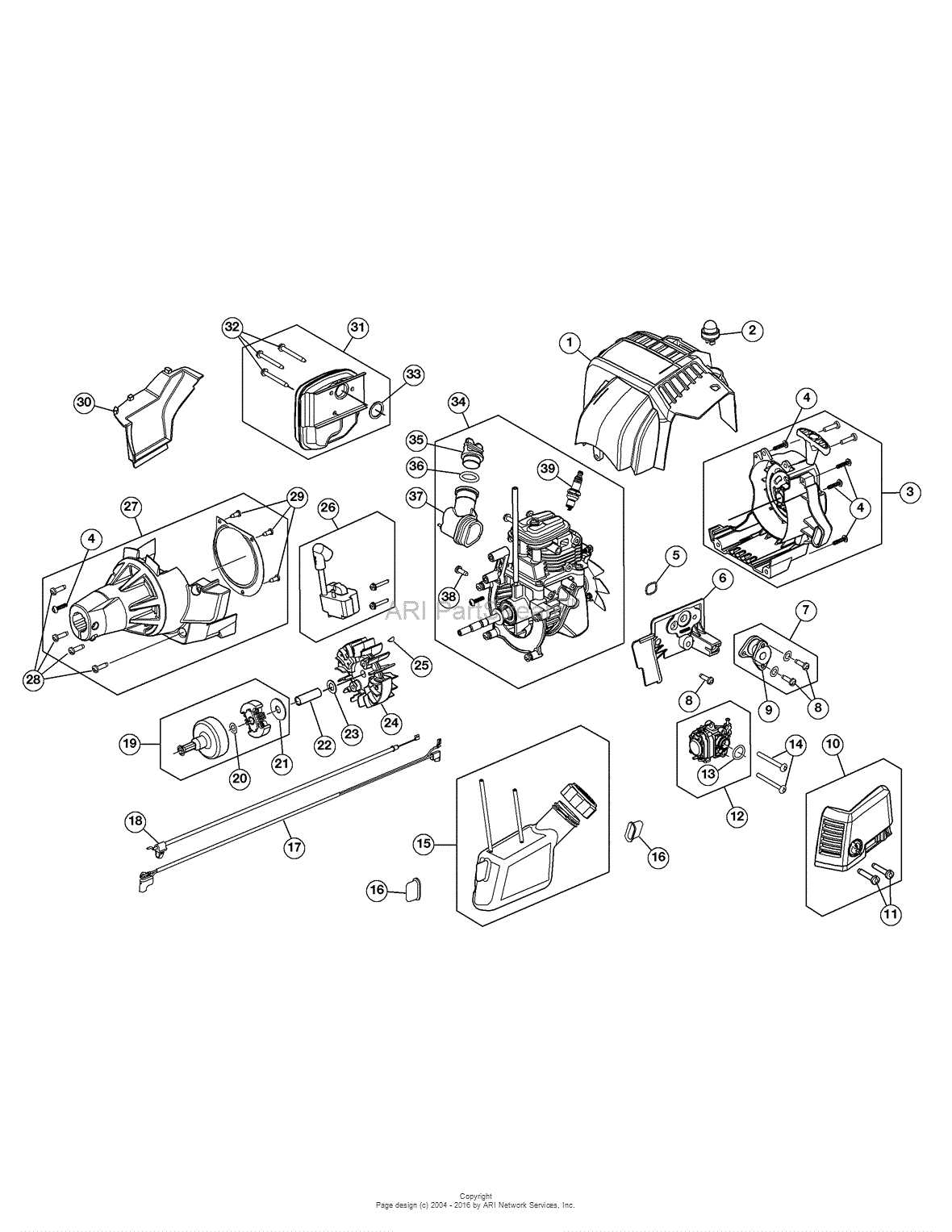

Common Repairs for Craftsman YTS3000

Routine maintenance and timely repairs are essential for ensuring optimal performance of lawn care equipment. Over time, various components may wear out or malfunction, leading to decreased efficiency or functionality. Understanding the common issues that may arise can help users troubleshoot and resolve problems effectively.

1. Engine Troubles

Engine-related issues are among the most frequent concerns for lawn care machinery. Some common symptoms include:

- Difficulty starting

- Unusual noises during operation

- Reduced power output

To address these issues, consider the following steps:

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the air filter is clean and free from debris.

2. Cutting Deck Adjustments

Another common area requiring attention is the cutting deck. Issues may manifest as uneven cutting or poor grass discharge. To maintain optimal cutting performance:

- Regularly inspect the blades for dullness or damage.

- Adjust the cutting height to match lawn conditions.

- Clear any grass clippings or debris from the deck.

Performing these maintenance tasks will help ensure a clean and efficient mowing experience.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential to ensure optimal performance and longevity. Whether you’re seeking out original pieces or compatible alternatives, there are several reliable sources to consider. Understanding where to look can save you time and help you avoid potential pitfalls.

One of the best starting points is the manufacturer’s official website. They typically offer a comprehensive catalog of available items, ensuring that you find exactly what you need. Additionally, authorized dealers and retailers often carry a selection of essential replacements, providing convenience and peace of mind.

For those looking for budget-friendly options, online marketplaces can be a great resource. Websites like eBay, Amazon, or specialty platforms dedicated to machinery may have both new and gently used items available at competitive prices. Just be sure to verify the seller’s ratings and return policies before making a purchase.

Lastly, local repair shops and service centers may also have spare components or can assist in sourcing them. Establishing a relationship with a knowledgeable technician can provide further insights and recommendations tailored to your specific needs.

| Source | Description |

|---|---|

| Manufacturer’s Website | Official catalog of items, ensuring authenticity. |

| Authorized Dealers | Convenient access to essential components. |

| Online Marketplaces | Budget-friendly options with a range of new and used items. |

| Local Repair Shops | Personalized assistance and sourcing options. |

Maintenance Tips

Proper upkeep of your lawn equipment is essential for optimal performance and longevity. Regular maintenance helps prevent unexpected breakdowns and ensures your machine operates efficiently. Here are some valuable suggestions to keep your equipment in top shape.

- Regular Cleaning: Remove grass clippings, dirt, and debris from the exterior and undercarriage to prevent corrosion and ensure efficient operation.

- Check Fluid Levels: Regularly inspect and refill fuel, oil, and coolant as needed to maintain proper function and avoid overheating.

- Sharpen Blades: Keep cutting blades sharp for a clean cut, which promotes healthy grass growth and reduces strain on the engine.

- Inspect Belts and Cables: Regularly check for wear and tear on belts and cables. Replace any that show signs of damage to prevent further issues.

- Battery Maintenance: If equipped with a battery, ensure it is charged and free of corrosion. Clean terminals as needed.

Following these maintenance tips will help extend the life of your equipment and enhance its performance, allowing you to enjoy a well-kept lawn throughout the season.

Tools Needed for DIY Repairs

Undertaking repairs on various equipment can be a rewarding experience, providing both a sense of accomplishment and the opportunity to save money. To effectively tackle these tasks, having the right tools at your disposal is essential. A well-equipped toolkit not only simplifies the process but also enhances safety and efficiency.

Firstly, a reliable set of hand tools is crucial. This includes screwdrivers, wrenches, pliers, and hammers. Each of these tools serves a specific purpose and is vital for loosening or tightening components, as well as handling different types of fasteners.

Additionally, power tools can significantly speed up the repair process. A cordless drill is invaluable for drilling holes and driving screws, while a saw may be necessary for cutting through materials. Having access to these tools allows for more complex repairs to be completed with ease.

Measurement tools, such as tape measures and levels, are also important. Accurate measurements ensure that parts fit together correctly, preventing future issues. Finally, safety equipment like gloves and goggles should not be overlooked, as they protect against potential injuries during repairs.

By assembling a comprehensive collection of tools and ensuring proper safety precautions, DIY enthusiasts can successfully navigate repair projects with confidence and skill.

Assembly Instructions for YTS3000

Proper assembly of the equipment is crucial for optimal performance and longevity. This section provides clear guidance on how to assemble the various components efficiently, ensuring all parts are correctly positioned and secured. Following these steps will facilitate a smooth setup process, enabling users to maximize the utility of their machinery.

Preparation Steps

Before starting the assembly process, gather all necessary tools and components. It is important to work in a clean, organized space to avoid losing any small pieces. Ensure that all components are free of damage and ready for installation.

Assembly Procedure

Begin by laying out all components according to the assembly order. Follow the sequence outlined below:

| Step | Component | Description |

|---|---|---|

| 1 | Main Frame | Attach the main frame to the base securely. |

| 2 | Engine | Mount the engine onto the designated brackets and fasten it tightly. |

| 3 | Wheels | Install the wheels by aligning them with the axles and securing them. |

| 4 | Handle | Attach the handle to the main body, ensuring it is stable. |

| 5 | Control Panel | Connect the control panel wiring according to the specifications. |

Once all components are assembled, conduct a thorough inspection to ensure everything is properly aligned and secured. This will help in achieving efficient operation and prolonging the lifespan of the equipment.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also safeguard the equipment being serviced. Understanding and adhering to safety guidelines can greatly reduce the risk of unforeseen incidents.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) when engaging in repair work. This includes gloves to protect your hands from sharp edges, goggles to shield your eyes from debris, and steel-toed boots to guard your feet against heavy objects. Additionally, consider using a dust mask or respirator when working with materials that generate harmful particles.

Work Environment

Maintaining a clean and organized workspace is essential for safe repairs. Ensure that your area is free from clutter, which can lead to trips and falls. Keep all tools and equipment within reach to minimize movement while working. Proper lighting is also important; it helps to identify potential hazards and ensures that tasks are performed accurately.

By following these safety measures, individuals can significantly enhance their protection and promote a safer working environment during repair activities.

Troubleshooting Common Issues

Identifying and resolving typical problems is essential for maintaining optimal performance and extending the lifespan of your equipment. This section provides insights into common malfunctions and practical solutions to help you effectively address them.

Below are some frequent issues encountered and their possible solutions:

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh and free of contaminants.

- Inspect the battery connections for corrosion or looseness.

- Examine the spark plug for wear and replace it if necessary.

- Unusual Noises:

- Listen for loose components; tighten any screws or bolts as needed.

- Inspect belts for signs of wear or damage and replace if required.

- Ensure that all moving parts are properly lubricated.

- Overheating:

- Check the air filters for blockages and clean or replace them accordingly.

- Ensure the cooling fins are free of dirt and debris.

- Verify that the coolant levels are appropriate and top off if necessary.

- Poor Performance:

- Inspect the fuel filter for clogs and replace if needed.

- Check tire pressure and adjust to the recommended levels.

- Ensure that all blades or cutting components are sharp and in good condition.

By following these guidelines, you can effectively troubleshoot and resolve many common problems, ensuring your equipment continues to function smoothly.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. When original elements are incorporated into repairs or replacements, users can experience enhanced reliability and efficiency. These components are designed specifically for the equipment, guaranteeing compatibility and superior functionality.

Improved Performance

Authentic components are engineered to meet the exact specifications of the machinery. This precise alignment leads to better performance, as these parts work seamlessly together. Users can expect enhanced efficiency, smoother operation, and ultimately a more enjoyable experience when utilizing genuine replacements.

Increased Longevity

Choosing original components often results in extended life for the equipment. These parts undergo rigorous testing and quality control processes, ensuring they can withstand the demands of regular use. Investing in authentic elements means reducing the frequency of repairs and replacements, ultimately saving time and money.

Upgrades and Modifications for YTS3000

Enhancing the performance and versatility of your machine can lead to a more enjoyable and efficient experience. Various adjustments and improvements can be made to elevate its capabilities, allowing for greater adaptability to different tasks and conditions.

One popular modification is the installation of a more powerful engine. This can significantly boost the overall performance, enabling the equipment to handle tougher jobs with ease. Additionally, upgrading the blades or attachments can enhance cutting efficiency and precision, making the work process smoother.

Another worthwhile enhancement is improving the suspension system. By upgrading to higher-quality components, you can increase stability and control, which is particularly beneficial when navigating uneven terrain. This not only enhances safety but also contributes to a better overall user experience.

Customizing the ergonomics of the equipment can also lead to improved comfort and reduced fatigue during prolonged use. Consider adding padded grips or adjustable seating options to create a more user-friendly setup tailored to individual preferences.

Lastly, incorporating modern technology, such as GPS systems or smart sensors, can provide real-time data and analytics, allowing for more informed decision-making and better task management. These advancements can significantly improve productivity and efficiency, making your machine an even more valuable asset.