Understanding the essential components of large-scale cutting machinery is crucial for effective maintenance and operation. This section delves into the various elements that contribute to the functionality and efficiency of these machines. A clear visualization of these components allows users to identify parts and ensure optimal performance.

By examining the intricate layout of the equipment, users can gain insights into how each segment interacts with others. Familiarity with these components not only aids in troubleshooting but also enhances the overall experience of managing such powerful tools. Proper comprehension of the setup is vital for both novice and experienced operators.

This guide serves as a valuable resource for those looking to enhance their knowledge of cutting machinery. It emphasizes the importance of recognizing individual components, enabling users to address issues swiftly and maintain their equipment in peak condition. A well-informed operator is key to achieving excellent results in landscaping and agricultural tasks.

60 Inch Deck Kubota RCK60 Overview

This section provides a comprehensive look at a specific type of cutting equipment designed for efficient lawn maintenance. Known for its durability and performance, this model is essential for achieving a well-manicured lawn.

The following features highlight the capabilities of this equipment:

- Cutting Width: Offers a broad cutting area for swift lawn care.

- Build Quality: Constructed from robust materials to withstand rigorous use.

- Compatibility: Designed to work seamlessly with various tractors, enhancing versatility.

- Ease of Use: User-friendly controls allow for effortless operation and adjustments.

- Maintenance: Simple maintenance procedures ensure longevity and optimal performance.

In summary, this model stands out due to its reliable performance and practical features, making it a valuable addition to any landscaping arsenal.

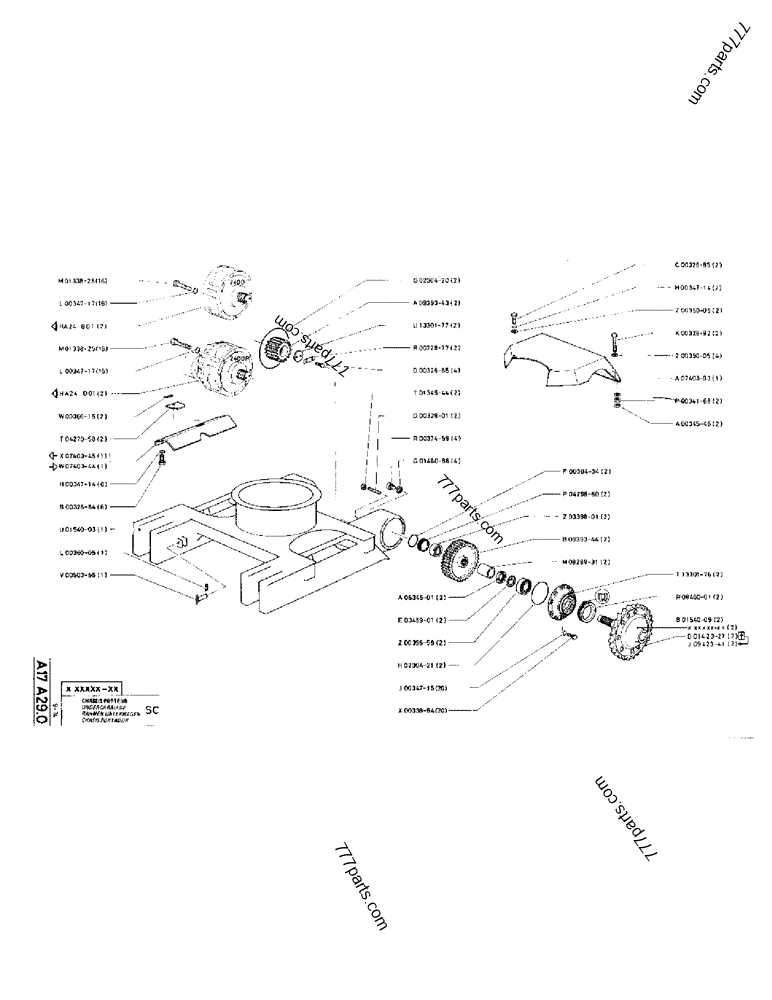

Essential Components of Mower Deck

The effectiveness of a lawn maintenance machine relies heavily on its core elements. Understanding these critical components enhances performance and extends the lifespan of the equipment. Each part serves a specific function, contributing to the overall efficiency of grass cutting and lawn care.

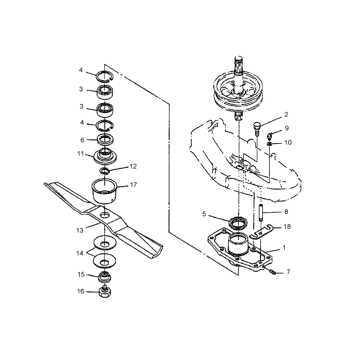

Blades are the primary elements responsible for the cutting action. They come in various shapes and sizes to suit different mowing needs, ensuring a clean and even cut. Regular inspection and sharpening are vital for optimal performance.

Spindles play a crucial role in connecting the blades to the motor. They facilitate the rotation of the blades and must be well-lubricated to avoid wear and tear. Ensuring they are in good condition is essential for smooth operation.

Chassis forms the frame that supports the machine’s structure. It provides stability and durability, allowing the mower to withstand rough terrain and heavy usage. A sturdy chassis contributes significantly to the overall performance.

Wheels ensure mobility and ease of maneuvering. The right size and type of wheels can greatly affect traction and handling, making it easier to navigate different landscapes.

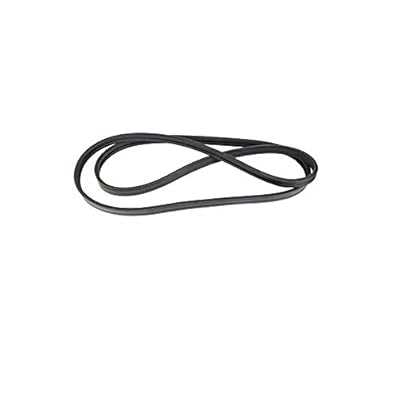

Drive Belts transmit power from the engine to the blades. These components need regular checks for signs of wear or damage, as they are vital for maintaining the machine’s cutting speed.

In summary, familiarizing oneself with these essential components helps in maintaining a lawn care machine, ensuring it operates efficiently and effectively for years to come.

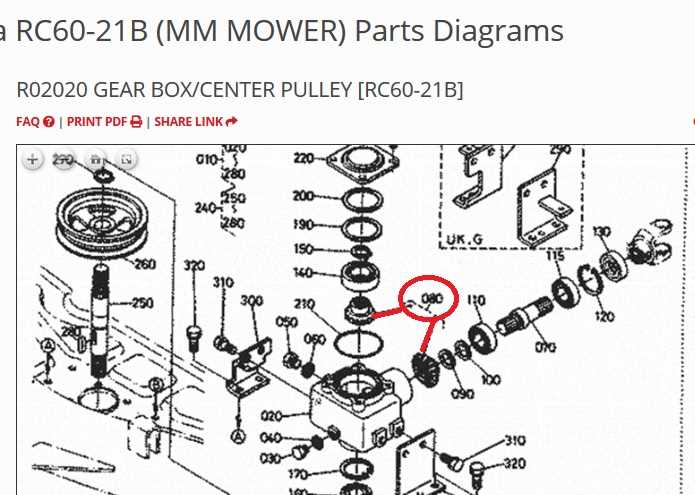

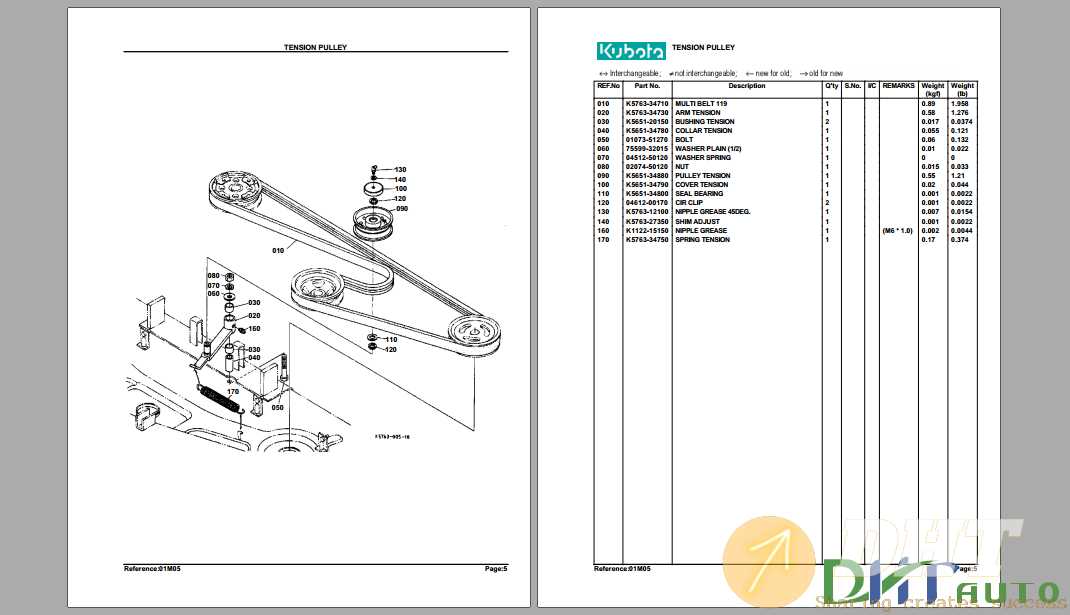

Parts Identification for Kubota RCK60

Understanding the various components of a lawn maintenance implement is essential for effective operation and maintenance. This section provides insight into the key elements that comprise the cutting apparatus, ensuring users can easily recognize and replace any necessary components. Familiarity with these elements can enhance the longevity and efficiency of the equipment.

Key Components Overview

The following table outlines the primary elements associated with the cutting mechanism, including their descriptions and functions. This reference is useful for users looking to perform maintenance or repairs effectively.

| Component | Description | Function |

|---|---|---|

| Blade | Sharp cutting tool | Trims grass to the desired height |

| Spindle Assembly | Housing for blade rotation | Supports and drives the blade |

| Lift Lever | Control for raising and lowering | Adjusts the cutting height |

| Drive Belt | Transmits power from the engine | Powers the spindle assembly |

| Housing | Enclosure for all components | Protects and supports the internal parts |

Maintenance Tips

Regular inspections and timely replacements of these components are vital for optimal performance. Keeping the blades sharp and ensuring the drive mechanism functions correctly will lead to a more efficient cutting experience. Always refer to the specific maintenance guidelines for your model to ensure proper care and longevity of the equipment.

Maintenance Tips for Mower Deck

Proper upkeep is essential for ensuring the longevity and efficiency of your lawn care equipment. Regular attention to components can prevent wear and tear, enhance performance, and save on costly repairs. By adopting a proactive maintenance routine, you can keep your machine operating smoothly and effectively.

Regular Cleaning

After each use, it’s crucial to remove grass clippings, debris, and dirt from the undercarriage. This practice prevents rust and corrosion, which can compromise functionality. Use a stiff brush or a scraper to dislodge stubborn material, ensuring the surface is clear and clean.

Inspection of Blades

Check the cutting implements regularly for signs of damage or dullness. Sharp blades provide a cleaner cut, which promotes healthy grass growth. If you notice any nicks or bends, consider sharpening or replacing them as needed. A well-maintained cutting edge enhances the overall effectiveness of your equipment.

By adhering to these maintenance tips, you can ensure that your lawn care machine remains in optimal condition, providing reliable service season after season.

Common Issues with RCK60 Deck Parts

When maintaining your cutting equipment, various challenges can arise that may affect its performance. Understanding these potential problems is crucial for effective troubleshooting and ensuring the longevity of your machine. Here are some frequent issues that operators encounter with their cutting apparatus.

Frequent Problems

- Wear and Tear: Components may experience degradation over time due to regular use, leading to decreased efficiency.

- Alignment Issues: Misalignment can result in uneven cutting, requiring adjustments to restore proper function.

- Corrosion: Exposure to moisture can cause rusting, impacting both functionality and appearance.

- Blockages: Debris accumulation can obstruct the cutting mechanism, hindering performance.

Signs of Malfunction

- Uneven Cuts: If the lawn appears inconsistent after cutting, it may indicate underlying problems with the equipment.

- Unusual Noises: Grinding or rattling sounds during operation can signal issues with the assembly.

- Vibrations: Excessive shaking can point to loose or damaged components that need immediate attention.

- Difficulty in Operation: If adjustments or manual interventions are required frequently, it may signify wear or malfunction.

Regular inspections and timely maintenance can help mitigate these issues, ensuring smooth operation and optimal results for your equipment.

Replacement Parts Availability and Sources

Finding suitable components for maintenance or repair is crucial for the longevity of any lawn care equipment. Various sources offer a range of options to ensure that users can easily obtain the necessary replacements, enhancing the overall performance and efficiency of their machinery.

Authorized Dealers and Retailers

One of the most reliable sources for obtaining components is through authorized dealers. These retailers often carry genuine components, ensuring compatibility and quality. In addition to physical locations, many authorized dealers provide online purchasing options, making it convenient to find the required items without leaving home.

Online Marketplaces and Specialty Stores

Numerous online marketplaces specialize in outdoor equipment components. These platforms often feature a wide selection of items, including aftermarket options that may be more cost-effective. Users should ensure they are purchasing from reputable sellers to guarantee the quality and fit of the components they choose.

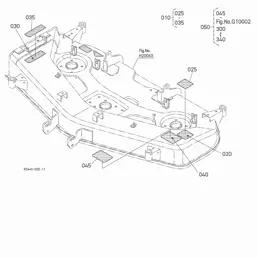

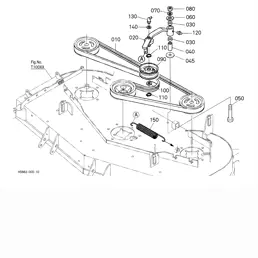

Assembly Instructions for Mower Deck

This section provides detailed guidance on how to properly assemble the cutting mechanism of your equipment. Following these steps will ensure optimal performance and longevity of the unit. Each component plays a vital role in the overall function, so attention to detail is essential during the assembly process.

Required Tools

Before starting the assembly, make sure you have the following tools available:

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening bolts and nuts |

| Screwdriver | For securing screws |

| Pliers | For gripping and twisting components |

| Socket Set | For easier access to fasteners |

Assembly Steps

Follow these steps to ensure a successful assembly:

1. Begin by positioning the main frame securely on a flat surface. This will provide stability as you attach the various components.

2. Attach the blade holders to the main frame using the provided fasteners. Ensure they are tightened adequately to avoid any movement during operation.

3. Connect the support arms to the frame. These will help maintain the structure’s integrity during use.

4. Install the belt system, ensuring that it is aligned properly with the pulleys for efficient power transfer.

5. Finally, double-check all connections and tighten any loose components to ensure safety and reliability during operation.

Understanding Mower Deck Functionality

The functionality of a cutting assembly is essential for maintaining a healthy lawn. This component serves as the main interface between the machine and the grass, allowing for efficient cutting, collection, and distribution of clippings. An understanding of how this assembly operates can significantly enhance its performance and longevity.

Key Components and Their Roles

Each element of the cutting assembly plays a critical role in its overall effectiveness. Blades are crucial for achieving a clean cut, while spindles support the blades and ensure smooth rotation. Additionally, the housing provides protection for these moving parts while contributing to the overall aerodynamics of the machine.

Maintenance and Care

Regular upkeep is vital for ensuring optimal performance. Cleaning the area after use prevents grass buildup, which can hinder functionality. Sharpening blades regularly is also necessary to maintain cutting efficiency, while checking the tension of belts and connections helps prevent unexpected breakdowns.

Comparative Analysis of Mower Deck Models

This section provides an overview of various cutting apparatus models available in the market. Each type has its own features, advantages, and limitations, which cater to different landscaping needs. Understanding these differences is crucial for selecting the most suitable option for individual requirements.

Key Features Comparison

When evaluating different cutting devices, several key characteristics play a significant role in performance and usability. Factors such as blade configuration, construction material, and adjustability can greatly influence the overall effectiveness of the apparatus.

| Model | Blade Configuration | Material | Adjustability |

|---|---|---|---|

| Model A | Triple Blade | Steel | Manual |

| Model B | Dual Blade | Aluminum | Hydraulic |

| Model C | Single Blade | Composite | Manual |

Performance Metrics

In addition to design features, performance metrics such as cutting height, operational speed, and efficiency also vary among models. These elements are essential in determining how well the equipment meets the demands of specific tasks.

| Model | Cutting Height Range | Speed (mph) | Fuel Efficiency |

|---|---|---|---|

| Model A | 1-4 inches | 5 | 30 mpg |

| Model B | 1.5-4.5 inches | 6 | 25 mpg |

| Model C | 2-5 inches | 4 | 35 mpg |

Upgrades for Enhanced Mower Performance

Improving the efficiency and effectiveness of your lawn care equipment can significantly enhance its performance. By implementing various enhancements, you can achieve a smoother operation, better cutting precision, and increased durability. Here are several upgrades to consider that will elevate the functionality of your machinery.

Performance Enhancements

- High-Quality Blades: Switching to premium blades can improve cutting efficiency and ensure a cleaner finish. Look for materials that resist dulling and wear.

- Engine Tuning: Regular maintenance and tuning of the engine can lead to improved power output and fuel efficiency.

- Improved Tires: Upgrading to high-traction tires can enhance stability and maneuverability on various terrains.

Comfort and Usability Upgrades

- Ergonomic Seats: Investing in comfortable seating can reduce fatigue during extended use, allowing for better focus and control.

- Advanced Control Systems: Incorporating user-friendly controls can enhance the overall experience, making operations smoother and more intuitive.

- Custom Canopies: Adding a canopy can provide protection from the elements, making mowing tasks more comfortable in varying weather conditions.

Incorporating these enhancements will not only improve your equipment’s performance but also create a more enjoyable experience while maintaining your landscape.

Safety Guidelines for Mower Operation

Ensuring a safe working environment is paramount when operating any type of cutting equipment. Following established safety practices not only protects the operator but also enhances the longevity and performance of the machinery. Awareness and adherence to these guidelines can significantly reduce the risk of accidents and injuries during operation.

Pre-Operation Safety Checks

Before starting the equipment, it is essential to conduct thorough inspections. Check for any loose or damaged components, and ensure that all safety features are functioning correctly. Familiarize yourself with the user manual to understand the machine’s specific safety requirements. Additionally, ensure that the surrounding area is clear of obstacles, debris, or any bystanders that may pose a risk during operation.

Proper Operation Techniques

While operating the machine, maintain a firm grip on the controls and stay focused on the task at hand. Avoid distractions, and do not operate the equipment under the influence of alcohol or drugs. Always wear appropriate personal protective equipment, such as sturdy footwear, gloves, and eye protection. If you need to adjust or service the machine, turn it off and allow it to come to a complete stop before proceeding.