Exploring the intricacies of power tools reveals a fascinating interplay of functionality and design. Recognizing how each element contributes to the overall performance is essential for both users and enthusiasts alike.

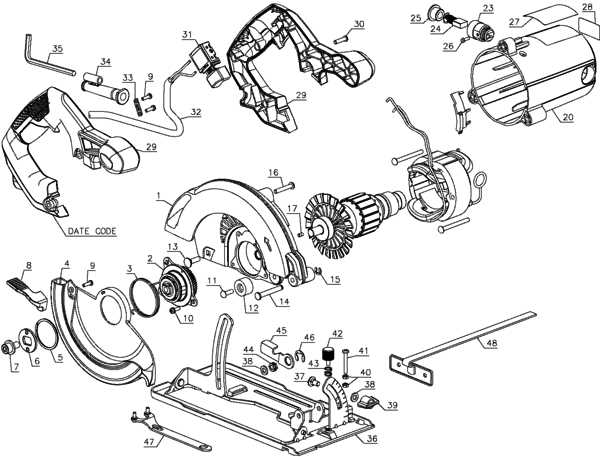

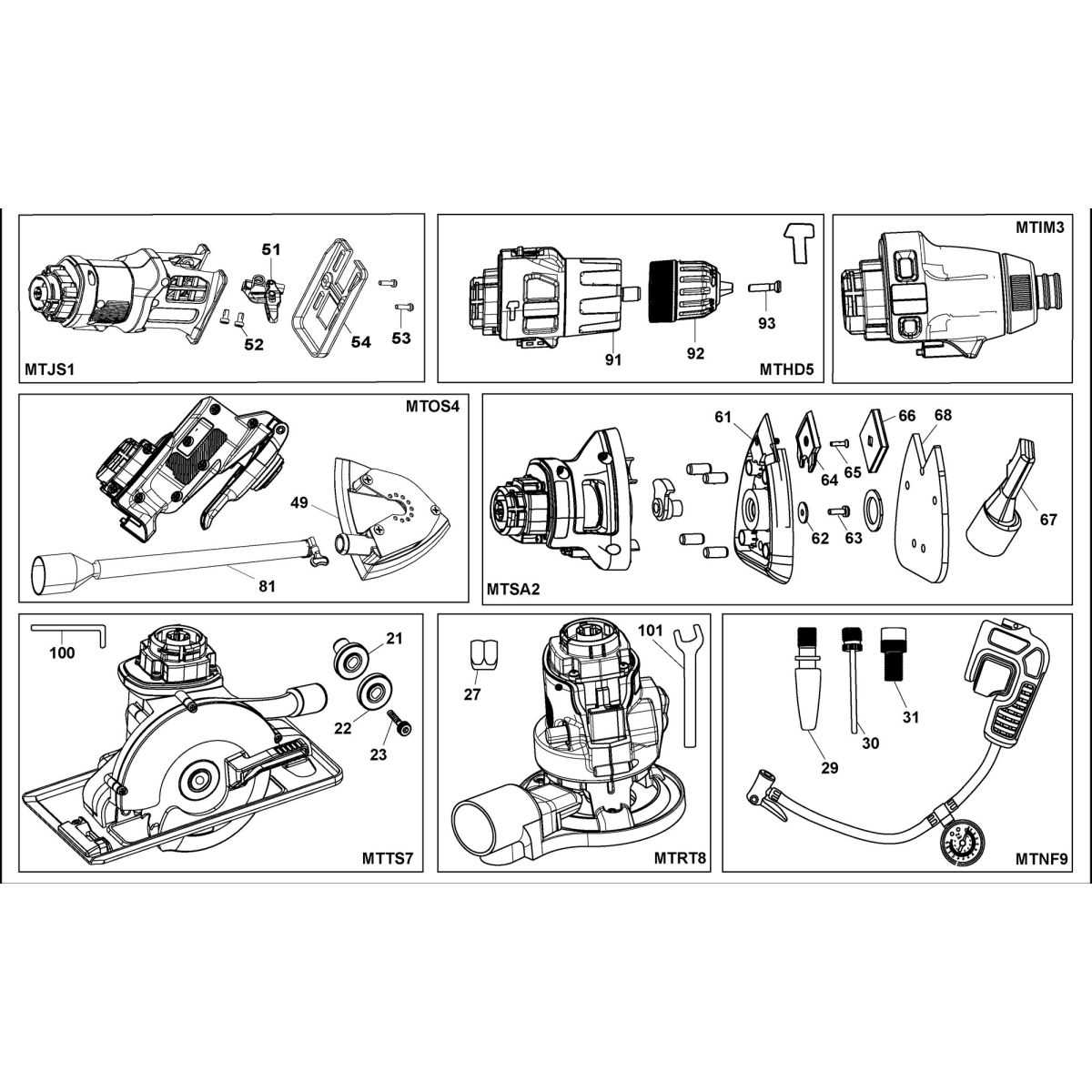

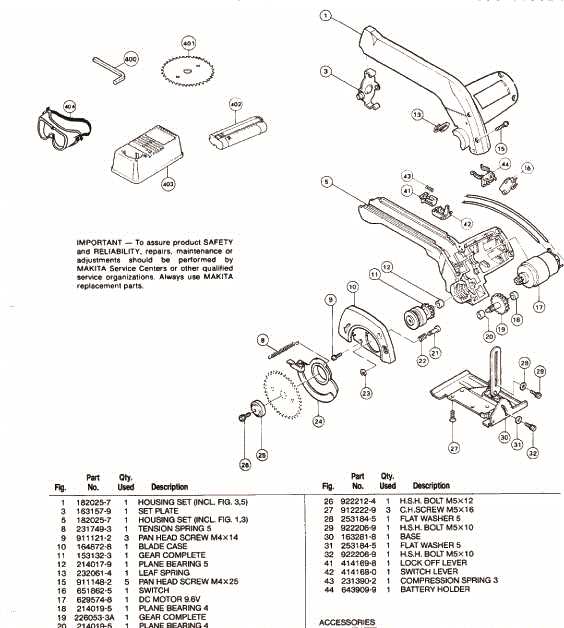

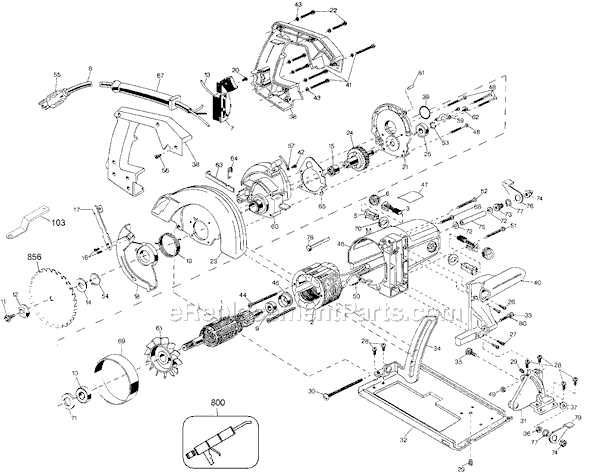

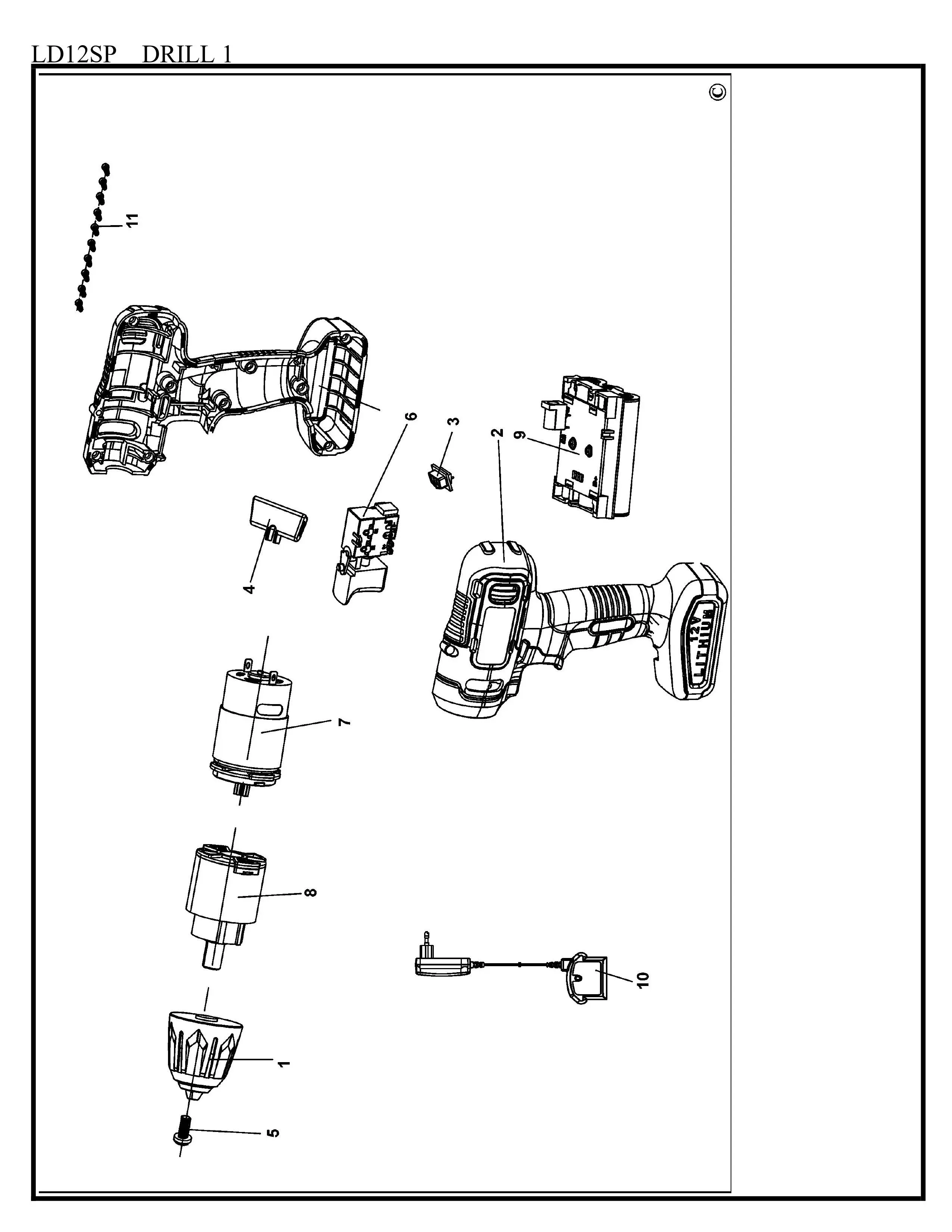

In this section, we will focus on a specific model’s essential components, outlining their roles and relationships. A well-organized schematic can significantly enhance the user experience, making maintenance and troubleshooting far more intuitive.

By delving into the arrangement of these critical pieces, one can gain insights that elevate proficiency and safety during operation. This knowledge serves as the ultimate guide for both novice and seasoned craftsmen aiming to master their equipment.

Understanding Circular Saw Components

The intricacies of a cutting tool encompass various essential elements that contribute to its functionality and performance. Each component plays a pivotal role, enabling precision and efficiency in diverse applications. Gaining insight into these parts can enhance one’s mastery of this indispensable equipment.

Power Source: The driving force behind the tool, whether electric or battery-operated, directly influences its effectiveness and mobility.

Blade: The cutting edge varies in size and type, tailored for specific materials, ensuring optimal results.

Base Plate: This component provides stability and support during operation, allowing for accurate cuts.

Guard: A crucial safety feature, it protects the user from accidental contact with the blade while in motion.

Handle: Designed for comfort and control, it enables better maneuverability and reduces fatigue during prolonged use.

Adjustment Mechanisms: These allow for changes in depth and angle, providing versatility for different cutting tasks.

By delving into these components, users can make informed decisions regarding maintenance, upgrades, and overall usage, leading to enhanced performance and safety.

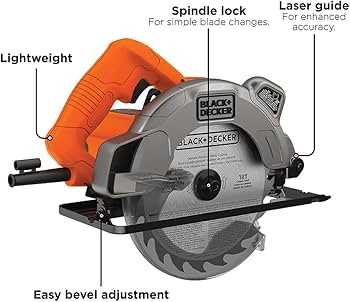

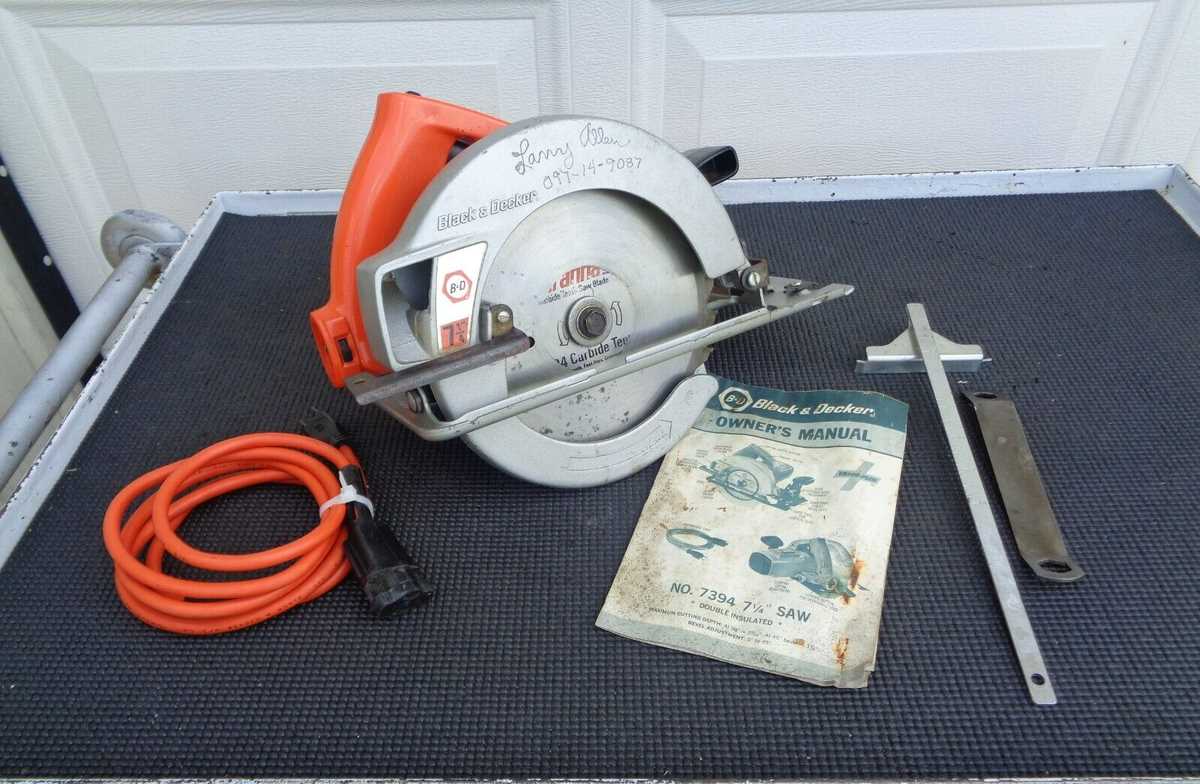

Key Parts of Black and Decker Saws

Understanding the essential components of these power tools is crucial for effective operation and maintenance. Each element plays a vital role in achieving precise cuts and ensuring safety during use.

- Motor: The powerhouse that drives the blade, influencing performance and cutting speed.

- Blade: The cutting instrument that determines the type of material that can be processed.

- Base Plate: The foundation that provides stability and supports accurate cutting angles.

- Guard: A protective feature that enhances safety by covering the blade when not in use.

- Trigger: The control mechanism that allows for easy activation and speed regulation.

Familiarity with these components enables users to maintain their tools effectively and select appropriate replacements when necessary.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These illustrations provide a visual guide, making it easier to identify individual elements and their functions within a device. By familiarizing yourself with these visual aids, you can enhance your troubleshooting skills and streamline your repair process.

Identifying Components

Each symbol or image in the schematic corresponds to a specific element. Take your time to study the legend or key, which often explains the symbols used. This will help you comprehend the relationships between different parts and understand how they interact within the system.

Understanding Relationships

Look for lines or arrows that indicate connections or flow. These visual cues can reveal how components fit together and the sequence of assembly. By analyzing these relationships, you can gain insights into potential failure points and improve your repair strategies.

In summary, mastering the art of reading these schematics can significantly enhance your ability to maintain and repair your tools effectively.

Common Circular Saw Issues Explained

Power tools can encounter various challenges that may hinder their performance and efficiency. Understanding these common problems can help users maintain their equipment and achieve optimal results.

- Blade Dullness: Over time, blades can lose sharpness, leading to inefficient cutting.

- Overheating: Excessive heat can arise from prolonged use or inadequate ventilation, causing potential damage.

- Vibration: Excessive shaking may indicate misalignment or imbalance, affecting precision.

- Power Issues: Intermittent power or failure to start may stem from electrical faults or battery problems.

- Kickback: Sudden jerks can occur if the blade binds, posing safety risks and requiring careful handling.

Regular inspection and maintenance can alleviate many of these concerns, ensuring tools perform at their best.

Identifying Essential Replacement Parts

Understanding the key components of your tool is crucial for maintaining its performance and longevity. Knowing which elements may need replacement can help you troubleshoot issues effectively and ensure smooth operation.

Common Components to Monitor

- Blades: Essential for cutting efficiency and precision. Regular inspection for wear is vital.

- Motor: The powerhouse of the equipment. Listen for unusual sounds as an indicator of potential issues.

- Guards: Safety features that protect the user. Check for damage regularly.

- Base Plate: Provides stability during use. Look for warping or signs of wear.

Steps to Identify Issues

- Conduct regular visual inspections of all major components.

- Test functionality by performing simple cutting tasks.

- Listen for any irregular noises that may suggest a malfunction.

- Consult the user manual for specific indicators of wear and tear.

By familiarizing yourself with these fundamental elements, you can ensure that your tool remains in optimal working condition, ready for any task at hand.

Maintenance Tips for Longevity

Ensuring the durability of your cutting tool requires regular upkeep and careful handling. By following essential maintenance practices, you can significantly extend the lifespan of your equipment and enhance its performance.

- Regularly inspect components for wear and tear.

- Keep the tool clean and free from debris.

- Lubricate moving parts to prevent friction and damage.

- Store in a dry, safe environment to avoid rust.

- Use the correct blade for the material to reduce strain.

Implementing these strategies will ensure optimal functionality and reliability for years to come.

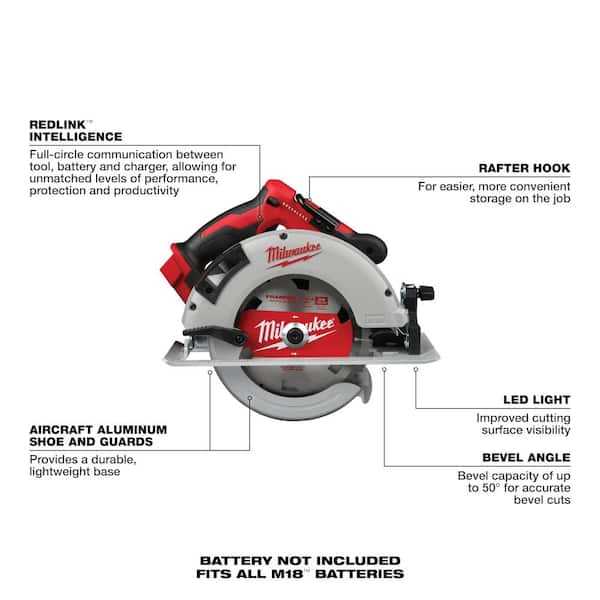

Upgrading Your Circular Saw Performance

Enhancing the efficiency of your cutting tool can significantly impact your projects. By making informed upgrades, you can improve precision, speed, and overall functionality, allowing for a smoother experience during tasks.

Essential Upgrades to Consider

- Blade Selection: Opt for high-quality blades suited for specific materials. Different teeth configurations can optimize performance.

- Power Supply: Ensure your tool is equipped with a reliable power source to maintain consistent energy levels during operation.

- Footplate Adjustment: A stable and adjustable base enhances cutting accuracy and safety, especially in varying thicknesses.

Maintenance Tips for Longevity

- Regularly clean the blade to prevent residue buildup.

- Inspect components for wear and replace them as needed to ensure optimal functionality.

- Lubricate moving parts periodically to reduce friction and extend the tool’s lifespan.

Safety Features of Black and Decker Models

Ensuring user safety is a paramount consideration in the design of power tools. Various mechanisms and features are integrated into equipment to minimize risks and enhance protection during operation. These advancements not only safeguard users but also promote confidence in utilizing these tools for various tasks.

Guard Systems

One of the most critical safety elements is the presence of guard systems. These shields are designed to protect users from accidental contact with blades, significantly reducing the likelihood of injuries. Additionally, some models are equipped with automatic retraction features that engage when the tool is not in use, providing an extra layer of security.

Ergonomic Design

Another vital aspect is ergonomic design, which promotes user comfort and control. Features such as rubberized grips and balanced weight distribution help minimize fatigue and enhance handling. When users feel comfortable and secure, they are less likely to make mistakes, ultimately contributing to a safer working environment.

Choosing the Right Blade for Projects

Selecting the appropriate cutting tool is essential for achieving optimal results in various tasks. The right blade can significantly enhance efficiency, accuracy, and the overall finish of your work. Understanding the characteristics and purposes of different blades will empower you to make informed decisions for your specific needs.

When determining the ideal cutting edge for your project, consider the following factors:

- Material Type: Different materials require specific blades for effective cutting. Common options include:

- Wood

- Metal

- Plastic

- Composite materials

lessCopy code

- High-speed steel (HSS)

- Carbide-tipped

- Diamond-coated

By taking these elements into account, you can select the best cutting edge to match your project’s requirements, ensuring a successful and satisfying outcome. Always prioritize safety and maintain your equipment to achieve the best performance.

Assembly Instructions for Beginners

Assembling power tools can seem daunting for those new to DIY projects. However, understanding the key components and their arrangement is crucial for successful assembly and safe operation. This guide will help you navigate the assembly process, ensuring you have the right tools and knowledge at your disposal.

Step 1: Gather all necessary components before starting. Familiarize yourself with each piece and its function within the overall system. This foundational knowledge will streamline the process and prevent confusion later on.

Step 2: Begin by reviewing the user manual. It typically contains a detailed overview of assembly steps and safety precautions. Pay close attention to any specific instructions regarding the alignment of parts and securing mechanisms.

Step 3: Start assembling by connecting the base and the main unit. Ensure that all fasteners are tightened properly to avoid any instability during operation. If unsure, consult the manual to verify the correct order of assembly.

Step 4: Attach any additional components, such as guards or extensions, as indicated in the instructions. These parts not only enhance functionality but also ensure user safety during use.

Step 5: Once assembly is complete, perform a thorough check. Ensure everything is secured, and there are no loose parts. This final inspection is critical for preventing accidents and ensuring optimal performance.

With these simple steps, even beginners can confidently assemble their power tools and embark on their DIY projects. Remember, practice makes perfect, and soon, you’ll find the assembly process becoming second nature.

Where to Buy Genuine Parts

Finding authentic components is essential for maintaining the performance and longevity of your equipment. There are several reliable sources to ensure you receive high-quality replacements that meet the manufacturer’s standards.

- Authorized Dealers: Visiting certified retailers ensures you get original items with warranty support.

- Online Marketplaces: Websites like Amazon or eBay often list genuine products, but check seller ratings and reviews.

- Manufacturer’s Website: The official site frequently offers a comprehensive catalog of items and direct purchasing options.

- Local Repair Shops: Many shops maintain a stock of authentic components and can assist with installations.

Always prioritize quality to maximize your investment and ensure optimal operation.

Tools Needed for Repair Work

When undertaking repair tasks, having the right instruments at your disposal is crucial for efficiency and effectiveness. Properly selected tools not only facilitate the repair process but also enhance safety and precision.

Essential Instruments

- Wrenches

- Screwdrivers

- Pliers

- Measuring tape

- Utility knife

Safety Equipment

- Safety goggles

- Gloves

- Ear protection

Equipping yourself with these essential tools will ensure that you are well-prepared to tackle any repair challenge that arises.

Frequently Asked Questions about Circular Saws

This section addresses common inquiries regarding rotary cutting tools. Whether you’re a novice or an experienced user, understanding these devices can enhance your woodworking skills and safety measures.

What should I consider when selecting a rotary cutting tool?

When choosing a model, consider factors such as power, size, weight, and blade type. These elements can significantly affect performance and ease of use.

How do I maintain my cutting instrument?

Regular maintenance includes cleaning the blade, checking for wear, and ensuring all parts are functioning correctly. Proper upkeep prolongs the lifespan and efficiency of your tool.

What safety measures should I follow?

Always wear protective gear, keep your workspace clear, and follow the manufacturer’s guidelines. Awareness of your surroundings is crucial for preventing accidents.

Can I use different types of blades?

Yes, various blade types are designed for specific materials. Selecting the appropriate blade enhances cutting efficiency and precision.

What is the importance of a guide when using this tool?

A guide helps ensure straight cuts and increases accuracy, making it easier to achieve your desired results.