Maintaining a well-kept garden requires not only dedication but also a clear understanding of the essential machinery involved. This section aims to provide insights into the various elements that make up a specific cutting apparatus, highlighting their roles and functions. By familiarizing yourself with these components, you can enhance your efficiency and the overall performance of your tools.

In this exploration, we will delve into the intricate details that constitute the mechanism behind effective grass trimming. Recognizing each component’s purpose can lead to better maintenance practices and informed decisions when replacements are needed. Ultimately, a solid grasp of these specifics contributes to a more seamless gardening experience.

Whether you are a seasoned professional or a novice gardener, understanding the inner workings of your equipment is paramount. As we break down the various segments, you will gain valuable knowledge that empowers you to take charge of your lawn care tasks with confidence.

Understanding John Deere Mower Decks

Maintaining a high-performing cutting system is essential for achieving a pristine lawn. This section aims to explore the components and functionalities that contribute to effective grass management, ensuring optimal results during each use.

Various elements within the cutting assembly play a crucial role in enhancing efficiency and durability. Each segment is meticulously designed to interact harmoniously, allowing for smooth operation and adaptability to different terrains.

Moreover, knowledge of these components aids in troubleshooting common issues, ultimately prolonging the lifespan of your equipment. By comprehensively understanding the structure and functionality, users can make informed decisions regarding maintenance and upgrades.

Overview of the John Deere 160

This section provides a comprehensive look at a popular model in the lawn maintenance industry, highlighting its features, benefits, and essential components. Understanding the various elements of this machine can enhance efficiency and ensure optimal performance for users.

Key characteristics of this equipment include:

- Durability and reliability for consistent usage

- Ergonomic design for user comfort

- Versatile applications suitable for various terrains

Common components integral to the operation of this machinery consist of:

- Cutting mechanism for precise grass trimming

- Power system that ensures robust performance

- Control features allowing for easy maneuverability

Maintenance practices play a crucial role in prolonging the lifespan of this equipment. Regular checks and timely replacements of worn-out elements are recommended.

In conclusion, this model serves as an effective solution for homeowners and professionals alike, combining functionality with ease of use.

Importance of Mower Deck Parts

Understanding the components that make up a cutting system is essential for optimal performance and longevity. Each element plays a crucial role in ensuring efficient operation, contributing to the overall effectiveness of the equipment.

Durability and efficiency are directly linked to the quality and condition of these elements. Regular maintenance and timely replacements can prevent costly repairs and enhance the lifespan of the machinery. High-quality components ensure that the system functions smoothly, providing a clean and even cut.

Moreover, familiarity with these components allows users to troubleshoot issues effectively. Identifying worn or damaged elements can lead to prompt action, minimizing downtime and enhancing productivity. Understanding the layout and function of each piece empowers operators to maintain their equipment better, ensuring it remains in peak condition.

In summary, a thorough knowledge of the individual components of a cutting assembly is vital for maintaining efficiency and extending the lifespan of the machinery. This not only improves performance but also leads to a more satisfying experience for the operator.

Common Issues with Mowing Equipment

Mowing tools can face various challenges that impact their performance and longevity. Understanding these typical problems is essential for effective maintenance and operation. Identifying and addressing these issues promptly can save both time and resources.

Uneven Cutting: One of the most frequent problems is uneven grass cutting. This can be caused by worn-out blades, incorrect height adjustments, or even uneven terrain. Regularly inspecting and sharpening blades, as well as ensuring proper alignment, can help mitigate this issue.

Clogging: Another common concern is clogging due to grass buildup. This can occur when cutting tall or wet grass, leading to reduced efficiency. Cleaning the underside of the unit after each use and adjusting the cutting height can prevent this problem.

Vibration: Excessive vibration during operation often indicates mechanical issues. This could be a result of imbalanced blades, loose parts, or damaged bearings. Regular checks and maintenance can help maintain a smooth operation.

Difficulty Starting: Equipment may also experience starting difficulties, which can stem from fuel issues, battery problems, or ignition failures. Ensuring proper fuel quality and regular battery maintenance can alleviate these concerns.

By being aware of these common challenges, operators can take proactive measures to enhance the efficiency and lifespan of their mowing tools.

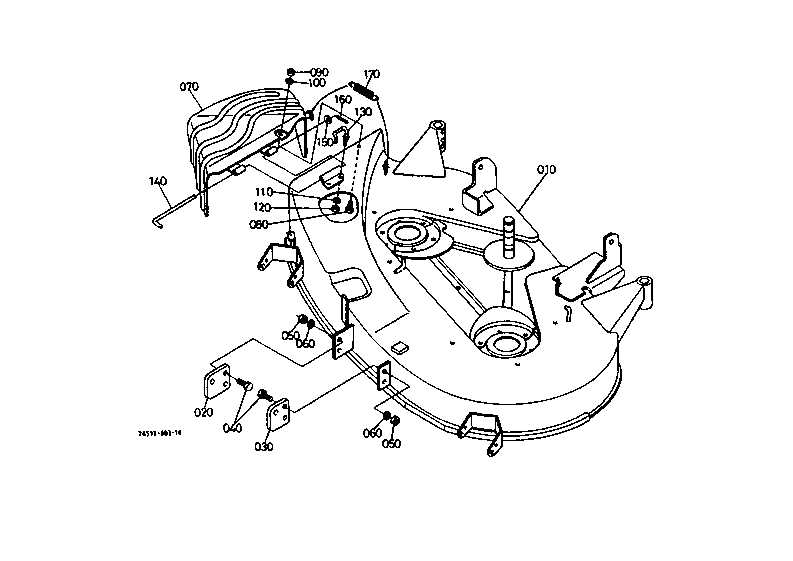

Key Components in the Diagram

This section explores the essential elements represented in the illustration, focusing on their functions and interrelations. Understanding these components is vital for effective maintenance and operation.

- Blades: Critical for cutting, they dictate the quality of the finish.

- Spindles: These rotate the blades and are key to their movement.

- Deck Housing: Provides structure and support for the entire assembly.

- Belt System: Transfers power from the engine to the blades.

- Height Adjustment Mechanism: Allows customization of cutting height for varying grass types.

Each of these parts plays a crucial role in achieving the ultimate performance and longevity of the equipment.

How to Interpret the Diagram

Understanding a technical illustration can significantly enhance your ability to maintain and repair your equipment effectively. These visuals provide a clear representation of components, their arrangement, and interconnections, making it easier to identify necessary actions and replacements.

To effectively interpret the illustration, follow these guidelines:

- Familiarize Yourself with Symbols:

- Look for legend keys that explain various symbols.

- Note any color coding used to distinguish different parts.

- Identify Major Components:

- Recognize the primary elements within the assembly.

- Understand the function of each part in relation to the whole.

- Follow the Connections:

- Observe how components link together, which can indicate assembly order.

- Pay attention to any notes on specific assembly techniques.

- Consult the Manual:

- Use the diagram in conjunction with your equipment manual for detailed instructions.

- Refer to troubleshooting sections for common issues related to specific components.

By mastering these elements, you can ensure that you approach maintenance tasks with confidence and clarity, leading to more efficient operations and longer equipment life.

Replacement Parts for the John Deere 160

Maintaining outdoor equipment is essential for optimal performance and longevity. When components wear out or become damaged, finding the right replacements is crucial. This section focuses on the key elements necessary for restoring your machinery to peak condition.

Identifying Components: Before sourcing any items, it’s important to recognize the specific elements that may require replacement. Regular inspections can help pinpoint wear and tear, ensuring that you address issues before they escalate.

Quality Over Cost: When selecting new components, prioritize quality over price. Investing in durable and reliable replacements can save you money in the long run, reducing the need for frequent repairs.

Compatibility: Always ensure that the replacements you consider are compatible with your equipment. Consulting the manufacturer’s specifications can provide valuable guidance, preventing potential issues during installation.

Availability: Many trusted retailers offer a wide selection of these components, both online and in-store. Taking the time to research options can lead you to the best deals and most reliable products.

Installation: Once you have acquired the necessary items, proper installation is key to functionality. Refer to user manuals or seek professional assistance if you’re unsure about the installation process.

By being proactive and informed about replacement options, you can enhance the efficiency and lifespan of your outdoor equipment.

Maintenance Tips for Mower Decks

Proper upkeep of cutting apparatus is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures a smoother operation, reducing the risk of unexpected breakdowns. By following a few straightforward practices, operators can extend the life of their equipment and maintain a pristine lawn.

Regular Cleaning

Accumulation of grass clippings, dirt, and debris can hinder performance. After each use, it’s advisable to clean the underside and surrounding areas of the cutting unit to prevent rust and buildup. A gentle rinse with water and a stiff brush can effectively remove stubborn residues.

Sharp Blades

Maintaining sharp blades is crucial for achieving clean cuts and promoting healthy growth of grass. Dull blades tear the grass rather than cutting it, which can lead to discoloration and disease. Inspect blades regularly, sharpening them at least once per season, or more frequently if cutting in rough conditions.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean Cutting Unit | After each use | Prevents rust and buildup |

| Sharpen Blades | Every 25 hours of use | More often in tough conditions |

| Check Belts and Cables | Monthly | Look for wear and proper tension |

| Oil Moving Parts | Every season | Ensures smooth operation |

By implementing these simple maintenance tasks, users can ensure their equipment remains in excellent working condition, providing a better cutting experience and reducing the likelihood of costly repairs.

Where to Find Replacement Parts

Locating the necessary components for your equipment can significantly enhance its performance and longevity. Various resources are available for sourcing these essential items, ensuring that you can keep your machine running smoothly.

| Source | Description |

|---|---|

| Online Retailers | Numerous websites specialize in agricultural machinery supplies, offering a wide range of components for easy online purchasing. |

| Local Dealers | Authorized dealerships often stock genuine items and can provide expert advice on compatibility and installation. |

| Salvage Yards | These locations can be treasure troves for used but functional components at a fraction of the new price. |

| Manufacturer’s Website | Visiting the official site can give access to a complete catalog of available items along with user manuals and installation guides. |

DIY Repairs for Mower Deck Issues

Maintaining and fixing your cutting equipment can save you time and money. Understanding common problems and how to address them is essential for optimal performance. Here’s a guide to help you tackle typical issues on your own.

Before starting any repair, ensure you have the right tools and safety gear. Familiarize yourself with the components and their functions to streamline the process.

- Common Issues:

- Uneven cutting

- Excessive vibration

- Loss of power

- Clogged discharge chute

Here are steps for troubleshooting and resolving some frequent concerns:

- Check Blade Condition:

- Inspect blades for dullness or damage.

- Sharpen or replace as needed.

- Adjust Cutting Height:

- Ensure height settings are consistent across all wheels.

- Use a ruler to measure the distance from the ground to the blade.

- Inspect Belts and Cables:

- Look for fraying or wear.

- Replace any damaged components immediately.

- Clear Clogs:

- Regularly remove grass buildup from under the machine.

- Use a brush or scraper to clean the discharge chute.

By following these guidelines, you can keep your equipment in peak condition and extend its lifespan. Regular maintenance not only enhances performance but also prevents major issues down the line.

Professional Repair Services Availability

Access to expert maintenance solutions is essential for ensuring optimal performance and longevity of your equipment. Skilled technicians offer specialized services that address a variety of mechanical issues, ensuring that your machinery operates efficiently and effectively.

Types of Services Offered

Professionals typically provide a range of services, including diagnostics, repairs, and routine maintenance. These services help to prevent breakdowns and enhance operational reliability.

Service Providers

| Provider Name | Location | Contact Information |

|---|---|---|

| Tech Solutions Inc. | New York | (123) 456-7890 |

| Machinery Masters | California | (987) 654-3210 |

Frequently Asked Questions About Mower Decks

Understanding the components and functionalities of lawn care equipment can enhance efficiency and performance. Many users have common inquiries regarding maintenance, troubleshooting, and general operation of these essential tools.

What are the signs that my equipment needs maintenance?

Frequent signs include unusual noises, uneven cutting, or visible damage. Regular inspections help prevent further issues and ensure optimal performance.

How often should I sharpen the blades?

Blades should be sharpened approximately every 20 to 25 hours of use, or whenever you notice a decline in cutting efficiency. Keeping them sharp promotes healthy grass growth.

Can I use my equipment on uneven terrain?

While some models are designed for rough surfaces, operating on highly uneven ground may lead to damage. Always consult the user manual for recommendations regarding terrain suitability.

What should I do if the equipment leaves uncut patches?

This issue may stem from dull blades or incorrect cutting height settings. Checking these factors can help resolve the problem effectively.

Is it necessary to clean after each use?

Yes, cleaning after each use helps prevent grass buildup and rust, extending the lifespan of your equipment. A simple rinse and brush can do wonders.

How can I ensure safety while using my equipment?

Always wear appropriate protective gear, follow operational guidelines, and maintain awareness of your surroundings to ensure a safe mowing experience.