Maintaining equipment in optimal condition often requires a detailed understanding of its various elements. Ensuring that each component is correctly positioned and functions smoothly plays a crucial role in the overall performance. By examining key structures, one can gain insight into how they interconnect and contribute to efficient operation.

Understanding the relationships between various elements helps streamline the maintenance process, making it easier to troubleshoot and replace individual parts when needed. This comprehensive approach not only ensures longevity but also maximizes the efficiency of the equipment in everyday use.

Whether you’re an experienced operator or new to equipment care, having a clear breakdown of how these elements fit together is invaluable. With the right knowledge, maintaining functionality becomes a more straightforward and manageable task.

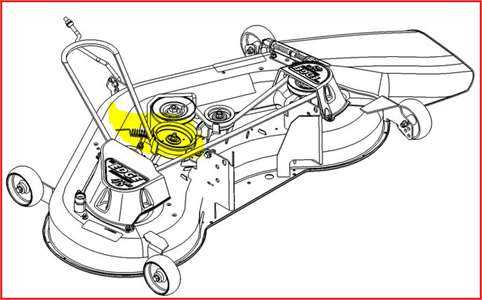

Understanding the Mechanism Behind This Grass-Cutting Equipment

To fully grasp how this particular cutting equipment operates, it’s essential to explore its structural layout and functionality. The system integrates several key elements that work in unison to deliver precise trimming and optimal performance. Each component is meticulously designed to ensure smooth operation, efficiency, and durability, making it a reliable choice for maintaining various outdoor spaces.

The central mechanism involves rotating blades that are strategically positioned to cut grass evenly. These blades, coupled with a robust housing, help protect both the equipment and its operator from debris. By ensuring a seamless interaction between all parts, the machine is capable of handling tough conditions while maintaining high efficiency over extended use.

Common Issues with Mower Deck Components

Components of grass-cutting equipment often face wear and tear over time, which can affect overall performance and efficiency. Regular use can lead to malfunctions that require attention to avoid more serious damage. Addressing these issues early can prolong the lifespan of the equipment and ensure smooth operation.

Uneven Cutting

A common issue seen with lawn equipment is uneven cutting. This can be caused by several factors, including misaligned blades, buildup of debris, or worn-out components. Regular cleaning and inspections help maintain optimal performance and avoid uneven results.

Excessive Vibration

Another problem users may encounter is excessive vibration. This often indicates an issue with the balancing of key parts or loose fasteners. Ensuring that all elements are securely fastened and properly aligned can minimize vibration and prevent further mechanical problems.

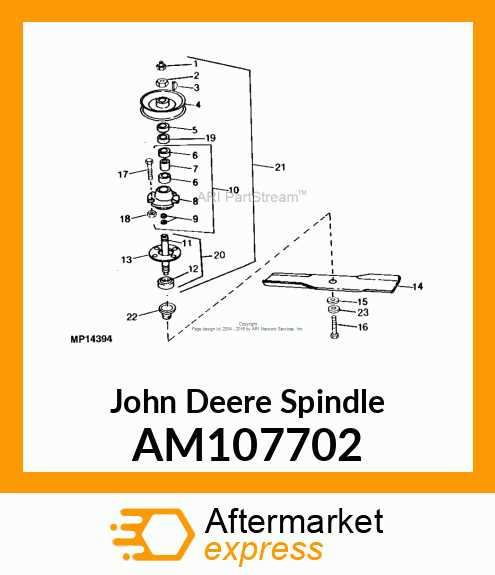

How to Identify Parts for Replacement

Recognizing the components that need to be changed is essential for maintaining the functionality of any equipment. Knowing what to look for can save time and prevent more serious mechanical failures. Understanding which elements are showing signs of wear or damage is the first step in ensuring your machine operates smoothly.

Check for Wear and Tear

Over time, different sections of machinery experience natural degradation due to constant use. Look for visible signs such as rust, cracks, or looseness. If any component seems fragile or no longer fits as securely as it once did, it’s likely time for a replacement. Regular inspections help detect these issues early.

Consult Manuals and Guides

Each piece of equipment comes with documentation that provides detailed information on its structure. By referring to these guides, you can compare your findings and pinpoint the exact part that needs attention. Using the proper terms from these resources will

Proper Maintenance for Long-Lasting Deck Parts

Ensuring the longevity of equipment components requires consistent attention and care. Regular upkeep can prevent wear and tear, allowing machinery to function smoothly over time. By focusing on key maintenance tasks, it is possible to extend the life of essential elements, avoiding the need for frequent replacements. This approach not only improves performance but also reduces overall costs associated with repairs.

Cleaning and lubrication are two essential tasks that should be carried out periodically. Removing debris and applying protective substances helps in minimizing friction, which can otherwise lead to premature degradation. Furthermore, inspecting connections and tightening any loose fasteners plays a crucial role in preventing breakdowns.

Another important aspect of care involves checking for rust or corrosion, especially on exposed metal surfaces. Applying protective coatings can shield these areas from moisture and other damaging factors. In addition, scheduling periodic inspections ensures that potential issues are identified early and addressed before they escalate into more serious problems.

Overall, proper maintenance not only extends the operational life of components but also enhances the overall efficiency of the machinery, making it a wise investment in the long term.

Compatible Blades for Efficient Mowing

Choosing the right cutting tools is essential for maintaining optimal performance in any lawn care task. The right blades can drastically improve the overall effectiveness, ensuring clean and even results across various types of grass and terrain.

- Standard blades: Ideal for everyday trimming, providing a balanced performance between precision and durability.

- Mulching blades: These are designed for chopping grass clippings into smaller pieces, making them perfect for nutrient-rich mulching without the need for additional equipment.

- High-lift blades: Known for their ability to create strong airflow, these blades excel in discharging clippings efficiently, especially in tougher conditions.

- Low-lift blades: Best suited for sandy or dusty environments, minimizing the amount of dust kicked up during cutting while still delivering a clean finish.

Each type of blade offers distinct advantages, and selecting the appropriate

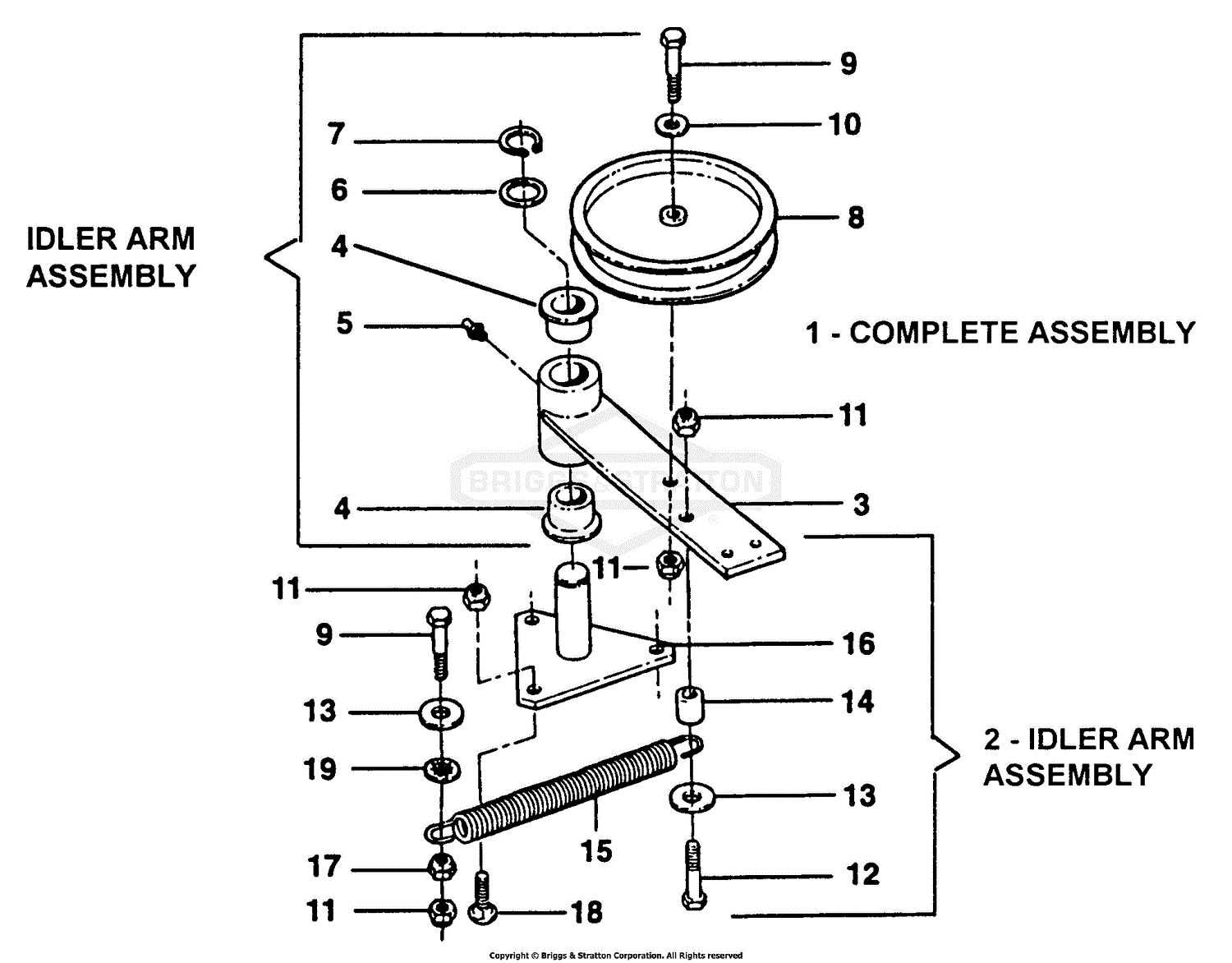

How to Clean and Maintain Deck Belts

Regular upkeep of belts is essential for ensuring optimal performance and longevity of your equipment. Proper cleaning and maintenance not only enhance efficiency but also prevent unnecessary wear and tear. This guide will walk you through effective techniques to keep these components in top shape.

Cleaning Procedures

Start by disconnecting the power source to ensure safety during the cleaning process. Use a soft brush or cloth to remove dirt, debris, and grass clippings that may have accumulated on the belts. For stubborn residue, a gentle solution of soapy water can be applied, followed by thorough rinsing. Make sure to dry the belts completely to avoid moisture buildup that could lead to deterioration.

Maintenance Tips

Inspect belts regularly for signs of wear such as fraying or cracking. Adjust tension as needed to ensure proper fit and function. Lubricating pulleys and other moving parts can also enhance performance and reduce friction. Keeping a schedule for these maintenance tasks will help prolong the lifespan of your belts and maintain your equipment’s reliability.

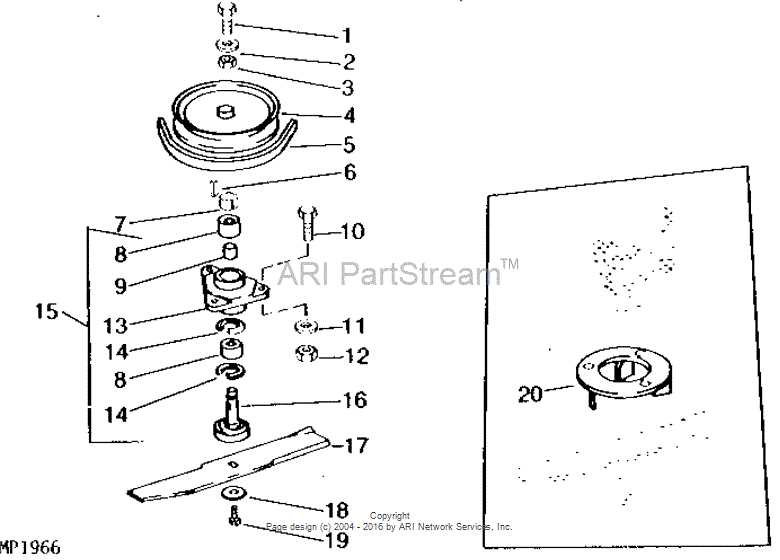

Choosing the Right Bearings for Your Mower

When it comes to maintaining optimal performance in your lawn care equipment, selecting the appropriate rolling elements is crucial. These components play a vital role in ensuring smooth operation and extending the lifespan of your machinery.

Understanding the different types of rolling elements available can help you make informed decisions. Here are some key factors to consider:

- Type of Load: Identify whether your equipment experiences radial or axial loads, as this will influence your choice.

- Material: Different materials offer varying levels of durability and resistance to environmental factors. Common options include steel, ceramic, and composite materials.

- Size and Fit: Ensure that the chosen components match the specifications of your equipment for proper installation and functionality.

- Speed Rating: Check the speed rating of the rolling elements to ensure they can handle the operational demands of your machinery.

By carefully considering these aspects, you can ensure that your lawn care equipment operates efficiently and effectively, minimizing downtime and maintenance costs.

Best Practices for Mower Deck Installation

Ensuring the proper attachment of cutting apparatus components is essential for optimal performance and longevity. Following established guidelines can significantly enhance functionality and safety during operation. Here are several recommended practices to keep in mind when installing these crucial elements.

1. Prepare the Workspace: Before beginning, ensure that the area is clean and well-organized. Remove any debris or obstacles that may hinder the installation process. A clutter-free environment reduces the risk of accidents and allows for efficient work.

2. Gather Necessary Tools: Collect all required tools beforehand to avoid interruptions during installation. Common tools include wrenches, sockets, and screwdrivers. Having everything on hand facilitates a smoother and faster assembly.

3. Consult the Manual: Familiarize yourself with the manufacturer’s guidelines. Reference materials provide essential information regarding component specifications and assembly procedures, ensuring that the process adheres to recommended standards.

4. Inspect Components: Check all parts for wear or damage prior to installation. Ensuring that every element is in good condition prevents potential issues during operation and promotes safety.

5. Follow a Systematic Approach: Install components in a logical order. Begin with the main frame, followed by additional elements such as brackets and fasteners. A systematic approach minimizes confusion and errors, leading to a more effective assembly.

6. Tighten Fasteners Securely: After assembling, ensure that all bolts and screws are tightened to the specified torque settings. Loose fasteners can lead to malfunction or damage, compromising both safety and efficiency.

7. Test Functionality: Once installation is complete, perform a thorough test to verify that all components function as intended. Regular checks ensure reliability and help identify any adjustments needed for optimal performance.

Implementing these best practices will result in a well-installed cutting apparatus, enhancing both safety and efficiency. A careful and informed approach ensures reliable operation for the long term.

Troubleshooting Mower Deck Performance Problems

When dealing with issues related to cutting equipment efficiency, it is essential to identify potential causes and implement effective solutions. Various factors can affect the functionality of the cutting mechanism, leading to subpar performance. By systematically analyzing these issues, operators can restore optimal operation.

Common Issues and Solutions

- Uneven Cutting: If the grass is not being cut evenly, check for:

- Worn or damaged blades

- Improper blade height adjustment

- Uneven tire pressure on the machine

- Excessive Vibration: Unusual vibrations can indicate:

- Loose or missing hardware

- Imbalanced blades

- Worn bearings or bushings

- Clogging: If the cutting area becomes clogged, consider:

- Inspecting for debris buildup

- Cleaning the underside regularly

- Using the appropriate cutting height for the grass type

Regular Maintenance Practices

To prevent performance issues, adhere to a consistent maintenance schedule. This should include:

- Regularly sharpening blades to ensure clean cuts.

- Inspecting belts for wear and proper tension.

- Cleaning components after each use to prevent buildup.

- Checking fluid levels and replacing filters as needed.

By addressing these common challenges and following maintenance guidelines, operators can significantly enhance the performance and longevity of their cutting equipment.

Improving Mower Efficiency with Proper Parts

Enhancing the effectiveness of grass-cutting equipment involves understanding the significance of various components. Each element plays a vital role in ensuring smooth operation and optimal performance. By maintaining and upgrading these essential features, users can experience improved results and longevity of their machines.

Key Components for Optimal Performance

Identifying and utilizing the right elements can greatly influence the efficiency of lawn maintenance equipment. Below are some crucial components to consider:

- Blades: Sharp and well-maintained cutting tools are essential for achieving a clean cut.

- Belts: High-quality drive belts ensure reliable power transfer, reducing the risk of slippage.

- Wheels: Properly functioning wheels contribute to smooth movement across various terrains.

Maintenance Tips for Longevity

Regular upkeep is crucial for sustaining the performance of cutting devices. Here are some maintenance strategies:

- Check and sharpen blades regularly to maintain cutting efficiency.

- Inspect belts for wear and replace them when necessary to prevent breakdowns.

- Keep wheels clean and free of debris to ensure optimal mobility.

By focusing on these aspects, users can significantly enhance their equipment’s effectiveness, leading to a more productive and enjoyable mowing experience.

Adjusting Mower Height for Different Terrains

Maintaining an appropriate cutting height is crucial for achieving optimal results across various landscapes. Whether navigating through uneven fields, manicured lawns, or rugged terrain, adjusting the elevation of the cutting apparatus ensures a uniform appearance and healthy growth.

Different environments demand specific height adjustments to accommodate grass types and soil conditions. The following table outlines recommended cutting heights for common terrains:

| Terrain Type | Recommended Height (inches) |

|---|---|

| Flat Lawn | 2 to 3 |

| Uneven Ground | 3 to 4 |

| Rough Terrain | 4 to 5 |

| Thick Grass | 3 to 4 |

Adjusting the cutting height according to these guidelines will enhance performance and prolong the lifespan of the equipment while ensuring a lush, well-kept appearance.

Essential Tools for Deck Part Replacements

When it comes to maintaining outdoor equipment, having the right tools is crucial for effective repairs and replacements. The following section outlines the fundamental instruments necessary to successfully carry out part replacements, ensuring your machinery operates at its best.

Wrenches and Sockets: A variety of wrenches and socket sets are indispensable for loosening and tightening bolts. Ensure you have both metric and imperial sizes to accommodate different fasteners.

Screwdrivers: Flathead and Phillips screwdrivers are essential for removing screws that hold components together. A set with varying lengths will provide better access to tight spaces.

Torque Wrench: This tool is vital for applying the correct amount of force to fasteners, preventing damage to components. Accurate torque settings are necessary for optimal performance.

Lubricants and Cleaners: Keeping parts well-lubricated and clean prolongs their lifespan. Use appropriate lubricants and cleaners to maintain efficiency and performance.

Safety Gear: Don’t forget to wear protective equipment such as gloves and goggles. Safety should always be a priority when working with machinery.

By equipping yourself with these essential tools, you can ensure that part replacements are performed smoothly and effectively, leading to a well-functioning machine.