Understanding the intricate assembly of outdoor maintenance machinery is crucial for effective upkeep. This section will explore the various elements that contribute to the functionality of these essential tools, focusing on their design and interconnections.

Maintenance and repair are vital for ensuring optimal performance and longevity. A clear representation of each component can enhance one’s ability to troubleshoot and replace any malfunctioning parts.

For enthusiasts and professionals alike, having access to a detailed visual guide simplifies the process of understanding how each segment interacts within the overall framework, ultimately leading to improved efficiency in lawn care tasks.

Understanding John Deere 430 Mower Deck

This section delves into the essential components and functionality of a specific cutting attachment designed for lawn care. Gaining insight into its structure and operation is crucial for effective maintenance and optimal performance.

Here are some key aspects to consider:

- Construction: The assembly is built from durable materials, ensuring longevity and resistance to wear.

- Components: Familiarize yourself with the various elements, including blades, spindles, and belts, that work together for efficient grass cutting.

- Functionality: Understanding how each part contributes to the overall performance can enhance user experience and reduce the need for repairs.

Regular inspection and maintenance of these elements are vital. Here are some recommended practices:

- Check the sharpness of the blades regularly to ensure clean cuts.

- Inspect belts for wear and proper tension.

- Lubricate moving parts to minimize friction and prolong lifespan.

By mastering these details, operators can ensure that their equipment runs smoothly and efficiently, leading to a well-maintained lawn and a productive experience.

Key Components of the Mower Deck

Understanding the essential elements of a cutting platform is crucial for maintaining its efficiency and longevity. Each component plays a significant role in ensuring optimal performance, making it vital to recognize how they interact and function together. From the blades to the housing, every piece contributes to achieving the ultimate cutting experience.

The cutting blades are at the heart of this assembly, designed to provide a clean and precise trim. The spindle assembly supports the blades, allowing them to rotate smoothly and effectively. Additionally, the housing encases these components, protecting them from debris and ensuring safety during operation.

Another important feature is the lift mechanism, which allows users to adjust the height of the cutting apparatus for varying grass lengths. This adaptability is key for achieving the desired finish across different terrains. Lastly, the discharge chute directs clippings away from the cutting area, promoting a tidy finish and preventing clumping.

How to Interpret the Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. This guide will assist you in navigating the intricacies of such illustrations, enabling you to identify and select the correct elements for your machinery.

Breaking Down the Visual Elements

Each section of the illustration typically represents a different assembly. Pay close attention to labels and numbers that correlate with a list, as these will guide you in identifying specific components. Look for color coding or other distinguishing features that can help in categorizing parts effectively.

Utilizing the Reference Guide

Always have the accompanying reference document at hand. This will not only provide detailed descriptions but also highlight compatibility and alternative options. By familiarizing yourself with this resource, you’ll enhance your understanding and improve your ability to tackle maintenance tasks confidently.

Common Issues with Mower Deck Parts

Understanding frequent problems related to cutting equipment components is crucial for optimal performance and longevity. Users often encounter various challenges that can affect efficiency and output.

Wear and Tear: Over time, certain elements may degrade due to constant usage, leading to diminished cutting effectiveness.

Misalignment: Components can shift or become misaligned, resulting in uneven cuts and increased strain on the engine.

Rust and Corrosion: Exposure to moisture can lead to rust, compromising the integrity of metal components and requiring timely replacement.

Clogging: Grass buildup can obstruct operation, necessitating regular cleaning to maintain functionality.

Vibration Issues: Excessive vibration may indicate loose fittings or worn-out elements, affecting overall performance and potentially causing damage.

Addressing these common challenges promptly can significantly enhance the reliability and effectiveness of cutting tools.

Maintenance Tips for Mower Decks

Regular upkeep of your cutting equipment is essential to ensure optimal performance and longevity. Proper maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some practical tips to help you care for your equipment effectively.

Routine Cleaning

Keeping the undercarriage free from grass clippings and debris is crucial. Follow these steps:

- After each use, inspect the area beneath the machine.

- Use a brush or scraper to remove any buildup.

- Consider washing with a hose, ensuring all components are dry afterward.

Inspection and Adjustment

Regularly check various elements to ensure they function correctly:

- Inspect blades for dullness and nicks; sharpen or replace as necessary.

- Check belt tension and condition, adjusting or replacing as needed.

- Examine mounting hardware for any signs of wear or loosening.

By following these maintenance practices, you can extend the life of your equipment and achieve a well-manicured lawn.

Tools Needed for Mower Repairs

Effective maintenance and restoration of lawn equipment require a specific set of implements. These tools not only facilitate the repair process but also enhance efficiency and ensure safety. Proper preparation is essential for successful upkeep.

Essential Tools

- Wrenches: For loosening and tightening various bolts.

- Screwdrivers: Flathead and Phillips for securing components.

- Pliers: Useful for gripping and twisting.

- Socket Set: For reaching tight spaces with precision.

- Blade Sharpener: To maintain cutting efficiency.

Safety Equipment

- Gloves: To protect hands from sharp edges and chemicals.

- Safety Goggles: To shield eyes from debris.

- Steel-Toed Boots: For foot protection during repairs.

Having these tools on hand will enable you to delve deeper into the maintenance tasks, ensuring that your equipment remains in optimal condition for the ultimate performance.

Where to Buy Replacement Parts

Finding the right components for your equipment can enhance its performance and longevity. Whether you need to replace worn-out elements or upgrade to new ones, knowing where to shop is essential for a seamless experience.

Online Retailers offer a vast selection, often at competitive prices. Websites dedicated to outdoor machinery frequently have comprehensive inventories and can provide detailed descriptions to help you choose.

Local Dealerships are another reliable option. They usually carry a range of products specifically suited for your model and can offer expert advice on installation and compatibility.

Aftermarket Suppliers also present a viable alternative. They produce compatible components that may come at lower prices, but ensure you research their quality and warranty offerings.

Regardless of where you shop, always cross-reference part numbers and consult user reviews to make the most informed choice.

Comparing OEM and Aftermarket Parts

When it comes to maintaining equipment, the choice between original and alternative components can significantly impact performance and longevity. Each option presents its own set of advantages and disadvantages, influencing the decision-making process for users.

Original components are typically manufactured by the same company that created the equipment. Here are some key points:

- High reliability and compatibility

- Warranty protection

- Assured quality control

On the other hand, alternative components often provide cost-effective solutions. Consider the following aspects:

- Lower prices

- Availability in various brands

- Potential for enhanced performance features

Ultimately, evaluating the specific needs and budget can help users make an informed choice between these two types of components.

Identifying Part Numbers on Diagrams

Understanding the numerical identifiers on schematics is essential for effective maintenance and repair. These numbers facilitate the quick location of components, ensuring that users can efficiently order or replace items as needed. A clear grasp of how these references are structured can significantly enhance the repair process.

When examining a schematic, part numbers are typically linked to specific components. This organization helps to streamline repairs and ensure compatibility with the intended machinery. Recognizing these identifiers allows users to avoid confusion and make informed decisions when sourcing replacements.

| Component | Part Number | Description |

|---|---|---|

| Blade Assembly | ABC123 | High-strength steel blade for cutting efficiency. |

| Spindle | DEF456 | Durable spindle for smooth rotation. |

| Gearbox | GHI789 | Powerful gearbox for optimal torque delivery. |

By consulting these identifiers, users can ensure they select the correct components, thereby minimizing the risk of ordering errors. Familiarity with the layout and numbering system enhances the overall experience of maintaining equipment.

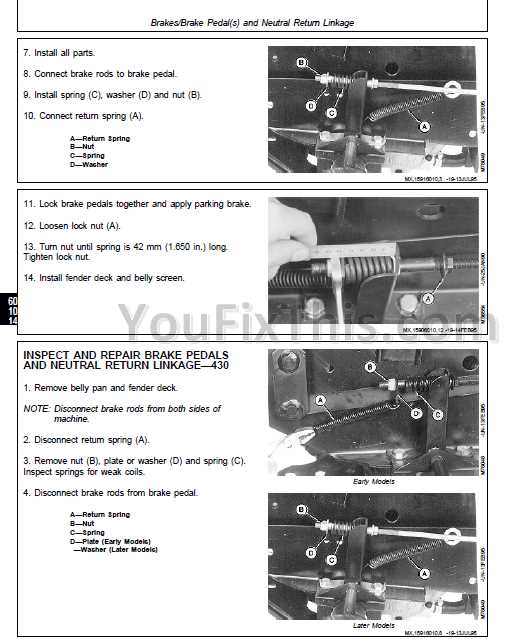

Step-by-Step Repair Guide

This section provides a comprehensive approach to effectively address issues with your outdoor equipment. By following a structured methodology, you can ensure that each component is inspected, diagnosed, and repaired or replaced as necessary.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and replacement items.

- Ensure a clean workspace for safety and efficiency.

- Consult the user manual for specific details on your model.

Repair Process

- Begin by disconnecting the power source to prevent accidents.

- Carefully remove the components needing attention, taking note of their arrangement.

- Inspect each part for wear and damage; replace any faulty items.

- Reassemble the components in reverse order, ensuring a secure fit.

- Reconnect the power source and test the equipment for proper functionality.

Safety Precautions When Repairing

When engaging in maintenance or repair tasks, ensuring personal safety is paramount. Adhering to specific guidelines can prevent accidents and promote a secure working environment.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Disconnect power sources before starting any repair work.

- Keep the workspace clean and free from clutter to avoid trips and falls.

Best Practices

- Read the manufacturer’s manual thoroughly to understand the machinery’s features and risks.

- Use tools that are in good condition and suitable for the specific tasks.

- Never work alone; have someone nearby in case of emergencies.

Upgrading Your Mower Deck Components

Enhancing the functionality and efficiency of your grass-cutting equipment can significantly improve your lawn care experience. By replacing outdated or worn elements with high-quality alternatives, you can achieve better performance, durability, and results. This section explores various components that can be upgraded to elevate the capabilities of your machinery.

Key Components to Consider

- Blades: Upgrading to sharper, more durable blades can enhance cutting performance and ensure a clean finish.

- Belts: Replacing old or frayed belts with stronger materials can prevent slippage and improve overall efficiency.

- Spindles: High-performance spindles reduce wear and provide smoother operation, ensuring longevity.

- Wheels: Opt for robust wheels that improve maneuverability and stability on uneven terrain.

Benefits of Upgrading

- Improved Efficiency: New components often operate more smoothly, reducing the time spent on maintenance.

- Enhanced Cutting Quality: Fresh blades and spindles provide a superior cut, resulting in healthier grass.

- Longer Lifespan: Investing in quality upgrades can extend the overall life of your equipment.

- Cost-Effective: Preventive upgrades can save money on repairs and replacements in the long run.

Resources for Further Learning

Expanding your knowledge about maintenance and repair techniques can enhance your skills and confidence when working with outdoor equipment. A variety of resources are available to help you gain a deeper understanding of the components and functionality of these machines.

Online Tutorials and Videos

- YouTube channels dedicated to outdoor machinery often provide step-by-step guides.

- Websites with instructional content frequently feature user-generated videos that cover specific repairs.

- Online forums where enthusiasts share their experiences can be invaluable for troubleshooting.

Books and Manuals

- Manufacturer’s manuals are essential for understanding specifications and assembly.

- Reference books focused on machinery repair offer in-depth insights and best practices.

- Local libraries may have a selection of technical books related to outdoor equipment maintenance.