Maintaining a lush and vibrant lawn requires not only dedication but also an understanding of the essential machinery involved in the process. Every piece of equipment has its own intricacies, and familiarizing yourself with the various elements can significantly enhance your efficiency in lawn care. Whether you are a seasoned gardener or just starting, knowing how the different components interact is crucial for optimal performance.

In this section, we will delve into the essential elements of a specific model that many users find indispensable. By exploring the layout and functions of each segment, you can gain insights into maintenance practices and troubleshooting techniques. A well-organized overview will empower you to address any challenges that may arise during usage.

Understanding the arrangement of the components not only aids in repairs but also enhances your overall experience with the equipment. With the right knowledge, you can ensure that your machinery operates smoothly and efficiently, allowing you to focus on creating the perfect outdoor space.

Understanding John Deere Mower Decks

The mechanics behind grass cutting equipment are essential for achieving a well-manicured lawn. Familiarity with these mechanisms can significantly enhance maintenance and operational efficiency. Each component plays a crucial role in the overall performance and durability of the machine.

| Component | Function |

|---|---|

| Blades | Cut grass to desired height |

| Spindle | Holds and rotates blades |

| Chassis | Supports and connects all components |

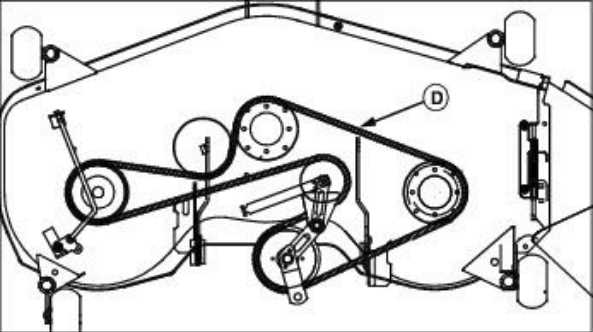

| Belts | Transfer power from the engine |

Understanding these elements allows users to make informed decisions about repairs and upgrades, ultimately leading to a more efficient grass cutting experience.

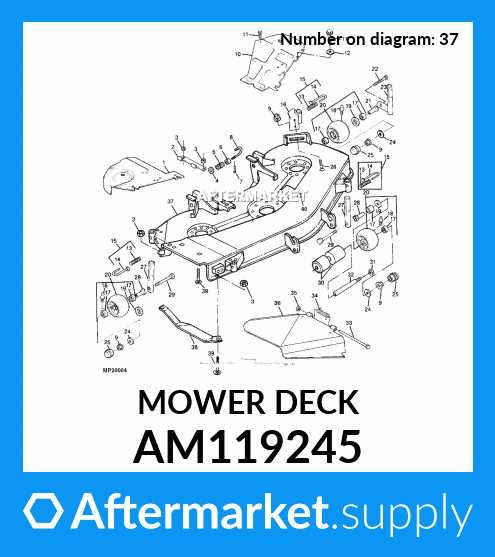

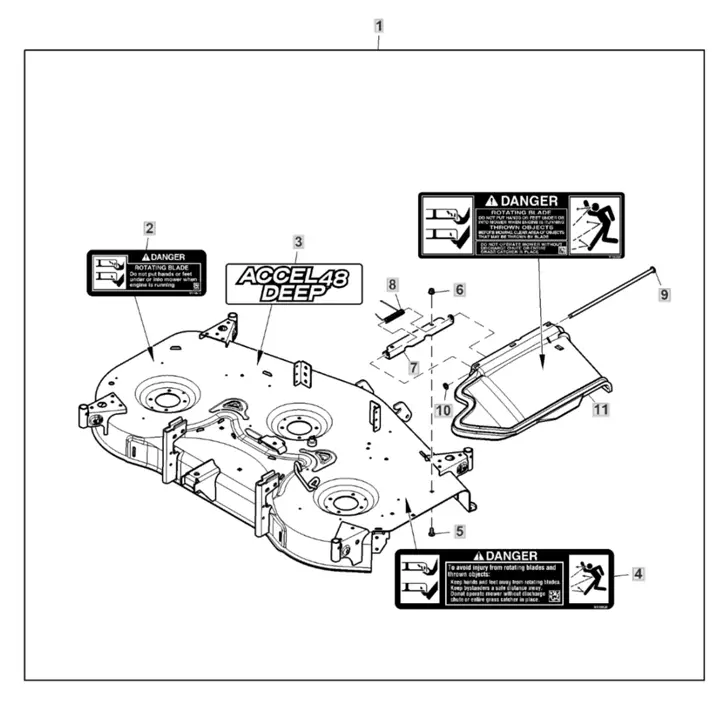

Parts Overview for 48-Inch Models

This section provides a comprehensive look at the various components associated with the 48-inch models, highlighting the essential elements that contribute to their efficient operation. Understanding these components can help users maintain and troubleshoot their equipment effectively.

Key Components

The primary elements include the cutting blades, which are vital for achieving a clean cut, as well as the housing that protects the internal mechanisms. Additionally, pulleys and belts play crucial roles in the transmission of power, ensuring smooth performance during operation.

Maintenance Essentials

Importance of Regular Maintenance

Identifying Common Replacement Parts

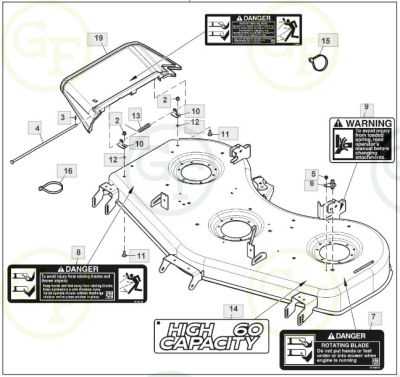

Understanding the essential components of your lawn equipment is crucial for effective maintenance and longevity. By recognizing the key elements that may require replacement over time, users can ensure optimal performance and a healthy landscape. This section aims to guide you through identifying these components, helping you keep your equipment in top shape.

Key Components to Monitor

Several components are frequently subject to wear and tear. Blades are one of the most critical elements, as they directly affect cutting efficiency. Additionally, belts that drive the cutting mechanism can experience fraying and damage. Keeping an eye on these items can prevent further complications and costly repairs.

Signs of Wear and When to Replace

It’s essential to recognize when these components show signs of wear. For instance, if you notice uneven cutting or excessive vibration, it may indicate that the blades need sharpening or replacing. Similarly, if the engine struggles to engage, the belts might require inspection. Regular checks will help you maintain your equipment’s performance and extend its lifespan.

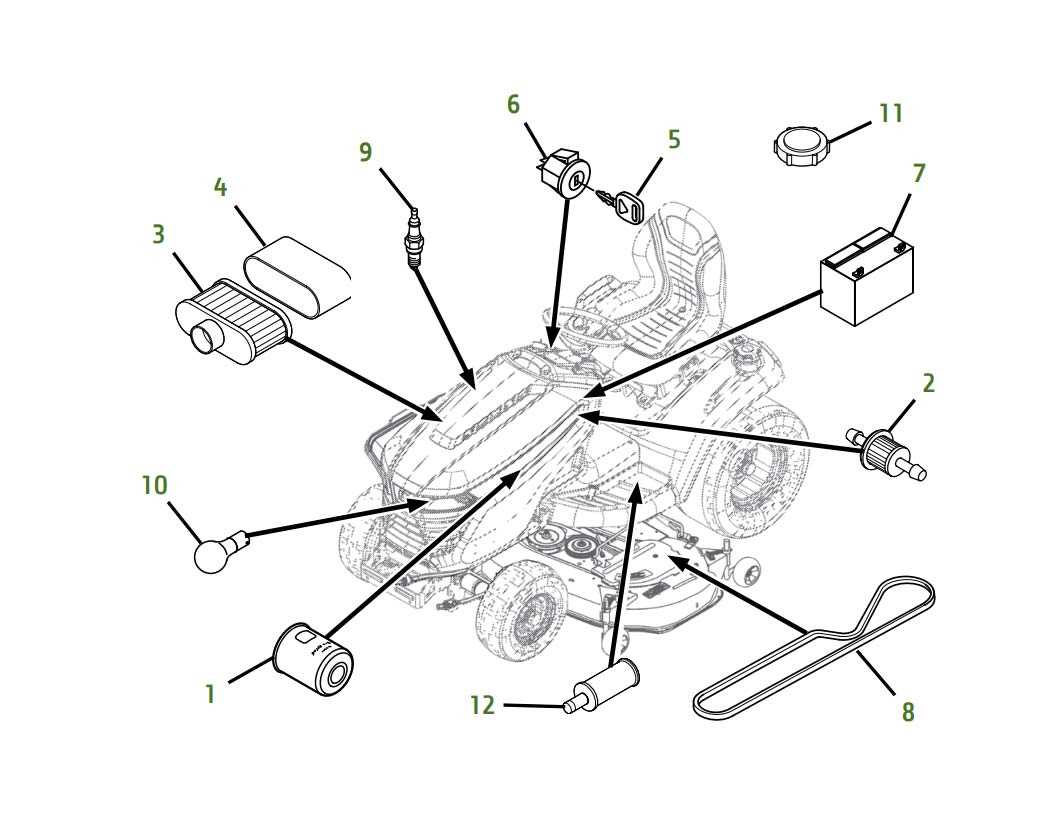

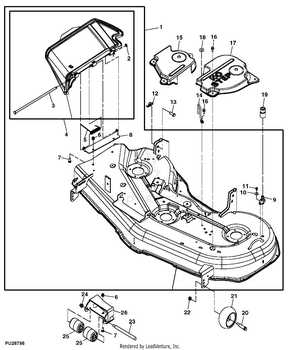

How to Use the Parts Diagram

Understanding the schematic representation of components is crucial for effective maintenance and repairs. This visual guide allows users to identify individual elements and their respective functions, facilitating a smoother restoration process. With the right approach, one can efficiently navigate through the various segments to pinpoint any needed replacements.

Step 1: Start by examining the overall layout, noting the arrangement of each component. This will give you a clear picture of how everything fits together.

Step 2: Focus on specific sections by following the labels, ensuring you recognize each item’s role. This clarity is essential for troubleshooting issues or planning upgrades.

Step 3: Make a list of components that require attention or replacement. Cross-referencing with the visual guide will help ensure accuracy in your selections.

Utilizing this schematic effectively can significantly enhance your repair experience and lead to optimal performance of your equipment.

Tools Needed for Mower Repairs

Proper maintenance and repairs require a variety of essential implements to ensure efficiency and effectiveness. Having the right tools not only simplifies the repair process but also enhances safety and precision. A well-equipped toolkit can make the difference between a frustrating experience and a smooth, successful job.

Basic hand tools, such as wrenches and screwdrivers, are fundamental for disassembling and reassembling components. Additionally, specialized tools like socket sets and pliers can provide the extra leverage needed for stubborn parts. For more intricate tasks, investing in diagnostic equipment can help pinpoint issues quickly and accurately.

Don’t forget about safety gear, including gloves and goggles, to protect yourself during repairs. Proper organization of your tools is equally important; a clean workspace allows for greater focus and minimizes the risk of losing important implements. By preparing adequately, you can tackle any maintenance or repair challenge that comes your way.

Step-by-Step Assembly Instructions

This section provides a comprehensive guide to correctly assembling your equipment for optimal performance. Following these instructions will ensure all components fit seamlessly and function effectively.

Preparation Steps

- Gather all necessary tools and components.

- Clear a workspace to allow easy access to each piece.

- Review the manual for specific guidelines.

Assembly Process

- Begin by attaching the main frame to the chassis.

- Secure all bolts and fasteners, ensuring they are tight.

- Attach the blades, aligning them according to the specified orientation.

- Connect any electrical components, checking for proper connections.

- Finally, conduct a thorough inspection to ensure everything is assembled correctly.

Troubleshooting Mower Deck Issues

Addressing common challenges associated with cutting equipment is essential for maintaining optimal performance and ensuring a clean, even cut. Understanding the potential problems and their solutions can significantly enhance the longevity and efficiency of your equipment.

Identifying Uneven Cuts

When your equipment leaves patches or uneven heights, it may indicate misaligned components or dull blades. Regularly inspect the alignment of the cutting elements and replace any worn-out tools to restore precision and performance.

Overheating and Unusual Noises

Excessive heat and strange sounds often signal underlying issues. Ensure that all moving parts are well-lubricated and free from debris. If the problem persists, consult a professional to delve deeper into mechanical concerns that could affect operation.

Finding Genuine John Deere Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for ensuring longevity and optimal performance. Reliable resources offer a variety of options, allowing users to select high-quality replacements that fit their machinery perfectly. This not only enhances efficiency but also extends the lifespan of your equipment.

Benefits of Authentic Components

Utilizing original items guarantees compatibility and functionality, which aftermarket alternatives often lack. Authentic components are designed to meet rigorous standards, ensuring your machinery operates smoothly and effectively. This investment in quality translates to less frequent repairs and a more reliable experience overall.

Where to Find Genuine Items

Authorized dealers and reputable online platforms are the best places to locate original components. These sources often provide comprehensive catalogs, allowing users to easily find what they need. Additionally, customer support from these vendors can help clarify any doubts regarding compatibility and installation.

Cost Considerations for Mower Repairs

When it comes to maintaining outdoor equipment, understanding the financial implications of repairs is crucial. Factors such as labor costs, availability of components, and the age of the machinery can significantly influence the total expenses incurred. A well-informed approach can lead to more effective budgeting and decision-making.

Labor Costs: The expense associated with hiring a technician can vary widely based on their expertise and your location. Often, it is beneficial to weigh the cost of professional repairs against potential DIY efforts.

Availability of Components: The price and accessibility of necessary items can fluctuate. Sourcing original versus aftermarket alternatives can affect your overall expenditure.

Age of Equipment: Older machinery may require more frequent attention and potentially more costly repairs. Assessing whether to invest in repairs or consider replacement is essential for long-term savings.

By examining these aspects, one can delve deeper into making the ultimate decision regarding maintenance and repair investments.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining equipment, the choice between original manufacturer components and alternatives can significantly impact performance and longevity. Each option has its own set of advantages and potential drawbacks, influencing both cost and reliability. Understanding these differences is crucial for making an informed decision that meets your needs.

Cost Considerations

One of the primary factors in selecting between original components and alternatives is price. Generally, alternatives tend to be more budget-friendly, making them attractive for those looking to save. However, this lower cost can sometimes come with trade-offs in quality and durability.

Quality and Reliability

Original components are typically designed to meet specific standards set by the manufacturer, ensuring optimal compatibility and performance. In contrast, alternative options may vary in quality, with some brands offering reliable products while others may not meet the same benchmarks. Therefore, thorough research and reviews are essential when considering alternatives.

| Feature | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Cost | Generally higher | Often lower |

| Quality | Consistent, high standards | Variable quality |

| Warranty | Typically includes a warranty | Warranties vary |

| Availability | Widely available through authorized dealers | Available from various retailers |

Tips for Extending Deck Lifespan

Maintaining your equipment’s performance is crucial for longevity. By adopting simple yet effective practices, you can ensure it remains in optimal condition for years to come. Here are some essential strategies to enhance its durability.

Regular Cleaning

Accumulation of debris can lead to wear and tear. After each use, clean the surface thoroughly to prevent rust and corrosion.

Inspection and Maintenance

Conduct periodic checks for any signs of damage. Addressing minor issues early can prevent more significant problems down the line.

| Action | Frequency |

|---|---|

| Clean the surface | After each use |

| Inspect for damage | Monthly |

| Lubricate moving parts | Every season |

| Store in a dry area | Always |