The efficiency and precision of any lawn maintenance machine largely depend on the proper functioning and arrangement of its cutting system. This crucial mechanism is designed to deliver a smooth and even cut, ensuring optimal performance across various terrains. By exploring the detailed components that make up this system, one can better understand how each element plays a role in achieving consistent results.

Each individual piece, from the rotating elements to the supporting framework, is essential for the overall operation. Knowing how these pieces interconnect allows for easier maintenance and repairs, especially when dealing with wear and tear from regular use. By familiarizing oneself with the layout and functionality of these parts, troubleshooting and replacement become much more straightforward.

For those who regularly maintain their mowing machinery, having a comprehensive visual and technical guide is invaluable. It aids in ensuring that every component is in its proper place, contributing to the longevity and effectiveness of the machine. A clear understanding of this assembly can also help in diagnosing issues, leading to quicker solutions and less downtime.

Understanding the Key Components of the D140 Deck

To maintain optimal performance and longevity, it is essential to understand the primary elements responsible for efficient operation. These elements work together to ensure smooth and reliable functioning, and identifying their roles can help with proper upkeep and troubleshooting.

Main Structural Elements

The primary structural frame is designed to support various mechanical systems, ensuring stability and balance. Key metal components provide the foundation for mounting additional mechanisms, distributing weight evenly for seamless motion and precise control during operation.

Critical Mechanisms for Functionality

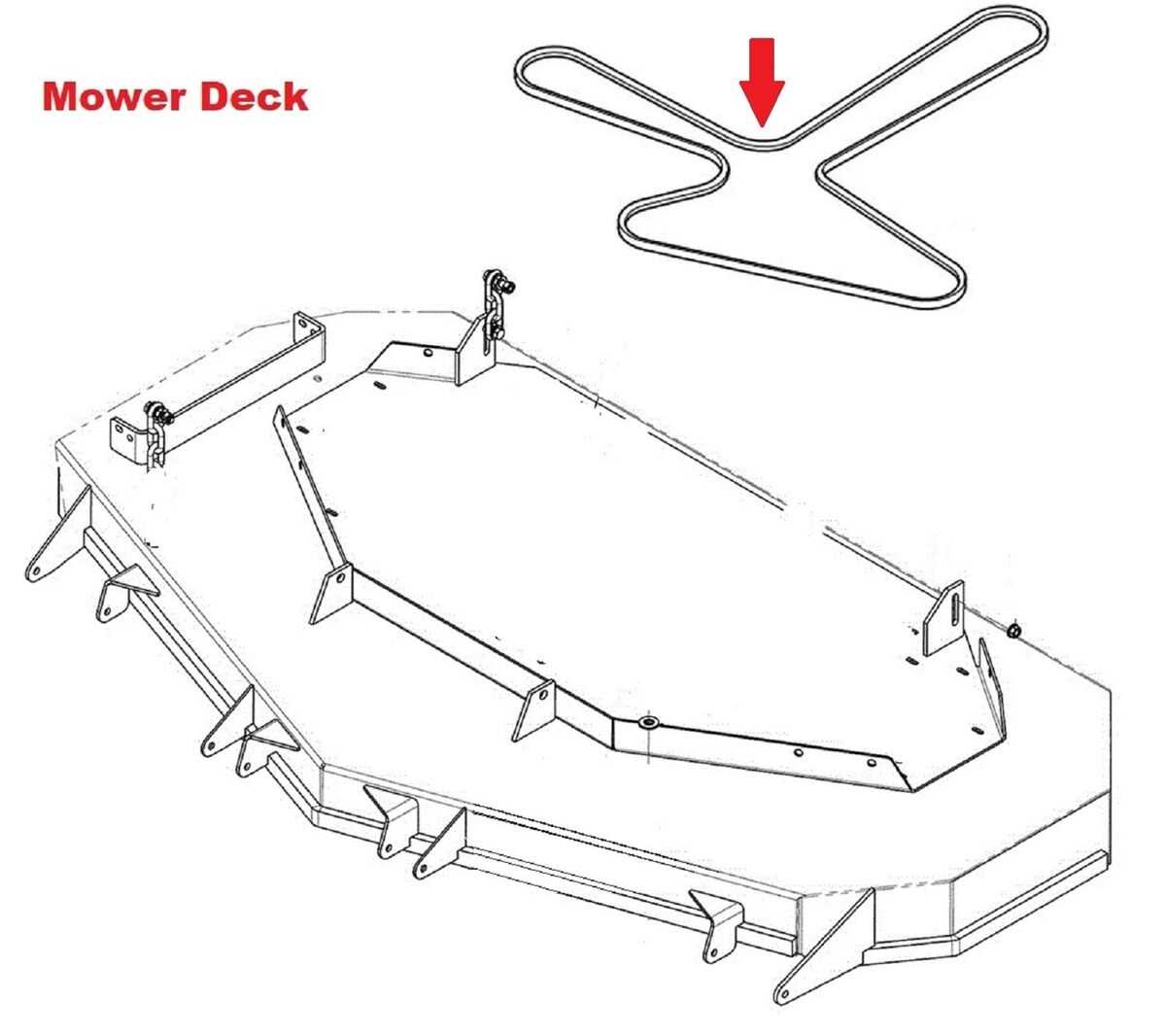

Among the vital mechanisms are the rotational systems, which drive essential movement. These include pulleys and belts, which transfer power to necessary areas. Their coordinated function ensures smooth rotation and consistency in movement. Proper tension and alignment of these systems are crucial for preventing wear and maintaining reliable operation over time.

Identifying Critical Wear Parts

Regular inspection and maintenance of key components is essential to ensuring the longevity and optimal performance of your machinery. Over time, certain elements are more susceptible to wear and tear, and identifying these vulnerable areas early can prevent larger issues from arising.

Below is a list of common elements that often require close attention during routine checks:

- Blades – Constant exposure to hard surfaces and debris can cause dulling or damage, affecting cutting efficiency.

- Bearings – Frequent rotation under load can result in degradation, leading to less effective movement and potential overheating.

- Belt – A high-tension area, subject to stretching or cracking, which can impact overall machine performance.

- Spindles – These elements endure high pressure and friction, making them prone to wear that may cause vibrations or uneven operation.

- Fasteners – Constant vibration can loosen bolts, screws, and other securing hardware, potentially leading to misalignment or malfunction.

Regularly replacing or maintaining these items can significantly extend the lifespan of your equipment and ensure smoother operation over time.

How to Maintain Your Mower Deck

Regular upkeep of your mowing equipment is crucial for ensuring its longevity and performance. Proper care not only helps prevent breakdowns but also guarantees a clean and efficient cut every time. In this section, we’ll cover essential steps to keep your equipment in optimal condition.

- Inspect Blades Regularly: Sharp blades are key to a neat and uniform trim. Make it a habit to check for dullness or damage and sharpen or replace them as needed.

- Clean After Each Use: Grass clippings, dirt, and debris can build up over time, leading to blockages and reduced performance. A simple cleaning routine after each mowing session will prevent this.

- Check Belt Tension: Loose or worn belts can affect the cutting mechanism’s efficiency. Always ensure that the belt is tight and in good condition, replacing it when necessary.

- Lubricate Moving Parts: Proper lubrication minimizes wear and tear on moving components, reducing friction and prolonging the life of your machinery. Be sure to follow the manufacturer’s guidelines for appropriate lubricants.

- Level the Cutting Platform: An uneven platform can result in an uneven cut. Regularly verify that your equipment is level and make adjustments if needed to achieve a uniform trim.

- Store Properly: Keep

Common Issues with the D140 Deck

When maintaining outdoor machinery, users often face several challenges related to the cutting system. Over time, these components can wear out, causing uneven performance, operational noises, or even malfunction. Identifying typical problems early can prevent more significant damage and extend the longevity of the equipment.

Uneven Cutting

An imbalanced cutting mechanism often leads to uneven grass trimming, resulting in unsightly patches on the lawn. This issue typically stems from misalignment or wear in the rotating elements. Regular inspection and adjustment of the blades are essential to ensure a smooth and level operation.

- Blade dullness or damage

- Improper leveling of the cutting structure

- Accumulation of debris affecting performance

Excessive Vibration

Vibration during use is another frequent problem. It can signal various underlying issues, ranging from loose fasteners to worn bearings. Continuous vibrations not only affect the quality of the job but can also lead to further deterioration of the equipment.

- Loose or damaged mounting bolts

- W

Replacing the Belt on a D140 Mower

Routine maintenance is essential for ensuring that your machine operates at peak performance. One crucial task in this process is swapping out the drive belt. Over time, the belt may wear down, causing a drop in efficiency and leading to more significant issues if neglected. Replacing it is a straightforward process that can greatly improve the overall function of your lawn equipment.

First, make sure the engine is completely turned off and cooled down to avoid any accidents. Position the mower on a flat surface and engage the parking brake. Removing any obstructions around the blade area ensures you have enough room to maneuver during the replacement.

Next, locate the protective covers that guard the pulley system. These covers are typically held in place by a few bolts. Use the appropriate tools to loosen and remove them, gaining access to the belt and pulleys underneath. Take note of how

Blade Alignment Tips for Smooth Operation

Ensuring optimal performance of cutting implements is essential for achieving a well-manicured landscape. Proper alignment plays a crucial role in maintaining efficiency and prolonging the lifespan of the equipment. This section will provide valuable insights into how to achieve precise positioning for enhanced operation.

Check the Level

Before starting the alignment process, it is important to verify that the cutting tool is level. An uneven setup can lead to uneven cutting and increased wear. Follow these steps to ensure proper leveling:

Step Action 1 Place the implement on a flat surface. 2 Use a level tool to check both front and rear edges. 3 Adjust the height as needed to achieve a level position. Adjust the Cutting Angle

After leveling, the next step is to adjust the angle of the cutting edges. This adjustment is vital for achieving a clean cut and preventing damage to the grass. Here are some guidelines:

Step Action 1 Identify the correct angle for the cutting edges. 2 Loosen the mounting bolts to allow for angle adjustments. 3 Tighten the bolts once the desired angle is achieved. Tools Needed for Deck Repair

When it comes to restoring and maintaining outdoor machinery, having the right equipment is essential. This section outlines the necessary instruments and supplies to effectively carry out repairs and ensure optimal functionality.

Tool Purpose Socket Wrench Used for loosening and tightening bolts and nuts. Torque Wrench Ensures bolts are tightened to the correct specifications. Screwdriver Set Essential for removing and securing screws in various components. Pliers Helpful for gripping and manipulating small parts. Utility Knife Used for cutting materials and removing old seals or gaskets. Shop Vacuum Ideal for cleaning debris and maintaining a safe workspace. Grease Gun Necessary for applying lubrication to moving parts. Equipping yourself with these tools not only streamlines the repair process but also enhances the longevity and performance of your machinery. Always ensure that your instruments are well-maintained and readily available for any maintenance tasks.

Signs Your Deck Needs Servicing

Regular maintenance is crucial for ensuring optimal performance and longevity of your lawn equipment. Recognizing the signs that indicate your cutting mechanism requires attention can save you time and money in the long run. Below are some common indicators that your apparatus may need servicing.

- Uneven Cutting: If you notice that the grass is being cut unevenly, it may be a sign that the blades are dull or misaligned.

- Excessive Vibration: Increased vibration during operation can indicate wear or damage to components, necessitating inspection.

- Noisy Operation: Unusual noises, such as grinding or rattling, can suggest loose or damaged parts that require immediate attention.

- Clumping Grass: If you observe clumps of grass being left behind, it could mean that the blades are not functioning properly.

- Debris Buildup: A buildup of grass and debris under the housing can restrict airflow and affect performance, indicating a need for cleaning and servicing.

Being attentive to these signs will help you maintain your equipment effectively and ensure a well-kept lawn. Regular inspections and timely servicing can prevent minor issues from developing into significant problems.

Choosing the Right Replacement Parts

When it comes to maintaining your outdoor equipment, selecting the appropriate components is crucial for ensuring optimal performance and longevity. Understanding the specifications and compatibility of each element can significantly enhance the efficiency of your machine, allowing it to function at its best. This section will guide you through the process of identifying and acquiring the correct items for your needs.

Understanding Compatibility

Compatibility is a key factor in choosing the right components. Not all items are interchangeable, and using mismatched elements can lead to operational issues or even damage to your equipment. It is essential to refer to the manufacturer’s recommendations or detailed manuals to determine which components are suitable for your specific model.

Quality vs. Cost

While it may be tempting to opt for the most affordable options available, considering quality is vital. High-quality components may have a higher upfront cost but can save money in the long run by reducing the frequency of replacements and repairs. Weighing the long-term benefits against immediate savings can help you make a more informed decision.

Factor Considerations Compatibility Ensure parts fit your equipment’s specifications Quality Opt for durable and reliable options Cost Evaluate long-term savings vs. initial expenses Brand Reputation Choose trusted manufacturers for better assurance Deck Cleaning and Care for Longevity

Regular maintenance is essential for ensuring the long-term functionality and performance of your lawn equipment. Proper cleaning and care not only enhance the efficiency of the machinery but also prolong its lifespan. By following a few simple practices, you can keep your equipment in optimal condition.

Here are some key steps to consider for effective maintenance:

- Remove Debris: After each use, ensure to clear away grass clippings, dirt, and other debris that may accumulate. This helps prevent rust and other forms of corrosion.

- Check for Damage: Regularly inspect the components for any signs of wear or damage. Early detection of issues can save time and money on repairs.

- Use Appropriate Cleaning Tools: Utilize brushes, scrapers, or pressure washers that are suitable for cleaning without damaging surfaces.

- Dry Thoroughly: After cleaning, allow the equipment to dry completely before storage to avoid moisture-related problems.

Following these guidelines can lead to enhanced performance and durability, ensuring that your machinery continues to operate smoothly for years to come.

Troubleshooting Performance Problems

Addressing performance issues in lawn maintenance equipment can often be a straightforward process if approached methodically. Identifying the root cause of operational inefficiencies requires careful observation and a systematic evaluation of various components. This section provides guidance on common challenges and practical solutions to enhance overall functionality.

Common Issues and Solutions

Issue Possible Cause Solution Uneven Cutting Worn or damaged blades Inspect blades for wear and replace if necessary. Excessive Vibration Loose or damaged components Tighten all screws and inspect for any broken parts. Poor Power Fuel quality issues Use fresh, high-quality fuel and clean the fuel system. Overheating Clogged air filters Clean or replace air filters to ensure proper airflow. Preventive Maintenance Tips

Regular upkeep is essential to prevent performance problems from arising. Routine inspections, timely replacements, and proper care can significantly extend the lifespan of the equipment. Always consult the manufacturer’s guidelines for recommended maintenance practices.

How to Ensure Proper Deck Assembly

Assembling the mowing unit correctly is essential for optimal performance and longevity. Attention to detail during the setup process can significantly enhance the machine’s efficiency and ensure a smooth cutting experience.

Key Steps for Successful Assembly

- Gather Necessary Tools

- Wrenches

- Screwdrivers

- Torque wrench

- Verify Component Integrity

- Inspect for wear and damage

- Clean all parts before assembly

- Follow Manufacturer Guidelines

- Refer to the assembly manual

- Ensure all fasteners are accounted for

- Over-tightening bolts, which can lead to breakage

- Neglecting to lubricate moving parts

- Failing to check alignment, causing uneven cutting

Common Assembly Mistakes to Avoid

By adhering to these guidelines and avoiding common pitfalls, you can ensure that the mowing apparatus is assembled correctly, maximizing both its performance and durability.