Understanding the structure and elements of machinery is crucial for maintaining its functionality and ensuring smooth operation. Various pieces of equipment consist of interconnected systems that require regular attention and replacement when necessary. By delving into the details of these elements, you can ensure that everything functions as intended and that repairs are efficiently handled.

Each mechanical system relies on specific sections to perform essential tasks. Proper knowledge of these individual sections allows for better troubleshooting and can significantly reduce downtime during maintenance. In this section, we will explore some critical aspects that are vital for seamless operation, offering a clear understanding of how these pieces fit into the overall system.

Routine inspections and timely replacements of specific components are essential practices for anyone looking to extend the lifespan of their equipment. Keeping a well-maintained system not only enhances performance but also helps avoid unexpected breakdowns.

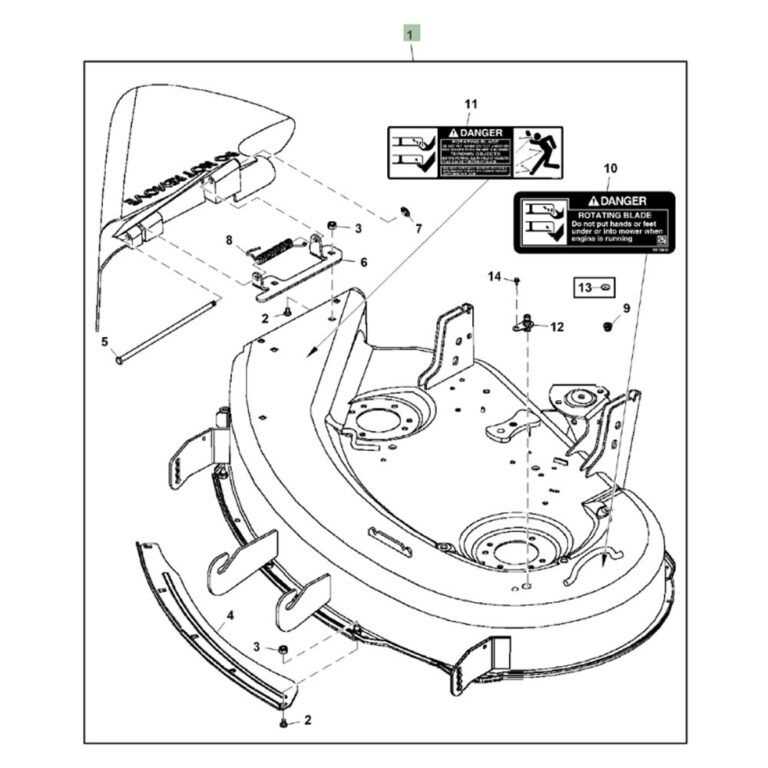

John Deere L110 Mower Deck Overview

The equipment’s cutting system is designed for consistent, precise performance, ensuring efficient operation on various types of terrain. Built with durability and ease of use in mind, this system integrates multiple key components, which together optimize the cutting experience. Proper alignment and maintenance of these elements contribute to the system’s long-lasting functionality.

Key Features of the Cutting System

Featuring a robust and reliable mechanism, the cutting system includes strategically placed blades and supporting elements, all working together to provide a seamless trimming experience. The components are engineered to handle a range of tasks, from regular trimming to more intensive landscape management.

Maintenance and Care

Regular upkeep is crucial to ensure smooth operation. Routine checks, lubrication, and timely replacement of worn-out parts help maintain the system’s performance and extend its operational life. Keeping the cutting mechanism clean and properly adjusted can significantly improve the overall efficiency and reduce the need for repairs.

Key Components of the L110 Deck

The machinery’s cutting system is composed of various essential elements that work together to ensure efficient grass trimming. These components are designed to provide a smooth and even finish, making the process more effective and reducing the effort needed for maintenance. Understanding how each element functions can help in troubleshooting and maintaining optimal performance.

The key sections include the rotating blades responsible for cutting, the framework supporting them, and the mechanical connections that drive the motion. Additionally, various safety mechanisms are in place to prevent accidents, ensuring safe and reliable operation.

Maintenance of these elements is crucial for consistent and reliable functioning. Regular inspection and cleaning of these parts can significantly extend the life of the equipment and ensure smooth operation over time.

Maintenance Tips for Mower Deck Parts

Regular upkeep is crucial to ensure the longevity and optimal performance of your lawn equipment. Proper attention to various components can prevent costly repairs and extend the life of the machinery. By implementing consistent care, you help maintain the efficiency and reliability of the cutting system.

Inspect the cutting blades frequently for signs of wear and damage. Sharp and balanced blades are essential for achieving a clean and even cut. Dull or unbalanced edges can cause strain on the motor and result in uneven trimming.

Cleaning is another important aspect of maintenance. Grass, debris, and dirt can accumulate under the cutting system, which may hinder performance over time. Regularly clearing this buildup ensures smoother operation and reduces the risk of rust or corrosion.

Finally, lubricating all moving parts helps to minimize friction and wear. Greasing the appropriate joints and bearings will keep the system running smoothly and reduce the likelihood of breakdowns.

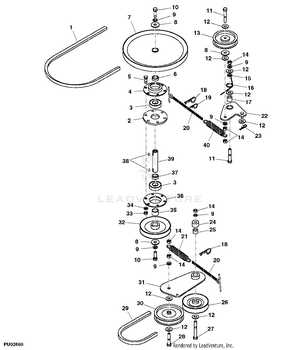

Understanding Belt Routing on the L110

Properly configuring the drive system is crucial for optimal performance. One of the key aspects of this system is ensuring the belt is routed correctly to facilitate smooth and efficient operation. This involves aligning the drive components in a way that maximizes power transfer and prevents unnecessary wear.

Routing the belt requires attention to detail. By following the correct path and tension guidelines, you ensure that the system operates efficiently. Proper belt placement not only enhances the machine’s performance but also extends the life of the components involved.

Incorrect routing can lead to a variety of issues, such as excessive friction, slippage, or even damage to the drive system. Therefore, it’s important to be familiar with the specific path the belt should take and to regularly check for proper alignment and tension.

Blades and Their Importance on the L110

The cutting components play a crucial role in the performance of any lawn care machine. They are responsible for ensuring a clean, precise cut, which directly affects the health and appearance of the grass. Without well-maintained cutting tools, the overall efficiency of the equipment diminishes, leading to uneven results and potential damage to the lawn over time.

To better understand the value of sharp and properly installed blades, it is important to focus on their specific benefits:

- Even Cutting: Well-maintained blades guarantee uniform grass trimming, which prevents the lawn from appearing patchy or uneven.

- Healthier Lawn: Sharp edges make clean cuts, reducing stress on the grass and minimizing the risk of disease and pest infestation.

- Fuel Efficiency: Properly functioning blades require less power, improving fuel

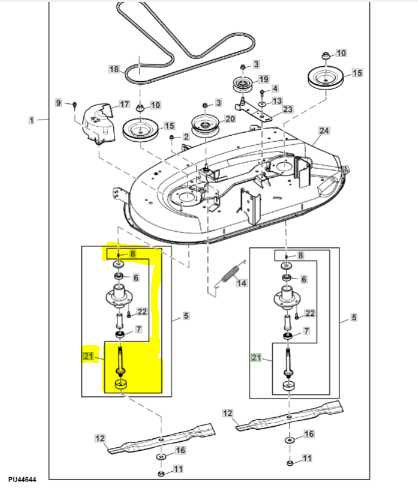

How to Replace a Spindle Assembly

Replacing the spindle assembly on a lawn cutting machine is a vital maintenance task that ensures smooth operation and effective grass cutting. The spindle assembly is responsible for rotating the blades, and over time it can wear out or become damaged. Replacing this component can significantly enhance the performance and longevity of your equipment.

1. Gather the Necessary Tools

Before starting, ensure you have the right tools at hand. Typically, you’ll need a wrench set, socket set, and possibly a hammer for loosening stubborn bolts. It’s also helpful to have a pair of gloves for safety.

2. Lift and Secure the Machine

For safety, lift the machine and secure it properly. You can use a jack or a lift to elevate the unit. Always make sure it is stable before proceeding to avoid accidents.

3. Remove the Existing Spindle Assembly

Locate the spindle assembly and unscrew the bolts securing it. Be cautious of the blade connections, ensuring they are safely detached before removing the assembly completely.

4. Install the New Spindle Assembly

Take the new spindle assembly and align it with the mounting points. Secure it with the bolts, ensuring everything is tightened properly. Once in place, check the blades for proper movement and ensure there is no excessive play or wobbling.

5. Test the Equipment

After the installation, lower the equipment and perform a test run. Watch for any unusual noises or vibrations, as these could indicate an improperly installed assembly.

Troubleshooting Mower Deck Issues

When dealing with challenges related to grass cutting equipment, identifying and addressing common issues is crucial for maintaining performance. Regular inspections and understanding how different components interact can help pinpoint the source of malfunction, ensuring smooth operation and optimal results. This section provides guidance on diagnosing typical problems and offers solutions to restore functionality effectively.

Common Signs of Equipment Malfunctions

Frequent signs of trouble include uneven cuts, unusual noises, or difficulty in maneuvering. These issues often stem from worn-out components, misalignment, or debris buildup. Checking the condition of blades, pulleys, and belts can reveal whether adjustments or replacements are needed to restore efficiency.

Steps to Resolve Performance Issues

Start by inspecting the blade sharpness and balance. Dull or damaged blades can lead to inconsistent cutting. Next, verify that all pulleys are functioning smoothly and that belts are properly tensioned. Finally, clear any grass or debris that might obstruct movement, as this can hinder performance and lead to unnecessary wear on parts.

Cleaning and Maintaining the Deck

Regular care and upkeep of your lawn cutting equipment are essential to ensure optimal performance and longevity. By maintaining the cutting mechanism, you can avoid clogs, rust, and other issues that can diminish efficiency. Proper maintenance also enhances the quality of the cut and ensures smoother operation during use.

Steps to Clean and Care for Your Equipment

To keep your equipment in top condition, it’s important to clean it after each use. Removing grass clippings, debris, and dirt helps prevent build-up that could affect functionality. In addition, periodic checks for rust and loose components will help avoid malfunctions over time.

Task Frequency Details Clean After Use After every session Remove debris and clippings from all moving parts. Check for Rust Monthly Inspect metal components for signs of corrosion and treat as necessary. Tighten Bolts Every 3 months Ensure all fasteners are secure to avoid vibrations and damage. Important Maintenance Tips

Always ensure that safety mechanisms are in place before performing any maintenance. Use a suitable brush or scraper to remove stubborn grass residue. Lubricate moving parts periodically to reduce friction and wear.

Adjusting Mower Deck Height on the L110

Properly setting the cutting height of your lawn equipment ensures an even and clean cut. Achieving the correct height adjustment is essential for maintaining a healthy lawn and optimizing the performance of your machine. This section outlines the steps required to adjust the height effectively.

- Check the current height setting before making adjustments.

- Ensure the equipment is on level ground for accurate adjustments.

- Locate the height adjustment mechanism, usually found near the wheel assembly.

- Use the adjustment levers or knobs to increase or decrease the cutting height.

- Test the new height by running the machine on a small patch of grass.

Regular height adjustments can improve cutting efficiency and prolong the life of the blades and other components. Always refer to the user manual for specific instructions related to your model to ensure the proper adjustment technique.

Signs of Worn Deck Parts

Maintaining the functionality of your lawn care equipment is essential for optimal performance. Over time, certain components that handle the cutting and movement may show signs of wear. These signs can affect both the quality of the job and the efficiency of the machine. It’s crucial to recognize these indicators early to avoid costly repairs and ensure smooth operation.

Visual Indicators of Wear

One of the first signs of worn components is visible damage or wear on the blades and surrounding areas. Components may become bent, cracked, or overly dull, leading to uneven cutting results. Rust or corrosion may also appear on metal surfaces, signaling the need for immediate attention.

Performance Changes

Changes in performance, such as a decrease in cutting efficiency or an increase in vibration, are clear indicators that something is not functioning properly. A machine that produces uneven cuts or struggles to handle thicker grass or uneven terrain may have worn out parts that need replacement.

Symptom Possible Cause Recommended Action Uneven cutting Dull or damaged blades Replace or sharpen blades Excessive vibration Loose or bent components Tighten or replace damaged parts Rust or corrosion Exposure to moisture Clean and treat with anti-corrosion products Tools Needed for Deck Repair

When it comes to restoring the cutting system of your lawn equipment, having the right tools is essential. A well-equipped workspace can make the repair process smoother and ensure that the job is done efficiently and safely. You will need a few specific instruments to tackle this task, each serving a unique purpose in the restoration procedure.

Basic hand tools like wrenches, screwdrivers, and pliers are necessary to remove and tighten various components. It’s important to use tools of the correct size to avoid damaging bolts or fasteners. Additionally, a socket set with both deep and standard sockets will come in handy for accessing hard-to-reach areas.

For cleaning and smoothing surfaces, a wire brush and scraper are useful to remove any built-up debris or rust. If more advanced tasks are needed, consider using a torque wrench to apply the proper amount of force without over-tightening.