Understanding the various elements that contribute to the smooth operation of equipment is crucial for maintaining its efficiency and longevity. This section delves into the essential mechanical systems that collaborate to ensure optimal performance. Each component plays a vital role in the overall functionality, making it important to become familiar with their structure and purpose.

We will explore the individual elements, focusing on their design and how they integrate to form a cohesive unit. By examining these details, you will gain insights into troubleshooting common issues and maintaining the equipment for extended use. Proper knowledge of these systems helps in identifying wear and tear and addressing potential problems before they escalate.

Regular maintenance and timely inspections of the mechanical parts can significantly extend the operational lifespan of your equipment. In the following sections, we will provide a detailed breakdown of these systems to ensure you have all the necessary information for effective upkeep.

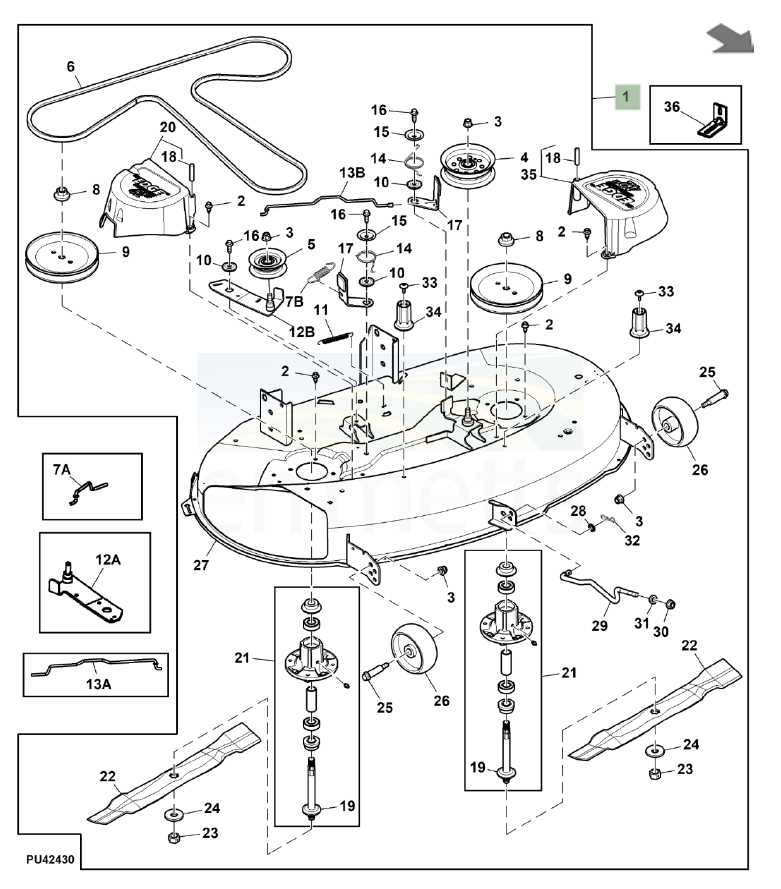

Understanding the Components of a Mower Deck

The cutting system of a lawn maintenance machine consists of various essential elements that work together to ensure efficient grass trimming. These components are engineered for durability and optimal performance, ensuring that the machine can handle various terrain types and cutting conditions.

Blades and Cutting Mechanism

The core of the system is its blades, which are responsible for the actual trimming. The sharpness and balance of these blades directly influence the quality of the cut. A well-maintained set of blades will provide a precise and even trim, enhancing the overall efficiency.

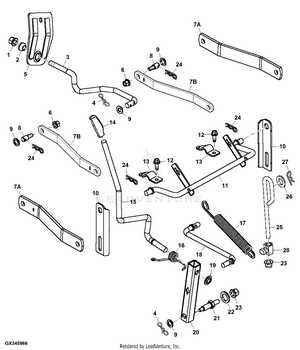

Support Structures and Controls

Another critical part of this system involves the supporting framework and control features. These structures ensure the cutting unit remains stable during operation. Additionally, the height adjustment controls allow users to set the cutting height, giving flexibility in managing different types of grass and ground levels.

Key Elements of a Cutting System

The functionality of a cutting system relies on various essential components that work together to ensure efficient and smooth operation. Each part plays a crucial role in delivering a precise and clean cut, contributing to the overall performance of the machinery. Understanding these elements is vital for maintaining optimal functionality.

Blades

Blades are a fundamental part of the cutting system, responsible for slicing through the grass or vegetation. Their sharpness and durability are key factors in ensuring a smooth cut. Regular maintenance, such as sharpening or replacing the blades, is necessary to sustain effective performance.

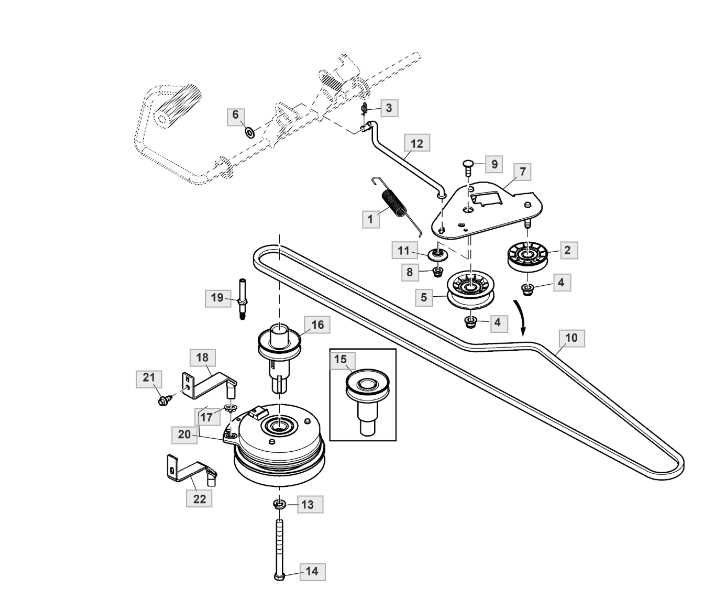

Belt and Spindle Mechanism

The belt and spindle system powers the rotation of the blades. This mechanism is critical for transferring energy from the engine to the cutting unit. Proper tension and alignment of the belt ensure that the system functions without unnecessary strain, preventing wear and enhancing the longevity of the components.

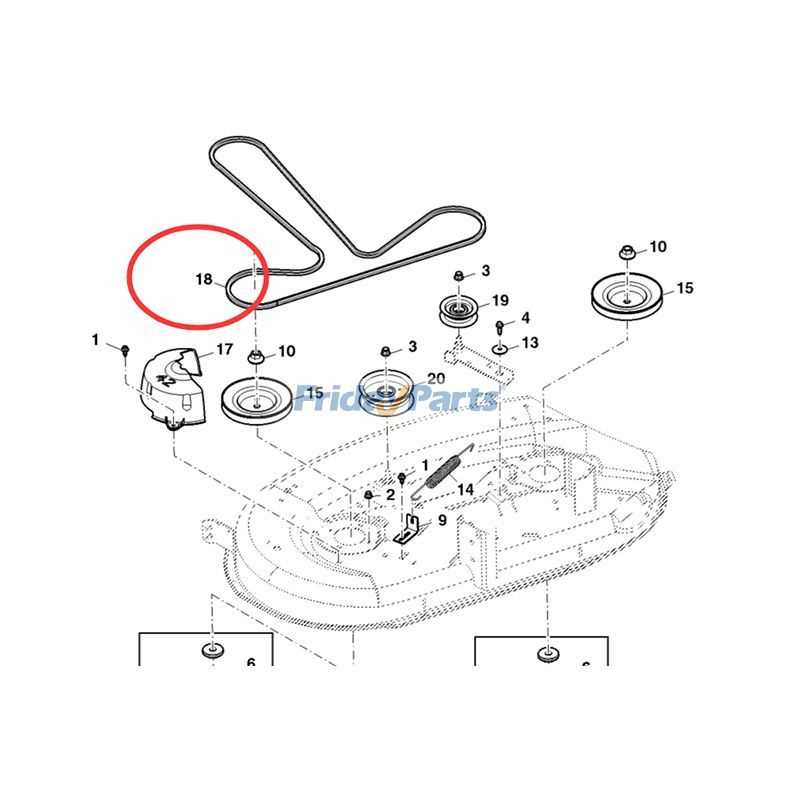

Belt Assembly and Its Functions

The belt assembly is a critical component in the operation of many machines, responsible for transferring power efficiently from one part of the system to another. Its proper function ensures that the mechanical system operates smoothly and with minimal energy loss.

The assembly consists of several key elements that work together to provide consistent motion and power distribution. Understanding its structure and roles can help maintain optimal performance and extend the machine’s lifespan.

- Power Transmission: The primary function of the belt is to transfer energy between different components. It helps drive pulleys that control various mechanical actions.

- Alignment Support: Proper alignment of the belt ensures that energy is transferred efficiently, reducing wear and tear on the system.

- Vibration Reduction: The belt assembly helps

Blades: Types and Maintenance Tips

Blades play a crucial role in ensuring efficient cutting performance and maintaining healthy grass. Choosing the right type and keeping them in optimal condition can significantly improve the overall function of your equipment.

There are several types of blades, each designed for different purposes. For instance, high-lift variants are ideal for bagging, while mulching versions chop clippings into finer pieces, returning nutrients to the soil. Understanding the specific needs of your lawn will help in selecting the appropriate blade type.

Regular upkeep is essential to prolong the lifespan of your blades. Sharpen them periodically to ensure clean cuts and prevent damage to the grass. It’s also important to check for signs of wear, such as dullness or chips, and replace them if necessary. Cleaning debris buildup will further enhance their performance and reduce strain on the machine.

Spindles and Their Role in Mowing

Spindles play a crucial role in ensuring the effective cutting performance of grass-maintenance equipment. Their main function is to transfer power from the engine to the cutting blades, enabling the blades to rotate at high speeds and efficiently trim vegetation. Without these components, the blades would not operate as intended, resulting in poor grass cutting and uneven results.

- Power Transfer: Spindles are essential for transmitting rotational energy, which drives the cutting blades, making sure they spin properly during operation.

- Blade Stability: By securely holding the blades in place, spindles ensure that they rotate smoothly without unnecessary vibrations, which is important for even cutting.

- Durability: Quality sp

How Pulleys Affect Deck Performance

Pulleys play a crucial role in the overall functionality of the cutting system. Their purpose is to transfer energy efficiently from the engine to the cutting mechanism, ensuring that the blades operate at the optimal speed. Without proper pulley operation, the performance of the cutting tool can be severely impacted, leading to uneven results or increased wear on the components.

Pulley Type Impact on Performance Drive Pulley Ensures efficient power transfer from the engine, affecting speed and smooth operation. Idler Pulley Maintains proper tension on the belt, preventing slippage and ensuring consistent performance. Adjusting the Mower Deck Height

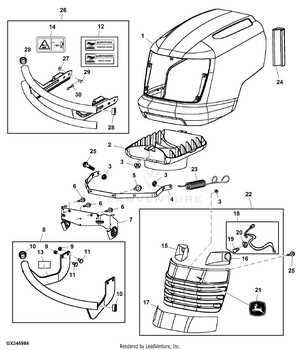

Properly setting the cutting height of your lawn care equipment is essential for achieving an even and healthy lawn. Adjustments allow for flexibility based on grass type, season, and desired appearance. Understanding how to modify the height effectively can enhance the performance of the equipment and improve the overall health of your grass.

Steps to Adjust Height

Follow these steps to achieve the desired cutting height:

- Park the equipment on a level surface.

- Ensure the engine is off and the ignition key is removed.

- Locate the height adjustment mechanism, which is usually a lever or a set of notches.

- Adjust the mechanism according to the desired height setting, ensuring both sides are equal for a balanced cut.

- Once adjustments are made, double-check the height by measuring from the ground to the blade.

Recommended Cutting Heights

Here are general recommendations for cutting heights based on grass types:

- Cool-season grasses: 2.5 to 4 inches

- Warm-season grasses: 1.5 to 3 inches

- Fine fescue: 1.5 to 2.5 inches

- Bermudagrass: 1 to 2 inches

Maintaining the correct height not only promotes a healthy lawn but also minimizes wear on the equipment, ensuring longevity and optimal performance.

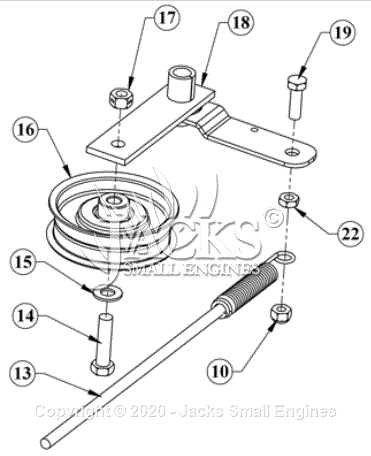

Examining the Tensioner and Its Parts

The tensioner plays a crucial role in the functioning of any cutting mechanism, ensuring optimal performance by maintaining the necessary tension on the belt system. Understanding its components and their interaction can significantly enhance the efficiency and durability of the overall equipment.

Components of the Tensioner

The tensioner consists of several key elements, including the spring, pulley, and arm. Each component contributes to the proper functioning of the tensioner, allowing it to effectively manage belt tension and prevent slippage during operation.

Maintenance Tips

Regular inspection and maintenance of the tensioner are essential for long-term performance. Check for signs of wear, such as cracks or fraying in the spring and belt. Ensuring that the pulley rotates smoothly can also prevent premature wear on other components, ultimately extending the life of the entire cutting system.

Common Mower Deck Problems and Solutions

Maintaining a healthy cutting mechanism is essential for optimal performance and longevity. Various issues may arise that can affect functionality and efficiency. Understanding these common challenges and their solutions can help ensure smooth operation.

Here are some frequent problems encountered:

- Uneven Cutting: This can be caused by dull blades, improper height settings, or uneven tire pressure.

- Clumping of Grass: This may occur due to wet conditions or clogged discharge areas, preventing proper grass flow.

- Strange Noises: Unusual sounds can indicate loose components or debris caught in the mechanism.

- Vibration Issues: Excessive vibration often points to imbalanced blades or worn-out bearings.

To address these concerns, consider the following solutions:

- Regularly sharpen or replace blades to ensure even cutting.

- Adjust the cutting height and check tire pressure to promote balanced operation.

- Clear any debris or clogs from the discharge area to enhance grass flow.

- Tighten any loose components and inspect for any damaged parts to reduce noise and vibration.

Implementing these practices can significantly improve performance and extend the life of your cutting apparatus.

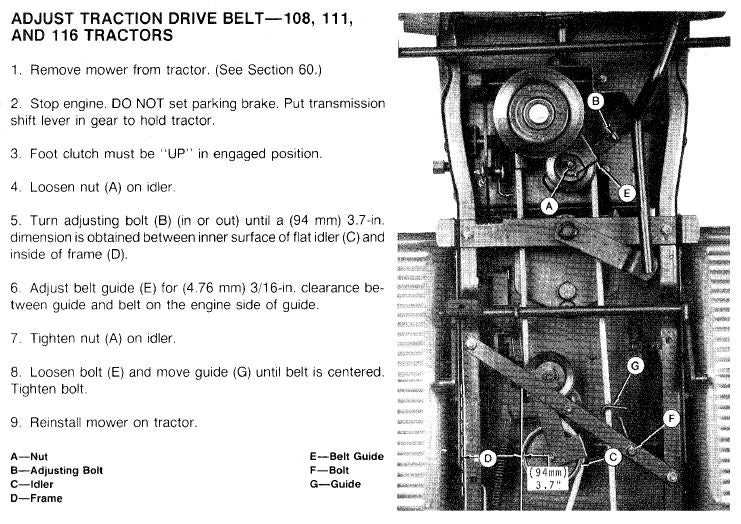

Guide to Replacing Worn-Out Deck Parts

Maintaining the efficiency of your cutting equipment is essential for achieving optimal performance and longevity. Over time, certain components may become worn or damaged, necessitating their replacement to ensure smooth operation. Understanding the signs of wear and knowing how to address them can help you keep your machinery in excellent condition.

Before beginning the replacement process, it is crucial to gather all necessary tools and new components. Make sure to consult your user manual or manufacturer specifications to identify the exact items you need. Having everything ready will streamline the task and minimize downtime.

Start by carefully removing the affected components, taking note of how they are attached. It may be helpful to document this process with photographs or notes. Once removed, inspect the area for any additional issues that may need attention. After addressing any concerns, install the new items following the reverse order of removal. Ensure that all fasteners are tightened securely to prevent any operational issues.

Finally, test the equipment after replacing the worn elements. A short trial run will allow you to confirm that everything is functioning correctly. Regular maintenance checks will help you catch wear early, prolonging the life of your machinery and ensuring that it remains efficient for future use.

Impact of Deck Size on Lawn Care

The dimensions of cutting equipment play a crucial role in maintaining a healthy and attractive lawn. A larger cutting width allows for more efficient coverage of the grass area, reducing the number of passes needed to achieve a clean cut. This efficiency can save both time and effort, allowing homeowners to manage their outdoor spaces more effectively.

In contrast, smaller cutting tools may require additional maneuvering and more frequent passes, which can lead to uneven results and increased wear on the grass. Moreover, different sizes can affect the ability to navigate around obstacles, such as trees and flower beds, thereby influencing the overall aesthetic appeal of the yard.

Choosing the right dimensions for cutting equipment can also impact the health of the turf. Equipment that is too large for a small yard may lead to scalping or damage to delicate grass types. Conversely, smaller tools may be more suitable for intricate landscaping, promoting a well-groomed appearance without risking harm to the lawn.

Ultimately, understanding the relationship between cutting dimensions and lawn care is essential for achieving optimal results. The right choice can enhance efficiency, improve the visual appeal of the landscape, and support the long-term health of the grass.

Choosing the Right Parts for Repair

Selecting the appropriate components for maintenance and repair is crucial to ensure optimal performance and longevity of your equipment. Understanding the specifications and compatibility of each element can greatly enhance the efficiency and reliability of your machinery. This section will guide you through essential considerations when sourcing replacements.

Identifying Compatible Components

Before making a purchase, it’s important to verify that the replacements you are considering will fit seamlessly with your existing machinery. Always refer to the manufacturer’s guidelines or seek assistance from a professional to guarantee compatibility. This diligence can prevent unnecessary issues during installation.

Quality vs. Cost

When evaluating options, consider both the quality and price of the components. While it may be tempting to opt for cheaper alternatives, investing in high-quality replacements can save you money in the long run by minimizing the need for frequent repairs. Look for reputable suppliers who offer warranties and customer support to ensure you receive durable products.