Maintaining an efficient and reliable lawn care system is crucial for achieving a well-manicured outdoor space. Within this realm, the intricate assembly of machinery plays a significant role in ensuring optimal performance and durability. A clear visual representation of these components can greatly enhance the user’s ability to troubleshoot and maintain their equipment effectively.

This section will delve into the various elements that constitute a specific model of a grass-cutting machine, emphasizing their functionality and interconnections. By exploring this visual guide, users will gain valuable insights into the assembly and operation of their equipment, enabling them to perform maintenance tasks with greater confidence and ease.

Understanding the arrangement of these vital components not only aids in repairs but also empowers operators to maximize the potential of their machinery. With this knowledge, users can extend the lifespan of their equipment and ensure that their outdoor maintenance activities are executed seamlessly.

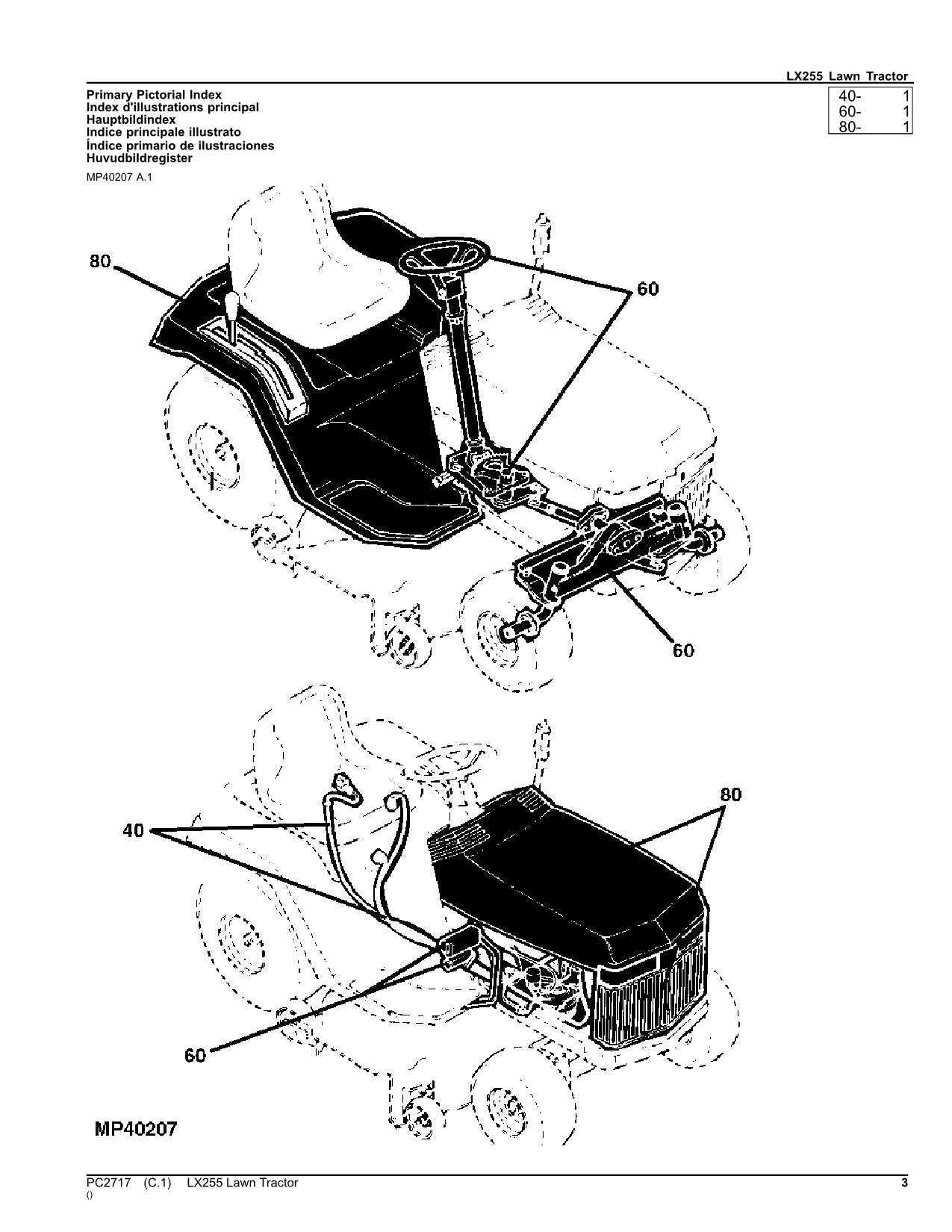

This section provides an insightful look into a specific model of gardening machinery, highlighting its key components and functionalities. Understanding the structure and assembly of this equipment is essential for maintenance and troubleshooting. By exploring the various elements involved, users can better appreciate how each part contributes to overall performance.

Key Features of the Equipment

This model is designed for efficiency and ease of use, making it a popular choice among homeowners and landscape professionals. Its robust design and user-friendly features allow for a seamless mowing experience, ensuring that users can maintain their lawns with minimal effort.

Component Overview

Here’s a detailed table that lists the critical components of the equipment along with their functions:

| Component Name | Description |

|---|---|

| Housing | The protective outer shell that encases all internal components. |

| Blades | Sharp implements responsible for cutting grass to the desired length. |

| Spindle Assembly | The rotating mechanism that drives the blades, ensuring smooth operation. |

| Drive Belt | A flexible band that transmits power from the engine to the spindle assembly. |

| Mounting Brackets | Supports the assembly, allowing for secure attachment to the main body. |

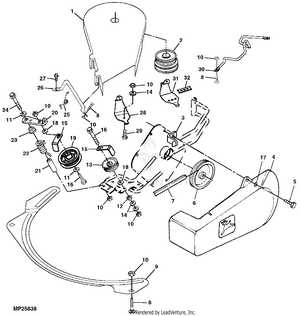

Mower Deck Components Explained

The assembly responsible for cutting grass comprises various elements, each playing a crucial role in ensuring efficiency and effectiveness during operation. Understanding these components can enhance maintenance practices and improve overall performance. Here, we delve into the essential parts that make up this vital system, offering insights into their functions and significance.

Key Elements of the Cutting Assembly

Among the primary components are the rotating blades, designed to deliver a clean cut. Their sharpness and durability significantly influence the quality of the trimming. Additionally, the housing encases these blades, providing protection while ensuring optimal airflow for a smooth cutting action.

Supporting Structures and Mechanisms

Support systems such as brackets and pulleys facilitate movement and stability. The height adjustment mechanism allows users to tailor the cutting height according to their preferences, promoting versatility in various mowing conditions. Proper knowledge of these structures not only aids in efficient operation but also contributes to prolonging the lifespan of the entire assembly.

Identifying Key Parts in Diagrams

Understanding the essential components within illustrations is crucial for effective maintenance and repair tasks. By familiarizing oneself with the various elements, users can navigate complex systems more easily and ensure proper functioning. Recognizing these key elements enables efficient troubleshooting and enhances overall performance.

Common Components to Look For

- Blades: Essential for cutting grass and achieving a neat finish.

- Spindles: The rotating shafts that support and drive the cutting blades.

- Belts: Connect different parts, transferring power to various components.

- Mounting Brackets: Provide stability and secure attachment to the main chassis.

- Wheels: Facilitate movement and maneuverability across different terrains.

Tips for Effective Identification

- Familiarize yourself with the layout of the illustration to understand how components are interconnected.

- Refer to the legend or key provided, which often explains the symbols and labels used.

- Cross-reference parts with the user manual for additional context and specifications.

- Use high-quality images for clearer visibility of intricate details.

Maintenance Tips for Mower Deck

Proper upkeep of your cutting apparatus is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps in identifying potential issues before they escalate. Here are some essential tips to keep your equipment running smoothly.

Regular Cleaning

After each use, it is important to remove any grass clippings, dirt, or debris that may accumulate. This not only prevents rust but also ensures a clean cut during operation. A soft brush or cloth can be used to reach tight spots, while a hose can help wash away stubborn residues.

Inspection and Lubrication

Frequent inspections of moving components are necessary to spot any signs of wear or damage. Ensure that all bolts and fasteners are secure. Additionally, applying lubricant to bearings and pivot points can minimize friction, resulting in smoother operation and reduced wear.

Common Issues with Mower Deck

Maintaining optimal performance in cutting equipment can be challenging. Various problems may arise, impacting the effectiveness and longevity of the apparatus. Identifying and addressing these concerns promptly can prevent more severe complications and ensure a well-groomed lawn.

Frequent Challenges

- Uneven Cutting: One of the most prevalent issues is the inability to achieve a uniform cut. This can result from improper leveling or worn-out blades.

- Clogging: Grass buildup can obstruct the cutting mechanism, leading to decreased efficiency. Regular cleaning is essential to avoid this issue.

- Noisy Operation: Excessive noise during operation often indicates problems with bearings or loose components that need attention.

- Vibration: Excessive shaking can stem from unbalanced blades or loose attachments, affecting the overall performance.

Preventive Measures

- Regularly inspect and sharpen the cutting tools to ensure clean cuts.

- Keep the cutting area clear of debris to prevent clogging.

- Perform routine maintenance checks to identify any loose or damaged components.

- Adjust the height settings appropriately to maintain an even cutting surface.

Tools Required for Repairs

Effective maintenance and restoration of outdoor equipment require a set of essential implements. Having the right tools at hand not only streamlines the process but also ensures that the job is completed efficiently and safely.

Below is a list of indispensable tools for carrying out repairs:

- Wrenches: Various sizes are necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are essential for removing and securing screws.

- Pliers: Useful for gripping, twisting, and cutting wires or other small components.

- Socket Set: A collection of sockets is vital for accessing hard-to-reach fasteners.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

In addition to these basic tools, consider having the following items for more specialized tasks:

- Diagnostic Tools: Equipment such as multimeters can help in troubleshooting electrical issues.

- Cleaning Supplies: Brushes, rags, and cleaning solvents are necessary for maintaining cleanliness and performance.

- Replacement Parts: Keeping common replacement components on hand can minimize downtime.

Equipping yourself with these tools will enable efficient handling of repair tasks and contribute to the longevity of your equipment.

Step-by-Step Assembly Guide

Assembling the components of your equipment can be a straightforward process when you follow a systematic approach. This guide will walk you through each step, ensuring all elements are properly aligned and securely attached. By the end of this section, you will be equipped with the knowledge to assemble the system efficiently.

Preparation of Components

Before beginning the assembly, ensure that all necessary components are gathered and organized. This includes verifying that you have the right tools and hardware. Having everything in one place can significantly streamline the assembly process.

| Component | Quantity |

|---|---|

| Housing Assembly | 1 |

| Fasteners | 10 |

| Wheels | 4 |

| Drive Belt | 1 |

Assembly Steps

To begin, attach the housing assembly to the main frame, ensuring that it fits snugly. Next, secure it with the provided fasteners, tightening each one gradually. Following this, install the wheels by aligning them with the designated slots and fastening them securely. Finally, route the drive belt according to the manufacturer’s guidelines to complete the assembly process.

How to Replace Deck Parts

Maintaining the performance of your outdoor equipment is essential for achieving optimal results. One crucial aspect of upkeep involves replacing worn or damaged components. This guide provides a comprehensive overview of the process, ensuring that you can efficiently handle the replacement of essential elements, enhancing the longevity and efficiency of your machine.

Preparation Steps

Before beginning the replacement procedure, it’s important to gather all necessary tools and components. Having everything ready will streamline the process and minimize downtime.

| Tools Required | Components Needed |

|---|---|

| Wrench set | New blades |

| Screwdriver | Spindle assembly |

| Pliers | Belts |

| Safety gloves | Washers and bolts |

Replacement Procedure

Once you have prepared, follow these steps to replace the necessary components:

1. Ensure the equipment is turned off and disconnected from the power source.

2. Remove any fasteners securing the elements to be replaced.

3. Carefully detach the worn components, taking note of their arrangement for proper reinstallation.

4. Install the new components by reversing the removal process, ensuring everything is securely fastened.

5. Finally, conduct a thorough inspection to ensure all elements are properly aligned and functioning as intended.

Understanding Mower Deck Adjustments

Properly calibrating the cutting equipment is crucial for achieving an even and effective cut. Adjustments can greatly influence performance, ensuring that the blades operate at the ideal height and angle. This not only enhances the quality of the cut but also promotes the longevity of the machine. Regular maintenance and fine-tuning can lead to improved efficiency and a better overall experience for the user.

Importance of Correct Height Settings

Maintaining the right height is vital for a healthy lawn. Cutting too low can stress the grass, making it vulnerable to disease and drought, while cutting too high may result in uneven growth. Adjusting the height settings allows for flexibility based on the grass type and seasonal conditions, ensuring optimal health and aesthetics.

Fine-Tuning the Angle

The angle at which the blades cut also plays a significant role in performance. An incorrect angle can lead to an uneven cut and may even cause damage to the blades over time. Making precise adjustments ensures that the blades operate efficiently, allowing for smooth and consistent results across the entire area being serviced.

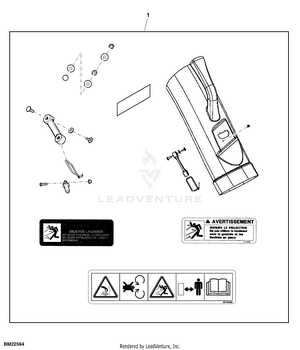

Safety Precautions During Repairs

Engaging in maintenance and repairs on outdoor machinery requires adherence to essential safety measures to prevent accidents and ensure a secure working environment. Proper precautions not only safeguard the individual performing the work but also help protect the equipment from damage. It is vital to follow guidelines that enhance safety and minimize risks associated with mechanical tasks.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial when conducting repairs. Essential items include safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges, and sturdy footwear to provide stability and guard against heavy objects. Additionally, using ear protection may be necessary if the equipment generates significant noise during operation.

Work Area Organization

Maintaining a tidy and organized workspace significantly contributes to safety. Clearing the area of clutter allows for easier movement and reduces the likelihood of tripping hazards. It is advisable to ensure that tools and equipment are stored properly and are readily accessible, preventing unnecessary distractions during the repair process.

Where to Purchase Replacement Parts

Finding suitable components for your outdoor equipment is essential for maintaining optimal performance. Numerous options are available for acquiring these necessary items, ensuring that your machinery runs smoothly and efficiently. Below are various avenues to explore when seeking out replacements.

- Authorized Dealers: Visiting an official dealer can guarantee authenticity and compatibility. They often carry a full range of items tailored for specific models.

- Online Retailers: E-commerce platforms provide a wide selection of components at competitive prices. Look for trusted websites that specialize in outdoor machinery.

- Local Hardware Stores: Many neighborhood stores stock a variety of tools and equipment. They may offer basic components, making it convenient for quick repairs.

- Second-Hand Markets: Consider checking out local classifieds or online marketplaces for gently used components. This can be a cost-effective option if you’re on a budget.

Ensure to verify compatibility with your specific model when purchasing. Prioritizing quality and reliability will contribute to the longevity and effectiveness of your equipment.

Benefits of Using Genuine Parts

Utilizing authentic components for your machinery offers numerous advantages that contribute to optimal performance and longevity. Genuine items are specifically engineered to fit perfectly and work seamlessly with your equipment, ensuring reliability in every task. This not only enhances operational efficiency but also minimizes the risk of unexpected failures and costly repairs.

Enhanced Performance and Reliability

Authentic components are crafted to meet stringent quality standards, which translates to improved functionality. When using these high-quality items, you can expect better performance from your equipment, allowing it to operate at peak efficiency. Additionally, these genuine options are designed to endure various working conditions, providing consistent reliability over time.

Cost-Effectiveness in the Long Run

While it may be tempting to opt for cheaper alternatives, investing in original components can save you money in the long term. Imitation parts often lead to complications and increased maintenance costs due to their subpar quality. By choosing genuine items, you ensure durability and reduce the likelihood of needing frequent replacements, making it a wise financial decision.