The intricate workings of lawn maintenance machinery can often seem overwhelming, yet grasping the essentials of its structure is crucial for effective upkeep and repair. Each element plays a significant role, contributing to the overall functionality and efficiency of the machine.

In this section, we will explore the various components involved in the cutting mechanism, providing clarity on their arrangement and interaction. By doing so, we aim to enhance your understanding and empower you to tackle maintenance tasks with confidence.

Whether you’re a seasoned technician or a homeowner looking to perform basic repairs, a thorough comprehension of these elements is your ultimate tool. Join us as we delve into the specifics and ensure your machinery operates at its best.

Understanding John Deere X300 Deck

This section aims to provide a comprehensive overview of a particular lawn care component that plays a crucial role in ensuring optimal performance and efficiency. By exploring its functionality and essential elements, users can enhance their maintenance knowledge and improve their equipment’s longevity.

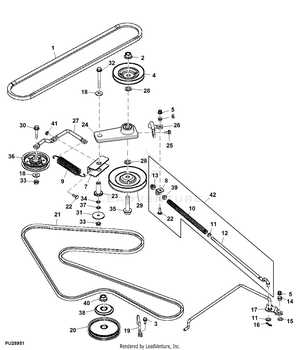

Key Components

Familiarizing oneself with the various elements involved in this assembly is vital for effective upkeep. Each component serves a unique purpose that contributes to overall operation.

| Component | Description |

|---|---|

| Blade | Responsible for cutting grass at a desired height. |

| Spindle | Holds the blade and allows for rotation. |

| Drive Belt | Transfers power from the engine to the cutting mechanism. |

| Chassis | Provides the structural framework for all components. |

Maintenance Tips

Regular inspection and servicing of these elements can prevent wear and ensure smooth operation. By addressing minor issues proactively, users can avoid significant repairs and extend the life of their equipment.

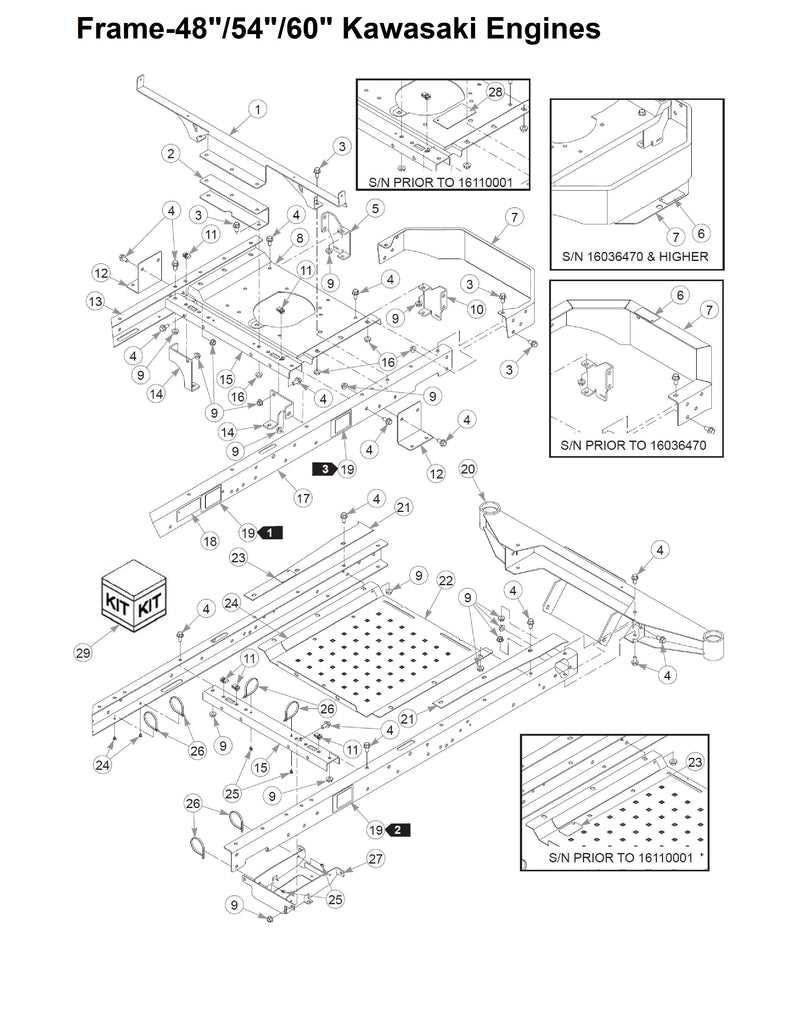

Components of the X300 Deck

This section explores the essential elements that contribute to the functionality and efficiency of the mowing system. Understanding these components is crucial for maintenance and optimization.

Main Elements

Several key components work in harmony to ensure effective grass cutting and collection. Each part plays a specific role, enhancing overall performance.

| Component | Description |

|---|---|

| Blade | Designed for precision cutting, ensuring a clean finish on the lawn. |

| Spindle | Holds the blade and allows for rotation, critical for cutting action. |

| Housing | Encases the blade assembly, providing protection and support. |

| Lift Mechanism | Facilitates raising and lowering of the cutting unit for various mowing heights. |

Maintenance Tips

Regular inspections and timely replacements of worn components ensure longevity and optimal performance of the mowing system.

Importance of Regular Maintenance

Maintaining machinery is essential for ensuring optimal performance and longevity. Regular upkeep not only enhances efficiency but also prevents costly breakdowns and repairs. By committing to routine inspections and servicing, operators can identify potential issues before they escalate, thereby safeguarding their investment.

Moreover, a well-maintained machine operates more smoothly, which can lead to better results and increased productivity. Neglecting maintenance can result in wear and tear, compromising functionality and safety. Ultimately, investing time and resources into regular care pays off in the form of reliability and reduced operational costs.

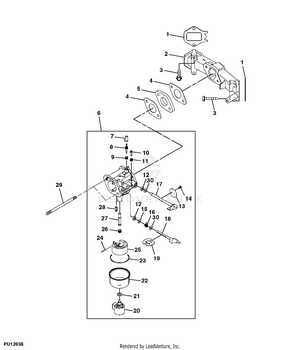

Common Issues with Deck Parts

Maintaining optimal performance in lawn care equipment often reveals various challenges related to component functionality. Users frequently encounter malfunctions that can affect overall efficiency and longevity. Understanding these prevalent problems is essential for effective upkeep and repair.

One of the most common concerns involves wear and tear on rotating components, which can lead to uneven cutting or decreased efficiency. Over time, blades may become dull or damaged, necessitating regular inspection and replacement. Additionally, issues with attachment mechanisms can disrupt operation, making it crucial to ensure proper alignment and secure fittings.

Another frequent issue is debris accumulation, which can hinder performance and create safety hazards. Regular cleaning and maintenance can mitigate this problem, ensuring that all components function smoothly. Lastly, improper adjustments or settings can result in subpar performance, highlighting the importance of following manufacturer guidelines for optimal operation.

How to Replace Deck Components

Maintaining your lawn equipment is essential for optimal performance and longevity. Replacing specific components can significantly enhance efficiency and ensure a clean cut. Understanding the steps involved in this process is crucial for a successful outcome.

1. Gather Your Tools: Before beginning, ensure you have all necessary tools at hand, such as wrenches, screwdrivers, and safety gloves. This preparation will streamline the replacement process.

2. Disconnect Power: Always start by disconnecting the power source to prevent accidental starts. Safety should be your top priority during maintenance.

3. Remove Old Components: Carefully detach the worn-out parts using the appropriate tools. Take note of their arrangement for easier reassembly later.

4. Install New Components: Position the new parts in the same configuration as the old ones. Ensure they are securely fastened to avoid any operational issues.

5. Test Functionality: After reassembly, reconnect the power and test the equipment to verify that everything is functioning correctly. Address any abnormalities immediately.

By following these steps, you can effectively enhance the performance of your lawn equipment and extend its lifespan.

Where to Find Replacement Parts

Locating suitable components for maintenance can be essential for ensuring optimal performance. Various sources are available to help users find the right items needed for repairs or upgrades.

Online Resources

- Manufacturer’s Website: Visit the official site for detailed catalogs and direct purchases.

- Online Retailers: Platforms like Amazon and eBay often have a wide selection of components.

- Specialized Parts Stores: Websites focused on garden machinery can provide specialized options.

Local Options

- Authorized Dealers: These locations usually offer genuine products with expert guidance.

- Hardware Stores: Many carry a range of essential components for common repairs.

- Salvage Yards: A cost-effective alternative for finding used items in good condition.

Comparing OEM vs Aftermarket Parts

When it comes to maintaining machinery, the choice between original components and alternative options can significantly impact performance and longevity. Understanding the distinctions between these two categories is essential for informed decision-making. Each type offers its own advantages and drawbacks, influencing both functionality and budget considerations.

Quality and Performance

Original components are typically manufactured by the same company that produced the machine, ensuring compatibility and reliability. In contrast, alternative options may vary widely in quality, as they are produced by different manufacturers. This inconsistency can affect how well they function and how long they last.

Cost Considerations

Original components usually come with a higher price tag, reflecting their guaranteed quality and performance. However, alternative options often appeal to budget-conscious consumers, offering lower prices that can help reduce overall maintenance expenses. Evaluating the potential trade-offs between cost and reliability is crucial when making a selection.

| Aspect | OEM Components | Aftermarket Options |

|---|---|---|

| Quality | High and consistent | Varies significantly |

| Compatibility | Perfect fit | May require adjustments |

| Cost | Generally higher | Often lower |

| Warranty | Manufacturer’s warranty | Varies by supplier |

Tools Needed for Deck Repair

Proper maintenance requires specific implements to ensure efficient and effective restoration. Having the right tools can significantly ease the process and enhance the quality of the work performed.

Essential Implements

- Socket set for loosening and tightening bolts.

- Wrenches for various sizes of nuts.

- Safety goggles to protect your eyes during repairs.

- Gloves to safeguard your hands.

- Cleaning brush for removing debris.

Additional Recommendations

- Grease gun for lubrication.

- Level to ensure proper alignment.

- Torque wrench for accurate tightening.

- Utility knife for cutting materials.

- Measuring tape for precise dimensions.

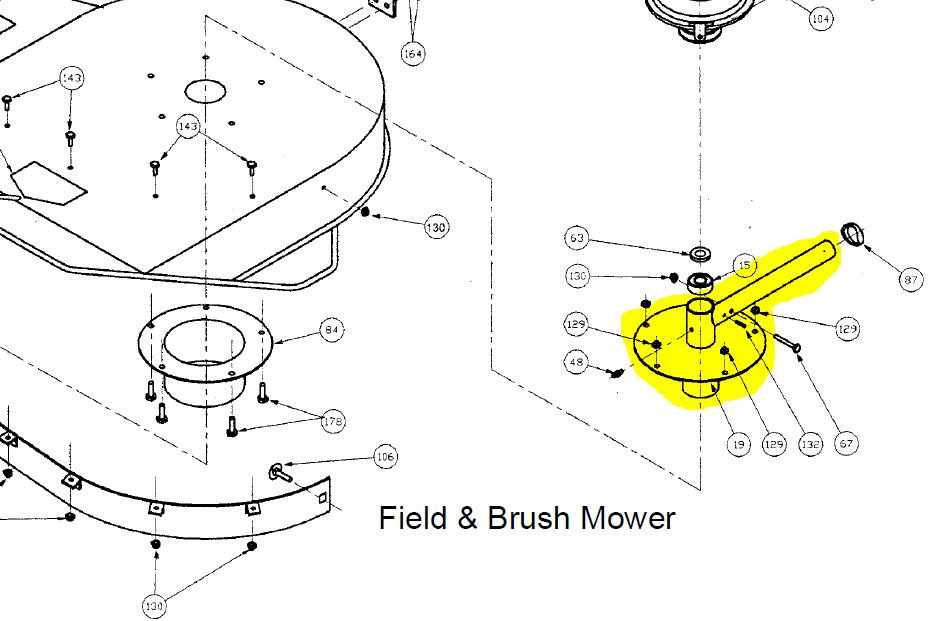

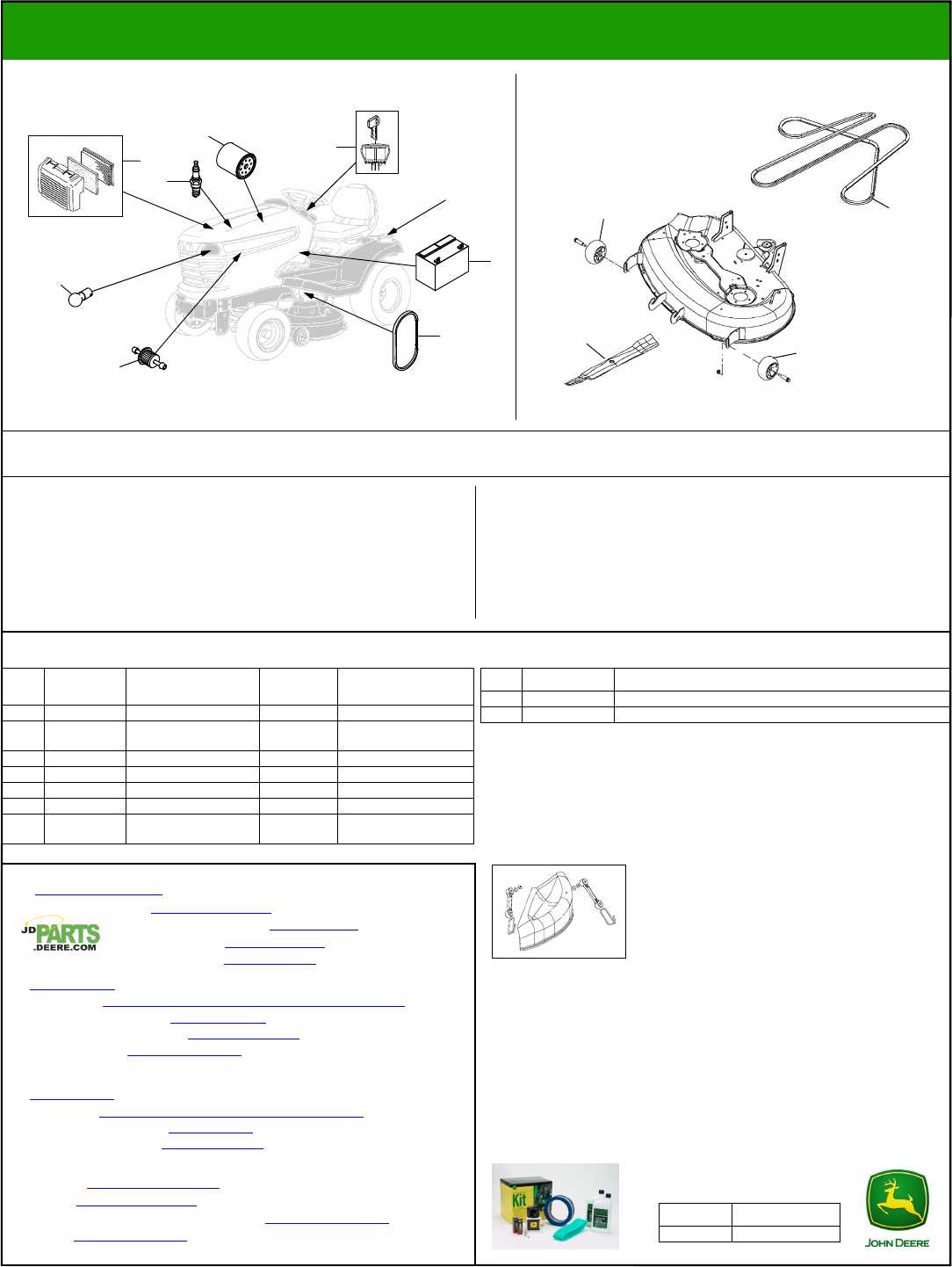

Visual Guide to Deck Assembly

This section provides a comprehensive overview of the assembly process for a lawn care apparatus. Understanding the various components and their arrangement is crucial for optimal performance and maintenance.

Key Components

- Cutting Blades

- Spindles

- Support Brackets

- Belts

- Washers and Nuts

Assembly Steps

- Begin by laying out all components for easy access.

- Attach the spindles securely to the main frame.

- Install the cutting blades, ensuring proper alignment.

- Connect the belts to the drive mechanism.

- Finalize the assembly by securing all fasteners tightly.

Following these steps will lead to a well-structured setup, ensuring longevity and effective operation.

Tips for Deck Troubleshooting

Maintaining optimal performance of your mowing equipment requires a keen eye and proactive measures. Identifying and resolving issues promptly can prevent further damage and enhance the longevity of your machine. This guide offers practical insights to help you troubleshoot common concerns effectively.

Visual Inspection

Begin with a thorough visual assessment. Look for signs of wear or damage, such as cracks, rust, or loose components. Ensure that all connections are secure and that no debris is obstructing the blades. Regularly checking these elements can help catch potential problems before they escalate.

Performance Evaluation

Monitor the functionality of your equipment during operation. Pay attention to unusual noises, vibrations, or uneven cutting patterns. If the performance deviates from the norm, it may indicate underlying issues. Addressing these symptoms promptly can save time and costs associated with more significant repairs.

Enhancing Performance of Your Mower

Improving the efficiency of your lawn care equipment can significantly impact the quality of your landscape. By focusing on key areas such as maintenance, upgrades, and proper usage, you can achieve optimal results while extending the lifespan of your machinery.

Regular Maintenance

- Check and replace the air filter regularly.

- Sharpen the blades to ensure a clean cut.

- Inspect belts and cables for wear and tear.

- Keep the machine clean to prevent rust and debris buildup.

Upgrades and Accessories

- Consider high-performance blades for improved cutting.

- Add a mulch kit to enhance lawn health.

- Invest in quality tires for better traction.

- Utilize smart attachments for increased versatility.

By implementing these strategies, you can delve into a realm of enhanced performance and achieve the ultimate mowing experience.