Understanding the intricate structure and elements responsible for seamless performance is crucial for anyone aiming to maintain their equipment in peak condition. By exploring the key elements of the machinery, one can ensure not only longevity but also optimal efficiency in everyday tasks.

Each section of the equipment plays a vital role in its overall functionality, and a deep dive into these specific components will shed light on how they work in harmony. Knowing the layout and the roles of these components empowers users to troubleshoot issues effectively and replace elements with precision.

This guide provides detailed insights into the structural design and the interaction between various elements, allowing users to grasp how to maintain and enhance their machine’s performance. Whether for repair or improvement, this resource serves as a comprehensive reference for users at all levels.

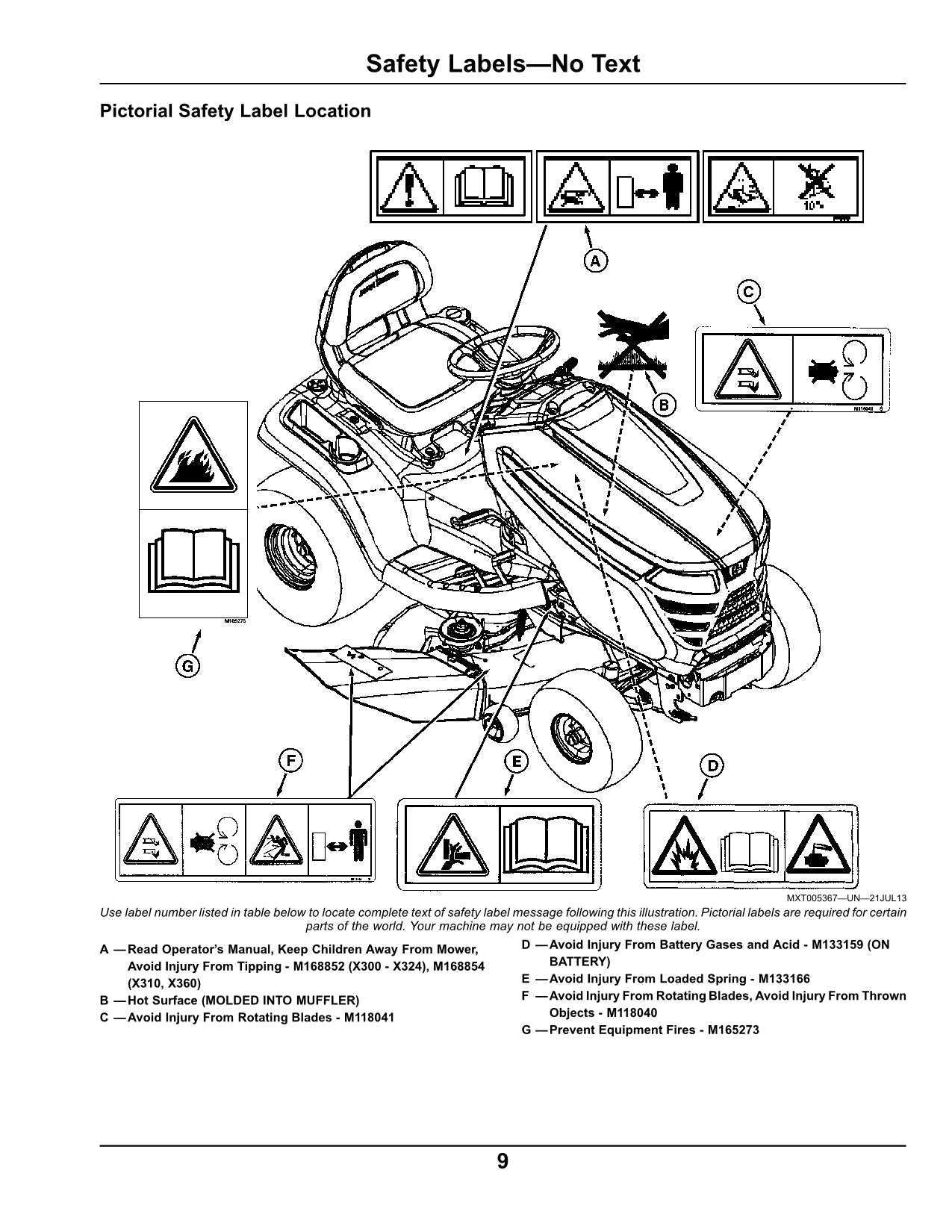

Understanding the Mower Deck of John Deere X324

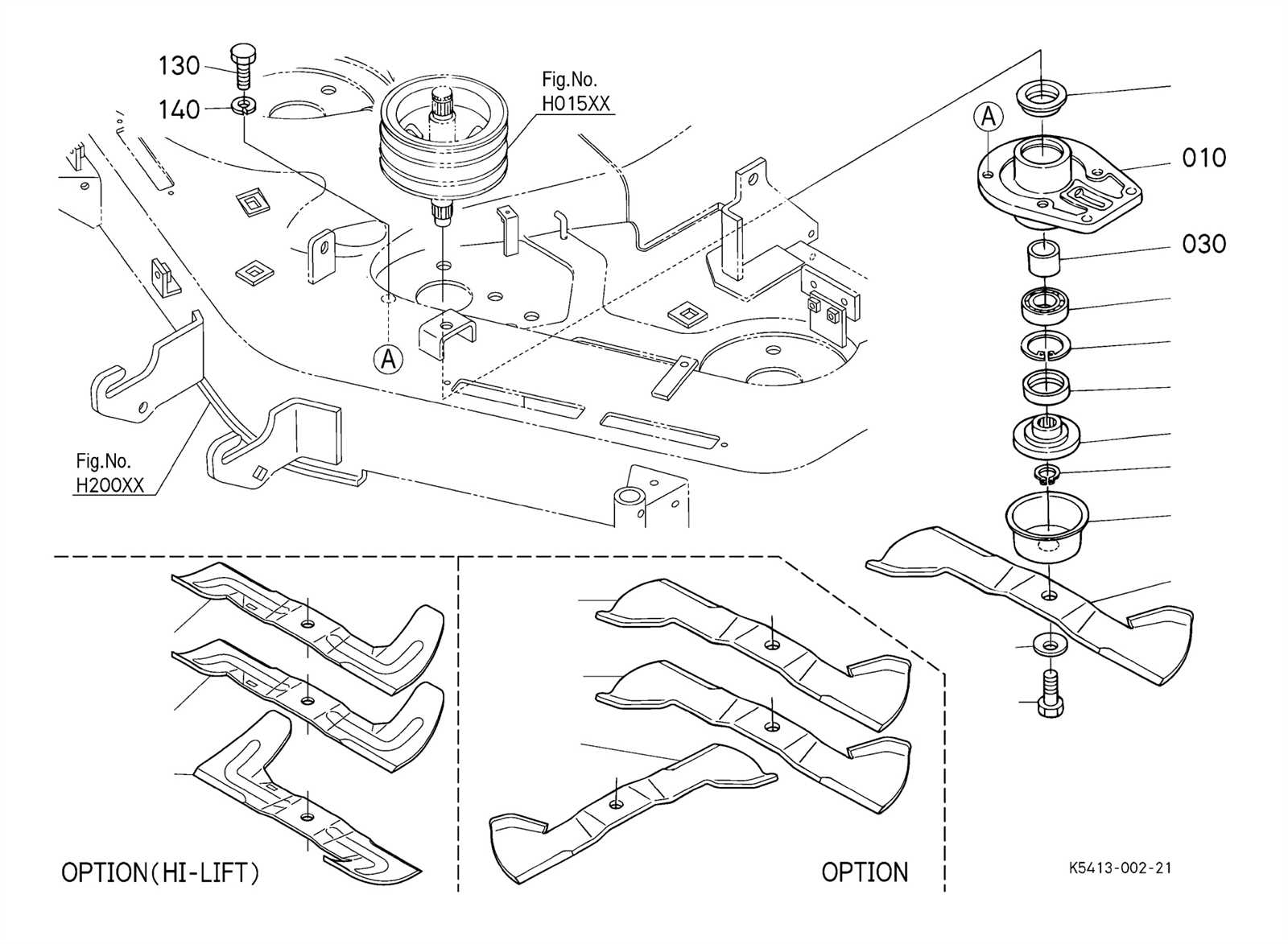

The lower cutting assembly plays a crucial role in the overall performance of any lawn equipment, ensuring even trimming and smooth operation. Its functionality depends on a combination of mechanical components that work together to deliver precise results. This assembly is designed to balance durability with efficiency, providing the best cutting experience for various terrain types.

Blade arrangement is one of the key elements that directly impacts cutting quality. Properly aligned and sharpened blades ensure clean cuts and minimize wear on the machine. Additionally, the lift mechanism enhances the cutting process, allowing the operator to adjust the height of the grass for different lawn conditions.

Other vital components include the drive system, which powers the rotating parts, and the structural frame, which holds everything securely in place. Together, these parts ensure the reliable performance of the equipment, giving the operator full control over lawn maintenance tasks.

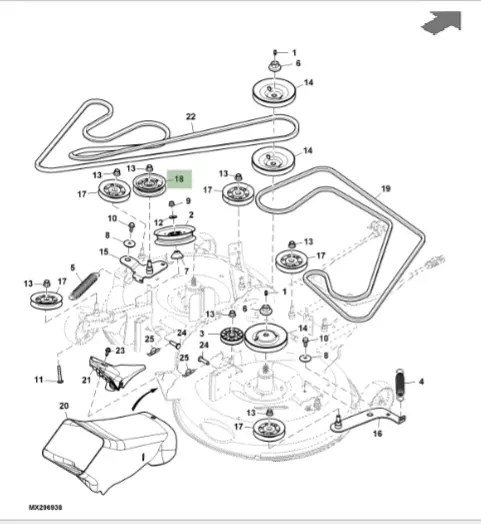

Key Components of the Mower Deck Assembly

The cutting mechanism in any lawn maintenance equipment is a complex system of interrelated parts. Understanding these elements helps ensure optimal performance, longevity, and proper care. Each segment of this system plays a unique role, contributing to the overall efficiency of the equipment during operation. In this section, we will explore the essential components that make up the assembly, focusing on their function and interaction.

Blades

Blades are the primary cutting tools, designed to provide a clean and precise trim. Their sharpness and alignment are crucial for consistent performance. Proper maintenance and regular sharpening ensure smooth operation, reducing the strain on the engine and increasing the quality of the cut.

Spindles

The spindles serve as the central axis for the rotating elements. They connect the blades to the power source, ensuring smooth and efficient motion. These components require regular lubrication to minimize friction and prevent wear, allowing the entire assembly to function at peak performance.

How to Identify Wear on Deck Parts

Prolonged use of cutting equipment often leads to gradual wear, which can affect performance and efficiency. Recognizing the signs of wear is essential for maintaining smooth operation and preventing damage. This section explains how to spot common issues that develop over time.

Visible Signs of Deterioration

- Discoloration: Faded or uneven coloring on components can signal excessive heat or friction, indicating areas of stress.

- Bending or Warping: Look for any irregular shapes or misalignment, as these can reduce effectiveness and increase strain.

- Fraying or Cracking: Check for small cracks, especially around edges, as they may expand and lead to further damage.

Performance Issues to Notice

In addition to visual cues, performance can provide clues to wear.

- Uneven output: A noticeable change in smoothness or consistency can result from worn-out components affecting functionality.

- Strange noises: Grinding or squeaking sounds often indicate that

Replacing Blades for Optimal Performance

Maintaining sharp and balanced blades is essential for ensuring the best cutting results. Over time, the cutting edges can become dull or damaged, leading to uneven trimming and excessive strain on the machine. Regular inspection and replacement of worn blades will not only improve efficiency but also extend the overall lifespan of the equipment.

Choosing the right blades is the first step in ensuring smooth operation. Different materials and designs are available depending on the specific conditions and terrain, and selecting the appropriate one can greatly influence the quality of the cut.

Once the proper blades are acquired, installation requires precision and safety. It’s important to disconnect the power source before beginning, and to securely fasten the blades in the correct position. Misalignment or improper tightening can lead to vibrations and reduced performance, so following the recommended procedures for your equipment is key.

By regularly replacing blades and maintaining them in top condition, you can achieve more consistent results, improve the efficiency of the machine, and reduce wear on other components.

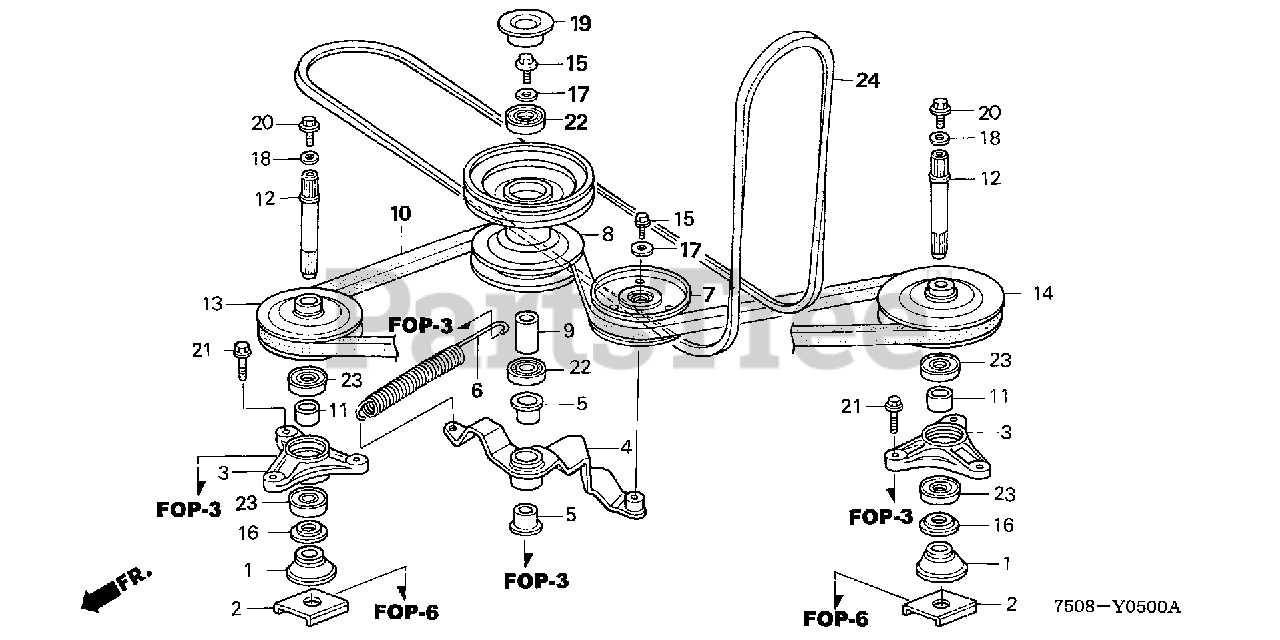

Common Issues with the Mower Deck Belt

The belt in a cutting system is a crucial component that ensures efficient operation. Over time, it may face several problems that can lead to decreased performance or even complete failure. Regular maintenance and timely identification of these issues can prevent more significant malfunctions and extend the lifespan of the equipment.

Belt Slipping

One of the most common problems is the belt slipping off during use. This can occur due to various reasons, such as incorrect tension, worn-out pulleys, or debris getting lodged in the system. Slipping not only impacts performance but can also cause damage to other components if not addressed promptly.

Cracking or Fraying

Another frequent issue is the cracking or fraying of the belt. This is usually caused by prolonged use or exposure to extreme temperatures. Cracked or frayed belts lose their efficiency and should be replaced to avoid sudden breakdowns during operation.

Issue Possible Cause Solution Slipping Loose tension, worn pulleys, debris Check tension, inspect Spindle Assembly Function and Maintenance

The spindle assembly plays a critical role in the efficient operation of the cutting system, allowing the blades to rotate smoothly and with precision. Its purpose is to support the rotating components, ensuring they function effectively under various conditions. Proper maintenance of this assembly is essential for optimal performance, minimizing wear and preventing potential damage to other parts.

Function of the Spindle Assembly

The spindle assembly consists of several components that work together to transfer power from the engine to the blades. The main function is to provide a stable, rotating hub that supports the blades securely, allowing them to cut grass evenly. The spindle is designed to withstand the high torque and pressure generated during operation, making it a critical part of the cutting system.

Maintenance Tips

Regular maintenance of the spindle assembly is crucial for extending its lifespan and maintaining cutting efficiency. Periodic lubrication of the spindle bearings ensures smooth rotation and reduces friction, which can cause premature wear. Inspecting the assembly for loose or damaged parts, such as the bearing or blade attachments, should be done frequently. Additionally, keeping the area around the spindle clean from grass clippings and debris helps prevent clogging and potential overheating.

Key Maintenance Practices: Grease the spindle bearings regularly, check for any signs of wear or damage, and replace any worn-out components to avoid more extensive repairs in the future.

Best Practices for Cleaning the Deck

Maintaining a clean cutting system is essential for optimal performance and longevity of your equipment. Regularly removing debris, grass clippings, and dirt not only helps prevent buildup that can hinder efficiency, but also reduces the risk of rust and corrosion. Proper cleaning techniques ensure smoother operation and a more even cut with every use.

1. Regular Cleaning After Each Use

It’s important to clear away any grass, dirt, or debris after every operation. Leaving these materials to accumulate can cause clogs and lead to inefficient functioning. Use a brush or hose to remove any buildup, ensuring all surfaces are free of residue. For tougher spots, a plastic scraper can be helpful without damaging the surfaces.

2. Dry the Equipment Properly

After washing the system, make sure to dry it thoroughly. Moisture left behind can promote rust, which is detrimental to metal parts. Using a clean cloth or letting the components air dry in a well-ventilated area will help prevent any long-term damage.

3. Check for Build-Up in Hard-to-Reach Areas

Some areas may be harder to access, such as under the components or in between tight spaces. Regular inspection and cleaning of these hidden spots can prevent excessive dirt accumulation, which could compromise the overall performance. Utilize small brushes or compressed air to reach these difficult spots.

4. Use Appropriate Cleaning Solutions

When cleaning, avoid harsh chemicals that could cause damage to the materials. Opt for gentle soap and water solutions or mild degreasers to remove stubborn grime. Always ensure that the cleaning agents are suitable for the type of materials your equipment is made of.

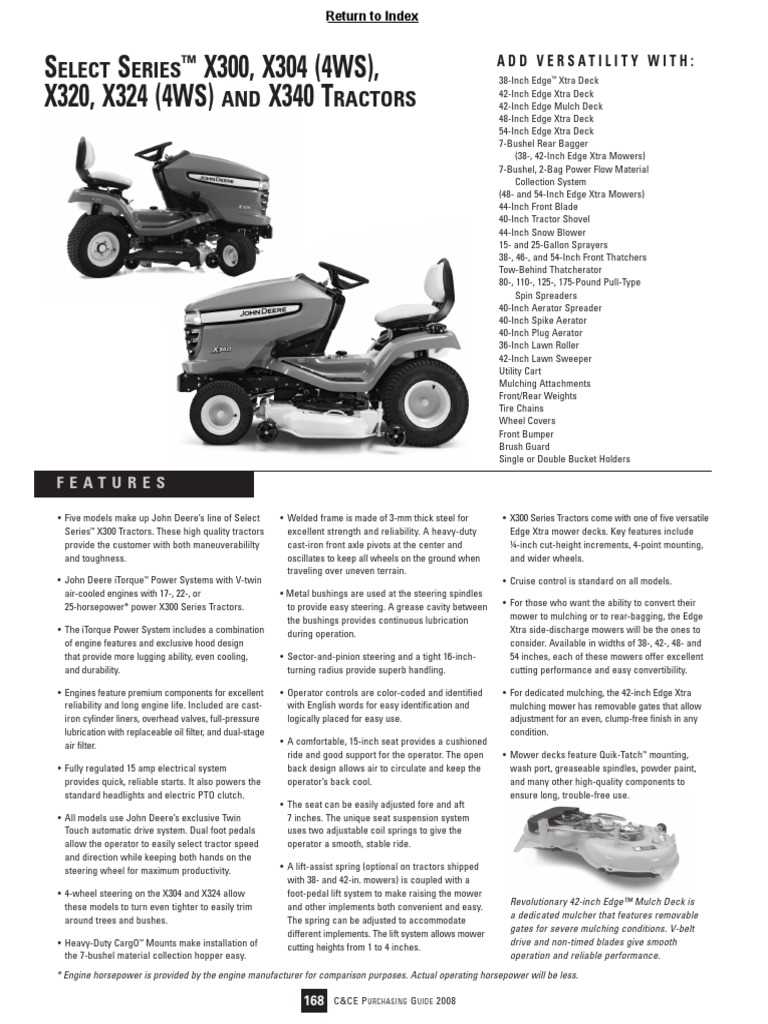

Adjusting the Mower Deck for Even Cutting

Achieving a consistent cut requires proper adjustment of the cutting components. Ensuring that these components are aligned and functioning efficiently will result in a smooth, uniform finish on your lawn. Regularly maintaining and calibrating the cutting mechanism prevents uneven results and promotes better grass health.

Understanding the Importance of Leveling

Proper leveling ensures that the blades cut evenly across the surface. If the cutting tool is not properly aligned, it may leave uneven patches or scalped areas. Checking the balance of the system is essential to ensure optimal performance, which also minimizes strain on the engine and other components.

Steps for Adjusting the Cutting Mechanism

Begin by checking the height settings on both sides of the cutting system. Adjust the height uniformly to ensure both sides are level. This may involve loosening the necessary bolts and fine-tuning the height with precision. Additionally, inspect the blade sharpness and condition, as dull or damaged blades can cause an uneven cut. Finally, check the overall alignment of the components to ensure smooth operation.

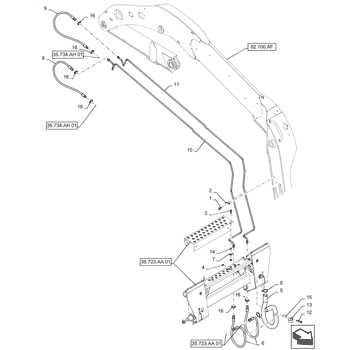

Lubricating the Mower Deck Bearings

Maintaining the rotating components of your cutting system is essential for smooth operation and longevity. Proper lubrication of the bearings ensures the blades spin efficiently and minimizes wear and tear, preventing unnecessary repairs and ensuring optimal performance. A well-lubricated system also reduces friction, heat buildup, and the risk of seizing, which can disrupt the cutting process.

Choosing the Right Lubricant

When selecting a lubricant, it’s important to use a high-quality grease designed for outdoor equipment. This helps protect the bearings from moisture, dirt, and debris while providing the necessary friction-reducing properties. A grease with water resistance will offer better protection against rust and corrosion, ensuring the longevity of the moving parts.

Application Process

Before applying the lubricant, clean the bearings thoroughly to remove any accumulated dirt or old grease. This can be done with a brush or compressed air. Once cleaned, apply the lubricant evenly to the bearing points, ensuring that it fills the entire bearing cavity. Rotate the components manually to distribute the grease evenly, and wipe off any excess to prevent dirt buildup.

Deck Height Adjustment and Its Importance

Proper adjustment of the cutting height plays a critical role in the performance and longevity of your equipment. Ensuring that the blades are set at the optimal position helps achieve a clean and uniform cut, while also preserving the health of your grass. It also impacts the overall efficiency of the machine and prevents unnecessary wear on the components.

Why Height Adjustment Matters

Maintaining the correct height can lead to several key benefits:

- Ensures an even cut across the lawn.

- Promotes healthier grass growth by preventing scalping.

- Improves the overall efficiency of the machine, reducing strain on the engine.

- Reduces the chances of clogging and debris buildup.

How to Adjust the Height Properly

Follow these steps to achieve the correct cutting height:

- Check the manufacturer’s guidelines for recommended height settings.

- Adjust the wheels or other mechanisms to raise or lower the cutting surface.

- Test the adjustment by mowing a small section and evaluating the result.

- Make fine adjustments as needed for consistency in cut quality.

Troubleshooting Mower Deck Noises

Unusual sounds from your grass cutting equipment can indicate underlying issues that need attention. Identifying the source of these noises is crucial for maintaining optimal performance and preventing further damage. Whether it’s a high-pitched whine, grinding sound, or a rattling noise, each type of sound can point to different problems with the mechanical components. Proper diagnosis allows for timely repairs, ensuring smoother operation and a longer lifespan for the equipment.

Common Sources of Unwanted Sounds

One of the most frequent causes of noise is worn or loose components. Belts that are out of alignment or damaged can create a squealing noise, while debris caught in the moving parts can cause grinding sounds. Another common culprit is improper tension on the cutting blades, which can produce a thumping or vibrating noise. Checking for these issues regularly can help avoid unnecessary wear and tear on your machine.

Steps to Diagnose the Problem

Start by examining the belts, pulleys, and other moving parts for signs of wear or damage. If the noise persists, inspect the cutting blades for sharpness and alignment. Ensure that all bolts and fasteners are securely tightened. Lubrication of moving parts can also reduce friction and eliminate squeaky or grinding noises. If the issue is unclear, consulting a professional may be the best option for in-depth diagnostics.

How to Choose Replacement Parts for X324

When selecting new components for your outdoor machine, it’s essential to consider several factors to ensure compatibility and performance. Choosing high-quality alternatives not only maintains the efficiency of your equipment but also extends its lifespan. Understanding the specific requirements and conditions of your machine will guide you in picking the most suitable options.

Assessing Compatibility

Before purchasing, verify the compatibility of the replacement items with your specific model. Check the manufacturer’s recommendations and consult manuals or online resources to confirm that the components align with your machine’s specifications. This helps avoid unnecessary replacements and ensures seamless integration.

Quality and Durability

While affordability is important, it is crucial to prioritize durability when selecting replacements. Look for components made of robust materials designed to withstand wear and tear. Strong, long-lasting parts will reduce the need for frequent replacements, saving time and money in the long run.