Maintaining a pristine outdoor space requires knowledge of the various elements that contribute to efficient gardening tools. This section delves into the intricate aspects of a specific cutting apparatus, highlighting its essential features and how they work together to enhance performance. Familiarity with these components ensures better upkeep and longevity of the machinery.

In the realm of turf maintenance, understanding the layout and function of each segment can significantly improve operational effectiveness. Each element plays a crucial role, influencing the overall functionality and ease of use. By exploring the arrangement and specific roles of these components, users can make informed decisions regarding repairs and upgrades.

For those engaged in regular landscaping tasks, grasping the essential functions of the various attachments can lead to more productive work sessions. Recognizing how each piece interacts within the system allows for a more efficient approach to tackling lawn care challenges. Knowledge in this area empowers users to address issues proactively and maintain their equipment in optimal condition.

Understanding L110 Mower Deck Design

The design of this cutting apparatus plays a crucial role in enhancing efficiency and ensuring a smooth operation. It integrates various components that work harmoniously to deliver optimal performance during grass trimming activities. Understanding its structure is essential for maintenance and achieving the best results.

Key Components

- Blade Assembly: Responsible for cutting through grass effectively.

- Spindle Housing: Supports the blade and allows it to rotate.

- Deck Shell: Encloses the working parts and provides durability.

- Anti-Scalp Wheels: Prevents the device from scalping uneven surfaces.

Importance of Design

A well-structured system not only improves cutting quality but also enhances maneuverability. The placement of components affects how the device interacts with the terrain, contributing to its overall effectiveness. Regular inspection and understanding of each element can lead to better maintenance and longevity.

Key Components of the L110 Deck

Understanding the essential elements of the cutting assembly is crucial for optimal performance and maintenance. Each component plays a significant role in achieving a precise cut and ensuring durability during operation.

| Component | Description |

|---|---|

| Blades | Sharp and robust, designed to provide a clean cut. |

| Spindles | Support the blades and allow for smooth rotation. |

| Belts | Transmit power from the engine to the blades. |

| Housing | Encloses the components, protecting them from debris. |

| Adjustment Levers | Enable height changes for varying grass lengths. |

Benefits of Proper Maintenance

Regular upkeep of equipment plays a crucial role in ensuring optimal performance and longevity. By adhering to a consistent maintenance schedule, users can enhance the efficiency and reliability of their tools, leading to a more productive experience.

Enhanced Performance

Maintaining machinery can significantly boost its overall functionality. Some key advantages include:

- Smoother operation with reduced vibrations.

- Improved fuel efficiency, leading to cost savings.

- Better cutting and trimming capabilities for superior results.

Prolonged Lifespan

Investing time in maintenance not only optimizes current performance but also extends the lifespan of the equipment. Benefits include:

- Fewer breakdowns and unexpected repairs.

- Lower replacement costs over time.

- Consistent performance, maintaining value throughout its use.

Identifying Common Issues

Understanding the typical problems that can arise with your cutting equipment is essential for maintaining its efficiency and longevity. Recognizing these issues early can save time and resources, ensuring smooth operation throughout the season. Below are some frequently encountered complications and their potential causes.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Uneven Cutting | Worn blades, improper height adjustment, uneven tire pressure | Sharpen or replace blades, adjust height, check and equalize tire pressure |

| Strange Noises | Loose components, damaged bearings, debris buildup | Tighten screws, inspect bearings, clean debris |

| Stalling | Fuel issues, clogged filters, battery problems | Check fuel quality, replace filters, test or replace battery |

| Difficulty Starting | Worn spark plug, low battery charge, fuel starvation | Replace spark plug, recharge or replace battery, check fuel line |

By familiarizing yourself with these common issues and their solutions, you can ensure that your equipment remains in optimal working condition, ready for any task ahead.

Essential Tools for Repairs

When it comes to performing maintenance and fixes on outdoor equipment, having the right instruments is crucial for ensuring efficiency and quality. This section will outline the fundamental tools that every enthusiast should consider having in their toolkit to tackle repairs effectively.

- Wrenches: A variety of sizes will allow for the loosening and tightening of nuts and bolts.

- Screwdrivers: Both flathead and Phillips head screwdrivers are essential for various fastening tasks.

- Pliers: Useful for gripping, twisting, and cutting wire or small components.

- Socket Set: A comprehensive socket set enables quicker work on nuts and bolts, especially in tight spaces.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

In addition to these basics, certain specialized tools can enhance your repair experience:

- Oil Filter Wrench: A must-have for easy removal of oil filters during maintenance.

- Blade Sharpener: Keeping blades sharp enhances performance and efficiency.

- Multimeter: Essential for diagnosing electrical issues and ensuring proper functionality.

Equipping yourself with these tools will not only simplify repairs but also contribute to the longevity of your equipment.

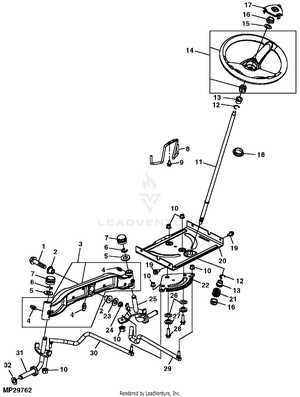

Step-by-Step Assembly Guide

This guide provides a clear and concise approach to assembling your equipment efficiently. By following these instructions, you can ensure that every component is correctly fitted, enhancing both functionality and safety.

Gather Your Tools

Before starting the assembly process, make sure to collect all necessary tools. Having everything on hand will streamline the process and reduce frustration. Common tools needed include:

- Wrenches

- Screwdrivers

- Pliers

- Safety gloves

Assembly Steps

Follow these steps for a successful assembly:

- Prepare the Workspace: Ensure that your area is clean and well-lit. This will help you locate parts easily and prevent any accidents.

- Identify Components: Refer to the provided guide to familiarize yourself with each piece. This will aid in proper placement during assembly.

- Start with the Base: Secure the main unit first, ensuring it is level and stable.

- Attach Additional Elements: Gradually add each component, following the order specified in the instructions.

- Check Connections: After assembly, go over all connections to ensure they are tight and secure.

By adhering to these steps, you can successfully assemble your equipment and ensure it operates smoothly for all your outdoor tasks.

How to Replace the Blades

Maintaining a sharp cutting edge is essential for achieving a clean and efficient cut. Regularly changing the blades not only enhances performance but also prolongs the lifespan of your equipment. This guide provides a step-by-step approach to ensure a smooth replacement process.

Tools Needed

Before starting, gather the necessary tools to make the replacement efficient:

| Tool | Purpose |

|---|---|

| Wrench | To loosen and tighten the blade bolts |

| Safety Gloves | To protect your hands during the process |

| Work Light | To ensure visibility under the unit |

Steps for Replacement

Follow these steps for a successful blade swap:

- Ensure the machine is turned off and on a flat surface.

- Disconnect the spark plug to prevent accidental starts.

- Lift the unit if necessary to access the blades easily.

- Use a wrench to remove the bolts holding the blades in place.

- Carefully detach the old blades and replace them with new ones.

- Reattach the bolts securely, ensuring they are tightened properly.

- Reconnect the spark plug and test the equipment.

Regular blade replacement will maintain optimal cutting performance and efficiency. Always refer to the manufacturer’s guidelines for specific instructions related to your model.

Parts List for Easy Reference

This section provides a comprehensive overview of essential components that enhance the functionality of your equipment. By having a clear list at your fingertips, you can streamline maintenance and ensure that your machine operates smoothly. Knowing each element helps in identifying replacements and understanding the overall assembly.

Key Components

Among the vital items to consider are the following:

- Blades: Crucial for effective cutting performance.

- Belts: Essential for driving mechanisms, ensuring smooth operation.

- Spindles: Provide rotation for the cutting elements, critical for efficiency.

- Washers and Nuts: Important for securing various assemblies and preventing loosening.

Maintenance Tips

Regular inspection of these components is advisable. Replacing worn-out items promptly can significantly enhance performance and longevity. Keeping a checklist of these elements ensures that you are always prepared for any maintenance needs that may arise.

Exploring Aftermarket Options

In the realm of outdoor maintenance equipment, exploring alternative components can lead to enhanced performance and cost-effectiveness. Many enthusiasts and professionals alike find value in assessing these aftermarket offerings, which often provide unique features or superior durability compared to original items.

Benefits of Aftermarket Components

One of the primary advantages of aftermarket solutions is their affordability. Typically, these products are priced lower than their original counterparts, allowing users to save money without sacrificing quality. Additionally, aftermarket items may offer specialized enhancements tailored to specific needs, empowering users to optimize their machinery’s functionality.

Considerations Before Purchase

While aftermarket options can be enticing, it’s essential to conduct thorough research before making a purchase. Checking compatibility and reading reviews can help ensure that the selected components will deliver the desired results. Quality assurance and warranty considerations should also be taken into account to avoid future inconveniences.

Tips for Seasonal Storage

Proper preparation for seasonal storage is essential to ensure longevity and optimal performance of your equipment. By following a few simple guidelines, you can protect your machinery from the adverse effects of temperature changes and moisture buildup.

Before storing, thoroughly clean all components to remove dirt, grass clippings, and debris. This helps prevent rust and corrosion. Additionally, it’s crucial to check and change fluids, as old oil can lead to engine damage over time.

Another important step is to inspect and maintain all moving parts. Lubricating these areas can help reduce wear and tear, ensuring they remain in good condition when the season resumes.

| Storage Tip | Description |

|---|---|

| Clean Thoroughly | Remove all dirt and debris to prevent rust. |

| Change Fluids | Replace old oil and check other fluids to maintain engine health. |

| Inspect Parts | Check for wear and lubricate moving components. |

| Use a Cover | Protect your equipment with a weather-resistant cover. |

| Store in a Dry Place | Avoid moisture to reduce the risk of corrosion. |

By following these essential tips, you can ensure that your equipment remains in excellent condition throughout its downtime and is ready for action when the season begins again.

Importance of Regular Inspections

Benefits of Regular Check-ups

- Prevents costly repairs

- Enhances efficiency

- Ensures safety during operation

- Extends the lifespan of the machinery

Key Areas to Inspect

- Blades and cutting mechanisms

- Belts and pulleys

- Oil levels and filters

- Battery and electrical components

Establishing a routine inspection schedule not only safeguards your equipment but also contributes to a more productive and satisfying experience in outdoor tasks.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair components for a specific lawn care machine. Here, users can find essential information that helps enhance understanding and efficiency in operation.

Common Queries

- What are the key components of the system?

- How can I identify worn or damaged pieces?

- Where can I purchase replacement items?

Maintenance Tips

- Regularly inspect the machinery for any signs of wear.

- Keep all components clean and well-lubricated.

- Follow the manufacturer’s guidelines for installation and replacement.

Finding OEM Parts Online

In today’s digital age, sourcing original equipment manufacturer components has become easier than ever. With just a few clicks, you can access a wide range of resources to ensure you acquire the precise items needed for your equipment. Understanding where to look and how to navigate these platforms can make all the difference in maintaining your machinery effectively.

Reputable Online Retailers

When searching for authentic components, it’s crucial to rely on established online vendors. Many websites specialize in selling original components, providing customers with detailed descriptions and specifications. Always verify that the retailer is authorized to distribute the specific brand to ensure quality and compatibility.

Utilizing Manufacturer Websites

Another excellent option is to visit the official websites of manufacturers. These sites often feature dedicated sections for replacement components, including detailed catalogs and diagrams. You can find accurate information about each item, ensuring you choose the right ones for your needs.

| Source | Benefits | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive pricing | Check for authenticity, shipping times |

| Manufacturer Websites | Direct access to genuine items, detailed info | Limited to specific brands, potentially higher prices |

| Forums and Community Groups | Expert advice, shared experiences | Verification of sources needed |