Having a clear understanding of the component layout for your lawn care machinery is essential for maintenance and repairs. This knowledge allows users to identify parts easily, ensuring that any necessary replacements or upgrades are made efficiently. When it comes to maintaining the longevity and performance of your equipment, familiarity with its internal structure is invaluable.

Within this section, we will explore the intricate arrangement of various elements that make up this specific model of grass management equipment. By delving into the functional roles of each part, operators can better appreciate how their machinery works and recognize potential issues before they escalate. Moreover, this understanding facilitates smoother troubleshooting processes and empowers users to make informed decisions regarding service and care.

Whether you are a seasoned operator or a newcomer to lawn maintenance, having access to detailed information about the configuration of your machinery enhances your ability to keep it in peak condition. This resource serves as a guide, providing insights that will contribute to a more effective and enjoyable mowing experience.

D105 John Deere Parts Diagram

This section provides an overview of the components and their arrangement for a specific model of riding mower. Understanding the configuration of these elements is crucial for maintenance, repairs, and ensuring optimal performance. Each element plays a vital role in the functionality and efficiency of the machine, making it essential to familiarize oneself with their respective locations and functions.

Typically, these visual representations illustrate various assemblies and individual components, allowing users to identify and locate each part accurately. From the engine to the chassis, every section contributes to the overall operation. Regularly referencing these visual guides can facilitate easier troubleshooting and promote effective servicing practices.

In addition, having access to a detailed reference can aid in sourcing replacements when needed. Whether you are a professional technician or a hobbyist, a thorough understanding of the arrangement of these components will enhance your ability to maintain and repair the equipment efficiently.

Understanding D105 Model Specifications

The specifications of this lawn care equipment are crucial for optimal performance and functionality. Knowing the essential features helps users make informed decisions regarding maintenance, upgrades, and compatibility with other machinery. Understanding the specific attributes can enhance the overall user experience and extend the lifespan of the unit.

Engine Characteristics: The engine is a vital component, providing the necessary power for effective operation. Its size, type, and efficiency play significant roles in determining how well the machine handles various tasks, such as mowing and landscaping. Fuel efficiency and emissions standards are also important considerations for environmentally conscious users.

Cutting Mechanism: The cutting system is designed to provide a clean and precise finish. Users should be aware of the blade configuration, cutting width, and height adjustments available. This information aids in selecting the appropriate settings for different lawn conditions and desired outcomes.

Drive System: The drive mechanism determines how the machine moves across different terrains. Understanding whether the system is manual or automatic, along with its transmission type, is essential for effective maneuverability and ease of use.

Dimensions and Weight: The overall size and weight of the equipment influence its transportability and storage. Knowing these specifications helps users plan for adequate space and ensures that the machine can be easily handled and stored when not in use.

By familiarizing themselves with these critical specifications, users can ensure that their lawn care equipment meets their specific needs, ultimately leading to more efficient and enjoyable operation.

Common Issues and Solutions

When operating a lawn maintenance machine, users may encounter various challenges that can affect performance and efficiency. Understanding these common complications and their respective remedies is essential for maintaining optimal functionality and extending the lifespan of the equipment.

1. Engine Starting Problems: One frequent issue is difficulty in starting the engine. This can be attributed to a weak battery, clogged fuel lines, or a faulty ignition system. To resolve this, check the battery’s charge, inspect fuel lines for blockages, and ensure all electrical connections are secure.

2. Uneven Cutting: Another common concern is uneven grass cutting, which may result from dull blades or improper deck height settings. Regularly sharpen the blades and adjust the cutting deck to the recommended height for even results.

3. Overheating: Overheating can occur due to debris accumulation around the engine or insufficient coolant. To prevent this, regularly clean the engine area and ensure that coolant levels are adequate to maintain proper operating temperatures.

4. Transmission Issues: Users may also experience problems with the transmission, such as slipping or failure to engage. This can often be resolved by checking the fluid levels and looking for any leaks in the system. If problems persist, professional service may be required.

5. Battery Drain: A rapidly draining battery can hinder functionality. Ensure that all electrical components are turned off when not in use and consider replacing the battery if it no longer holds a charge effectively.

By addressing these common issues promptly and following recommended maintenance practices, users can ensure their equipment remains in top condition and operates smoothly.

Key Components of the D105

This section explores the essential elements that contribute to the functionality and performance of a popular lawn care machine. Understanding these components can enhance maintenance and repair efforts, ensuring optimal operation.

Engine System

The power unit is crucial for driving the equipment. It typically includes several important elements:

- Fuel Tank: Stores the necessary fuel for operation.

- Air Filter: Cleans incoming air to ensure efficient combustion.

- Starter Mechanism: Engages the engine for ignition.

Cutting Mechanism

The cutting system is vital for achieving a well-manicured lawn. Key features include:

- Blades: Sharp components that perform the actual cutting of grass.

- Deck: The housing that holds the blades and guides the cutting process.

- Height Adjustment: Allows customization of cutting height for different grass types.

Understanding these fundamental aspects enables users to operate their machine effectively and maintain its longevity.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the efficient functioning of your equipment. By following a structured maintenance routine, you can significantly enhance the longevity and reliability of your machine. This section outlines key strategies that will help maintain peak performance, reduce unexpected breakdowns, and improve overall efficiency.

Routine Inspections

Conducting frequent examinations is crucial for identifying potential issues before they escalate. Inspect critical components such as belts, filters, and fluids. Look for any signs of wear or damage, and address them promptly to avoid more extensive repairs.

Proper Cleaning

Keeping your machinery clean not only improves its appearance but also aids in optimal operation. Remove dirt, debris, and residue that can hinder performance. Pay special attention to cooling systems, as blockages can lead to overheating and reduced efficiency.

Remember that consistent maintenance practices are the key to achieving a reliable and high-performing unit. By dedicating time to these essential tasks, you will ensure that your equipment remains in excellent condition.

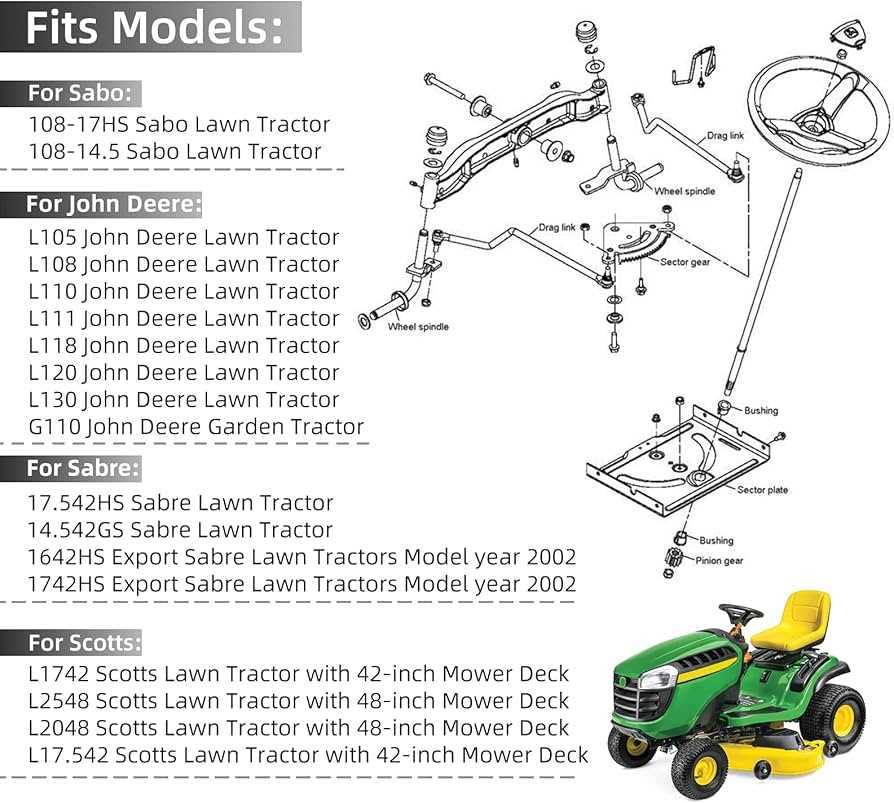

Identifying Replacement Parts Easily

Finding suitable components for your machinery can seem daunting, but with the right approach, the process becomes much simpler. Understanding how to recognize the necessary elements can save time and ensure that repairs are done efficiently. This section will guide you through effective strategies to identify and obtain the correct items for your equipment.

Utilizing Reference Materials

One of the most effective methods to determine which components are needed is to consult reference materials. These resources provide essential information that can greatly assist in identifying the correct replacements.

- Owner’s Manual: This document often includes essential details about specific items and their specifications.

- Catalogs: Manufacturer catalogs typically list available replacements along with part numbers and descriptions.

- Online Resources: Websites and forums dedicated to machinery enthusiasts can offer valuable insights and diagrams.

Visual Inspection Techniques

Another important method is conducting a thorough visual inspection. This can help in recognizing worn or damaged components that require replacement.

- Examine the item closely for any visible signs of wear, such as cracks or breaks.

- Take note of any markings or labels that might indicate the model or series number.

- Compare the existing element with online images or diagrams to ensure accurate identification.

By following these strategies, you can effectively locate the necessary items to keep your machinery in optimal working condition.

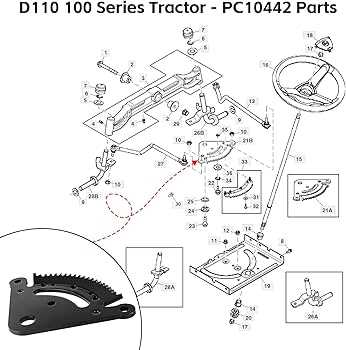

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair of machinery. These visuals serve as guides that help identify individual elements and their relationships within the overall assembly. Knowing how to interpret these representations can streamline troubleshooting and facilitate accurate ordering of necessary components.

Here are key steps to effectively interpret component illustrations:

| Step | Description |

|---|---|

| 1 | Examine the layout to get an overview of the assembly structure. Familiarize yourself with the general arrangement of elements. |

| 2 | Look for labels or numbers associated with each element. These references are crucial for locating specific items in catalogs. |

| 3 | Identify groups of components that function together. This understanding aids in recognizing how parts interact during operation. |

| 4 | Pay attention to any accompanying notes or symbols. These often provide additional insights into installation or maintenance procedures. |

| 5 | Use the gathered information to verify compatibility when sourcing replacements or upgrades. Ensuring correct matches is vital for optimal performance. |

Differences Between D105 and Similar Models

This section examines the distinctions between a specific lawn mower model and its counterparts in the same category. While many machines may appear similar at first glance, various features and specifications set them apart, influencing performance, usability, and overall user experience.

Performance Features

The performance capabilities of different lawn care machines can vary significantly. Factors such as engine power, cutting width, and transmission type play crucial roles in determining how effectively a mower operates in diverse conditions. Understanding these differences helps users select the right equipment for their needs.

Design and Ergonomics

Ergonomic design features also distinguish various models. Elements like seat comfort, control placement, and overall maneuverability impact how easily a user can operate the equipment for extended periods. Evaluating these aspects is essential for ensuring a comfortable mowing experience.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 18 HP | 20 HP | 17 HP |

| Cutting Width | 42 inches | 42 inches | 48 inches |

| Transmission Type | Automatic | Hydrostatic | Automatic |

| Seat Comfort | Standard | High-back | Standard |

Sources for Authentic Replacement Parts

When it comes to maintaining machinery, sourcing genuine components is crucial for optimal performance and longevity. Authentic replacements ensure compatibility and reliability, reducing the risk of malfunction. Various avenues exist for acquiring these essential items, each with its unique benefits.

Authorized Dealers

One of the most reliable sources for acquiring genuine components is through authorized dealerships. These outlets often have direct access to original equipment manufacturers, guaranteeing that the items sold meet the highest standards of quality. Additionally, staff at these locations can provide expert advice and assistance, ensuring that customers select the correct components for their specific needs.

Reputable Online Retailers

In today’s digital age, numerous online platforms specialize in authentic replacements. It is important to choose reputable websites that focus on high-quality items, as this can prevent the purchase of counterfeit or subpar products. Reading customer reviews and checking return policies can help ensure a satisfactory shopping experience. Comparing prices across various retailers can also lead to better deals without compromising on quality.

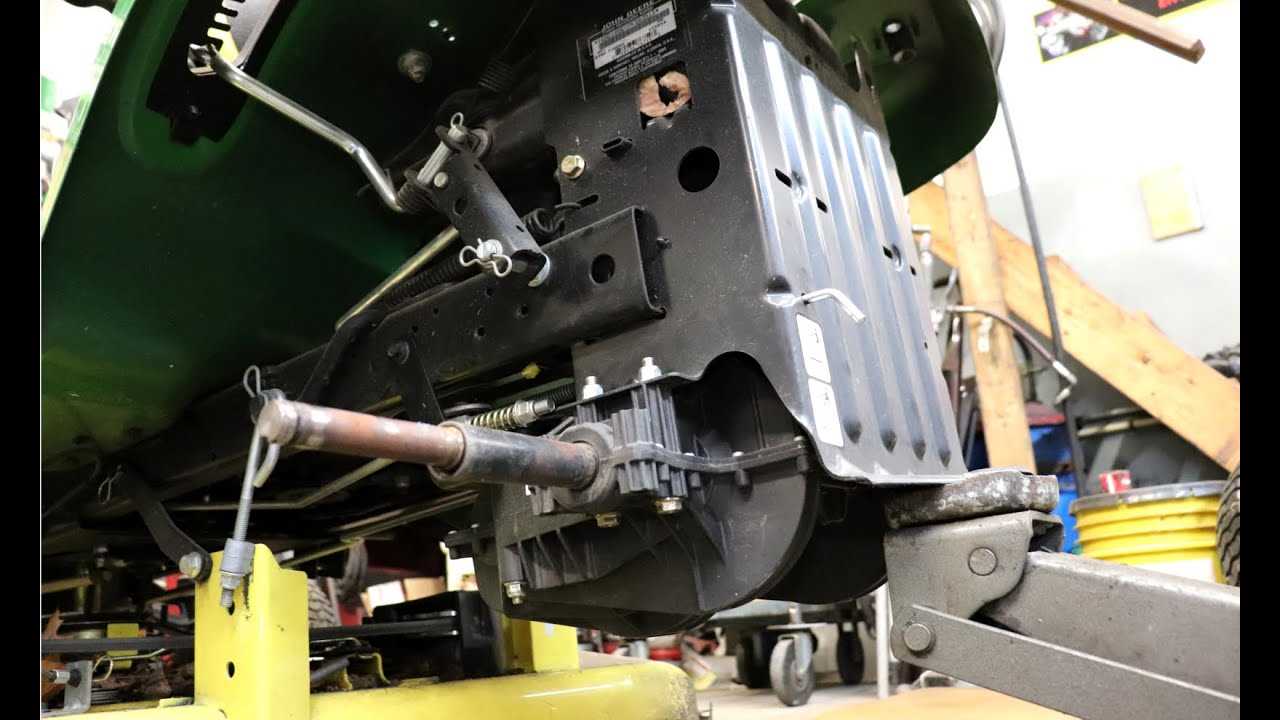

Installation Process for New Components

Installing new elements in your machinery requires careful planning and attention to detail to ensure optimal functionality. This section outlines the key steps to successfully incorporate new components into your equipment, promoting efficiency and longevity.

Preparation and Tools

Before beginning the installation, gather all necessary tools and ensure you have the right replacements on hand. Common tools include wrenches, screwdrivers, and pliers. Having a clean workspace can greatly improve efficiency and prevent damage to new items.

Step-by-Step Installation

Follow these essential steps for a seamless installation process:

| Step | Description |

|---|---|

| 1 | Turn off the equipment and disconnect it from any power sources to ensure safety during installation. |

| 2 | Remove the old components carefully, noting how they are attached to assist with the installation of the new elements. |

| 3 | Align the new components according to the manufacturer’s guidelines, ensuring all connections are secure. |

| 4 | Test the functionality of the new elements by reconnecting the power and running the equipment at low capacity first. |

| 5 | Monitor the installation for any unusual noises or issues, making adjustments as necessary. |

Cost Considerations for Parts Replacement

When it comes to maintaining machinery, understanding the financial aspects of component replacement is crucial. Evaluating the costs associated with acquiring and installing new elements can significantly impact the overall budget and operational efficiency. This section explores the various factors that influence expenses and offers guidance on making informed decisions.

Initial Investment vs. Long-Term Savings

While the upfront cost of new components may seem high, it is essential to consider the long-term savings they can provide. Investing in high-quality replacements often leads to increased reliability and efficiency, reducing the likelihood of future breakdowns. Additionally, improved performance can enhance productivity, making the initial investment worthwhile.

Labor and Installation Costs

Another critical factor to consider is the expense of labor and installation. Hiring skilled professionals for installation may increase initial costs, but their expertise can ensure proper fitting and functionality. This investment in skilled labor can prevent future issues and minimize downtime, ultimately contributing to a more cost-effective maintenance strategy.

Benefits of Regular Maintenance Checks

Conducting routine inspections and upkeep on machinery is essential for optimal performance and longevity. Regular evaluations help identify potential issues before they escalate, ensuring that equipment operates smoothly and efficiently. This proactive approach minimizes downtime and enhances overall productivity, providing peace of mind for operators and owners alike.

Increased Equipment Longevity

One of the primary advantages of frequent maintenance is the extension of equipment lifespan. By addressing minor wear and tear early, operators can prevent more significant damage that could lead to costly repairs or replacements. Timely adjustments and replacements safeguard vital components, allowing machinery to function effectively over the years.

Enhanced Performance and Efficiency

Regular maintenance not only protects machinery but also enhances its performance. Properly maintained equipment runs more efficiently, which can lead to reduced fuel consumption and improved operational speed. This efficiency translates to lower operational costs and better output, contributing to the overall success of the tasks at hand.

Frequently Asked Questions about D105

This section aims to address common inquiries related to a popular model known for its efficiency and reliability in lawn care. Users often seek clarification on various aspects to enhance their experience and maintenance practices.

One of the most common questions revolves around the appropriate maintenance schedule. Regular upkeep is crucial for ensuring optimal performance and longevity. Owners are encouraged to refer to the user manual for specific intervals for tasks such as oil changes and filter replacements.

Another frequent inquiry pertains to troubleshooting issues. Many individuals wonder how to diagnose common problems such as starting difficulties or uneven cutting. Understanding the basic components and their functions can assist users in identifying and resolving minor issues before they escalate.

Additionally, users often seek recommendations on accessories and enhancements. Knowing which attachments can improve functionality or efficiency is essential for maximizing the potential of the machine. It’s advisable to consult with experts or authorized retailers for guidance on compatible add-ons.

Lastly, inquiries about warranty coverage and service options are prevalent. Owners want to ensure they are aware of their rights and the support available in case of defects or malfunctions. Familiarizing oneself with warranty terms can provide peace of mind and assurance when investing in this equipment.