When it comes to maintaining or repairing agricultural equipment, it’s crucial to have a clear understanding of how various mechanical systems are interconnected. Whether you’re dealing with a machine’s engine, transmission, or hydraulic systems, identifying key elements and their placements is an essential first step. This guide aims to provide a detailed overview of the essential elements, ensuring that all the major components are easily understood and accessible for service or replacement.

Exploring component arrangements often helps users streamline their maintenance process. By visualizing the layout, operators can quickly pinpoint specific areas that may require attention, such as the fuel delivery system, cooling mechanisms, or electrical wiring. In this section, we will walk through the crucial areas of focus, helping to demystify the internal structure of your machinery.

Having a well-organized system overview is not only helpful for repairs but also increases the longevity of the equipment through better preventive care. Knowing where everything

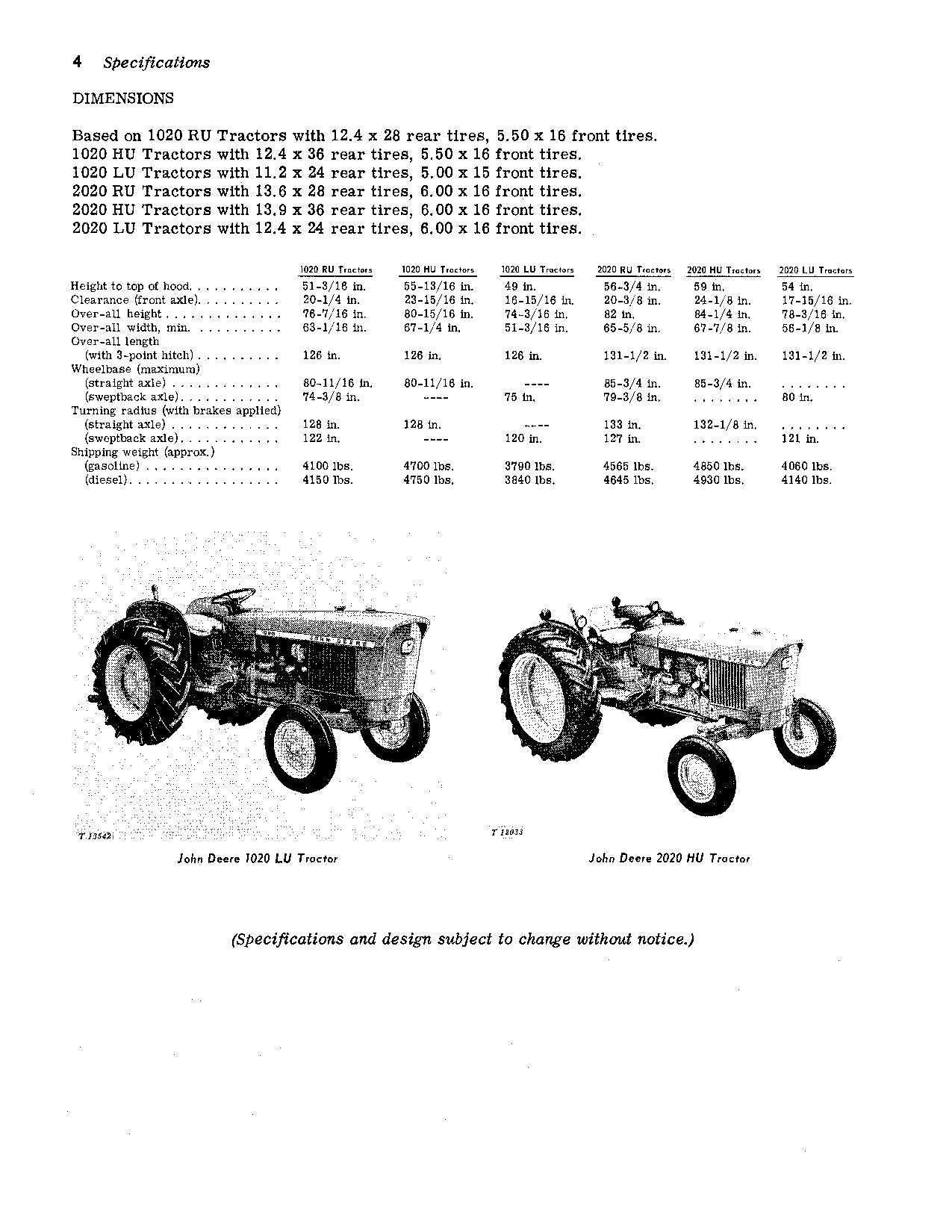

Understanding the Components of the John Deere 1020

Familiarizing yourself with the various elements that make up this agricultural machine is crucial for effective maintenance and repairs. By understanding the main systems and their individual functions, you can ensure that every part works together smoothly to maximize performance and longevity.

Engine and Power Systems

The heart of the machine is its engine, which drives all key operations. It is essential to keep this system in optimal condition, as it generates the power necessary for the machine’s functions. Regular upkeep of fuel delivery, cooling, and lubrication systems plays a vital role in its efficiency.

Transmission and Hydraulics

The transmission is responsible for transferring power to the wheels, allowing the operator to control speed and direction. Meanwhile, the hydraulic system controls essential operations, such as lifting and tilting attachments. Both systems require proper care to ensure smooth performance during various tasks.

Key Elements of the Engine Assembly

The engine assembly consists of various interconnected components that work together to deliver power and efficiency. Understanding the critical sections of this system helps ensure optimal performance and maintenance. Below, we outline the major areas involved in this essential machinery, offering insights into their roles and interactions.

- Cylinder Block: The foundation of the engine, this element houses the cylinders and provides structural support for the other components.

- Pistons: Located within the cylinders, they move up and down to convert pressure into mechanical energy.

- Crankshaft: This component translates the linear motion of the pistons into rotational energy, driving the rest of the system.

- Camshaft: It controls the opening and closing of the intake and exhaust valves, ensuring proper timing in the engine cycle.

- Valves: These control the flow of fuel and air into the combustion chamber, as well as the release of exhaust gases.

- Fuel Injector: Delivers the appropriate amount of fuel into the combustion chamber to create the necessary air-fuel mixture.

- Cooling System: Essential for maintaining the engine’s temperature,

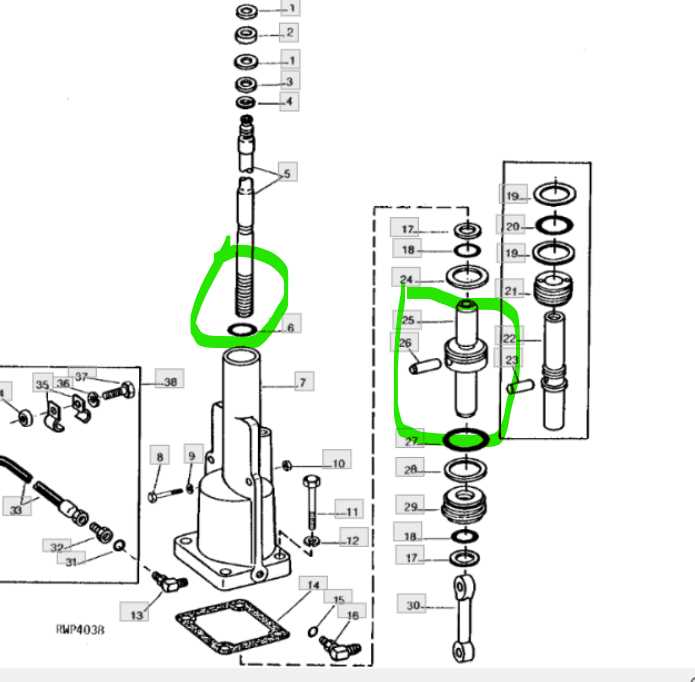

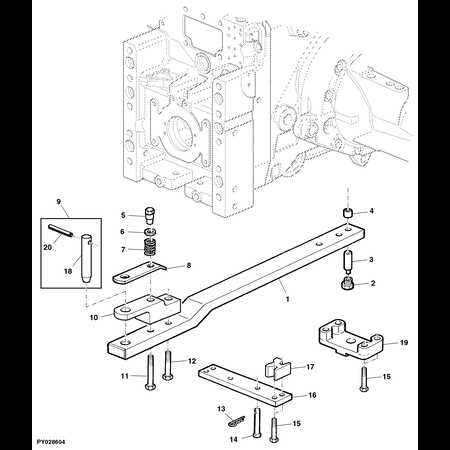

Identifying Transmission Parts in the John Deere 1020

The heart of any machinery lies in its ability to transfer power efficiently, and the transmission system plays a key role in this process. This section focuses on recognizing and understanding the essential components involved in the power delivery mechanism. Each element is crucial for ensuring smooth operation, and learning to identify these elements can help in maintaining and troubleshooting the machine effectively.

Gears are one of the primary components, responsible for controlling speed and torque. These mechanical devices interlock to transmit motion, allowing for various speed ranges depending on the operator’s requirements.

Clutch systems enable seamless engagement and disengagement of the engine’s power, preventing excessive wear and tear on other critical components. A properly functioning clutch ensures smooth transitions between speeds and prevents overheating.

Another significant component is the driveshaft, which connects the power source to the wheels, allowing the machinery to move. Any issues with this shaft could result in reduced

How to Maintain Proper Functioning

Ensuring the long-term reliability of your equipment involves consistent and careful upkeep. By following recommended maintenance routines and using appropriate methods, you can prevent breakdowns and extend the lifespan of your machinery.

Regular Inspections

- Check all moving components frequently to identify signs of wear or damage.

- Ensure that bolts, nuts, and fasteners are securely tightened to prevent loose parts.

- Monitor fluid levels such as oil and hydraulic fluid, topping off as needed.

Lubrication and Cleaning

Proper lubrication is essential for smooth operation. Ensure all joints and bearings are well-lubricated to minimize friction. Additionally, keeping your machinery clean helps avoid dirt buildup, which can lead to mechanical issues.

- Lubricate key areas as specified in the manufacturer’s guidelines.

- Clean all surfaces regularly, paying attention to filters and

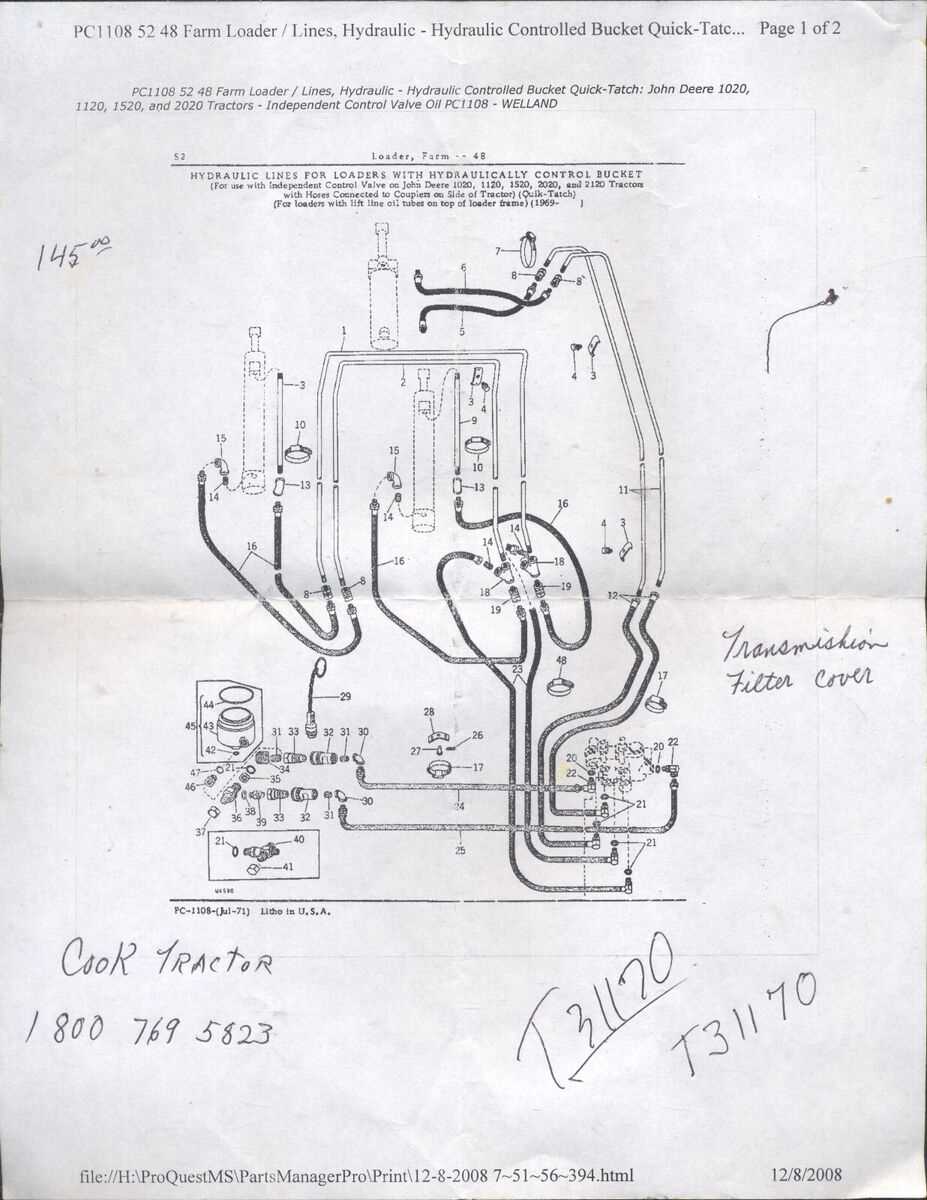

Exploring the Hydraulic System of the John Deere 1020

The hydraulic mechanism in this tractor model plays a vital role in ensuring smooth operation and functionality. This system enables various components to work in harmony, providing the necessary force for multiple tasks. Understanding how the hydraulic flow is controlled and distributed is essential for maintaining optimal performance. The system’s efficiency is crucial for tasks ranging from lifting to steering, contributing to the overall utility of the machine.

Key elements within this setup include pumps, valves, and cylinders, each designed to handle specific functions. The pump generates the pressure needed to drive hydraulic operations, while the valves control the flow direction and regulate pressure levels. The cylinders convert this fluid power into mechanical motion, powering essential tasks such as lifting and tilting.

Regular inspection and maintenance of the hydraulic components are essential to avoid system failures. Checking for leaks, ensuring proper fluid levels, and replacing worn-out parts can prevent downtime and extend the system’s lifespan. Familiarizing oneself with the specific layout and components helps troubleshoot potential issues efficiently.

Parts Crucial for Effective Operation

Understanding the essential components that contribute to the seamless functioning of agricultural machinery is vital for optimal performance. Each element plays a specific role in ensuring the equipment operates efficiently and effectively, ultimately impacting productivity and longevity. A thorough knowledge of these critical components allows operators to maintain their equipment better and address any issues that may arise during use.

Key Components to Consider

Among the various elements, the engine assembly stands out as the powerhouse of the machinery. This assembly is responsible for generating the necessary energy for operation, making its condition paramount for effective functionality. Additionally, the transmission system, which transfers power from the engine to the wheels, is essential for smooth movement and maneuverability.

Maintenance and Replacement

Regular maintenance of these key components is crucial to avoid unexpected breakdowns and ensure continuous operation. Identifying wear and tear early on can help in scheduling timely replacements, thus preventing further complications and extending the lifespan of the machinery. Operators should familiarize themselves with the maintenance procedures associated with each component to maximize efficiency.

Steering System Breakdown for the John Deere 1020

The steering mechanism is a vital component that ensures the accurate navigation and control of agricultural machinery. Understanding its structure and functionality can enhance maintenance and repair efforts, leading to improved operational efficiency.

This section delves into the key elements that make up the steering system, highlighting their roles and interconnections.

- Steering Wheel: The primary interface for the operator, allowing for directional changes.

- Steering Column: Connects the wheel to the rest of the mechanism, transmitting movement.

- Gearbox: Converts the rotational motion from the steering wheel into linear motion for the wheels.

- Linkage: A series of rods and joints that connect the gearbox to the wheels, facilitating their movement.

- Wheels: The final element that responds to the steering commands, enabling the vehicle to maneuver.

Regular inspection of these components is crucial for ensuring a responsive and reliable steering experience. Addressing any wear or damage promptly can prevent larger issues down the line.

Detailed Look at Key Components

This section provides an in-depth examination of essential elements that contribute to the functionality and performance of agricultural machinery. Understanding these components allows operators and technicians to maintain and troubleshoot effectively, ensuring optimal operation and longevity.

Component Description Functionality Engine The primary power source that drives the machinery. Generates power for operation and performs various tasks. Transmission System responsible for transferring power from the engine to the wheels. Allows for speed changes and torque adjustments for different tasks. Hydraulic System A network of components that uses fluid power to perform work. Enables lifting and movement of implements and attachments. Chassis The framework that supports all other components. Provides stability and structure for the entire machine. Electrical System Includes wiring, batteries, and sensors for operation. Powers controls and monitoring systems for efficient usage. Essential Brake Components for the John Deere 1020

The braking system is crucial for the safe operation of any machinery, providing the necessary control and stability during use. Understanding the key elements of this system is essential for effective maintenance and troubleshooting. This section outlines the fundamental components that contribute to the braking functionality in a specific tractor model.

Key Components Overview

Several critical components work together to ensure efficient braking performance. These parts must be well-maintained and regularly inspected to prevent potential issues and enhance longevity.

Component Description Brake Pads These friction elements press against the rotor to create the necessary stopping power. Brake Rotor The surface that the brake pads clamp onto, converting kinetic energy into thermal energy. Caliper A device that houses the brake pads and applies pressure to them against the rotor. Brake Lines Hoses that transmit hydraulic fluid from the master cylinder to the calipers. Master Cylinder The main component that generates hydraulic pressure to activate the braking system. Maintenance Tips

Regular maintenance of these components is vital to ensure optimal performance. Periodic inspections for wear and tear, along with timely replacements of any damaged parts, can significantly enhance the reliability and safety of the braking system.

Understanding Function and Maintenance

This section focuses on the essential roles and upkeep of various components in agricultural machinery. Understanding how each element operates is crucial for ensuring optimal performance and longevity. Proper maintenance not only enhances efficiency but also prevents potential breakdowns, allowing for smoother operations during critical tasks.

Component Roles

Every piece of equipment serves a specific purpose, contributing to the overall functionality of the machine. From the drive mechanisms to the hydraulic systems, each part plays a vital role in facilitating tasks such as plowing, planting, and harvesting. Familiarizing oneself with these roles helps users identify issues and optimize performance.

Maintenance Practices

Regular inspection and maintenance are fundamental to prolonging the lifespan of equipment. This includes checking fluid levels, replacing worn-out parts, and ensuring that all systems are functioning correctly. Implementing a routine maintenance schedule can significantly reduce the risk of unexpected failures, ensuring that machinery remains reliable and efficient in the field.

Electrical Wiring and Diagram Overview

This section provides a comprehensive insight into the electrical layout and connectivity within a specific machine model. Understanding the intricacies of the wiring system is crucial for effective maintenance and troubleshooting. A well-organized schematic representation serves as a valuable tool for anyone working on the equipment, ensuring proper connections and functionality.

Key Components of the Electrical System

- Power Source: The main battery that supplies energy to the entire system.

- Wiring Harness: A network of wires that facilitates communication between various electrical components.

- Control Units: Devices that regulate the operation of different functionalities within the machinery.

- Connectors: Junctions that allow for easy assembly and disassembly of wiring for maintenance.

Importance of Proper Wiring

Ensuring accurate wiring is essential for optimal performance. Faulty connections can lead to a range of issues, from minor malfunctions to complete operational failures. Regular inspections and adherence to the outlined schematic can prevent such problems, contributing to the longevity and reliability of the equipment.

- Inspect connections for signs of wear or corrosion.

- Follow the schematic closely during any repairs or modifications.

- Use high-quality components to maintain the integrity of the electrical system.

Crucial Parts and Their Functions

The intricate machinery of agricultural equipment relies on a variety of essential components, each serving a unique role to ensure optimal performance. Understanding these key elements is vital for effective maintenance and operation, allowing users to maximize productivity in their farming activities.

Engine and Transmission

The heart of any machinery is its engine, which converts fuel into mechanical energy, providing the necessary power for various tasks. Coupled with the transmission, which transfers this power to the wheels or other attachments, these elements work in harmony to facilitate smooth movement and functionality.

Hydraulic System

This system plays a significant role in enhancing the versatility of the equipment. By utilizing fluid under pressure, it enables the operation of various attachments and implements, allowing for tasks such as lifting, digging, and plowing. The effectiveness of this system greatly influences the overall efficiency of agricultural operations.

Fuel System Components in the John Deere 1020

The fuel mechanism in agricultural machinery plays a crucial role in ensuring efficient operation and optimal performance. Understanding the various elements that comprise this system is essential for effective maintenance and troubleshooting. This section delves into the key components that facilitate the proper functioning of the fuel system.

Key Elements of the Fuel Mechanism

This system is composed of several integral components, each serving a distinct function. The fuel tank stores the essential liquid, while the fuel pump ensures a consistent flow to the engine. Additionally, filters are vital for removing impurities, safeguarding engine integrity. Properly functioning injectors distribute the fuel evenly, promoting efficient combustion and power generation.

Maintenance Considerations