When working with machinery, having a clear understanding of the layout and functions of various elements is crucial for efficient operation and maintenance. This section aims to provide insights into the configuration and functionality of specific components, enabling users to better navigate the complexities of their machines. A comprehensive overview can enhance both troubleshooting efforts and routine upkeep.

By examining the intricate relationships between different pieces, operators can develop a more informed approach to repairs and enhancements. This knowledge not only streamlines the maintenance process but also empowers users to make educated decisions regarding replacements and upgrades. As you delve into the specifics, you will gain a deeper appreciation for how each element contributes to the overall functionality of the equipment.

Whether you are a seasoned technician or a novice user, familiarizing yourself with these schematics will undoubtedly aid in your understanding. With this foundational knowledge, you can approach any repair or upgrade with confidence, ensuring that your machinery remains in optimal condition for years to come.

Overview of John Deere 111H

This section provides a comprehensive look at a well-known model designed for various tasks, emphasizing its functionality and versatility. This equipment is popular among users for its reliability and efficiency, making it a go-to choice for landscaping and maintenance work. With a focus on its design and operational capabilities, this overview aims to highlight the key features that set it apart in its category.

Key Features

One of the standout aspects of this machine is its robust construction, which ensures durability and longevity. Users appreciate the ease of maneuverability, allowing for efficient operation in tight spaces. Additionally, the model is equipped with various attachments, enhancing its adaptability for different tasks. These features contribute to a seamless experience, making it suitable for both professional landscapers and homeowners alike.

Operational Insights

Understanding the operational mechanics of this equipment can greatly enhance its usability. Proper maintenance is crucial for optimal performance, ensuring that all components function smoothly. Regular inspections and timely servicing can prevent potential issues, thereby extending the lifespan of the unit. Familiarizing oneself with the operating guidelines can lead to a more effective and enjoyable experience.

Key Components of 111H Model

The 111H model showcases a variety of essential elements that contribute to its efficient operation and performance. Each component plays a significant role in ensuring that the equipment functions smoothly, enabling users to tackle various tasks with ease.

One of the primary parts is the engine, which provides the necessary power for operation. The engine’s design emphasizes durability and efficiency, allowing it to perform well under different conditions. Additionally, the transmission system is crucial, as it facilitates seamless power transfer to the wheels, enhancing maneuverability.

Another vital aspect is the steering mechanism, which ensures precise control during use. This feature is particularly important for navigating tight spaces or performing intricate tasks. Furthermore, the chassis contributes to the overall stability and robustness of the model, providing a solid foundation for all components.

Lastly, the hydraulic system is integral for various attachments, enabling versatile functionality. This system allows for the operation of implements and enhances the versatility of the equipment, making it suitable for a wide range of applications.

Understanding the Parts Layout

This section provides an overview of the arrangement and configuration of components in a particular machine model. A well-structured layout is essential for identifying and replacing elements effectively, ensuring optimal performance and maintenance.

Familiarity with the configuration can aid in troubleshooting issues and understanding how each element interacts within the system. Below are some key points to consider:

- Each component plays a specific role in the overall functionality of the machine.

- The arrangement often follows a logical sequence, making it easier to trace connections and dependencies.

- Recognizing the layout can significantly reduce the time required for repairs or upgrades.

When examining the arrangement, consider the following aspects:

- Component Identification: Learn to recognize different elements and their respective functions.

- Connectivity: Understand how various parts connect and interact with each other.

- Accessibility: Note which components are easily reachable for maintenance and which may require additional disassembly.

By comprehensively understanding the layout, users can ensure that their machinery operates efficiently and reliably over time.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a proactive approach to maintenance. Regular care not only enhances performance but also extends the lifespan of critical components. Implementing a routine maintenance schedule will help in identifying potential issues before they escalate, thus preserving the functionality of the machine.

Routine Checks

Establishing a routine for inspections can significantly contribute to the longevity of your machinery. Here are essential checks to incorporate:

- Examine fluid levels and replace fluids as necessary to ensure optimal performance.

- Inspect belts and hoses for signs of wear and tear, replacing them when needed.

- Clean air filters regularly to prevent clogging and ensure proper airflow.

- Monitor tire pressure and tread depth to maintain traction and stability.

Proper Storage

Storage conditions play a vital role in maintaining your equipment. Follow these guidelines:

- Keep the machinery in a dry, sheltered area to protect it from moisture and corrosion.

- Use protective covers to shield against dust and debris.

- Ensure the fuel system is clean and free of contaminants before long-term storage.

- Periodically run the equipment to keep the engine components lubricated.

By implementing these strategies, you can significantly enhance the performance and lifespan of your equipment, ultimately leading to cost savings and increased efficiency in the long run.

Common Issues and Solutions

When working with machinery, it is not uncommon to encounter a range of challenges that can affect performance and efficiency. Understanding these frequent problems and their corresponding solutions can significantly enhance the longevity and effectiveness of equipment. Below, we explore some prevalent issues faced by users and provide practical solutions to address them.

Electrical Failures

Electrical malfunctions can lead to operational disruptions. Common symptoms include flickering lights or complete power loss. These issues often stem from faulty wiring, blown fuses, or weak connections.

| Issue | Solution |

|---|---|

| Flickering lights | Check and tighten all electrical connections; replace faulty bulbs. |

| Power loss | Inspect fuses and wiring for damage; replace as necessary. |

Hydraulic System Problems

Hydraulic issues can manifest as slow or unresponsive operation. These can often be attributed to low fluid levels, leaks, or air in the system.

| Issue | Solution |

|---|---|

| Slow operation | Check fluid levels and refill if low; bleed the system to remove air. |

| Leaks | Inspect hoses and connections; replace damaged components immediately. |

How to Order Replacement Parts

Ensuring your equipment runs smoothly often requires obtaining new components when wear and tear occurs. Understanding the process of sourcing these elements can simplify maintenance and enhance performance. This section outlines the steps necessary to procure the required items efficiently.

Identifying the Required Components

The first step in acquiring the necessary items is to determine which specific components need replacement. Consult the manual or reference materials to identify the exact names or numbers associated with the required pieces. This clarity will aid in avoiding potential errors during the ordering process.

Finding a Reliable Supplier

Once the needed components are identified, the next step is to locate a trusted supplier. Consider both online and local resources. Reliable retailers will provide accurate descriptions and availability of the desired items. Before making a purchase, verify that the supplier is reputable and offers customer support for inquiries.

| Supplier Type | Examples |

|---|---|

| Authorized Dealers | Local equipment dealers, online authorized retailers |

| Aftermarket Suppliers | Third-party retailers, online marketplaces |

| Manufacturer Direct | Official company website, factory outlet |

After identifying a trustworthy source, you can proceed with placing your order. Always double-check the item specifications and shipping details to ensure timely delivery. Properly following these guidelines will help maintain your equipment’s functionality and reliability.

Exploring Compatibility with Other Models

Understanding the interchangeability of components between different machinery can significantly enhance maintenance efficiency and reduce costs. This section delves into how certain assemblies and elements from other equipment can seamlessly integrate with a specific model, providing insights into which alternative units share similar specifications and functionalities.

When assessing compatibility, it is essential to consider various factors such as design similarities, functional performance, and part specifications. Below is a comparative table showcasing several models that may offer compatible components, facilitating easier access to replacements and upgrades.

| Model | Compatible Components | Notes |

|---|---|---|

| Model A | Transmission, Tires | Similar transmission ratios enhance performance. |

| Model B | Engine Assembly, Chassis | Engine mounts are identical, simplifying upgrades. |

| Model C | Hydraulic System, Control Panels | Hydraulic specifications align closely, ensuring proper function. |

Tools Needed for Repairs

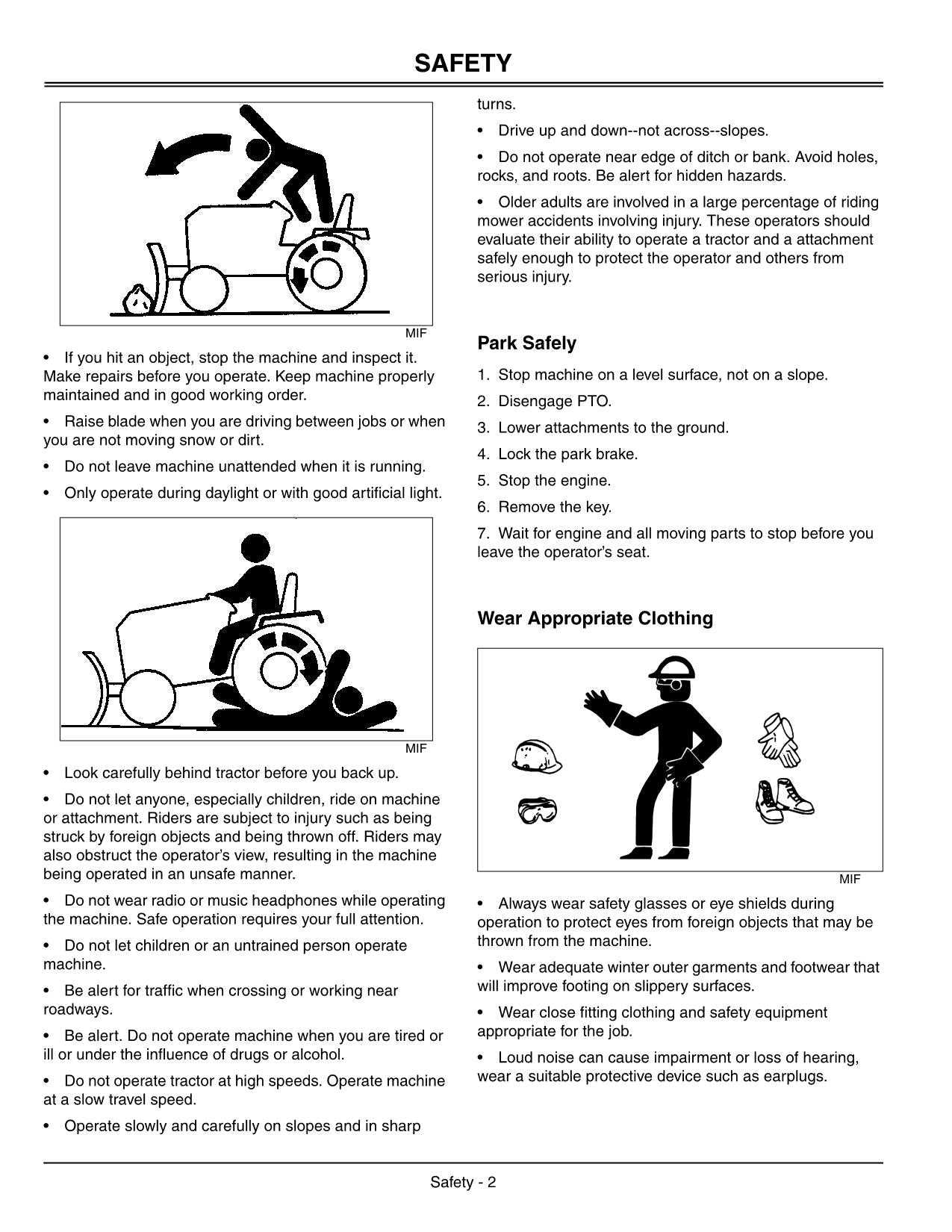

Proper maintenance and repairs of agricultural machinery require a selection of essential tools. Having the right equipment at hand can significantly streamline the process and ensure effective troubleshooting and fixes.

Basic hand tools are vital for any repair task. A set of wrenches, screwdrivers, and pliers will allow for adjustments and replacements of various components. Additionally, a quality socket set can provide versatility when dealing with different fasteners.

For more complex repairs, power tools may be necessary. A drill can assist in making holes for new fittings, while an impact wrench can facilitate the removal of stubborn bolts. Safety gear, such as gloves and goggles, should never be overlooked to protect oneself during repairs.

Lastly, having access to diagnostic equipment can prove invaluable. These tools help in identifying issues quickly and accurately, allowing for efficient problem-solving. Investing in quality tools not only enhances repair effectiveness but also contributes to the longevity of the machinery itself.

Visual Guide to Assembly

This section provides a comprehensive overview of the assembly process, focusing on the key components and their arrangement. By understanding how these elements fit together, users can ensure a smooth reassembly experience, enhancing the functionality and longevity of the equipment.

| Component | Description | Assembly Steps |

|---|---|---|

| Frame | The main structure that supports all other parts. | Align the subassemblies and secure them with bolts. |

| Engine | The power source that drives the machinery. | Position the engine onto the frame and attach using specified fasteners. |

| Wheels | Components that provide mobility and support weight. | Install the wheels onto the axle, ensuring proper alignment. |

| Control Panel | The interface for operating the equipment. | Connect the wiring harness and mount the panel securely. |

Importance of Regular Inspections

Conducting routine evaluations of machinery is crucial for maintaining optimal performance and extending the lifespan of equipment. These assessments help identify potential issues before they escalate into significant problems, ultimately saving time and costs associated with repairs and downtime.

Regular inspections not only enhance operational efficiency but also ensure safety during usage. By systematically examining components, operators can verify that all systems function correctly, reducing the risk of unexpected malfunctions. Moreover, a proactive approach to maintenance fosters a culture of responsibility and care, encouraging users to treat their equipment with respect and diligence.

In addition to preventing failures, routine checks facilitate compliance with industry standards and regulations. Adhering to established guidelines contributes to the overall reliability of machinery, instilling confidence in both operators and stakeholders. By prioritizing these evaluations, one can achieve a well-maintained and dependable asset that performs at its best.

Resources for Technical Support

Accessing reliable information and assistance is crucial when dealing with machinery and equipment. Numerous resources are available to provide guidance, troubleshooting tips, and solutions to common issues. Whether you are seeking detailed manuals, community forums, or professional support, these avenues can enhance your understanding and help resolve technical challenges effectively.

Online Manuals and Documentation

Comprehensive guides and documents can be found online, offering insights into various components and systems. These resources often include:

- User manuals for operational instructions

- Maintenance guides outlining routine care

- Service manuals detailing repair procedures

Community Support and Forums

Connecting with fellow enthusiasts and experts can be beneficial. Consider exploring:

- Online forums dedicated to equipment discussion

- Social media groups where users share experiences

- Video tutorials that demonstrate common repairs

Utilizing these resources can empower you to manage equipment efficiently and address any technical concerns that may arise.