In the world of agricultural machinery, comprehending the intricacies of equipment assembly is essential for optimal performance. This section will explore the various elements that contribute to the functionality and efficiency of these powerful machines.

Identifying individual components allows operators and technicians to troubleshoot effectively and maintain equipment with ease. By examining the relationships between these components, one can gain deeper insights into their operational mechanics.

Furthermore, a thorough grasp of component layouts enhances the ability to implement repairs and upgrades, ultimately leading to improved productivity. This exploration aims to equip users with the knowledge necessary to navigate the complexities of machinery effectively.

Understanding John Deere 145 Overview

This section aims to provide a comprehensive understanding of a specific model in the agricultural machinery lineup. By exploring its features, functionalities, and design elements, readers will gain insights into its practical applications and overall performance.

Key aspects to consider include:

- Engine specifications and capabilities

- Transmission options and their benefits

- Hydraulic systems and their efficiency

- Comfort features for the operator

Moreover, understanding the maintenance requirements and common enhancements can further optimize performance and longevity.

Key Features of John Deere 145

This section highlights the essential characteristics that define the remarkable qualities of this renowned agricultural machinery model. Understanding these features is crucial for users seeking optimal performance and efficiency.

Performance and Efficiency

- Powerful engine designed for various tasks

- Efficient fuel consumption for extended operation

- Robust transmission for smooth gear transitions

Ease of Use

- User-friendly controls for seamless operation

- Adjustable settings to suit different applications

- Compact design for improved maneuverability

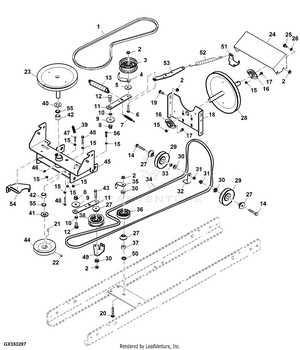

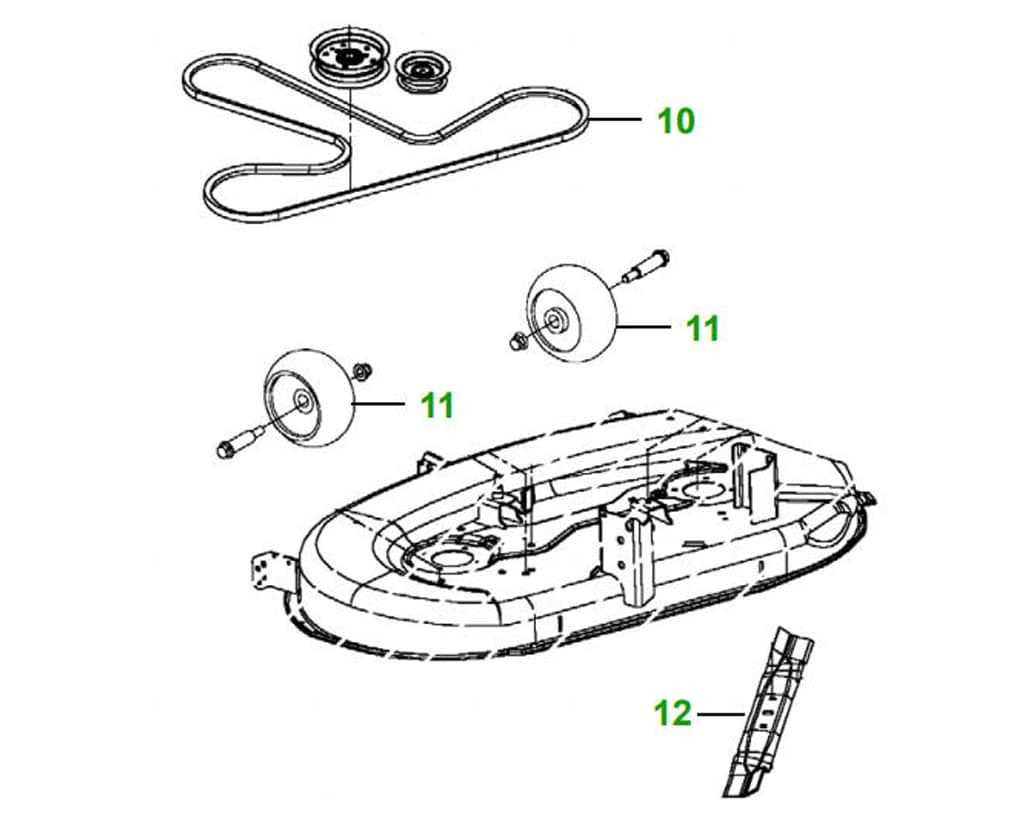

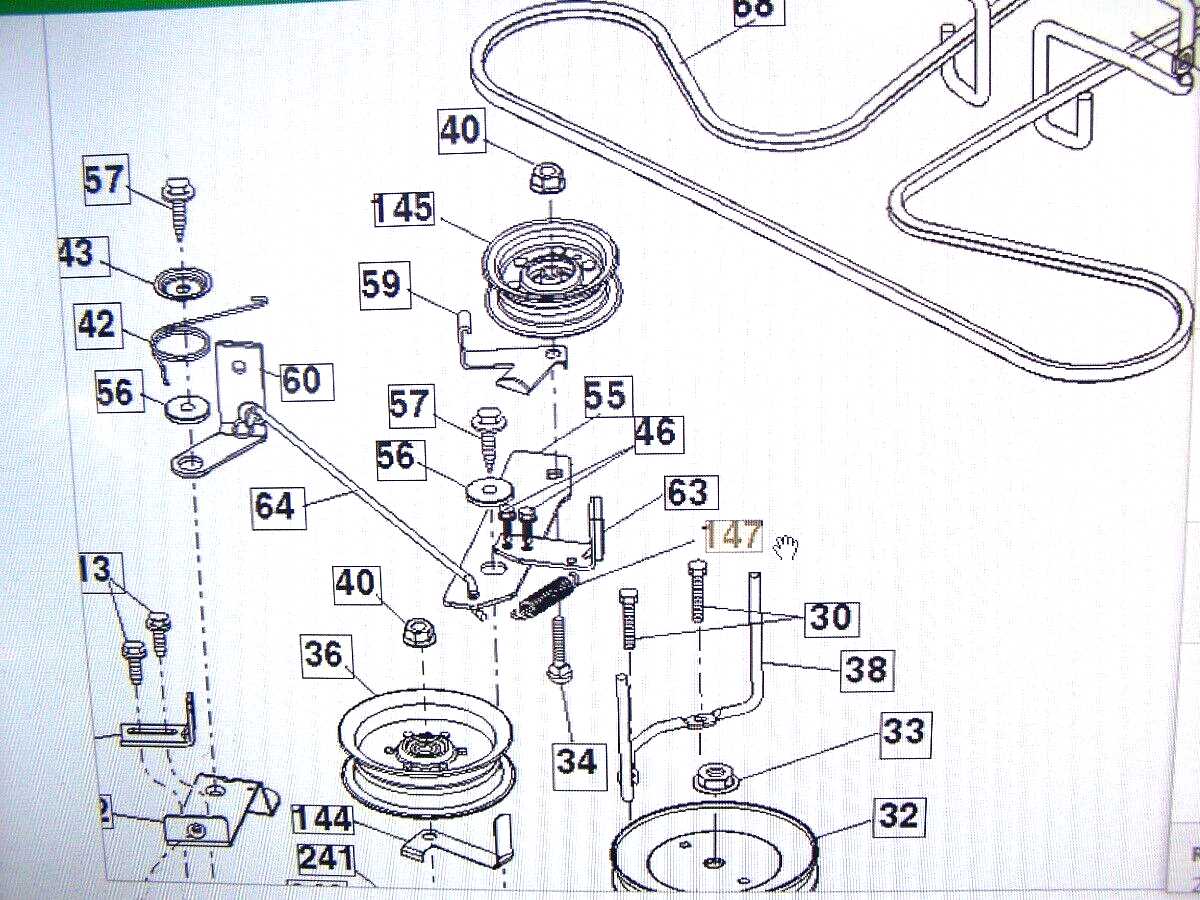

Importance of Automatic Parts Diagram

Understanding the layout and components of a machine is crucial for effective maintenance and repair. A visual representation of the internal mechanisms provides clarity, helping operators and technicians identify specific elements quickly. This knowledge not only streamlines the repair process but also minimizes downtime and enhances operational efficiency.

Such illustrations serve multiple purposes, from guiding users during assembly to aiding in troubleshooting by highlighting connections and functions. They also assist in training new personnel, enabling them to familiarize themselves with the equipment in a structured manner.

| Benefits | Description |

|---|---|

| Clarity | Visual aids simplify complex information, making it easier to comprehend. |

| Efficiency | Quick identification of components reduces repair time. |

| Training | Facilitates onboarding of new staff by providing a clear reference. |

| Accuracy | Minimizes the risk of errors during maintenance tasks. |

In conclusion, having a detailed representation of the machine’s components is invaluable for anyone involved in its upkeep. It enhances understanding, fosters better practices, and ultimately leads to improved performance and longevity of the equipment.

Identifying Main Components of the Diagram

This section aims to explore the essential elements depicted in the schematic, providing insights into their functions and interrelations. Understanding these components is crucial for effective maintenance and troubleshooting.

Key Elements

- Engine Assembly

- Transmission System

- Hydraulic Components

- Control Panel

- Chassis Structure

Functional Importance

Each element plays a vital role in the overall operation. For instance, the engine assembly serves as the power source, while the transmission system ensures efficient power transfer. Recognizing these functions helps in identifying potential issues during operation.

Common Issues with John Deere 145

Equipment of this nature can encounter several challenges over time, affecting performance and efficiency. Understanding these common problems can aid in timely maintenance and repairs, ensuring smooth operation for years to come.

One prevalent issue is related to the engine performance. Users may experience difficulties starting the engine, which can stem from a variety of factors such as fuel quality or ignition system faults. Regular checks and prompt addressing of these factors can help prevent more severe problems.

Another frequent concern involves hydraulic system malfunctions. If the hydraulic fluid level is low or if there are leaks, it can lead to decreased functionality. Monitoring the hydraulic components and ensuring proper fluid levels can mitigate these issues.

Additionally, tire wear is a common challenge. Uneven wear can indicate improper tire pressure or misalignment. Regular inspections and adjustments can prolong tire life and enhance overall performance.

Finally, electrical system failures may occur, often manifesting as malfunctioning lights or starting issues. Regular maintenance of electrical connections and components can help ensure reliability.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure your equipment operates efficiently and reliably. Adopting a systematic approach to maintenance can significantly enhance performance and longevity. By addressing common issues proactively, you can minimize downtime and optimize functionality.

Routine Inspections

Conducting frequent inspections is crucial for identifying wear and tear early. Check components for signs of damage or malfunction. Pay special attention to fluid levels, filters, and belts, as these elements are vital for smooth operation. Implementing a checklist can help streamline this process and ensure no aspect is overlooked.

Cleaning and Lubrication

Maintaining cleanliness is vital for preventing dirt and debris from causing mechanical issues. Regularly clean surfaces and components to prevent buildup that could hinder performance. Additionally, proper lubrication of moving parts reduces friction and wear, contributing to a smoother operation. Use high-quality lubricants suited for your machinery to maximize effectiveness.

Where to Find Parts Online

In today’s digital age, sourcing components for machinery has become significantly more accessible. With just a few clicks, individuals can locate various suppliers and distributors offering a wide array of options for their needs. Online platforms have revolutionized the way enthusiasts and professionals alike procure essential elements for their equipment.

Online marketplaces are a great starting point, providing a vast selection of items from numerous vendors. Websites such as eBay and Amazon often feature new and used components, allowing users to compare prices and conditions easily. Additionally, specialized online retailers cater to specific machinery types, ensuring that users find the exact match for their requirements.

Moreover, forums and communities dedicated to equipment maintenance can be valuable resources. These platforms not only offer advice on installation and upkeep but often include recommendations for reliable suppliers. Members may share their experiences with various vendors, helping others make informed decisions.

Lastly, consider checking the manufacturer’s official website. They frequently list authorized dealers and provide a catalog of available items. This ensures that the components purchased are genuine and compatible with the specific model.

Comparing OEM and Aftermarket Options

When it comes to sourcing components for machinery, understanding the differences between original equipment manufacturer (OEM) products and aftermarket alternatives is crucial. Each option has its advantages and potential drawbacks, which can impact both performance and cost. Evaluating these factors can help users make informed decisions based on their specific needs and budget.

Advantages of OEM Products

- Quality Assurance: OEM items are designed and tested by the original manufacturer, ensuring they meet specific performance standards.

- Compatibility: These products are guaranteed to fit and function seamlessly with the machinery they were intended for.

- Warranty Protection: Most OEM options come with a warranty, providing peace of mind regarding durability and reliability.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Aftermarket solutions are often more affordable, making them an attractive choice for budget-conscious buyers.

- Variety: The aftermarket offers a wide range of choices, giving consumers the flexibility to select products that meet their unique requirements.

- Innovation: Many aftermarket manufacturers invest in research and development, resulting in enhanced performance features or improved designs.

Ultimately, the choice between OEM and aftermarket options depends on individual priorities, whether they lean towards guaranteed quality and compatibility or prefer cost savings and variety.

Using the Parts Diagram Effectively

Understanding a component layout can significantly enhance your ability to maintain and repair machinery. A visual representation of various elements provides essential insights into their arrangement and interconnections, enabling users to identify and locate specific parts swiftly.

Familiarity with the layout is crucial. By studying the illustration, you can grasp how components fit together and function as a cohesive unit. This knowledge will help streamline the troubleshooting process, allowing you to focus on the exact areas that require attention.

When approaching repairs, always refer to the visual guide for accurate identification of elements. Cross-referencing the schematic with physical inspections can uncover hidden issues and prevent oversight. Additionally, keep the guide handy during assembly or disassembly to ensure that every piece is correctly placed and secured.

Lastly, take advantage of the clarity that such representations provide. They can simplify complex tasks, making even the most daunting projects manageable. By leveraging these resources effectively, you can enhance your confidence and competence in handling repairs.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to the assembly process of the specified machinery. Following a structured methodology ensures that each component is correctly fitted, enhancing the overall functionality and efficiency of the equipment.

1. Prepare Your Workspace: Before starting, ensure that your workspace is clean and organized. Gather all necessary tools and components to facilitate a smooth assembly process.

2. Review the Manual: Familiarize yourself with the assembly instructions outlined in the manual. Understanding the sequence of assembly will help prevent errors.

3. Start with the Base: Begin by securing the base frame. Use the appropriate fasteners to ensure a stable foundation for the subsequent components.

4. Attach the Power Unit: Carefully position the power unit onto the base. Align the mounting holes and secure it with bolts, ensuring that it is tightly fitted to prevent any movement during operation.

5. Install Auxiliary Components: Proceed to attach auxiliary components such as the control panel and safety features. Make sure to follow the specific instructions for each part to guarantee proper installation.

6. Connect the Wiring: Ensure that all wiring is connected correctly. Double-check the connections to avoid any electrical issues that may arise during operation.

7. Final Checks: Once all components are assembled, conduct a thorough inspection. Ensure that all fasteners are tightened and that there are no loose parts.

8. Testing: After assembly, perform a test run to verify that everything operates smoothly. Address any discrepancies immediately.

By following these steps diligently, you can achieve a successful assembly, ensuring that your machinery operates at its best.

Understanding Hydraulic Systems in John Deere

Hydraulic systems play a crucial role in the functionality of various machinery, allowing for efficient power transfer and operation. These systems utilize fluid under pressure to transmit energy, facilitating movement and control in equipment. A comprehensive understanding of hydraulic mechanisms is essential for ensuring optimal performance and maintenance.

Typically, hydraulic systems consist of several key components that work in harmony to create effective functionality. Below is a table outlining the primary elements and their respective roles in the hydraulic setup:

| Component | Function |

|---|---|

| Hydraulic Pump | Generates flow by converting mechanical energy into hydraulic energy. |

| Hydraulic Fluid | Transmits power and lubricates components within the system. |

| Actuator | Converts hydraulic energy back into mechanical energy for movement. |

| Valves | Regulate fluid flow and pressure to control the operation of the system. |

| Reservoir | Holds hydraulic fluid and provides a space for fluid expansion and separation. |

Understanding these components and their interactions is vital for troubleshooting and enhancing the efficiency of hydraulic systems. Regular maintenance and inspection can prevent common issues, ensuring longevity and reliability in machinery operation.

Troubleshooting Electrical Problems

Electrical issues can significantly impact the performance of your machinery, causing disruptions and inefficiencies. Identifying the root causes of these problems is essential for effective resolution. This section provides guidance on diagnosing and rectifying common electrical malfunctions that may arise in your equipment.

Identifying Symptoms

Begin by observing any irregular behavior in your machine. Look for signs such as flickering lights, unresponsive controls, or unusual sounds. These symptoms can indicate underlying electrical faults. Take note of when these issues occur, as specific conditions may trigger them, aiding in the troubleshooting process.

Testing Components

Once you have identified potential symptoms, proceed to test the relevant components. Use a multimeter to measure voltage levels and ensure they are within the expected range. Check connections for corrosion or looseness, as these can lead to poor electrical contact. Regular maintenance of electrical components can help prevent future issues.

Customer Reviews and Feedback

In this section, we explore the experiences and opinions of users regarding a specific agricultural equipment model. Feedback from customers plays a crucial role in understanding the performance, reliability, and overall satisfaction with the machinery. Here, we gather insights to help potential buyers make informed decisions.

Many users appreciate the functionality and ease of use of the machinery. Common themes from the reviews include:

- Durability and robustness, with many highlighting how well the equipment withstands tough working conditions.

- Efficiency in completing tasks, which often leads to increased productivity on the farm.

- Support from the manufacturer, with customers noting the availability of assistance when needed.

However, some feedback also points out areas for improvement:

- A few users have mentioned challenges with specific features, suggesting enhancements could be made for better usability.

- Concerns regarding maintenance requirements were expressed, emphasizing the need for more accessible servicing options.

Overall, customer feedback provides valuable insights, highlighting both the strengths and areas needing attention. This information is essential for prospective users to consider when evaluating their options.