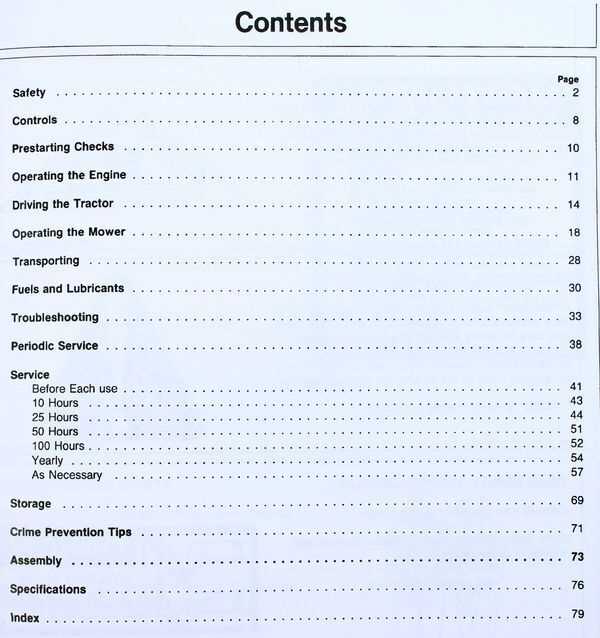

When maintaining complex machinery, visual representations of the various elements can be invaluable. These illustrations not only enhance comprehension but also simplify the repair and replacement process. By familiarizing oneself with the layout and function of each component, operators can ensure optimal performance and longevity.

In-depth exploration of the individual elements is essential for anyone looking to enhance their operational knowledge. Whether you are a seasoned technician or a novice, having access to clear visuals can guide you through the intricacies of maintenance. This ultimate resource serves as a reference to help identify and understand the essential parts involved.

By delving into the details, users can make informed decisions regarding repairs and upgrades. Understanding how each piece fits into the overall machinery framework is crucial for troubleshooting issues effectively. This article aims to provide clarity and facilitate a smoother maintenance experience.

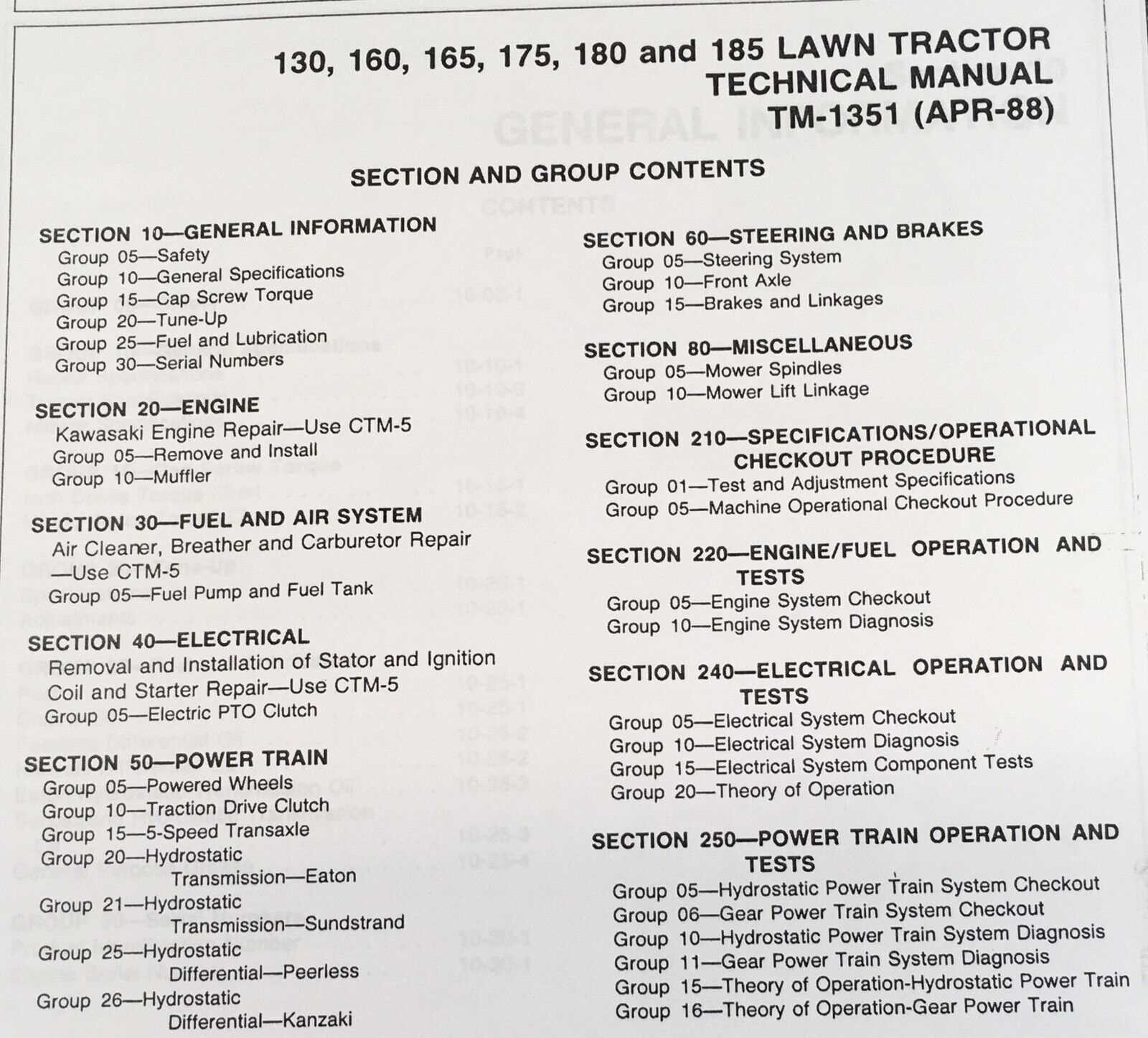

Understanding John Deere 165 Parts

This section aims to explore the various components essential for the efficient operation of a specific model of lawn equipment. Recognizing these elements helps in maintenance, troubleshooting, and ensuring optimal performance.

- Engine Assembly

- Transmission System

- Cutting Deck

- Steering Mechanism

- Electrical Components

Each component plays a crucial role in the functionality and reliability of the machine. Familiarity with these segments can enhance user experience and prolong the lifespan of the equipment.

- Inspect the engine regularly for any signs of wear.

- Ensure the transmission fluid is at appropriate levels.

- Keep the cutting deck free from debris to maintain cutting efficiency.

- Check steering for responsiveness and accuracy.

- Test electrical systems to prevent starting issues.

Importance of Parts Diagrams

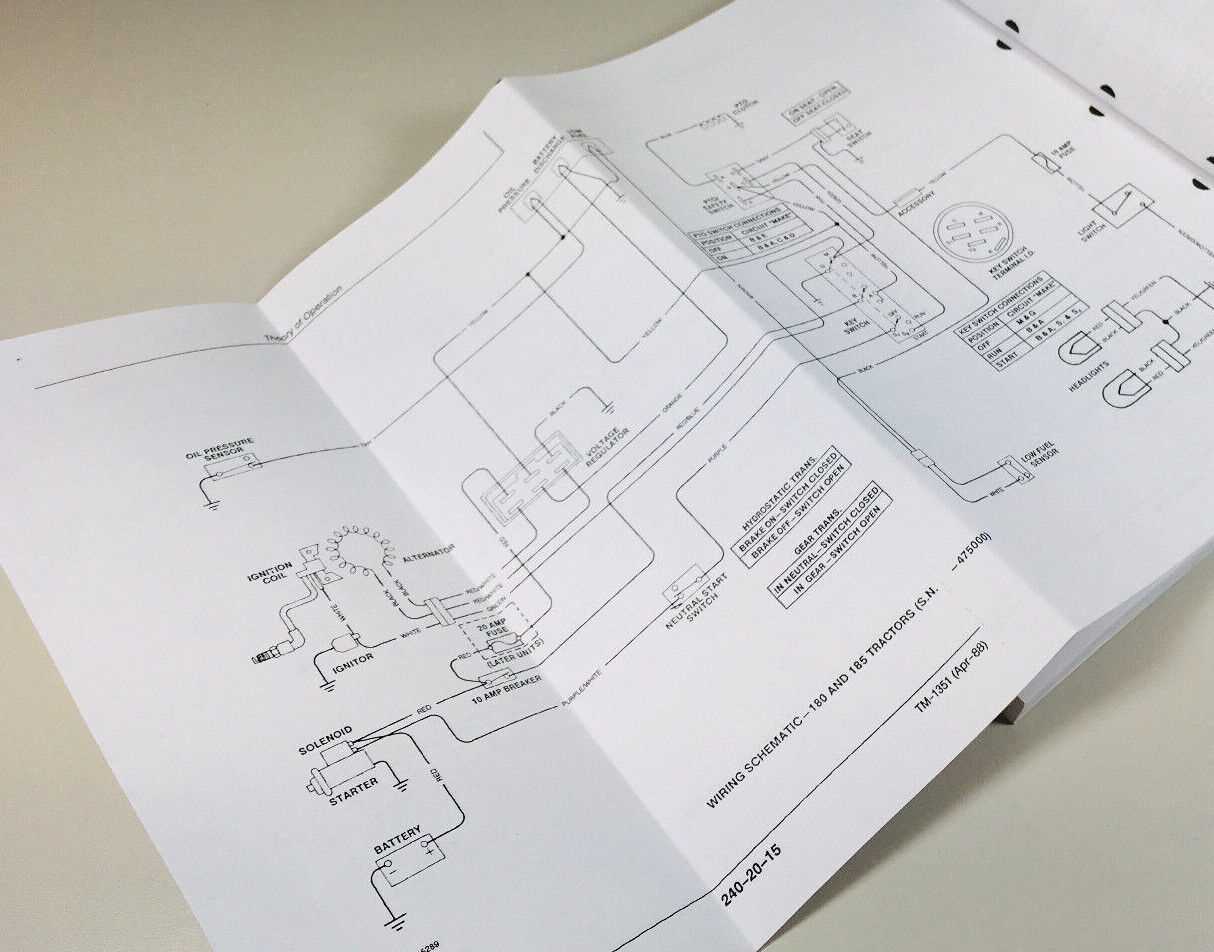

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. Visual representations play a vital role in simplifying complex structures, allowing users to identify and locate essential elements quickly. This clarity enhances efficiency and minimizes errors during servicing.

Enhanced Troubleshooting

Accurate visual aids facilitate faster problem-solving by enabling users to pinpoint malfunctioning areas. By providing a clear overview, these illustrations allow technicians to quickly diagnose issues without unnecessary disassembly.

Streamlined Maintenance

Utilizing visual references ensures that maintenance tasks are performed systematically. This organization not only saves time but also reduces the likelihood of missing critical components during service.

| Benefit | Description |

|---|---|

| Efficiency | Quick identification of components for faster repairs. |

| Accuracy | Reduces the risk of errors during maintenance. |

| Organization | Ensures systematic approach to servicing tasks. |

Common Issues with John Deere 165

Understanding the frequent challenges faced by users of this well-known lawn care machine can enhance its performance and longevity. Many owners encounter a variety of operational difficulties that can stem from routine wear and tear or maintenance oversights.

One prevalent problem involves engine starting issues, often caused by fuel delivery or ignition system malfunctions. Additionally, irregular cutting performance may arise from dull blades or improper deck leveling, impacting the quality of the lawn finish.

Transmission-related complications are also common, including slipping or failure to engage properly. Regular inspections and timely replacements of worn components are essential in preventing these issues and ensuring optimal functionality.

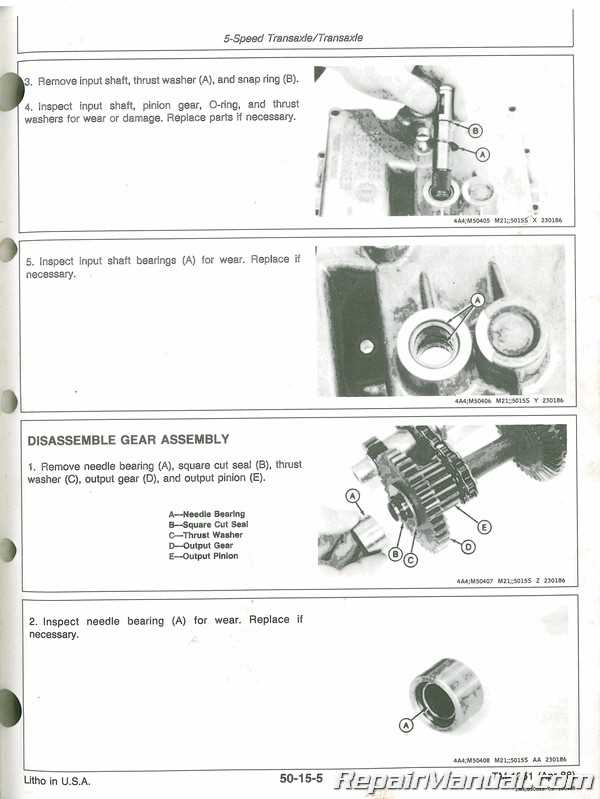

Identifying Key Components

Understanding the essential elements of machinery is crucial for effective maintenance and repair. By recognizing these components, operators can ensure optimal performance and longevity of their equipment.

Engine: The heart of any machine, responsible for power generation and overall functionality.

Transmission: This component transfers power from the engine to the wheels, enabling movement and maneuverability.

Hydraulic System: Essential for operating various attachments, this system relies on fluid pressure to perform tasks efficiently.

Chassis: The framework that supports all other components, providing stability and structure to the equipment.

Control Panel: The interface that allows users to operate and monitor the machine’s functions, crucial for effective management.

By exploring these fundamental parts, operators can better troubleshoot issues and enhance the performance of their machinery.

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its functionality and longevity. Various resources are available that cater to different needs, ensuring you can restore your machine to optimal performance.

Online Retailers

Numerous online platforms specialize in offering a wide range of replacement components. Websites dedicated to agricultural machinery often provide detailed catalogs and user reviews, helping you make informed decisions.

Local Dealerships

Your local dealerships can be invaluable for sourcing specific items. These establishments not only carry genuine components but also offer expert advice on compatibility and installation, ensuring you get the right fit for your machinery.

Tips for Effective Maintenance

Proper upkeep of machinery is essential for ensuring longevity and optimal performance. Regular attention to specific components can prevent breakdowns and reduce repair costs. By adhering to a systematic maintenance routine, operators can enhance the efficiency and reliability of their equipment.

Establish a Routine

Creating a consistent schedule for inspections and servicing is crucial. This should include daily checks for fluid levels and weekly evaluations of key components. Setting reminders can help ensure that maintenance tasks are not overlooked, promoting a proactive approach to care.

Use Quality Replacement Parts

When it comes to replacements, opting for high-quality components is vital. This not only enhances performance but also minimizes the risk of future issues. Always consult reliable sources to acquire the best products, ensuring compatibility and durability.

Utilizing Online Resources

In today’s digital age, accessing information about machinery components and their configurations has never been easier. The internet is a vast repository of knowledge, offering a wealth of tools and materials that can assist users in understanding and maintaining their equipment. By leveraging these resources, individuals can enhance their repair skills and make informed decisions about replacements and upgrades.

Benefits of Online Resources

One of the primary advantages of using online platforms is the availability of comprehensive guides and tutorials. These resources often include step-by-step instructions, making complex procedures more manageable. Additionally, users can connect with online communities where they can share experiences, seek advice, and gain insights from others who have encountered similar challenges.

Finding Reliable Information

When searching for information, it’s crucial to identify trustworthy sources. Reputable websites, forums, and manufacturer resources typically provide accurate and detailed data. Utilizing search engines effectively and cross-referencing information can also help ensure that the guidance obtained is both reliable and applicable.

Working with Authorized Dealers

Collaborating with certified representatives is essential for maintaining the efficiency and longevity of your machinery. These professionals provide access to a wealth of knowledge, ensuring that you receive the best possible support for your equipment. Engaging with authorized dealers guarantees not only quality service but also peace of mind when it comes to repairs and maintenance.

Benefits of Partnering with Certified Representatives

Utilizing the services of licensed vendors offers several advantages, including:

| Advantage | Description |

|---|---|

| Expert Knowledge | Certified representatives possess specialized training and experience, allowing them to diagnose and resolve issues efficiently. |

| Genuine Components | Authorized dealers provide original components that meet manufacturer specifications, ensuring optimal performance. |

| Warranty Support | Working with certified vendors helps maintain warranty coverage, protecting your investment over time. |

| Comprehensive Service | Authorized dealers often offer complete maintenance solutions, from routine inspections to complex repairs. |

Finding the Right Dealer

When searching for a suitable representative, consider factors such as proximity, customer reviews, and the range of services offered. It’s vital to select a partner that aligns with your specific needs to ensure a smooth and effective working relationship.

DIY Repair Techniques

Engaging in hands-on maintenance can empower individuals to tackle equipment issues effectively. Utilizing accessible resources and a bit of ingenuity, one can address common malfunctions without the need for professional assistance. This section explores various methods and strategies to facilitate successful repairs.

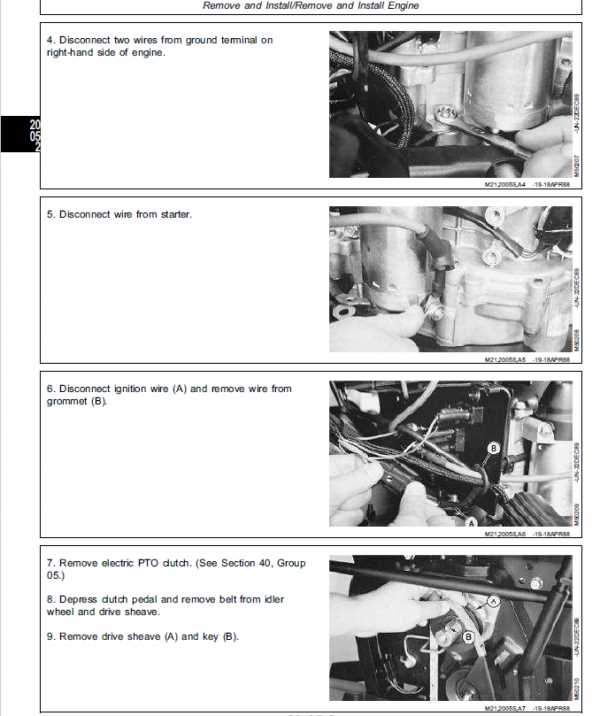

Assessment and Diagnosis: The first step in any repair process is identifying the underlying problem. Carefully inspecting the machinery can help pinpoint issues. Look for wear, leaks, or unusual noises, and document findings to develop a clear action plan.

Utilizing Manuals and Resources: Reference guides and online resources can provide valuable information regarding repair techniques. Familiarizing oneself with the structure and components of the equipment enhances understanding and simplifies the repair process. Consider downloading maintenance manuals or watching tutorial videos.

Gathering the Right Tools: Having the proper tools is crucial for effective repairs. Invest in quality equipment that suits the specific needs of the task. A well-organized toolkit can streamline the process, making repairs quicker and more efficient.

Step-by-Step Approach: Breaking down the repair into manageable steps can reduce overwhelm. Approach each task methodically, ensuring that all components are addressed. This technique not only minimizes mistakes but also builds confidence as progress is made.

Testing and Evaluation: Once repairs are completed, thorough testing is essential. Ensure that the equipment operates smoothly before returning it to regular use. This step confirms that the issues have been resolved and helps to identify any remaining problems that need attention.

Learning from Experience: Each repair presents an opportunity for growth. Reflecting on what worked well and what didn’t can improve future repair efforts. Documenting experiences can serve as a helpful reference for similar projects down the line.

Cost Considerations for Repairs

When addressing the financial aspects of equipment maintenance, several factors play a crucial role in determining overall expenses. Understanding these elements can help owners make informed decisions and avoid unexpected costs.

Factors Influencing Repair Costs

- Type of Damage: The severity and nature of the issue greatly affect repair expenses.

- Labor Costs: Skilled technicians may charge varying rates based on experience and location.

- Availability of Components: Rare or discontinued items can drive up prices significantly.

- Warranty Status: Coverage can significantly lower out-of-pocket costs if applicable.

Budgeting for Maintenance

- Conduct Regular Inspections: Preventative checks can identify issues before they escalate.

- Set Aside Emergency Funds: Having a financial buffer ensures you’re prepared for unexpected repairs.

- Research Repair Shops: Compare prices and services to find the best fit for your needs.

Enhancing Performance with Upgrades

Upgrading machinery can significantly boost efficiency and extend its lifespan. By incorporating advanced components and technology, operators can experience improved functionality and reliability. This section will explore various enhancement options available to optimize performance and achieve ultimate results.

Types of Upgrades

When considering enhancements, it’s crucial to focus on key areas such as power, control, and comfort. Upgrades can include engine modifications, transmission improvements, and ergonomic adjustments that contribute to overall productivity.

Benefits of Upgrading

Investing in upgrades can lead to increased output, reduced downtime, and enhanced user experience. Upgraded equipment often results in better fuel efficiency and lower maintenance costs, making it a smart choice for operators aiming for excellence.

| Upgrade Type | Potential Benefit |

|---|---|

| Engine Enhancement | Improved power and torque |

| Transmission Upgrade | Smoother operation and better gear shifts |

| Comfort Features | Reduced operator fatigue and increased productivity |