This section aims to provide a comprehensive overview of the layout and functionality of essential machinery elements. By exploring various components, users can enhance their understanding and ensure optimal performance of their equipment.

Through detailed illustrations and descriptions, readers will gain insights into how each part contributes to the overall efficiency. Familiarity with these elements is crucial for maintenance and repair tasks, ultimately leading to improved machinery longevity.

Understanding John Deere 2010 Components

This section provides an overview of the essential elements found in a specific agricultural machine. Recognizing these components is crucial for effective maintenance and operational efficiency.

Main Functional Elements

Every agricultural machine consists of several core parts that work together to ensure optimal performance. Familiarity with these elements can enhance user experience and prolong the life of the equipment.

Typical Assembly Overview

Understanding the typical assembly of these machines can aid in troubleshooting and repairs. Below is a table illustrating some of the main components and their functions.

| Component | Function |

|---|---|

| Engine | Provides power for operation |

| Transmission | Transmits power from the engine to wheels |

| Hydraulics | Controls various functions and movements |

| Steering | Allows for directional control |

| Frame | Supports all other components |

Overview of Parts and Functions

This section provides a comprehensive look at the various components and their respective roles within the machinery. Understanding the structure and functionality of these elements is essential for effective maintenance and operation.

Key Elements: Each component plays a vital role, contributing to the overall efficiency and performance of the equipment. From the engine to the transmission system, every piece is designed to work in harmony, ensuring optimal functionality.

Maintenance Considerations: Regular inspection and knowledge of the different components help in identifying potential issues before they escalate. Familiarity with each part’s function enhances troubleshooting and repair efforts.

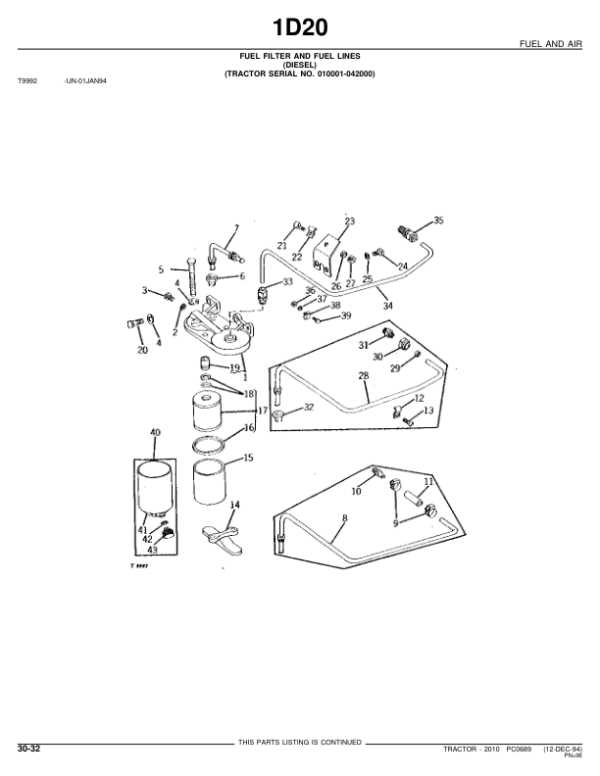

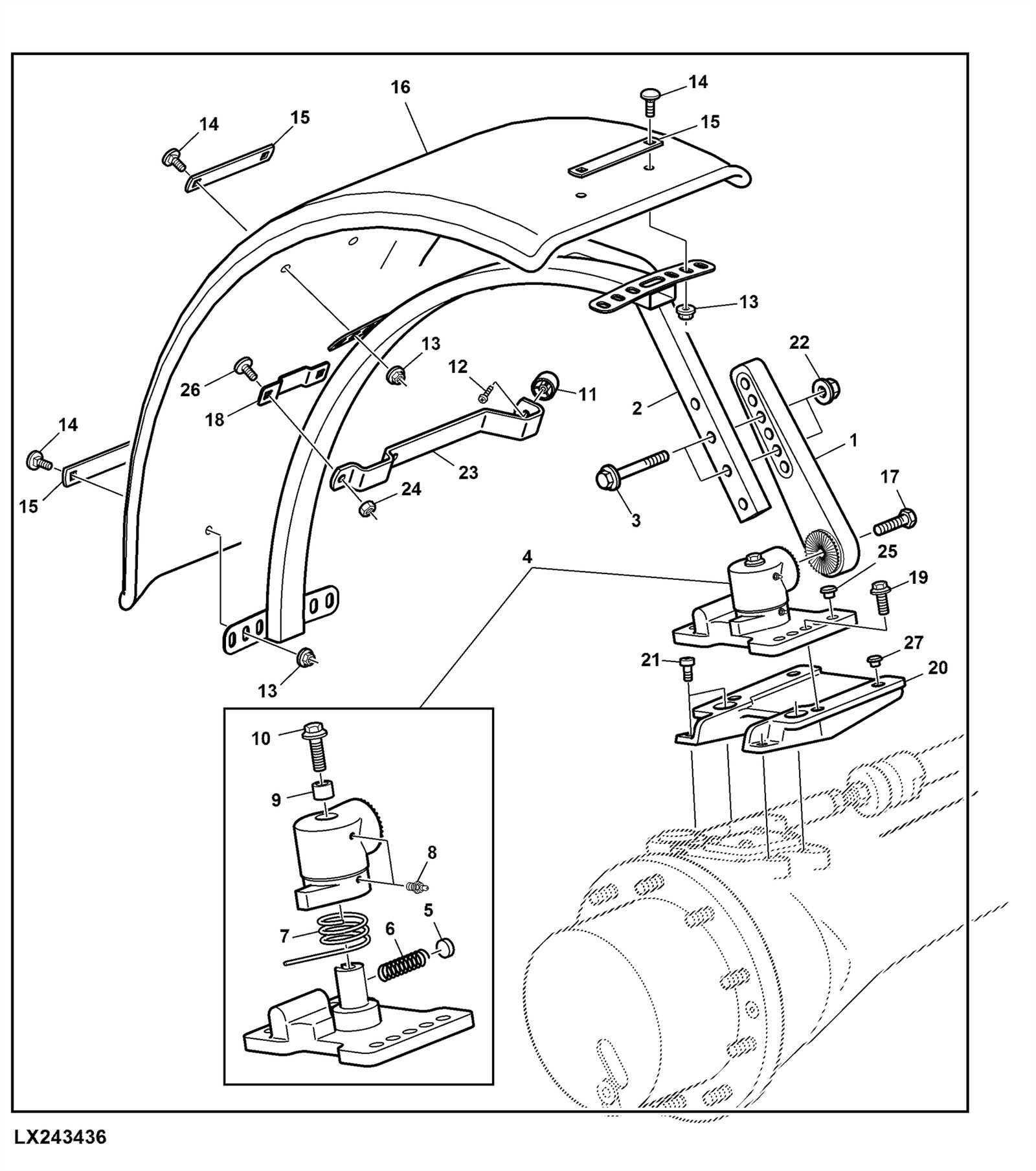

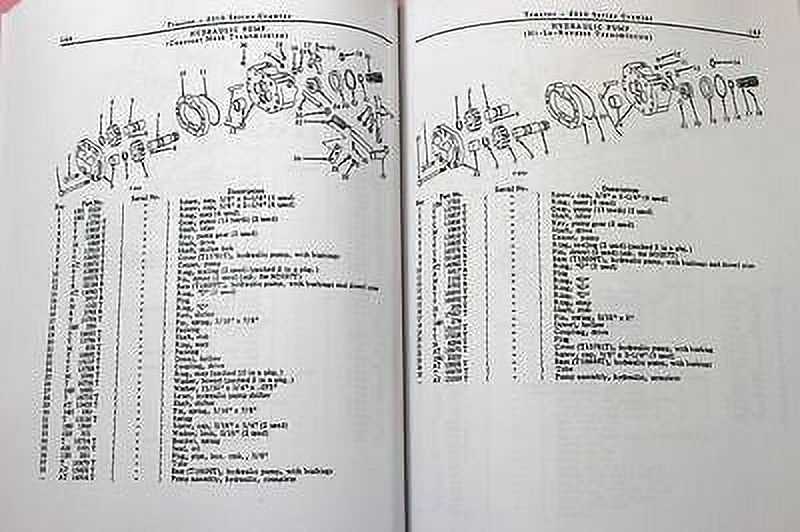

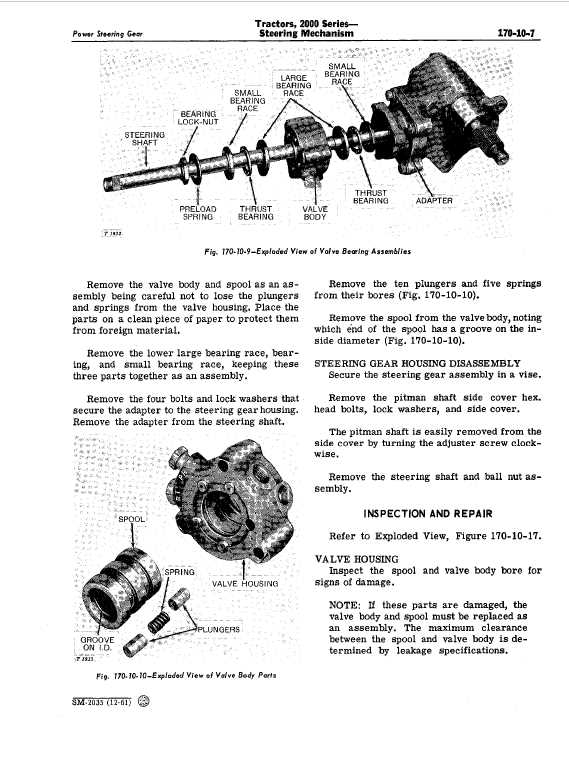

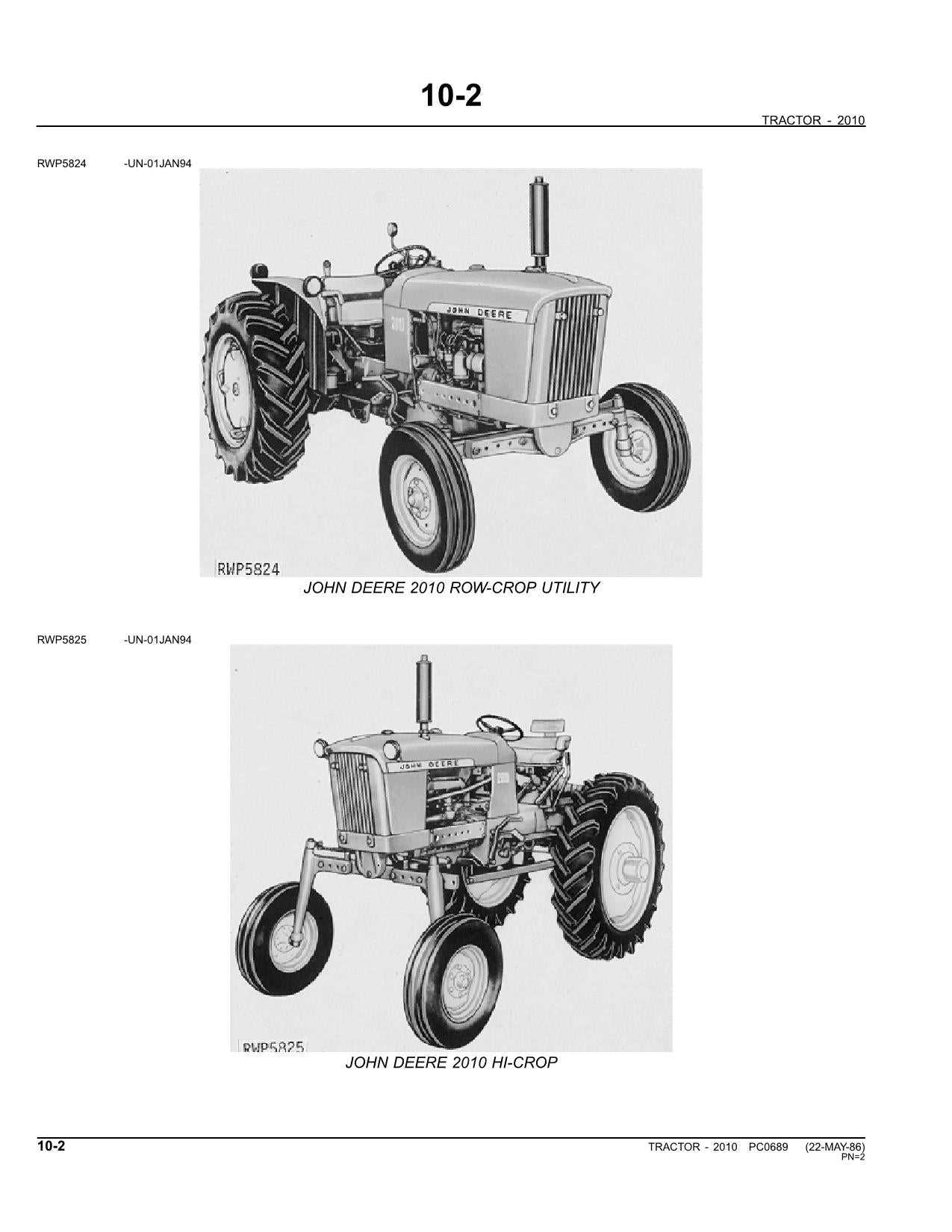

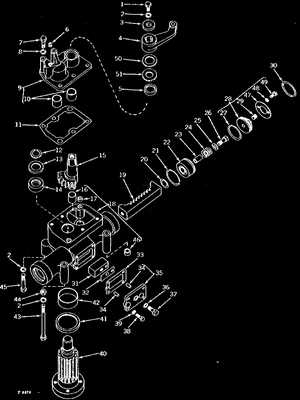

Visual Representation of Part Layout

The visual arrangement of components plays a crucial role in understanding the assembly and functionality of machinery. Clear illustrations help users identify various elements and their positions, facilitating easier maintenance and repairs.

Effective diagrams provide a comprehensive overview, showcasing how different sections interact within the overall structure. These visuals are essential for anyone seeking to enhance their knowledge about machinery operations.

Detailed graphics not only aid in troubleshooting but also serve as valuable references during assembly processes. Familiarity with the layout allows for efficient identification of parts, ensuring smoother workflows and better outcomes in maintenance tasks.

Essential Replacement Parts for Maintenance

Regular upkeep of machinery is crucial for optimal performance and longevity. Identifying the vital components that may need replacement helps ensure that equipment operates efficiently and reliably. Below are some key items to consider when maintaining your machine.

| Component | Description |

|---|---|

| Filters | These components help to remove impurities from fluids, ensuring smooth operation. |

| Belt | A critical part that connects various systems, providing necessary motion and power transfer. |

| Seals | Essential for preventing leaks and maintaining proper pressure within the system. |

| Fluids | Various oils and lubricants that ensure all moving parts function correctly. |

| Brake Pads | Key safety elements that require regular inspection and timely replacement. |

Common Issues and Solutions

Understanding typical challenges that arise with machinery can greatly enhance maintenance efforts. Addressing these concerns promptly ensures optimal performance and longevity of the equipment.

Frequent Problems

- Engine starting difficulties

- Hydraulic system malfunctions

- Transmission issues

- Electrical failures

Effective Resolutions

- Check the battery and connections if starting issues occur.

- Inspect hydraulic fluid levels and look for leaks in the system.

- Review transmission fluid and ensure proper engagement of gears.

- Examine wiring and fuses to resolve electrical problems.

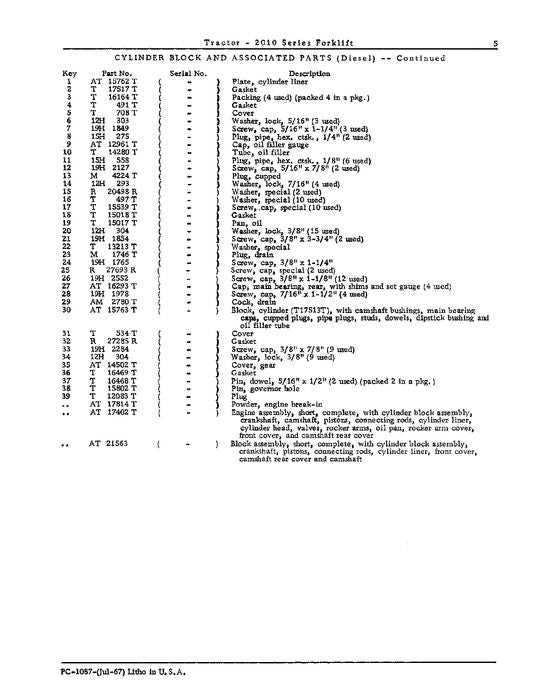

How to Identify Parts by Number

Recognizing components through numerical identifiers is essential for effective maintenance and repair. This method streamlines the process, allowing users to locate specific items quickly and accurately.

Steps to Identify Components

- Refer to the manual or catalog for a reference list of numbers.

- Cross-check the number with online databases or retailer websites.

- Consult with professionals or forums for guidance on identification.

Tips for Accurate Identification

- Ensure that the number is read correctly; verify each digit.

- Look for additional markings or labels that may assist in confirming the identifier.

- Keep a record of frequently used numbers for future reference.

Upgrades for Improved Performance

Enhancing machinery efficiency involves a range of modifications that can significantly boost overall functionality. These enhancements not only optimize power output but also improve reliability and longevity of the equipment.

- Engine Tuning: Adjusting fuel injection and ignition settings can lead to better fuel efficiency and increased power.

- Hydraulic System Improvements: Upgrading hydraulic components enhances lifting capacity and speed, ensuring smoother operations.

- Tire Selection: Choosing appropriate tires for specific tasks can improve traction and reduce wear on various terrains.

- Aftermarket Accessories: Implementing additional attachments can expand functionality, allowing for diverse applications.

Each of these modifications plays a vital role in maximizing performance and ensuring that the equipment meets the demands of various tasks effectively.

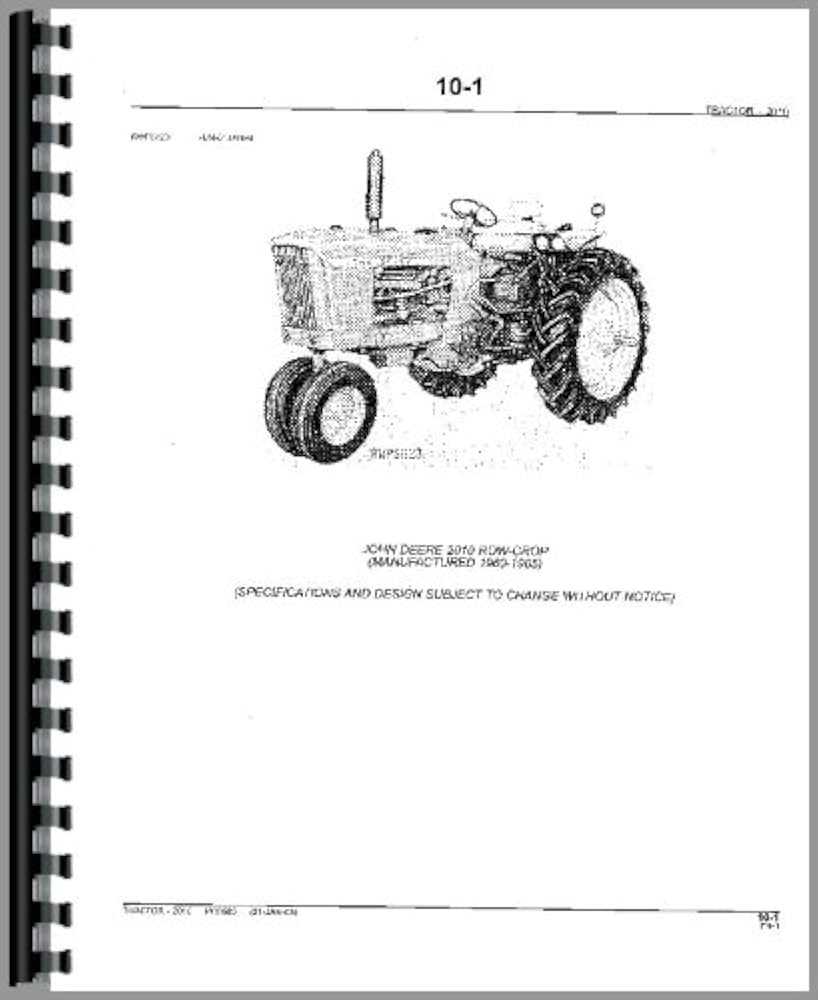

Historical Significance of the Model

This particular agricultural machine holds a notable place in the history of farming technology. It represented a shift towards greater efficiency and productivity in the industry, appealing to farmers looking for reliable equipment. With its innovative design and functionality, this model helped streamline various farming tasks, marking an important milestone in mechanized agriculture.

Over the years, this model has been appreciated not only for its practical applications but also for its role in shaping the future of agricultural practices. Its engineering and durability set a standard for subsequent models, influencing manufacturers and users alike. The legacy of this machine continues to resonate in modern farming techniques, showcasing its enduring impact on the agricultural sector.

Tips for Ordering Genuine Parts

When it comes to acquiring authentic components for your machinery, it’s essential to approach the process with care and precision. Ensuring you obtain the correct items will not only enhance the performance of your equipment but also extend its lifespan.

Research and Verify Sources

Before making a purchase, conduct thorough research to identify reputable suppliers. Look for authorized dealers who specialize in quality replacements. Reading customer reviews and ratings can provide insights into the reliability of the source.

Double-Check Compatibility

Always verify the compatibility of the components with your specific model. Refer to your equipment’s manual for detailed specifications. If unsure, consult with an expert or the supplier to avoid costly mistakes.

Comparison with Other John Deere Models

This section explores how a particular model aligns with its counterparts within the same brand, focusing on key features and performance aspects. By examining similarities and differences, users can better understand the advantages and disadvantages of each variant.

Notable differences may include engine specifications, design elements, and available attachments. Certain versions may offer enhanced capabilities for specific tasks, making them more suitable for particular applications. In contrast, other models might prioritize efficiency and ease of use.

When evaluating these machines, it’s essential to consider the intended use and specific requirements of the operator. This analysis helps potential buyers make informed decisions based on their unique needs and preferences.

Resources for Further Research

Exploring additional materials can greatly enhance your understanding of machinery components and their functionality. Numerous sources provide valuable insights, including manuals, online forums, and manufacturer websites. Engaging with these resources can lead to more informed decisions regarding maintenance and repairs.

Online Communities and Forums

Joining online groups dedicated to machinery enthusiasts can be beneficial. These platforms often feature discussions on various topics, allowing you to share experiences and gather advice from fellow users. Engaging with community members can provide practical tips and troubleshooting techniques.

Official Manufacturer Websites

Visiting the official websites of equipment manufacturers offers access to a wealth of information. You can find detailed specifications, maintenance guidelines, and the latest updates regarding available components. These resources ensure that you are equipped with the most accurate and relevant information.