The functionality and efficiency of modern farming machinery rely heavily on the intricate arrangement of various elements. These components work harmoniously to enhance performance and ensure optimal results in the field. A comprehensive overview of these elements is essential for operators and enthusiasts alike, enabling better maintenance and repair practices.

Within the realm of agricultural machinery, it is crucial to grasp how each segment contributes to the overall operation. Detailed visual representations aid in comprehending the connections and functions of these components, empowering users to identify potential issues and implement effective solutions. Such knowledge fosters a deeper appreciation for the engineering behind these remarkable tools.

Exploring the intricate relationships among these elements equips users with valuable insights. By familiarizing oneself with these connections, one can ensure longevity and reliability, ultimately enhancing productivity. A thorough examination of these aspects promotes a proactive approach to machinery care, leading to more efficient agricultural practices.

Overview of John Deere 210 Disc Parts

This section provides a comprehensive look at the components of a specific agricultural implement, focusing on their roles and functionalities. Understanding these elements is crucial for maintenance and optimal performance, ensuring that the equipment operates efficiently during various agricultural tasks.

Key Components and Their Functions

The assembly consists of several essential elements, each serving a distinct purpose. The frame provides structural integrity, supporting all other components. Blades, designed for cutting and tilling, are crucial for soil preparation, allowing for effective penetration and mixing of soil layers. Additionally, bearing assemblies play a vital role in facilitating smooth rotation and minimizing friction.

Maintenance Tips for Longevity

Regular inspection and maintenance of each component are vital for enhancing durability and performance. Lubricating moving parts reduces wear and tear, while timely replacements of worn-out elements prevent operational failures. Keeping the assembly clean from debris and soil build-up further contributes to its efficiency and extends its lifespan.

Key Components of the Disc System

The effective operation of a tillage system relies on several essential elements that work in harmony to ensure optimal performance. Understanding these key components is crucial for maintaining and enhancing the functionality of the equipment.

- Frame: The structural base that supports all other elements, providing stability and durability during operation.

- Blades: Sharp edges designed to penetrate the soil, creating a finely tilled surface and aiding in soil aeration.

- Bearings: These components allow for smooth rotation and reduce friction, ensuring the longevity of moving parts.

- Hitch: The attachment mechanism that connects the system to the towing vehicle, facilitating movement across various terrains.

- Adjustable Settings: Mechanisms that allow operators to modify the depth and angle of the blades, enhancing versatility for different soil conditions.

By familiarizing oneself with these vital components, operators can ensure their tillage equipment operates at peak efficiency, ultimately leading to improved crop yields and soil health.

Understanding the Functionality of Each Part

Grasping the purpose of individual components in agricultural machinery is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring that the equipment operates efficiently, contributing to its overall effectiveness in fieldwork.

Here is a breakdown of the key components and their respective functions:

| Component | Function |

|---|---|

| Frame | Serves as the structural foundation, providing stability and support for all attached elements. |

| Blade | Facilitates soil cutting and mixing, ensuring effective soil preparation for planting. |

| Hitch | Connects the implement to the tractor, allowing for proper attachment and operation. |

| Bearings | Support rotating parts, minimizing friction and wear during operation. |

| Depth Adjustment | Allows for modification of working depth, tailoring performance to different soil conditions. |

Maintenance Tips for Disc Components

Proper upkeep of implement components is essential for ensuring optimal performance and longevity. Regular attention to these elements can prevent unexpected failures and enhance overall efficiency. This section provides practical advice on maintaining these crucial parts, focusing on key practices to adopt.

Regular Inspections

Conducting consistent examinations of the equipment is vital. Look for signs of wear, rust, or damage that could compromise functionality. Early detection of issues can lead to timely repairs and prevent more significant problems down the line.

Lubrication and Cleaning

Keeping components clean and well-lubricated is crucial for smooth operation. Use appropriate lubricants to minimize friction and wear. Additionally, remove any debris or buildup that may accumulate during use, as this can hinder performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Before each use | Check for visible damage and loose parts. |

| Cleaning | After each use | Remove dirt and debris to prevent buildup. |

| Lubrication | Every 10 hours of operation | Use manufacturer-recommended lubricant. |

| Tightening Bolts | Monthly | Ensure all bolts are secure to avoid failure. |

Common Issues with Disc Parts

When operating agricultural machinery, several challenges may arise related to the components responsible for soil cultivation. Understanding these potential issues can help operators maintain optimal performance and prevent costly repairs. Commonly encountered problems can stem from wear and tear, improper adjustments, or environmental factors impacting the equipment’s functionality.

Worn Components

Degradation of various elements can significantly impact the efficiency of the equipment. Regular use can lead to thinning or damage, resulting in reduced effectiveness during tilling. It is essential to monitor for signs of wear and replace affected components promptly to maintain operational efficiency.

Misalignment and Adjustment Issues

Incorrect alignment or adjustments can lead to uneven soil penetration and inefficient operation. Operators should regularly check the settings and positioning of the components to ensure they are correctly calibrated. Neglecting this aspect can result in subpar performance and increased strain on the machinery.

Replacement Options for Worn Parts

Over time, components within machinery can experience wear and tear, leading to decreased efficiency and performance. It is crucial to address these issues promptly to maintain optimal functionality. There are several avenues to consider when replacing aged elements, ensuring your equipment remains reliable and effective.

Identifying Suitable Alternatives

When it comes to finding appropriate replacements, it’s important to evaluate various options that can meet the specific needs of your machinery:

- OEM Components: Original equipment manufacturer parts are designed specifically for your model, ensuring compatibility and performance.

- Aftermarket Solutions: Many third-party manufacturers produce alternatives that may offer similar quality at a more competitive price.

- Used Parts: Salvaged components from older machines can provide a cost-effective solution if they are in good condition.

Considerations for Replacement

Before making a decision on replacements, consider the following factors:

- Quality: Ensure the replacement parts meet or exceed the original specifications.

- Warranty: Look for options that come with a warranty, providing peace of mind regarding their durability.

- Cost: Balance the cost against the expected lifespan and performance to make an informed choice.

Comparative Analysis of Different Models

This section provides an in-depth examination of various agricultural implements, focusing on their unique features and functionalities. By comparing these models, users can better understand how each design caters to specific farming needs, ensuring optimal performance and efficiency in field operations.

Model A showcases advanced engineering with enhanced durability, making it suitable for challenging soil conditions. Its innovative design allows for greater soil penetration and uniform tillage, resulting in improved crop yields.

In contrast, Model B emphasizes versatility, equipped with adjustable components that enable quick modifications based on different agricultural tasks. This adaptability makes it a preferred choice for farmers seeking a multi-functional tool.

Model C stands out with its compact structure, ideal for smaller fields or tight spaces. Despite its size, it incorporates powerful features that provide effective soil management without compromising on quality.

Ultimately, each model presents distinct advantages, allowing users to select the one that aligns best with their specific agricultural practices and operational requirements. Understanding these differences is crucial for making informed decisions in equipment selection.

Importance of Genuine John Deere Parts

Utilizing authentic components in machinery is crucial for maintaining optimal performance and longevity. These high-quality elements are specifically designed to meet the stringent standards of the manufacturer, ensuring that the equipment operates efficiently and reliably.

Quality Assurance

Genuine components undergo rigorous testing and quality control measures. This guarantees that they will withstand the demands of rigorous use and contribute to the overall functionality of the machine. Non-authentic alternatives may compromise durability and lead to premature failures, ultimately affecting productivity.

Warranty Protection

Using authentic components helps protect the manufacturer’s warranty. In the event of an issue, using non-genuine elements may void warranty coverage, resulting in costly repairs. Ensuring that only certified components are used safeguards investments and provides peace of mind.

| Criteria | Genuine Components | Non-Genuine Components |

|---|---|---|

| Quality Control | Strict testing and standards | Variable quality |

| Performance | Optimized for specific machinery | May lead to inefficiencies |

| Warranty | Maintains manufacturer coverage | Risk of voiding warranty |

| Longevity | Designed for durability | Shorter lifespan |

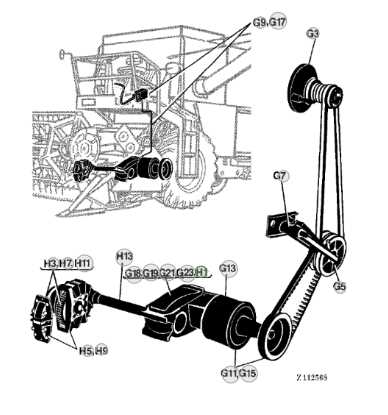

Diagrams and Visual References

This section aims to provide essential illustrations and visual aids that enhance the understanding of various components and their configurations. Visual representations play a crucial role in comprehending complex systems and ensuring accurate assembly or maintenance procedures.

Utilizing schematics and graphical depictions can significantly simplify troubleshooting processes and enhance user comprehension. Clear and detailed visuals allow users to identify specific elements more effectively, leading to better-informed decisions when dealing with repairs or modifications.

These resources are invaluable for anyone seeking to gain a deeper insight into the workings of the machinery, facilitating a more efficient approach to handling tasks associated with upkeep and enhancement.

Assembly Instructions for the Disc

This section provides essential guidance for the assembly of the cultivation implement. Following these steps will ensure proper alignment and functionality, leading to optimal performance during use.

Before starting the assembly process, it is crucial to gather all necessary components and tools. Ensure that you have a clean workspace to facilitate efficient assembly and avoid misplacing any parts.

| Step | Description |

|---|---|

| 1 | Begin by attaching the main frame to the support brackets. Ensure the bolts are securely fastened for stability. |

| 2 | Install the cutting elements onto the frame. Align each piece carefully and tighten the fastening mechanisms. |

| 3 | Connect the adjustment levers to the designated positions on the frame, allowing for easy manipulation during operation. |

| 4 | Finally, conduct a thorough inspection to verify that all connections are tight and that there are no loose components. |

Once the assembly is complete, it is advisable to perform a test run to ensure everything functions as intended. Make any necessary adjustments before putting the implement into full operation.

Resources for Parts and Support

When maintaining machinery, having access to reliable resources for components and assistance is essential. Numerous options are available to ensure the proper functioning and longevity of your equipment. These resources can include online platforms, local suppliers, and official service centers that provide guidance and materials necessary for effective repairs and upgrades.

Online Platforms: Various websites offer extensive catalogs and schematics to help identify the required items. Users can search for specific components, compare prices, and read reviews to make informed purchasing decisions. Some platforms even provide video tutorials and customer support to enhance the overall experience.

Local Suppliers: Establishing a relationship with nearby vendors can be advantageous. They often have a deep understanding of the equipment and can recommend suitable items. Additionally, local suppliers may offer quick access to items that are not readily available online, minimizing downtime.

Official Service Centers: For those seeking expert advice and authentic components, authorized service centers are invaluable. They have trained personnel who can diagnose issues, suggest the right materials, and perform repairs. Utilizing these centers can ensure that the equipment continues to operate at optimal levels.

By exploring these resources, owners can maintain their machinery effectively, ensuring that it remains in peak condition for years to come.

Expert Recommendations for Upgrades

Improving the efficiency and functionality of agricultural machinery can significantly enhance performance and longevity. By considering various enhancements, operators can optimize their equipment for better productivity and reliability. This section outlines key recommendations to consider when upgrading components.

1. Assessing Current Components

Before implementing upgrades, it’s essential to evaluate existing elements. This assessment helps in identifying areas that require improvement. Consider the following:

- Age and condition of the components

- Performance issues encountered during use

- Compatibility with potential upgrades

2. Recommended Upgrades

Once the evaluation is complete, operators can consider specific enhancements that can lead to better performance:

- Improved Cutting Blades: Upgrading to high-quality, durable blades can enhance cutting efficiency and reduce maintenance needs.

- Enhanced Gearbox: Investing in a reliable gearbox can improve power transfer and overall efficiency.

- Advanced Attachment Options: Consider adding specialized attachments for versatility in various tasks.

- Monitoring Systems: Implementing technology to monitor performance in real time can provide valuable insights for future improvements.