In the world of farming machinery, having a thorough grasp of the individual elements that make up each implement is crucial for optimal functionality and maintenance. Recognizing how these components interact can significantly enhance performance and longevity. This guide aims to provide clarity on the various sections involved in modern agricultural tools.

Visualization of these components allows operators and technicians to troubleshoot issues effectively, ensuring that every piece operates in harmony. Whether you are a seasoned professional or a newcomer, mastering these details is essential for achieving the ultimate efficiency in your agricultural practices.

As we explore this topic, we will delve into the specifics, examining each segment and its role in the overall system. Gaining insights into these intricacies will empower users to make informed decisions regarding repairs and enhancements.

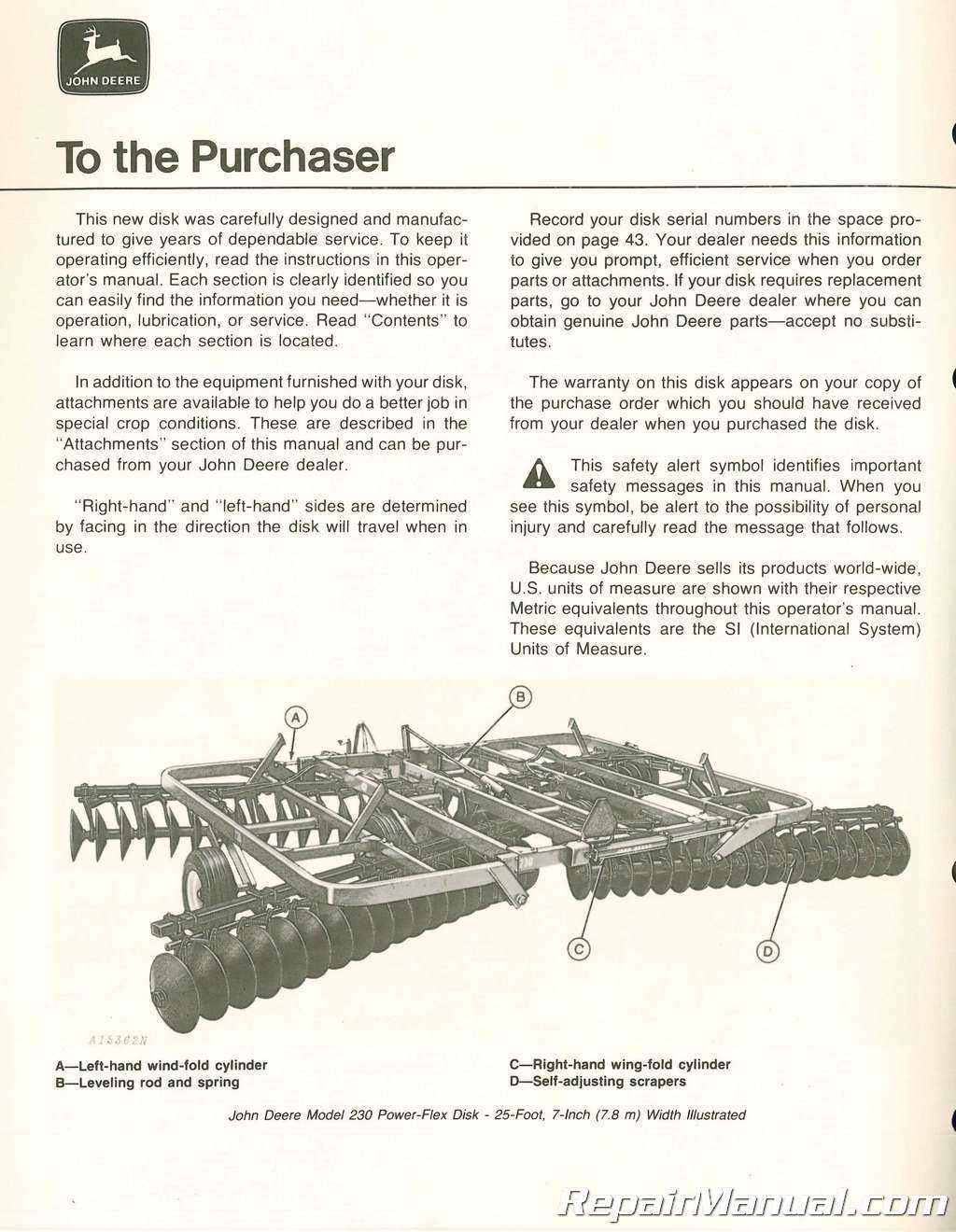

Understanding the John Deere 230 Disc

This section delves into the essential features and components of a specific agricultural implement, highlighting its significance in soil preparation and management. Grasping the mechanics behind this tool can enhance operational efficiency and ensure optimal performance in various farming tasks.

Key Features

- Durable construction designed for heavy-duty usage

- Adjustable settings for varying soil conditions

- Efficient design for enhanced maneuverability

- Versatile application across different farming environments

Common Components

- Frame: Provides structural integrity and support

- Blades: Essential for cutting and tilling the soil

- Hitch: Connects the implement to the towing vehicle

- Gang Assemblies: Arranged in configurations to optimize performance

Understanding these elements aids in maintenance and troubleshooting, ensuring longevity and effectiveness of the implement in agricultural operations.

Components of the 230 Disc

This section explores the essential elements that contribute to the functionality and efficiency of the implement. Understanding each component’s role helps in maintaining optimal performance and ensuring longevity.

Key Elements

- Frame: Provides structural support and stability.

- Blades: Crucial for cutting and turning the soil.

- Bearings: Facilitate smooth rotation of moving parts.

- Hitch: Connects the implement to the towing vehicle.

- Scrapers: Prevent soil buildup on blades.

Maintenance Considerations

- Regularly inspect bearings for wear.

- Check blade sharpness and replace if necessary.

- Ensure frame integrity to avoid malfunctions.

- Monitor hitch connections for safety.

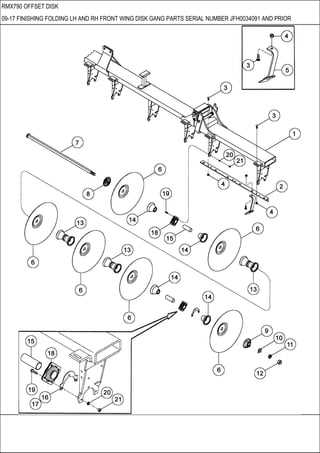

Importance of Accurate Parts Diagrams

Precision in visual representations of components is crucial for effective maintenance and repair operations. These illustrations serve as vital references, guiding users through the intricate details of assembly and disassembly. When every element is clearly marked and accurately depicted, the likelihood of errors diminishes significantly, leading to improved efficiency and reliability in machinery performance.

Moreover, accurate schematics enable technicians to identify the correct components quickly, reducing downtime and minimizing the risk of costly mistakes. A well-crafted visual guide not only enhances understanding but also fosters confidence among operators, allowing them to tackle repairs with assurance. In a fast-paced environment, such clarity can be the difference between seamless operation and unexpected interruptions.

Furthermore, detailed representations can aid in training new personnel, ensuring they grasp the complexities of machinery without overwhelming them. By providing a straightforward, visual approach to learning about various elements, these illustrations play a pivotal role in skill development and knowledge retention. Ultimately, the value of precise component representations cannot be overstated in the context of maintenance and operational excellence.

Common Issues with 230 Disc Parts

Various challenges can arise with the components of agricultural equipment designed for soil cultivation. Understanding these issues is essential for maintaining optimal performance and extending the lifespan of the machinery. Frequent problems can lead to decreased efficiency and increased downtime, making it vital for operators to be aware of potential faults.

One prevalent concern is the wear and tear of blades, which can affect the cutting ability and overall effectiveness. Regular inspection and timely replacement of worn-out blades can mitigate this issue. Additionally, improper alignment of the attachments can result in uneven soil disruption, leading to inconsistent field conditions.

Another issue often encountered is the accumulation of debris around the components, which can hinder movement and functionality. Ensuring regular cleaning and maintenance can help prevent this buildup. Lastly, inadequate lubrication of moving parts can lead to increased friction and wear, emphasizing the importance of adhering to recommended maintenance schedules.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in machinery maintenance and repair. These visual aids provide a clear representation of components, helping users identify parts and their functions. Familiarity with these images can significantly streamline the process of ordering replacements and ensuring proper assembly.

Interpreting Symbols and Labels

Each illustration typically includes various symbols and labels that correspond to specific elements within the machinery. Familiarizing yourself with these notations is crucial, as they often indicate part numbers, sizes, and other relevant details. Pay close attention to the legend, as it offers essential explanations for the symbols used in the visual representation.

Identifying Relationships Between Components

The layout of the illustration shows how different elements interact and fit together. Analyzing the arrangement can help you understand the assembly process and pinpoint any potential issues during disassembly or reassembly. By recognizing how components connect, you can enhance your troubleshooting skills and ensure optimal functionality.

Replacing Worn Parts Effectively

Maintaining machinery involves regularly updating components that show signs of wear. This practice ensures optimal performance and longevity, reducing the risk of unexpected breakdowns. By recognizing when to replace items and understanding the process, operators can enhance efficiency.

Identifying Wear and Tear

- Visual Inspection: Regularly check for cracks, dents, or signs of fatigue.

- Performance Monitoring: Notice any changes in functionality or efficiency.

- Sound Analysis: Unusual noises may indicate a need for replacement.

Replacement Process

- Gather Tools: Ensure you have all necessary equipment before starting.

- Follow Manufacturer Guidelines: Adhere to specific instructions for the best results.

- Test After Replacement: Always run a performance check to confirm the fix.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. Implementing proper maintenance practices can significantly extend its lifespan and enhance performance.

- Regular Inspection: Frequently check all components for wear and damage.

- Cleanliness: Keep the machinery free from dirt, debris, and residue.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction.

- Storage: Protect the equipment from harsh weather conditions when not in use.

- Adjustments: Periodically verify and adjust settings for optimal functionality.

By adhering to these guidelines, you can delve deeper into the maintenance routine and ultimately achieve a reliable operation over time.

Where to Find Genuine Parts

Locating authentic components for your agricultural machinery is crucial for maintaining optimal performance and longevity. Quality parts ensure that your equipment operates efficiently and safely. Below are some reliable sources to explore for obtaining genuine items.

Authorized Dealers

Visiting authorized dealerships is one of the best ways to find legitimate components. These establishments offer:

- Expert guidance and support

- Direct access to manufacturer warranties

- A wide selection of high-quality items

Online Marketplaces

Several online platforms specialize in providing original components. Consider the following options:

- Manufacturer’s official website

- Reputable e-commerce sites

- Dedicated agricultural parts suppliers

Upgrading Your John Deere Equipment

Enhancing your agricultural machinery can significantly boost performance and efficiency. Investing in modern components and technologies not only improves functionality but also prolongs the lifespan of your equipment. With various options available, making informed choices is essential for optimal results.

Consider the benefits of upgrading systems such as hydraulics, electronics, or attachments. These enhancements can lead to increased productivity and reduced maintenance costs. Additionally, staying current with innovations ensures your machinery remains competitive in the market.

Before proceeding, evaluate compatibility with existing machinery to ensure seamless integration. Researching reputable suppliers and reviewing user feedback can guide you in selecting the best upgrades. Ultimately, well-planned enhancements can transform your equipment into a powerhouse on the field.

Cost Considerations for Repairs

When it comes to maintenance and restoration of agricultural machinery, understanding the financial implications is crucial. Various factors can influence the overall expenses associated with repairs, from labor costs to the price of components. Evaluating these elements can aid in making informed decisions that enhance equipment longevity.

Labor Costs: The expense of hiring skilled technicians can vary significantly based on location and expertise. Investing in qualified personnel can prevent further damage and additional costs in the long run.

Component Quality: Choosing between original and aftermarket parts can impact the budget. While cheaper alternatives may seem attractive, they might compromise performance and durability.

Frequency of Repairs: Assessing how often repairs are needed can provide insight into whether to continue patching up existing machinery or consider investing in new equipment.

Ultimately, careful planning and budgeting are essential to managing repair costs effectively, ensuring that machinery remains operational without unexpected financial burdens.

User Experiences and Reviews

This section delves into the thoughts and feedback shared by users regarding a popular agricultural implement. Many operators emphasize the importance of understanding the functionality and reliability of such equipment to make informed decisions.

Positive Feedback: Numerous users have praised the efficiency and performance of the machinery, highlighting its robust construction and ease of use. Many found it to be a valuable asset for their farming practices.

Challenges Encountered: Some operators have reported difficulties with specific components, noting that maintenance can be a challenge. However, most agree that regular upkeep significantly enhances overall performance.

Overall Impression: User reviews often point to a balance between functionality and maintenance, providing potential buyers with a comprehensive overview to guide their purchases.