In the realm of machinery, having a comprehensive grasp of various components is essential for optimal performance and maintenance. This section aims to provide a detailed overview of the intricacies involved in the functionality of a specific type of construction equipment.

Mechanisms and their corresponding elements play a crucial role in ensuring seamless operation. By exploring the layout and relationships between these elements, operators and technicians can enhance their understanding and troubleshooting skills.

Whether you’re an experienced professional or a novice, delving into the schematic representation of these components will ultimately empower you to make informed decisions regarding repairs and upgrades, ensuring longevity and efficiency in your operations.

Understanding the John Deere 245 Loader

This section explores the essential aspects of a popular piece of heavy machinery designed for various agricultural and construction tasks. The equipment’s structure and functionality are critical for maximizing efficiency in daily operations. By grasping the components and their interrelations, operators can enhance performance and ensure longevity.

Key Features and Benefits

The machine is equipped with advanced capabilities that streamline various processes. Its powerful lifting mechanism enables users to handle substantial loads with ease, making it ideal for both farm and site work. Moreover, the versatility offered by different attachments allows for tailored solutions to meet specific needs.

Maintenance and Care

Proper upkeep is vital for sustaining operational efficiency. Regular inspections of critical components ensure that the equipment remains in peak condition. Operators should familiarize themselves with the essential elements to avoid unexpected breakdowns and extend the machinery’s lifespan.

Key Components of the Loader

The effectiveness of a construction machine relies heavily on its fundamental elements, each playing a crucial role in overall functionality. Understanding these core components enhances operational efficiency and ensures proper maintenance.

One vital element is the lifting mechanism, which enables the machine to raise and lower materials smoothly. Coupled with this is the bucket, designed for optimal material handling, offering various shapes and sizes for different tasks. Additionally, the hydraulic system serves as the powerhouse, facilitating movement and control through fluid pressure.

Support structures, such as the chassis, provide stability and strength, while the drive system allows for agile maneuvering across various terrains. Each of these parts is integral to the seamless operation of the equipment, highlighting the importance of comprehensive knowledge for users and technicians alike.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. The advantages of choosing original over aftermarket alternatives can significantly impact operational efficiency.

- Quality Assurance: Genuine items are manufactured to meet specific standards, ensuring reliability.

- Perfect Fit: These components are designed to fit seamlessly, reducing the risk of mechanical issues.

- Longevity: Authentic parts typically last longer, minimizing the need for frequent replacements.

- Warranty Protection: Using original components often helps maintain manufacturer warranties.

- Enhanced Safety: Genuine items reduce the risk of malfunctions, promoting safer operation.

Investing in authentic components is ultimately a wise choice for maintaining machinery integrity and performance.

Common Issues with Loader Parts

When operating heavy machinery, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems is crucial for maintaining optimal functionality and ensuring longevity. Below, we explore typical issues that arise with essential components and provide insights for effective troubleshooting.

Wear and Tear

One of the most prevalent concerns is the natural degradation of components over time. Frequent usage can lead to diminished effectiveness and potential failures. Regular inspections are necessary to identify signs of fatigue and address them promptly to prevent costly repairs.

Hydraulic System Failures

Hydraulic systems are vital for operation, but they can encounter several complications, such as leaks, pressure drops, and fluid contamination. These issues can severely hinder performance. Ensuring proper maintenance and fluid quality is essential for reliable operation.

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Excessive Wear | Reduced efficiency, unusual noises | Regular inspections, replace worn components |

| Hydraulic Leak | Puddles under machinery, low fluid levels | Check seals and hoses, repair leaks immediately |

| Fluid Contamination | Discoloration of fluid, erratic movement | Change hydraulic fluid, check filters |

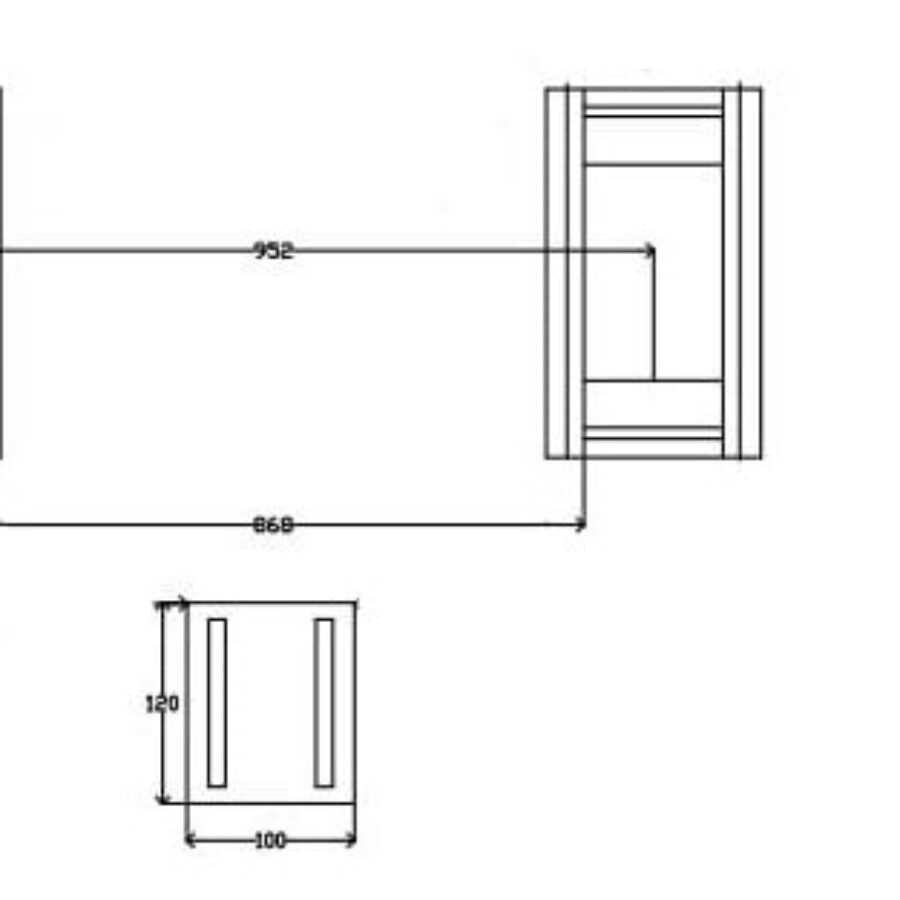

How to Access the Parts Diagram

To effectively navigate the components of your machinery, obtaining a visual reference is essential. This guide will outline the steps to locate detailed schematics that provide insights into the assembly and individual elements of your equipment.

Start by visiting the manufacturer’s official website, where you can often find a dedicated section for resources and manuals. Utilize the search function by entering the model or type of your equipment. Additionally, consider checking online forums and community resources, as they frequently share links to valuable documentation.

If you prefer printed resources, local dealerships or authorized service centers may offer catalogs that include these visuals. Always ensure that you have the correct model information handy to streamline your search for accurate resources.

Importance of Regular Maintenance

Routine upkeep is crucial for ensuring the longevity and efficiency of machinery. Regular checks and servicing can prevent minor issues from escalating into significant problems, ultimately safeguarding the investment made in equipment. By adhering to a consistent maintenance schedule, operators can enhance performance and reduce downtime.

Moreover, maintaining equipment not only maximizes operational efficiency but also improves safety for users. Regular inspections can identify potential hazards and ensure that all components function correctly, contributing to a secure working environment. Ultimately, this proactive approach leads to better reliability and extends the overall lifespan of the machinery.

Tips for Identifying Replacement Parts

When it comes to finding suitable components for your equipment, understanding the nuances of identification can save you time and effort. Whether you’re dealing with a malfunction or simply looking to upgrade, knowing how to pinpoint the correct elements is crucial for seamless operation.

First, consult the user manual or service guide for your machinery. These documents typically include detailed information about compatible components, specifications, and part numbers. Make sure to keep these references handy during your search.

Next, examine the existing components closely. Look for any serial numbers or identifying marks that can help narrow down your options. Taking high-quality photos can also assist when consulting with suppliers or forums for advice.

Utilizing online resources can be incredibly beneficial. Many manufacturers and aftermarket suppliers provide searchable databases where you can enter your equipment’s model information to find appropriate replacements. Engaging with online communities can also yield insights from other users who have faced similar challenges.

Lastly, don’t hesitate to reach out to local dealers or specialized retailers. Their expertise can guide you to the right solutions and ensure compatibility with your specific model, helping you avoid costly mistakes.

Comparing Aftermarket vs. OEM Parts

When it comes to machinery maintenance, the choice between alternative and original components is crucial for optimal performance. Each option presents its own advantages and disadvantages, influencing not only the functionality of the equipment but also the long-term costs and reliability.

Original components are manufactured by the same company that produced the machinery. They typically offer assurance of quality, compatibility, and adherence to specific standards set by the manufacturer. These components are often recommended for those seeking to maintain the integrity and longevity of their equipment.

On the other hand, alternative components are produced by third-party manufacturers and can provide a more economical solution. They may offer similar performance at a lower price, appealing to budget-conscious operators. However, the quality can vary significantly, and potential risks include reduced durability and compatibility issues.

Ultimately, the decision hinges on individual priorities such as budget constraints, performance requirements, and maintenance expectations. Careful consideration of these factors can help in making an informed choice that aligns with operational needs.

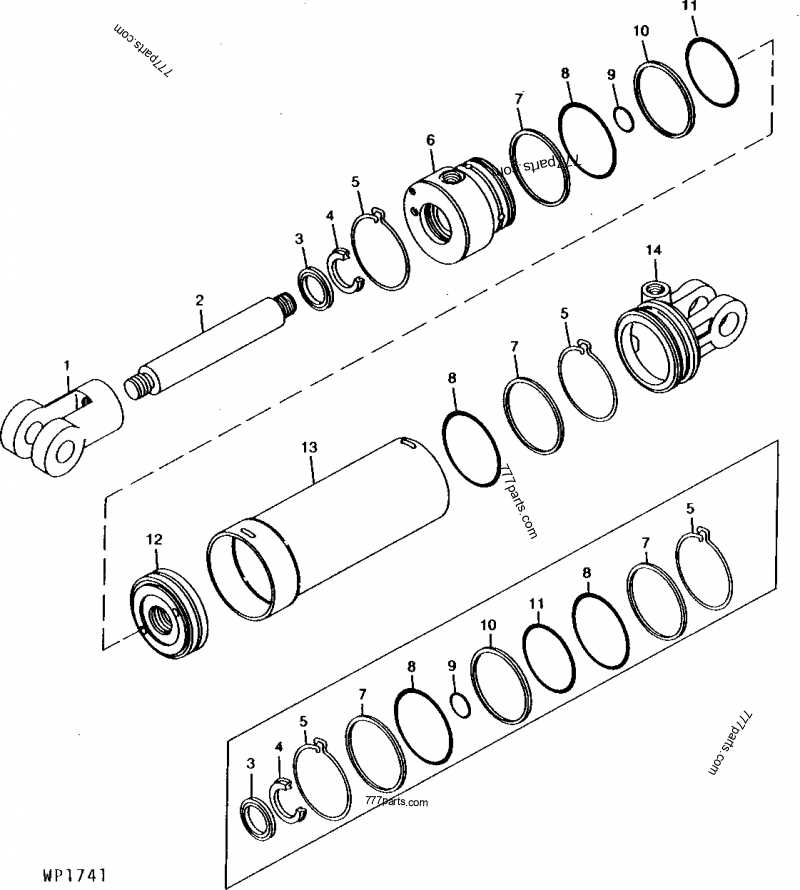

Assembly Instructions for Key Components

Assembling essential machinery components requires precision and attention to detail. This section provides step-by-step guidance to ensure proper installation and functionality of crucial elements. Follow these instructions carefully to achieve optimal performance.

Preparation Steps

- Gather all necessary tools and equipment.

- Ensure that the workspace is clean and free from debris.

- Review the assembly manual for any specific guidelines related to the components.

Assembly Process

- Start by aligning the main frame with the designated support brackets.

- Secure the frame using bolts and nuts, ensuring they are tightened to the specified torque.

- Attach the hydraulic cylinder to the appropriate mounting points, confirming proper alignment.

- Connect the control linkage, making sure it moves freely without obstruction.

- Install any additional components, such as hoses or electrical connections, following the layout provided in the manual.

Upon completion, double-check all connections and fittings to confirm everything is secure. Regular maintenance will enhance longevity and performance.

Finding Reliable Suppliers

When seeking components for heavy machinery, locating trustworthy vendors is crucial for ensuring quality and longevity. A dependable supplier not only provides genuine items but also enhances the overall maintenance experience. Establishing a solid relationship with these sources can lead to better service and exclusive insights into product innovations.

Research is essential in identifying reputable providers. Start by exploring online platforms, industry forums, and reviews from other customers. Look for suppliers with a proven track record and positive feedback regarding their service and product quality.

Additionally, consider local options as they often offer quicker access to needed items and may provide personalized support. Engaging with local businesses can foster a community-based approach that benefits both parties.

Finally, always verify the warranty and return policies of potential suppliers. A reliable vendor will stand behind their products, offering clear terms for replacements or refunds. This not only protects your investment but also builds confidence in the supplier’s commitment to customer satisfaction.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance and repairs is essential to prevent accidents and injuries. Proper precautions help create a secure environment, enabling efficient work without unforeseen risks. Familiarizing oneself with safety guidelines and utilizing protective equipment is crucial for every task.

Essential Safety Gear

Wearing appropriate safety gear can significantly reduce the risk of injury. This includes items that protect the head, eyes, ears, hands, and feet.

| Safety Equipment | Purpose |

|---|---|

| Hard Hat | Protects against head injuries from falling objects |

| Safety Glasses | Prevents eye injuries from debris |

| Hearing Protection | Reduces exposure to loud noises |

| Gloves | Protects hands from cuts and abrasions |

| Steel-Toed Boots | Prevents foot injuries from heavy objects |

Work Area Safety

Maintaining a clean and organized workspace is vital. Ensure that tools and materials are properly stored, and avoid clutter that can lead to tripping or accidents. Proper lighting and ventilation are also important factors to consider.

Upgrading Your John Deere Equipment

Enhancing your machinery can significantly improve performance and efficiency. By integrating modern components and technology, you can ensure that your equipment remains reliable and effective in tackling demanding tasks.

Benefits of Upgrading

Investing in new features can lead to better productivity, reduced downtime, and increased safety. Upgraded models often come equipped with advanced functionalities that streamline operations and minimize wear and tear.

Choosing the Right Upgrades

Consider the specific needs of your projects and evaluate which enhancements will provide the ultimate benefit. Researching available options and consulting with experts can help you make informed decisions for optimal results.