The intricate systems of agricultural machinery play a vital role in ensuring efficient operations on the field. Understanding the layout and functionality of various elements is crucial for both maintenance and repair. This section delves into the essential aspects of a specific model, offering a detailed look at its structure.

From the engine to the transmission, each section is designed to optimize performance and durability. Familiarizing oneself with these components can enhance not only the operational efficiency but also the longevity of the equipment. In this exploration, we will highlight significant features and their interconnections, enabling users to grasp the overall mechanics involved.

For enthusiasts and professionals alike, having access to a comprehensive representation of the machinery’s elements serves as an invaluable resource. Whether you are troubleshooting or upgrading, this information can guide you through the complexities of assembly and functionality.

This section aims to provide a comprehensive outline of a renowned agricultural machine, detailing its components and functionalities. Understanding these elements is crucial for effective maintenance and operation, ensuring optimal performance for various farming tasks.

1. Introduction to the Model

Discover the significance of this agricultural equipment in modern farming practices.

2. Key Specifications

- Engine details

- Weight and dimensions

- Power output

3. Major Components

Explore the essential parts that contribute to the functionality of the machine.

- Transmission system

- Hydraulic components

- Electrical systems

4. Maintenance Practices

Understand the best practices for ensuring longevity and efficiency.

5. Troubleshooting Common Issues

- Engine performance problems

- Hydraulic system failures

- Electrical malfunctions

6. Upgrading Components

Learn about potential upgrades to enhance machine efficiency and performance.

7. Safety Considerations

Review critical safety measures to observe during operation and maintenance.

8. Parts Availability

Find out where to source quality components for repairs and upgrades.

9. Comparisons with Similar Models

- Strengths and weaknesses

- Market positioning

10. User Experiences

Read testimonials and reviews from operators to understand practical aspects.

11. Conclusion

Summarize the importance of familiarizing oneself with the various components to ensure effective use and care.

Key Features of the Model

This agricultural machine stands out due to its robust design and exceptional functionality. Its engineering ensures reliability and efficiency, making it a valuable asset for various farming tasks.

Durability is one of the primary characteristics, allowing it to withstand harsh working conditions. The materials used in construction contribute to its longevity, ensuring it can handle heavy loads over extended periods.

Another significant aspect is its versatility. The equipment can adapt to a range of applications, from tilling to transporting materials, providing users with a multifunctional tool for their farming needs.

Moreover, the model is designed with user-friendly controls that enhance the overall operating experience. This feature simplifies the learning curve for new operators, allowing for efficient and effective use from the start.

Additionally, fuel efficiency plays a crucial role in the operational costs, making it an economical choice for farmers. This aspect not only reduces expenses but also minimizes environmental impact, aligning with modern sustainability practices.

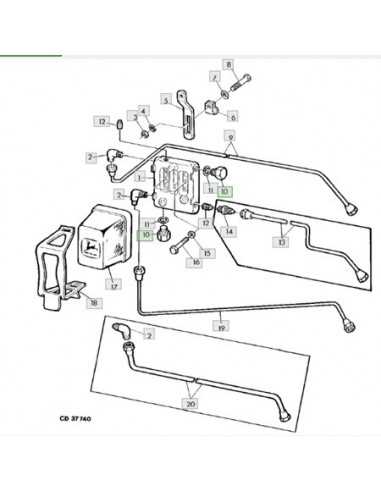

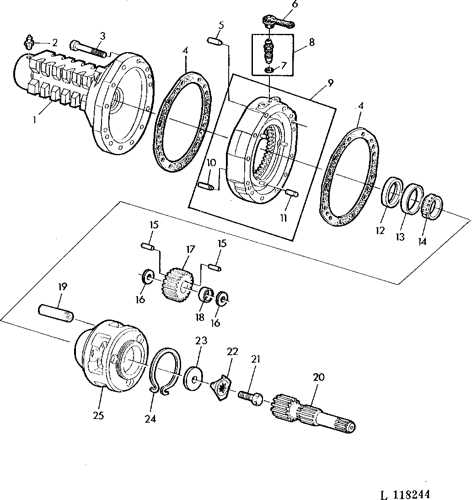

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and enthusiasts alike, enabling them to identify specific elements and their functions within the overall system. These illustrations facilitate a deeper comprehension of how each element interacts, leading to more efficient troubleshooting and servicing.

Clarity and Accuracy: Detailed visuals provide a clear overview of the various elements, reducing the likelihood of errors during maintenance. Technicians can quickly reference the images to ensure that they are working on the correct components, thus streamlining the repair process.

Enhanced Communication: These visual aids foster better communication among team members, particularly in collaborative repair environments. When everyone can refer to the same reference material, discussions become more focused and productive, resulting in faster resolutions to mechanical issues.

Time Efficiency: By utilizing visual references, technicians save time that would otherwise be spent searching for specific parts or understanding their layout. This efficiency ultimately leads to quicker turnaround times for repairs and maintenance, allowing operators to minimize downtime.

Resource for Training: Illustrations serve as valuable educational resources for those new to the field. They provide a foundational understanding of machinery components, helping trainees to grasp complex concepts more easily. This foundational knowledge can lead to increased confidence and competence in their roles.

Understanding Component Identification

Accurate recognition of various elements within machinery is essential for effective maintenance and repair. This process involves familiarizing oneself with the individual components that make up a machine, allowing for better diagnostics and efficient troubleshooting. By grasping the layout and functionality of these parts, operators can ensure optimal performance and longevity of the equipment.

Key Elements of Recognition

Each component serves a specific purpose, contributing to the overall functionality of the system. Familiarity with the shape, size, and positioning of these elements aids in quick identification during inspections. Moreover, understanding how these parts interact enhances the operator’s ability to detect potential issues before they escalate.

Importance of Clear Labeling

Proper labeling and organization of components play a significant role in the identification process. Clear markings assist technicians in locating specific parts swiftly, reducing downtime and improving efficiency during repairs. Investing time in understanding these labels fosters a more productive environment, ultimately benefiting the maintenance workflow.

Common Parts in John Deere 2750

Understanding the essential components of agricultural machinery is crucial for effective maintenance and operation. Each piece plays a vital role in the overall functionality and performance of the equipment. Familiarity with these elements helps users make informed decisions about repairs and upgrades.

Key elements include the engine assembly, transmission system, and hydraulic components, all of which contribute to the efficiency and reliability of the machinery. Additionally, the electrical system and drivetrain are integral for seamless operation, ensuring that the equipment meets the demands of various agricultural tasks.

Regular inspection of these crucial components is essential for preventing downtime and extending the lifespan of the machinery. By maintaining these key elements, operators can ensure optimal performance and avoid costly repairs, ultimately enhancing productivity on the farm.

Maintenance Guidelines for Components

Ensuring the longevity and efficiency of machinery requires careful attention to various elements that comprise its structure. Regular upkeep is essential for preventing premature wear and optimizing performance. Following proper maintenance practices can significantly enhance reliability and reduce the risk of unexpected failures.

1. Regular Inspections: Conduct frequent evaluations of all critical components to identify signs of wear, damage, or corrosion. Look for loose connections, fluid leaks, and any irregularities in operation. Early detection of issues can save time and resources.

2. Lubrication: Proper lubrication is vital for reducing friction between moving parts. Utilize recommended lubricants and adhere to specified intervals for applying them to ensure smooth operation and extend the lifespan of the equipment.

3. Cleaning: Maintain cleanliness by regularly removing debris and contaminants from surfaces. Dirt accumulation can lead to overheating and hinder performance. Ensure that filters and cooling systems are clear to promote optimal functionality.

4. Component Replacement: Identify components that have reached the end of their service life and replace them promptly. Using quality replacement parts is crucial for maintaining operational integrity and efficiency.

5. Documentation: Keep detailed records of maintenance activities, including inspections, replacements, and repairs. This documentation not only aids in tracking performance but also assists in planning future maintenance schedules.

By adhering to these guidelines, operators can effectively prolong the service life of their equipment and enhance overall productivity.

Finding Replacement Parts

When it comes to maintaining machinery, identifying suitable components is crucial for ensuring optimal performance. Whether you’re dealing with a malfunction or simply conducting routine maintenance, knowing where to locate the right elements can save time and effort.

Online Resources

- Manufacturer’s Website: Many manufacturers provide a comprehensive list of available components on their official websites, complete with specifications.

- Parts Retailers: Various online retailers specialize in machinery components, offering detailed catalogs that allow you to filter by model and type.

- Forums and Communities: Engaging with online communities can yield valuable insights and recommendations on where to find specific items.

Local Suppliers

- Authorized Dealers: Visiting authorized dealers ensures access to genuine components tailored for your equipment.

- Salvage Yards: These facilities often have a range of used components at lower prices, which can be ideal for budget-conscious repairs.

- Local Hardware Stores: Some stores may stock common components or be able to order them for you.

By exploring these avenues, you can effectively source the required items to keep your equipment running smoothly.

Sources for Authentic Parts

Finding reliable sources for genuine components is crucial for maintaining the functionality and longevity of machinery. Quality replacements ensure optimal performance and reduce the risk of malfunctions. Below are several avenues to explore when searching for authentic items.

- Authorized Dealers: Local authorized distributors often provide original equipment manufacturer (OEM) items. These dealers can guarantee authenticity and typically offer support and advice for installation.

- Manufacturer’s Website: Visiting the official website of the equipment manufacturer can yield access to a catalog of genuine components. Many manufacturers offer online purchasing options directly from their platforms.

- Industry Trade Shows: Attending relevant exhibitions allows you to connect with manufacturers and suppliers who specialize in authentic products. Such events often feature new technologies and innovations in the industry.

- Online Marketplaces: Established e-commerce platforms frequently have sections dedicated to OEM items. When using these sites, ensure the seller is reputable and verify product authenticity through reviews and ratings.

- Local Repair Shops: Many repair facilities have established relationships with suppliers of genuine components. Consulting with a professional can provide insights into where to find reliable replacements.

By exploring these options, you can secure high-quality replacements that uphold the integrity of your equipment.

Installation Tips for Parts

Ensuring the proper setup of components is crucial for optimal performance and longevity. Following a few guidelines can significantly enhance the installation process and help avoid common pitfalls.

Preparation Before Installation

- Read the instruction manual thoroughly to understand the specific requirements.

- Gather all necessary tools and materials ahead of time to streamline the process.

- Inspect the new components for any damage or defects before proceeding.

Steps for Effective Installation

- Begin with cleaning the area where the components will be installed to prevent contamination.

- Follow the manufacturer’s guidelines for placement and alignment, ensuring a snug fit.

- Secure all fasteners adequately to avoid any looseness during operation.

- After installation, test the functionality to confirm everything operates as intended.

Troubleshooting Common Issues

This section addresses frequent challenges encountered with agricultural machinery and offers insights into their resolution. By understanding typical problems and their symptoms, users can effectively maintain their equipment and enhance performance.

Below is a table outlining some common issues, their possible causes, and recommended solutions:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, fuel issues, or faulty ignition | Check battery charge, ensure fuel flow, and inspect ignition components |

| Overheating | Low coolant level, clogged radiator, or malfunctioning thermostat | Inspect coolant level, clean the radiator, and test the thermostat |

| Poor Performance | Dirty air filter, fuel contamination, or incorrect settings | Replace the air filter, check fuel quality, and adjust settings as needed |

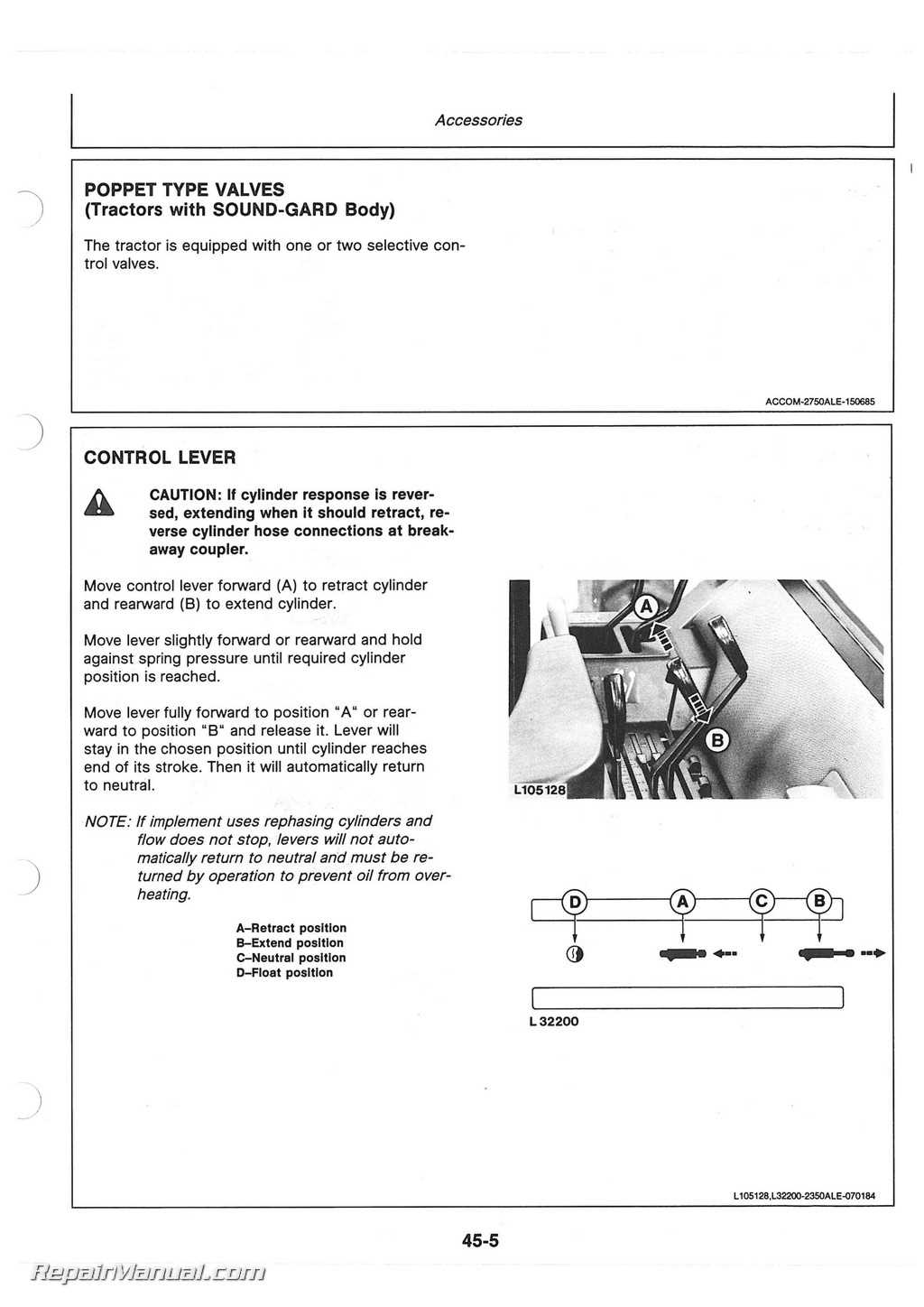

| Hydraulic Issues | Low fluid level, leaks, or air in the system | Top up hydraulic fluid, check for leaks, and bleed the system |

Upgrades and Enhancements Available

In the realm of agricultural machinery, there exists a wide array of modifications and improvements that can significantly boost performance and efficiency. These enhancements are designed to elevate the functionality of your equipment, ensuring that it operates at its best while meeting the evolving demands of modern farming practices.

From advanced technology integrations to improved components, operators can choose from various options to tailor their machinery to their specific needs. Below is a table highlighting some popular upgrades and their benefits:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Modifications | Enhancements to increase horsepower and torque. | Improved efficiency and productivity during heavy tasks. |

| Hydraulic System Upgrades | Upgrading pumps and valves for better fluid flow. | Increased lifting capacity and faster cycle times. |

| Cab Comfort Enhancements | Installation of ergonomic seats and climate control. | Enhanced operator comfort and reduced fatigue. |

| Precision Farming Technology | Integration of GPS and monitoring systems. | Optimized planting and fertilization processes. |