In the realm of machinery, comprehending the intricate elements that contribute to optimal performance is essential for effective maintenance and operation. A thorough grasp of these components can enhance productivity and extend the lifespan of your equipment.

Visual aids play a pivotal role in this understanding, offering clear representations of the various sections and features. Such resources allow operators and technicians to quickly identify and address issues, ensuring that the machinery runs smoothly.

By exploring the intricacies of your equipment’s assembly, you can delve into the ultimate details that facilitate seamless functionality. This knowledge empowers users to make informed decisions about repairs and upgrades, ultimately leading to better operational efficiency.

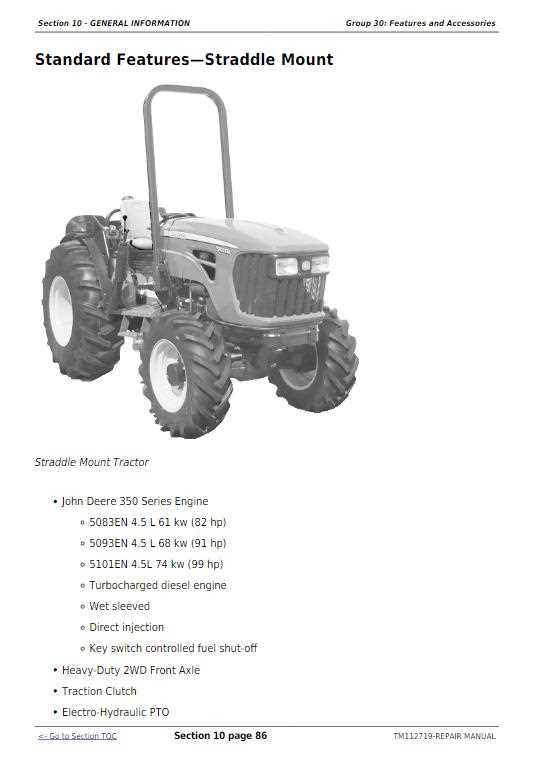

Understanding John Deere 300CX Loader

This section explores the essential aspects of a popular agricultural implement designed for various tasks. With its robust design and versatile functionality, it

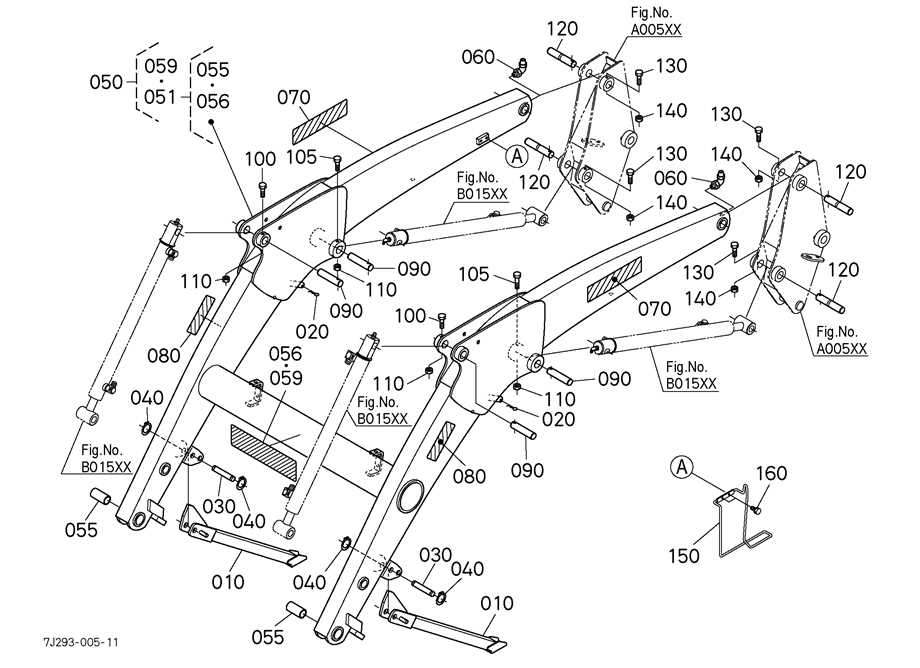

Importance of Parts Diagrams

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clear guidance on each element’s placement and function. These illustrations simplify complex structures, allowing operators to identify specific pieces and their interconnections easily.

Efficiency is significantly enhanced when utilizing these visual aids. Technicians can quickly locate the required elements, reducing the time spent searching for parts or understanding their roles. This not only streamlines repairs but also minimizes the risk of errors during reassembly.

Furthermore, training becomes more effective with these resources. New employees or less experienced individuals can familiarize themselves with the machinery more rapidly. By studying these visuals, they gain a better grasp of how various components work together, ultimately leading to improved skill levels and confidence.

In addition, having a reliable reference fosters safety. Knowing the exact location and function of components helps prevent accidents caused by improper handling or assembly. Overall, these visual guides are invaluable assets in the upkeep and functionality of any mechanical equipment.

Key Components of the 300CX Loader

This section explores the essential elements that make up the operational framework of the equipment. Understanding these components enhances efficiency and maintenance, ensuring optimal performance during tasks.

| Component | Description |

|---|---|

| Arm | Critical for lifting and moving materials, providing strength and flexibility. |

| Bucket | The primary tool for scooping, carrying, and dumping loads, varying in design for different applications. |

| Hydraulic System | Facilitates powerful movements, controlling the lifting and tilting functions with precision. |

| Frame | The sturdy structure that supports all other components, ensuring stability and durability. |

| Controls | Operator interface that allows for precise management of movements and actions. |

Common Issues with Loader Parts

Operational machinery often encounters various challenges that can hinder performance and efficiency. Understanding these common malfunctions is crucial for timely maintenance and ensuring the longevity of the equipment. Addressing issues promptly not only reduces downtime but also enhances overall productivity.

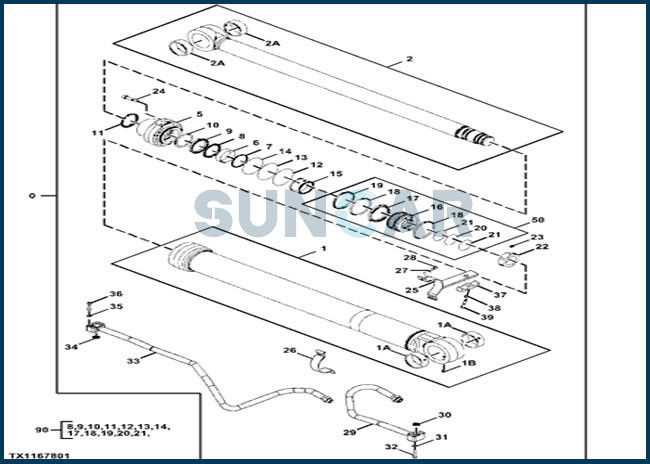

Wear and Tear

One of the most prevalent problems is the natural deterioration of components due to prolonged use. Frequent inspection is essential, as this can prevent unexpected breakdowns. Components like hydraulic cylinders and attachment points are particularly vulnerable and should be monitored closely for signs of wear.

Hydraulic System Failures

The hydraulic system is integral to the functionality of the equipment, and issues here can be quite serious. Leaks and pressure drops often indicate underlying problems. Regular checks and fluid maintenance are key to maintaining the efficiency of this critical system. Ignoring these signs can lead to major operational setbacks.

Where to Find Replacement Parts

When it’s time to replace certain components of your machinery, knowing where to source reliable alternatives is essential. Having a steady supply of compatible items ensures smooth operation and minimizes downtime.

Online Retailers are a convenient option, offering a broad range of items that cater to various machinery models. These platforms often provide detailed descriptions and customer reviews, making it easier to find the right match.

Local dealers and repair shops are another valuable resource. Their expertise can help in identifying suitable components, and they may offer installation services. Plus, their proximity allows for quicker access.

For those seeking affordability, used or refurbished parts from trusted sources can provide a cost-effective solution without sacrificing performance. Always ensure the condition and authenticity before making a purchase.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the durability and long-term performance of your equipment. Regular maintenance practices can significantly extend its lifespan, reduce wear, and prevent unexpected breakdowns. Adopting a routine inspection schedule and following best care practices can keep machinery in top condition for years to come.

Lubrication and Fluid Checks

Ensure that all moving parts are well-lubricated to minimize friction and wear. Periodically check the oil and hydraulic fluid levels, replacing or replenishing as necessary. Using the appropriate type and grade of lubricant is crucial for optimal performance.

Regular Cleaning and Inspection

Frequent cleaning of the equipment helps prevent dirt, debris, and rust buildup, which can lead to malfunctions. After each use, inspect critical components for signs of damage or excessive wear, addressing any issues immediately to avoid costly repairs.

Proactive maintenance and attention to detail will maximize operational efficiency and extend the life of your machine

How to Interpret Diagrams Effectively

Understanding visual representations of components or systems is essential for solving problems and performing maintenance tasks. Clear comprehension of these images can save time and prevent errors during assembly or repairs.

- Start by identifying key elements of the illustration. This includes labels, symbols, and numbers that provide guidance.

- Focus on the relationships between different parts. Recognizing how each element connects or interacts helps form a complete understanding of the whole structure.

- Break down complex sections into smaller, manageable parts. Analyze these individually to ensure that no details are overlooked.

- Locate the legend or key provided, which explains symbols and abbreviations. Refer to this as needed throughout the process.

- Follow the flow of the diagram from one section to another, ensuring you interpret the connections accurately.

- If instructions accompany the image, cross-reference them with the visual to confirm each step is clearly understood.

DIY Repairs for the 300CX

Handling your own equipment maintenance can save time and money, especially when it comes to common wear and tear. With the right tools and a little knowledge, you can address many issues on your own, ensuring that your machinery remains in optimal working condition. This guide provides practical advice for tackling essential fixes and replacements, avoiding costly service calls.

Essential Tools and Preparation

Before starting any repairs, it’s crucial to gather the necessary tools and create a clean workspace. Having the right wrenches, sockets, and grease on hand will make the process smoother. Additionally, ensure the equipment is parked on a level surface and properly secured to prevent accidents during repairs.

Common Issues and How to Fix Them

Many issues, such as hydraulic leaks or worn-out fittings, can be resolved with simple parts replacements or adjustments. For hydraulic leaks, inspect the hoses and fittings for cracks or wear. Replacing damaged components and ensuring tight connections will restore the system’s integrity

Tools Required for Loader Maintenance

Proper maintenance of heavy equipment is crucial for ensuring its longevity and optimal performance. Having the right tools on hand is essential for completing maintenance tasks efficiently and safely. Below is a list of essential equipment you will need to maintain your machine effectively.

- Wrenches and sockets: These are fundamental for loosening and tightening bolts and nuts of various sizes.

- Grease gun: Essential for lubricating joints and moving parts to reduce friction and prevent wear.

- Hydraulic fluid: Regularly checking and refilling hydraulic systems helps maintain smooth operation.

- Torque wrench: This tool ensures bolts and fasteners are tightened to the correct specifications, preventing over-tightening or under-tightening.

- Safety gloves and goggles: Personal protective equipment (PPE) is crucial for safety while handling sharp or hazardous components.

- Pressure gauge: Used to check the tire pressure and hydraulic systems, ensuring they are within the recommended range.

- Oil filter wrench:

Upgrading Your Loader’s Performance

Enhancing the efficiency and capability of your equipment can greatly improve productivity and reduce operational strain. Regular updates and strategic modifications allow for better handling, increased lifting power, and smoother control, contributing to a more reliable and durable machine.

Upgrade Option Benefits Hydraulic System Enhancement Improves lifting capacity and operational speed Attachment Adjustments Optimizes tool versatility and adaptability Reinforced Frame Increases durability for heavy-duty tasks Safety Precautions During Repairs

When working on heavy machinery, ensuring safety is critical to prevent accidents and injuries. Proper preparation and adherence to safety protocols are essential before and during any repair tasks. Following these measures can significantly reduce risks and ensure a safer work environment.

Preparing the Work Area

Before beginning repairs, it’s important to inspect and organize the workspace. Make sure the area is free of clutter, and all necessary tools are within reach. Always use appropriate lifting equipment if parts need to be moved or removed. Personal protective equipment (PPE), such as gloves, safety goggles, and helmets, must be worn to safeguard against potential hazards.

Working Safely with Equipment

During repairs, ensure that the machinery is properly deactivated and secured. Lockout/tagout procedures should be followed to prevent accidental activation while work is being done. Be cautious of moving parts and pressurized systems, which can cause injury if handled carelessly. Regularly

Resources for Further Learning

When it comes to exploring the intricate workings of various equipment, having access to the right educational materials can make a significant difference. Understanding the key components and their functionality is crucial for maintaining and troubleshooting machinery. To deepen your knowledge and stay updated, consider leveraging multiple resources that provide insights into both technical and practical aspects.

Online Guides and Tutorials

Numerous platforms offer detailed tutorials, covering everything from basic functionality to advanced repair techniques. Websites dedicated to machinery maintenance often feature step-by-step instructions, video demonstrations, and expert advice. These guides are invaluable for both beginners and seasoned professionals looking to enhance their skill set.

Technical Manuals and Forums

In addition to online tutorials, technical manuals provide in-depth specifications and operational guidelines. Many of these manuals are available through manufacturers’ websites or specialized distributors. Furthermore, online forums and community discussions are excellent spaces for exchanging knowledge, troubleshooting, and learning from experienced individuals.