In the world of construction machinery, comprehending the intricate layouts of equipment is essential for maintenance and repairs. Each machine comprises various components that work together to ensure optimal functionality. Familiarity with these elements not only aids in troubleshooting but also enhances the efficiency of operations.

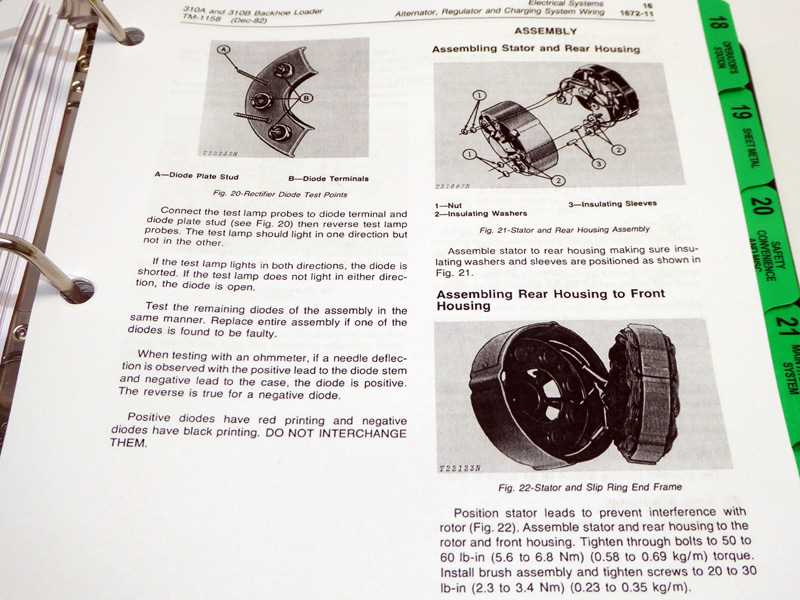

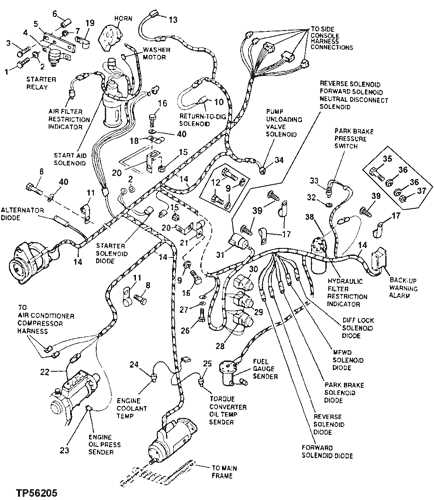

When it comes to heavy machinery, specific illustrations that detail the arrangement of parts play a crucial role. These visuals serve as a valuable resource for technicians and operators, allowing them to pinpoint issues quickly and understand the interconnections between different sections of the equipment. Recognizing how each piece fits into the larger system is fundamental for effective upkeep.

Moreover, these layouts can help in identifying compatible replacements, ensuring that the machinery continues to perform at its best. By studying these schematic representations, one gains insight into the assembly and disassembly processes, paving the way for improved hands-on experience. Mastering the components can lead to enhanced productivity and reduced downtime on the job site.

Understanding John Deere 310A Backhoe

This section aims to explore the essential aspects of a popular earth-moving machine known for its versatility and robust performance in construction and landscaping projects. By examining its components and functionalities, users can appreciate how this equipment operates effectively in various tasks.

Key Features and Capabilities

This machinery is equipped with advanced features that enhance productivity and ease of use. The powerful engine ensures reliable performance, while the hydraulic system enables smooth operation of the digging and lifting attachments. Additionally, its compact design allows for maneuverability in tight spaces.

Maintenance and Care

Proper upkeep is crucial for the longevity of this machine. Regular inspections of the hydraulic fluids, filters, and structural integrity can prevent costly repairs. Implementing a maintenance schedule will ultimately ensure optimal functionality and performance throughout its operational lifespan.

Key Components of the Backhoe

The efficiency and functionality of this versatile construction machine are driven by several critical elements. Understanding these components is essential for optimal performance and maintenance. Each part plays a significant role in the overall operation, contributing to the equipment’s ability to dig, lift, and transport materials effectively.

| Component | Description |

|---|---|

| Bucket | The primary tool used for digging and moving materials, available in various sizes for different applications. |

| Loader Arm | This arm provides the necessary reach and leverage for the bucket, allowing for effective lifting and dumping of loads. |

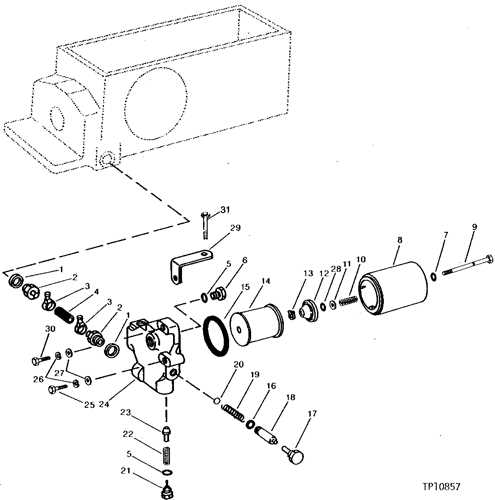

| Hydraulic System | Comprises pumps, hoses, and cylinders that facilitate smooth movement and operation of various components through pressurized fluid. |

| Chassis | The main frame that supports all other components and provides stability during operation. |

| Stabilizers | Extendable legs that secure the machine during operation, enhancing stability and preventing tipping. |

| Cab | The operator’s compartment, designed for comfort and visibility, housing controls and instrumentation for operation. |

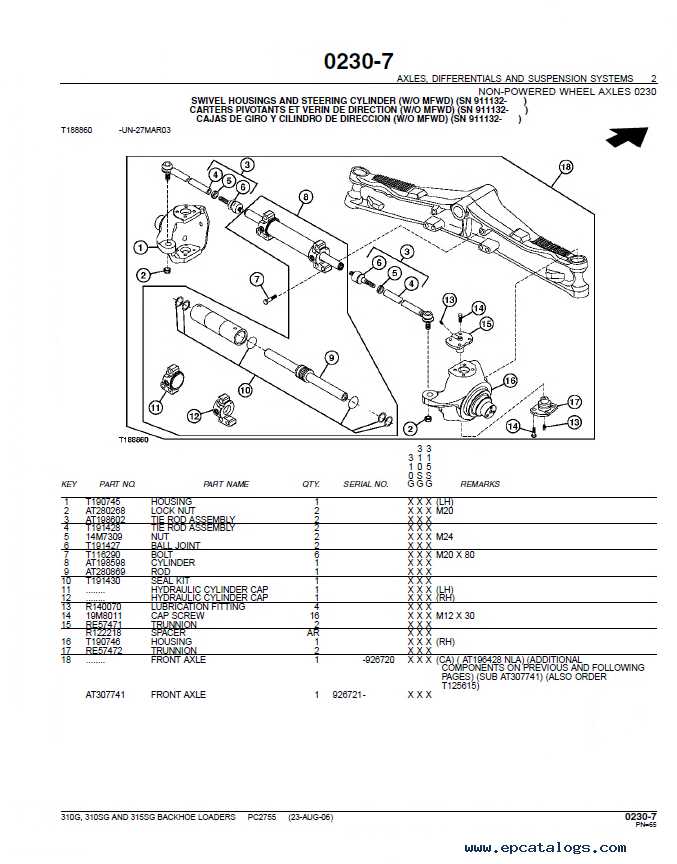

Importance of Accurate Parts Diagram

Having a precise representation of components is crucial for efficient maintenance and repair tasks. It ensures that users can easily identify each element, facilitating a smooth workflow and minimizing the risk of errors.

Enhanced Efficiency

When technicians have access to a clear and detailed schematic, they can quickly locate the necessary components. This not only speeds up the repair process but also reduces downtime, ultimately leading to better productivity.

Reduced Errors

A well-structured representation helps prevent mistakes during reassembly. When each piece is accurately depicted, it becomes easier to ensure that everything fits together correctly, thus avoiding potential damage and costly mistakes.

Common Issues with John Deere 310A

Heavy machinery often encounters a range of challenges that can affect performance and longevity. Understanding these common problems is essential for maintenance and effective operation. Regular inspections and awareness of typical failures can help operators mitigate downtime and costly repairs.

Hydraulic System Problems

One frequent concern involves the hydraulic system, which may experience leaks or pressure loss. Such issues can lead to inadequate lifting capabilities and sluggish response times, necessitating timely repairs to maintain efficiency.

Engine Performance Issues

Another area of concern is engine performance. Symptoms such as rough idling, reduced power, or overheating can indicate underlying problems. Regular servicing and attention to engine components can help prevent significant breakdowns.

Where to Find Parts Diagrams

Locating detailed visual representations of machinery components is essential for effective maintenance and repair. These resources provide insights into the assembly and functionality of various elements, ensuring that users can confidently address any issues that arise.

Online Resources

The internet offers a plethora of websites dedicated to heavy equipment. Many manufacturers host official platforms where you can access schematics and technical manuals. Additionally, numerous forums and communities allow enthusiasts to share valuable information and resources.

Local Dealers and Repair Shops

Visiting local dealerships or repair centers can also yield beneficial information. These establishments often have access to extensive catalogs and may provide printed materials upon request. Engaging with knowledgeable staff can enhance your understanding and help identify the specific components you need.

Identifying Parts by Diagram

Understanding machinery components is crucial for effective maintenance and repair. Visual representations serve as valuable tools in identifying various elements, allowing operators and technicians to recognize each section’s function and location. By analyzing these illustrations, users can enhance their knowledge of the equipment and ensure accurate replacements or adjustments.

Utilizing visual aids can streamline the repair process. Each labeled component provides clarity, reducing the likelihood of errors during assembly or disassembly. This approach not only aids in locating specific items but also fosters a deeper comprehension of the entire system’s layout.

Moreover, familiarity with the schematic promotes efficiency when troubleshooting issues. When problems arise, having the ability to quickly reference the graphical guide can save time and minimize downtime. Overall, these visuals are indispensable for anyone involved in the upkeep of machinery, contributing to both knowledge and operational effectiveness.

Maintenance Tips for 310A Backhoe

Proper upkeep of your excavation equipment is crucial for ensuring longevity and optimal performance. Regular maintenance not only prevents breakdowns but also enhances efficiency during operations. Here are some essential tips to keep your machinery in top shape.

- Regular Inspections: Frequently check all components for wear and tear. Look for signs of leaks, cracks, or corrosion.

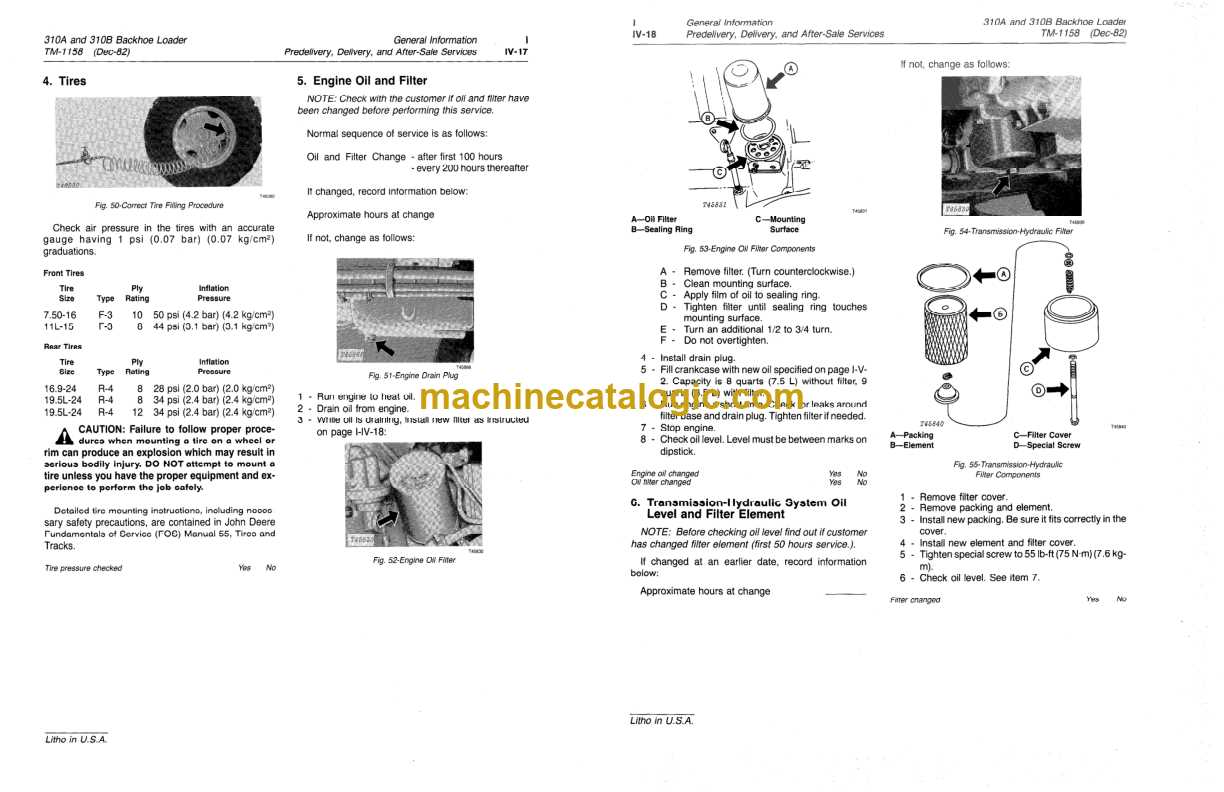

- Fluid Levels: Ensure that hydraulic fluid, engine oil, and coolant are at appropriate levels. Change these fluids according to the manufacturer’s schedule.

- Filter Replacement: Replace air, oil, and hydraulic filters regularly to maintain clean operation and prevent contamination.

- Battery Care: Inspect battery terminals for corrosion and ensure a tight connection. Clean and charge as necessary.

- Tire Maintenance: Check tire pressure and tread condition. Rotate or replace tires when needed to ensure stability and traction.

Implementing these practices can significantly enhance the performance and reliability of your equipment. Always refer to the manufacturer’s manual for specific maintenance schedules and recommendations.

Upgrading Parts for Performance

Enhancing the efficiency and capability of heavy machinery is essential for optimal operation. By selecting superior components, operators can achieve remarkable improvements in functionality, durability, and overall output. This process often involves evaluating existing elements and opting for advanced alternatives that align with specific performance goals.

Performance improvements can be realized through various upgrades, such as reinforced hydraulic systems, more efficient engines, or high-quality wear-resistant materials. Each modification contributes to enhanced power, speed, and reliability, which are crucial for tackling demanding tasks.

Additionally, proper installation and maintenance of upgraded components are vital to ensuring that machinery operates at its best. Investing time in understanding compatibility and specifications can lead to significant long-term benefits, reducing downtime and increasing productivity.

OEM vs. Aftermarket Components

The choice between original and alternative components significantly impacts equipment performance and longevity. Understanding the nuances of these options helps in making informed decisions that align with operational needs and budgetary constraints.

Original Equipment Manufacturer (OEM)

OEM components are crafted by the same manufacturer that produced the original machinery. They ensure:

- Perfect compatibility with existing systems

- Consistency in quality and performance

- Potential warranty benefits

Aftermarket Alternatives

Aftermarket options provide a variety of choices that may offer cost savings. Considerations include:

- Potential for innovation in design

- Variety in pricing and availability

- Risks of variability in quality

Repairing vs. Replacing Parts

When faced with equipment malfunctions, one must consider whether to fix or substitute components. Each option presents distinct advantages and disadvantages, influencing the overall efficiency and cost-effectiveness of machinery maintenance.

- Repairing:

- Cost-effective solution for minor issues.

- Preserves the original structure of the machinery.

- Can extend the life of existing components.

- Replacing:

- Provides an opportunity for upgraded technology.

- Ensures reliability and performance with new components.

- Saves time by eliminating repetitive repairs.

Ultimately, the decision hinges on factors such as the extent of damage, budget constraints, and long-term operational goals.

Cost Considerations for Parts

When maintaining heavy machinery, financial implications play a crucial role in decision-making. Understanding expenses related to components is essential for budgeting and ensuring optimal performance. Analyzing various factors helps in making informed choices that balance quality and affordability.

| Factor | Description |

|---|---|

| Quality | Higher quality components often lead to longer service life, reducing long-term costs. |

| Availability | Readily available items may be less expensive due to lower shipping costs and reduced wait times. |

| Compatibility | Using compatible items can prevent additional modifications, saving time and resources. |

| Supplier Reputation | Purchasing from reputable suppliers may incur higher upfront costs but ensures reliability and support. |

Common Maintenance Tools Required

Proper upkeep of heavy machinery is essential for optimal performance and longevity. A variety of essential tools facilitate effective maintenance, ensuring that equipment operates smoothly and efficiently.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for routine checks and repairs. These instruments enable quick adjustments and replacements, ensuring that components remain secure and functional.

Diagnostic Equipment

Utilizing diagnostic tools is crucial for identifying potential issues before they escalate. Instruments like multimeters and pressure gauges help monitor various system functions, allowing for timely interventions and maintaining peak operational efficiency.

Expert Resources for Backhoe Repairs

Finding reliable information and tools is crucial for effective machinery maintenance and repairs. Accessing quality resources can enhance your understanding and streamline the repair process, ensuring that your equipment remains operational and efficient.

Online Forums and Communities

- Participate in discussions to gain insights from experienced users.

- Share your challenges and receive tailored advice.

- Explore archived threads for solutions to common issues.

Manufacturer Websites

- Access official manuals and technical specifications.

- Utilize online parts catalogs for accurate replacements.

- Check for updates or recalls that may affect your equipment.

Leveraging these resources can significantly improve your repair outcomes and maintenance practices.