Understanding the arrangement of various components in construction machinery is crucial for effective maintenance and operation. This section provides insights into the configuration of essential elements, enabling operators and technicians to quickly identify and access the required parts for service and repair.

By familiarizing oneself with the structural layout, users can enhance their proficiency in troubleshooting issues that may arise during operation. Additionally, this knowledge facilitates informed decisions regarding repairs and replacements, ensuring optimal performance and longevity of the equipment.

Moreover, having a clear representation of the machinery’s assembly can significantly reduce downtime, allowing for efficient handling of maintenance tasks. This resource aims to serve as a practical guide, promoting a deeper understanding of the machinery’s inner workings.

This section provides a comprehensive introduction to the subject matter, focusing on the essential components and their functions within a specific model of excavation machinery. Understanding the various elements involved in the equipment’s design is crucial for maintenance and repair, ensuring optimal performance and longevity.

Key Features of the Equipment

This machinery is designed for efficiency and versatility in various excavation tasks. It includes a range of functionalities that make it suitable for both small and large projects.

Importance of Component Familiarity

Knowing the components is vital for operators and technicians alike. Familiarity with the machine’s anatomy allows for better troubleshooting and maintenance practices.

| Component Name | Description |

|---|---|

| Loader Bucket | Used for lifting and moving materials. |

| Excavator Arm | Enables digging and lifting functions. |

| Hydraulic System | Powers the movement of various components. |

| Chassis | Provides structural support and stability. |

Key Components of the Backhoe

This section delves into the essential elements that comprise a versatile digging machine. Understanding these vital components is crucial for effective operation and maintenance, ensuring optimal performance during various tasks.

Hydraulic System

The hydraulic system is fundamental for powering the various functions of the equipment. It utilizes pressurized fluid to enable the movement of attachments, allowing for efficient digging and lifting. Regular maintenance of this system is necessary to prevent leaks and ensure reliable operation.

Bucket and Arm Assembly

The bucket and arm assembly is designed for digging and loading materials. The shape and size of the bucket can vary depending on the application, and it works in tandem with the arm to provide a wide range of motion. Proper alignment and lubrication of this assembly are vital for achieving desired results and extending its lifespan.

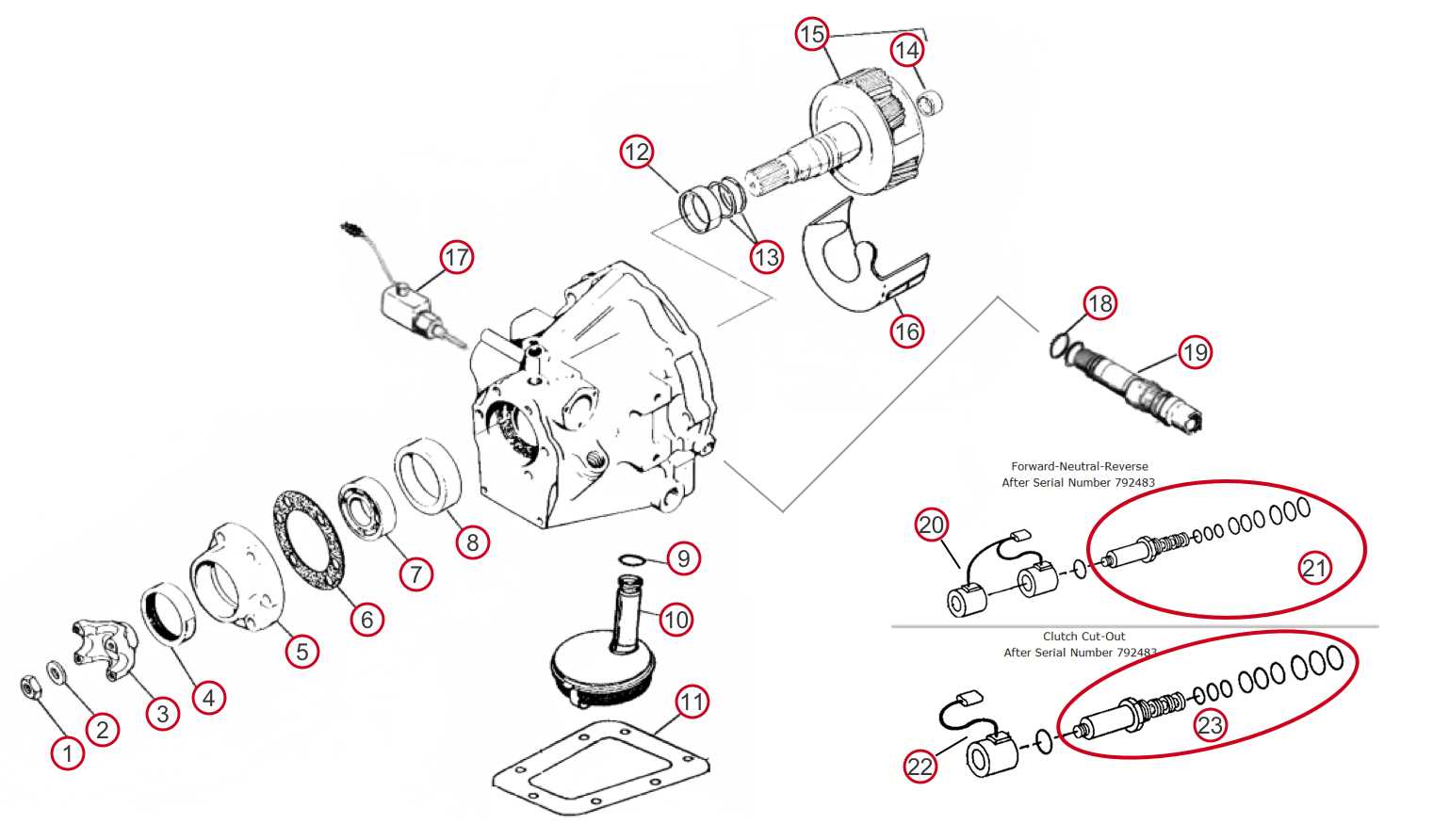

Understanding the Parts Layout

Having a clear grasp of the components arrangement is crucial for effective maintenance and repair of heavy machinery. A well-organized visual representation allows operators and technicians to quickly identify various elements, ensuring efficient troubleshooting and timely interventions.

The arrangement typically includes sections dedicated to major assemblies and subassemblies, facilitating a comprehensive understanding of how each part interacts within the overall structure. Familiarity with this layout enhances the ability to locate specific components swiftly, thus minimizing downtime during repairs.

Additionally, comprehending the spatial distribution of elements aids in recognizing wear patterns and potential failure points. This knowledge empowers users to perform proactive maintenance, extending the lifespan of the machinery and improving operational efficiency.

Common Issues and Solutions

Operating heavy machinery often presents various challenges that can affect performance and efficiency. Understanding these common complications and their corresponding solutions is crucial for maintaining optimal functionality.

Hydraulic System Failures

One prevalent issue involves the hydraulic system, which may exhibit signs of leaks or reduced pressure. Regular inspection of hydraulic hoses and connections can help identify leaks early. If a leak is found, replacing the damaged component promptly is essential to prevent further complications.

Engine Performance Problems

Another frequent concern is engine inefficiency, which can manifest as decreased power or unusual noises. Regular maintenance, including oil changes and filter replacements, is vital. If performance issues persist, a thorough diagnostic check may be necessary to determine if there are underlying mechanical problems.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure optimal performance and extend the lifespan of your equipment. By following a few key practices, you can prevent premature wear and enhance reliability.

- Routine Inspections: Conduct frequent examinations to identify any signs of wear or damage. Early detection can save time and resources.

- Fluid Checks: Regularly monitor and replace fluids such as oil, hydraulic fluid, and coolant. Proper lubrication is crucial for smooth operation.

- Cleaning: Keep all components clean and free from debris. Accumulated dirt can lead to overheating and mechanical failure.

- Proper Storage: When not in use, store the machinery in a dry and sheltered location to protect it from the elements.

- Follow Manufacturer’s Guidelines: Adhere to the maintenance schedule provided by the manufacturer to ensure all recommended tasks are performed timely.

Implementing these strategies will significantly contribute to the durability and efficiency of your machinery, allowing for better performance over time.

Parts Identification and Functions

Understanding the various components and their roles within a construction vehicle is essential for effective maintenance and operation. Each element is designed to fulfill a specific purpose, contributing to the overall functionality of the machine. This section will explore key components, their identification, and the functions they serve.

Key Components Overview

Among the primary elements, you will find hydraulic systems, transmission mechanisms, and structural frames. Each of these components plays a vital role in ensuring the equipment operates smoothly and efficiently. For example, the hydraulic system is responsible for powering various attachments and executing tasks with precision.

Functionality and Importance

The functionality of each component directly influences the performance of the machinery. Proper identification and understanding of these elements allow operators and technicians to troubleshoot issues effectively. Regular inspections and maintenance of these critical parts can enhance the lifespan of the equipment and improve productivity on the job site.

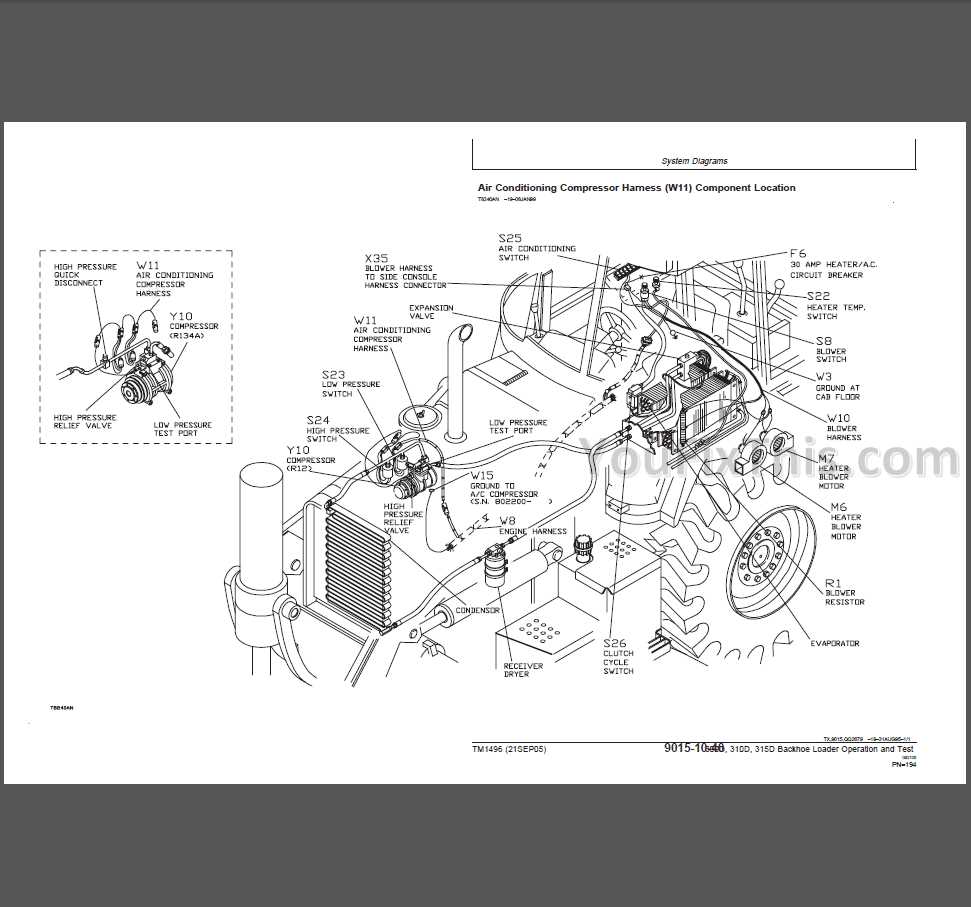

Diagrammatic Representation Explained

The visual illustration of components and their relationships serves as a fundamental tool for understanding complex machinery. This representation allows users to grasp how various elements interact and function together within the system.

Key aspects of these visual aids include:

- Clarity: Simplifies the interpretation of intricate designs.

- Structure: Displays the arrangement and connections of various elements.

- Functionality: Highlights how individual parts contribute to the overall operation.

Such visual guides are invaluable for maintenance, troubleshooting, and repair tasks, enabling users to easily identify specific sections and their respective roles within the machinery.

Where to Find Replacement Parts

Locating suitable components for heavy machinery can significantly enhance its longevity and performance. Various sources provide options for acquiring essential items to ensure seamless operation.

Authorized Dealers: One of the most reliable avenues is through official distributors. These vendors often stock a comprehensive range of components and offer expert assistance, ensuring compatibility with your equipment.

Online Retailers: Numerous e-commerce platforms specialize in machinery supplies. These websites often feature extensive catalogs, enabling you to browse and compare options conveniently from your home.

Local Suppliers: Visiting local hardware stores or specialized machinery shops can be beneficial. They may carry a selection of vital components and provide personalized recommendations based on your specific needs.

Salvage Yards: For those seeking budget-friendly alternatives, salvage yards can be a goldmine. Here, you can find used but functional items that can extend the life of your equipment without breaking the bank.

Online Forums and Communities: Engaging with fellow machinery enthusiasts through online forums can lead to valuable insights. Members often share recommendations for reputable sources and even sell their surplus items.

Comparative Analysis with Similar Models

This section provides an examination of comparable machinery, highlighting their similarities and differences in design, functionality, and performance. Understanding these aspects can aid in making informed decisions regarding equipment selection for various tasks.

Key Similarities

Several models within the same category share common features that enhance their operational efficiency. These similarities often include:

- Hydraulic systems designed for optimal power distribution

- Ergonomic controls for user comfort and accessibility

- Robust construction ensuring durability and longevity

Distinctive Features

Despite their similarities, there are distinctive attributes that set each model apart, such as:

| Model | Engine Power (HP) | Operating Weight (lbs) | Bucket Capacity (cu ft) |

|---|---|---|---|

| Model A | 80 | 10,000 | 1.0 |

| Model B | 75 | 9,500 | 0.9 |

| Model C | 85 | 11,000 | 1.1 |

Analyzing these specifications can help potential users identify which machine aligns best with their specific operational requirements.

Expert Recommendations for Repairs

When it comes to maintaining heavy machinery, seeking professional guidance is crucial for ensuring optimal performance and longevity. Experts emphasize the importance of understanding the various components involved and the specific challenges that may arise during repairs. Utilizing comprehensive resources can facilitate more efficient troubleshooting and execution of tasks.

Prioritize Quality Components

Always opt for high-quality replacement components to ensure the reliability and durability of your machinery. Using subpar parts may lead to frequent breakdowns and additional repair costs over time. Consult with trusted suppliers or manufacturers to identify recommended products that meet industry standards.

Regular Maintenance Practices

Implementing a consistent maintenance schedule is essential for identifying potential issues before they escalate. Regular inspections and timely servicing not only extend the lifespan of the equipment but also enhance its overall functionality. Documenting maintenance activities can also provide valuable insights for future repairs.

Resources for Further Learning

Expanding knowledge about equipment maintenance and repair can significantly enhance your skills and understanding. Numerous resources are available for individuals seeking to deepen their expertise in machinery components and functionality.

- Online Forums: Engage with communities where enthusiasts and professionals discuss various topics related to machinery.

- Manufacturer Manuals: Refer to official guides that provide detailed information on equipment specifications and maintenance procedures.

- Instructional Videos: Explore platforms like YouTube for visual tutorials covering a range of repair techniques and operational insights.

- Technical Books: Invest in literature focusing on mechanical engineering and equipment servicing to build a solid foundation.

- Workshops and Seminars: Attend local training sessions to gain hands-on experience and interact with industry experts.

Utilizing these resources can help enhance your understanding of machinery, improve repair skills, and foster a deeper appreciation for mechanical systems.