The intricate mechanisms behind modern agricultural equipment play a vital role in enhancing efficiency and productivity on the farm. Understanding how each segment contributes to the overall functionality can significantly aid in maintenance and troubleshooting. This exploration delves into the various elements that comprise a specific model of a hay handling machine, offering insights into their roles and interconnections.

From the drive systems to the cutting tools, every component is designed to work in harmony, ensuring seamless operation during the harvesting process. Familiarity with these elements not only helps in effective repairs but also empowers users to make informed decisions regarding upgrades and replacements. By visualizing the layout and relationships between these parts, operators can gain a deeper appreciation for the engineering behind their equipment.

As we navigate through this examination, we will highlight critical features, their functions, and maintenance tips. This knowledge serves as a valuable resource for both seasoned professionals and those new to the agricultural sector, fostering a better understanding of the machinery that drives modern farming practices.

When operating a hay or forage compression machine, several challenges can arise that may affect efficiency and productivity. Understanding these common concerns can help users maintain their equipment in optimal condition, ensuring smooth operation and minimizing downtime.

Mechanical Failures

One of the primary issues operators face is mechanical failure. These malfunctions can stem from various components, leading to performance issues. Common mechanical failures include:

- Worn-out belts causing slipping and inadequate compression

- Faulty bearings leading to increased friction and overheating

- Broken tines affecting the gathering mechanism

- Clogged intake systems resulting in inefficient feeding

Maintenance Oversights

Inadequate upkeep can significantly impact the functionality of the machinery. Regular maintenance checks are crucial to preventing issues. Common oversights include:

- Neglecting lubrication of moving parts, leading to accelerated wear

- Failing to inspect and replace damaged components promptly

- Overlooking adjustments that ensure proper alignment and tension

- Ignoring manufacturer-recommended service intervals

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any agricultural machinery. Regular attention to specific components not only ensures optimal performance but also minimizes the risk of unexpected failures. By following a few simple practices, operators can maximize efficiency and reliability.

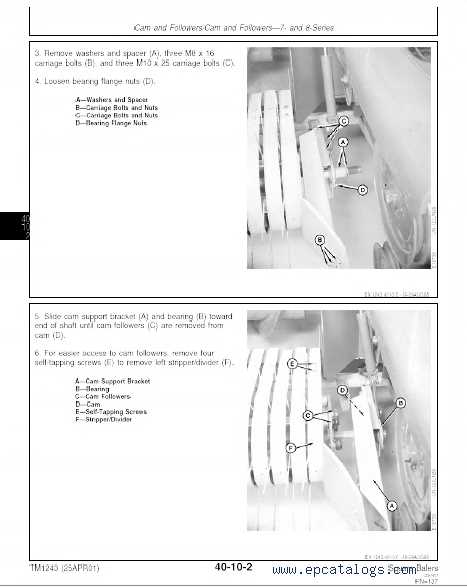

Regular Inspections

Conducting frequent evaluations of equipment is crucial. Look for signs of wear or damage on various elements, such as belts and gears. This proactive approach allows for early detection of potential issues, making repairs easier and less costly.

Lubrication and Cleaning

Keeping machinery clean and well-lubricated significantly enhances performance. Apply the appropriate lubricants to moving parts to reduce friction and prevent premature wear. Additionally, removing debris and buildup from surfaces helps maintain functionality and prevents overheating.

Identifying Replacement Parts

Recognizing components for repair or replacement is essential for maintaining equipment efficiency and longevity. Understanding the key elements of machinery allows operators to quickly identify what needs to be sourced, ensuring smooth operation during peak seasons. This process involves thorough inspection and familiarity with various mechanisms to facilitate timely replacements.

Common Components to Consider

When assessing machinery, focus on frequently replaced elements that may wear out over time. Identifying these components early can prevent unexpected breakdowns and extend the operational life of the equipment.

| Component Name | Function |

|---|---|

| Roller | Facilitates the movement of materials through the system. |

| Gearbox | Transfers power from the engine to operational parts. |

| Belt | Connects various components, transmitting motion and power. |

| Chain | Links together parts, enabling synchronized movement. |

Steps to Identify Necessary Components

Begin with a visual inspection of the equipment to locate any worn or damaged parts. Utilize reference materials such as manuals or online resources that provide detailed illustrations and descriptions. Document the specific characteristics of each component, including dimensions and material type, to ensure accurate replacements.

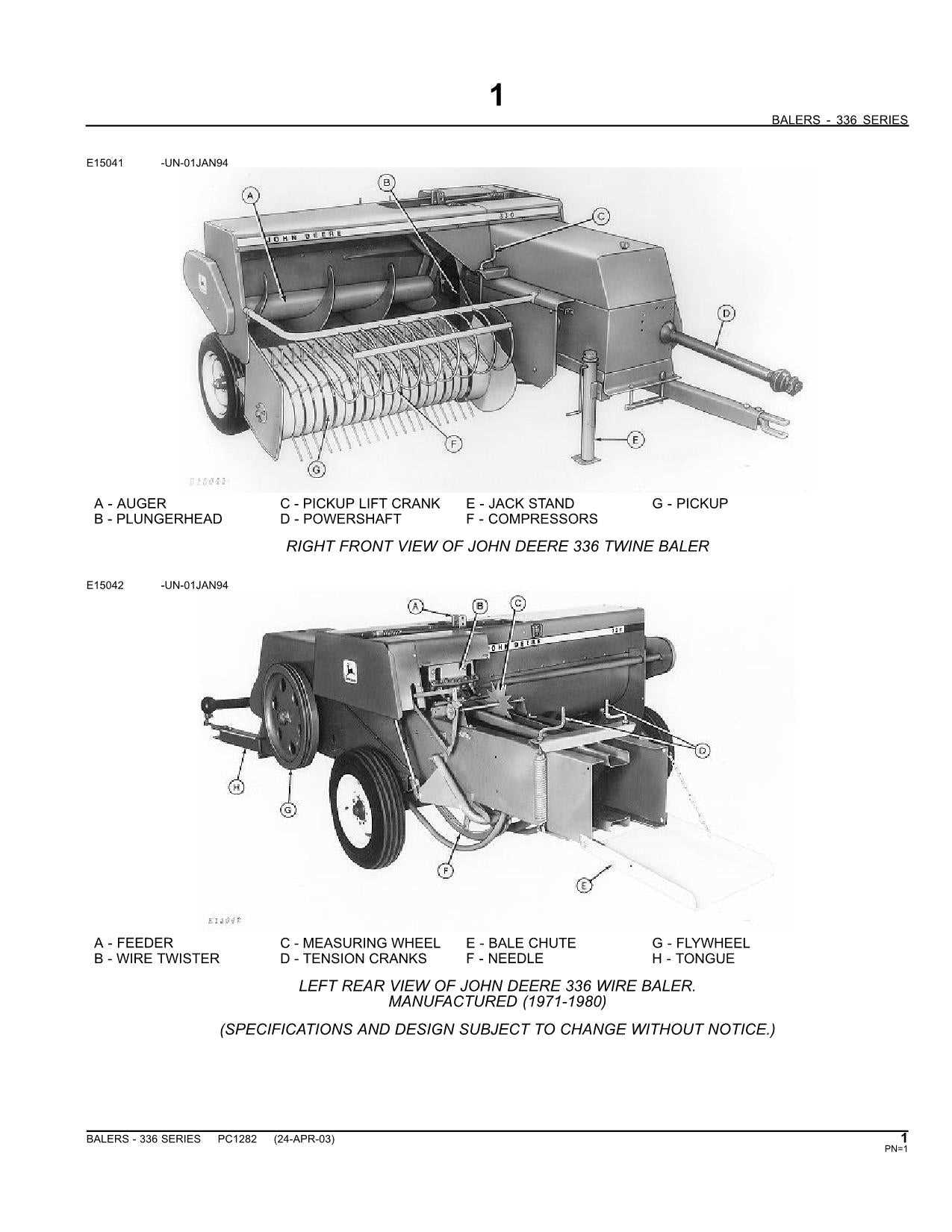

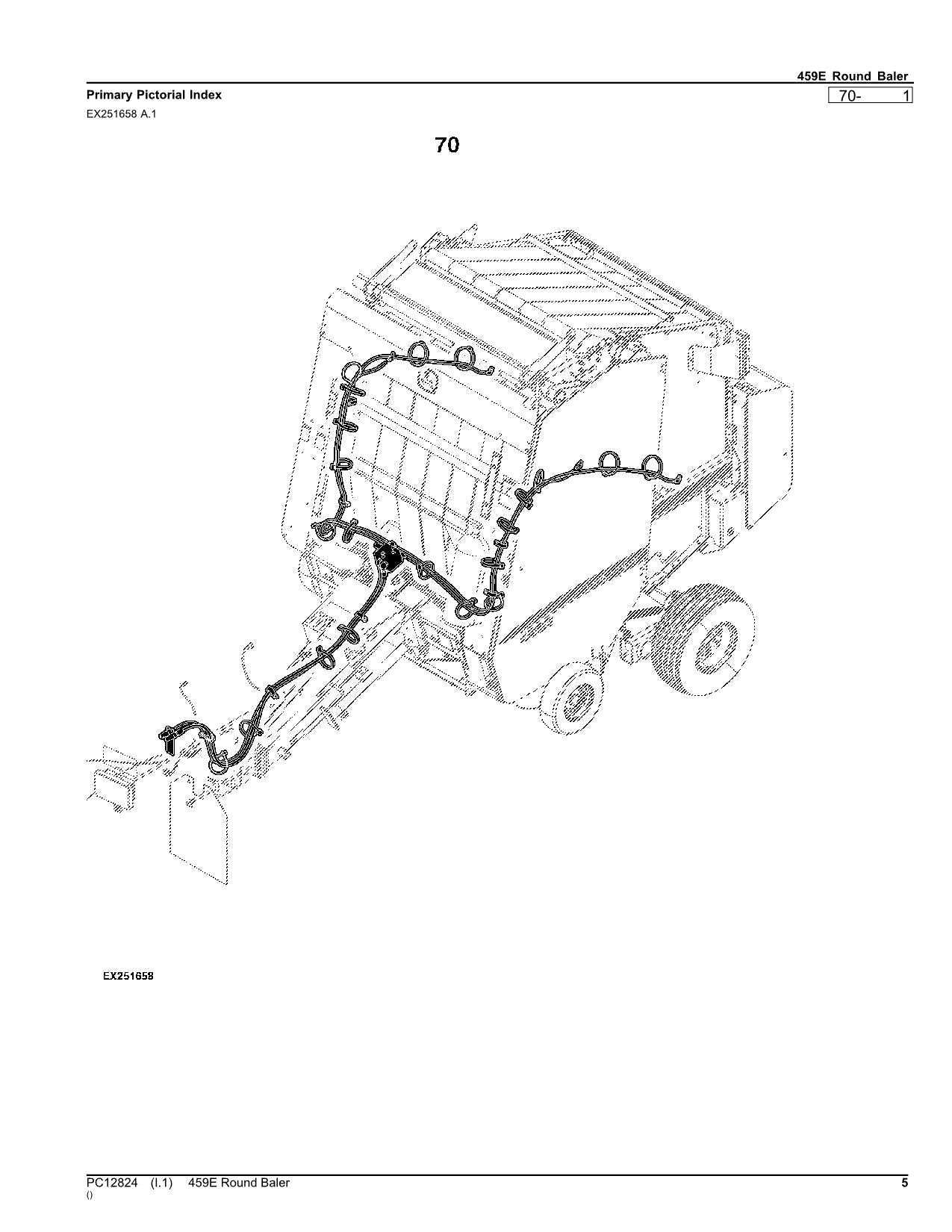

Understanding Baler Functionality

The process of converting loose organic material into compact, manageable units involves a series of intricate mechanisms. These systems work together to gather, compress, and secure the material for easy transport and storage. Understanding how these components interact can enhance operational efficiency and maintenance practices.

Core Components

The primary elements that contribute to the functionality of these machines include the feed mechanism, compression chamber, and tying system. The feed mechanism is responsible for drawing in the loose material, while the compression chamber compacts it into defined shapes. Finally, the tying system secures the compressed units, ensuring stability during handling.

Operational Considerations

Effective operation requires attention to several factors, such as material type, moisture content, and machine settings. Each variable influences the performance and end result, making it crucial for operators to understand how to adjust parameters accordingly. Regular maintenance also plays a vital role in sustaining efficiency and prolonging the lifespan of the equipment.

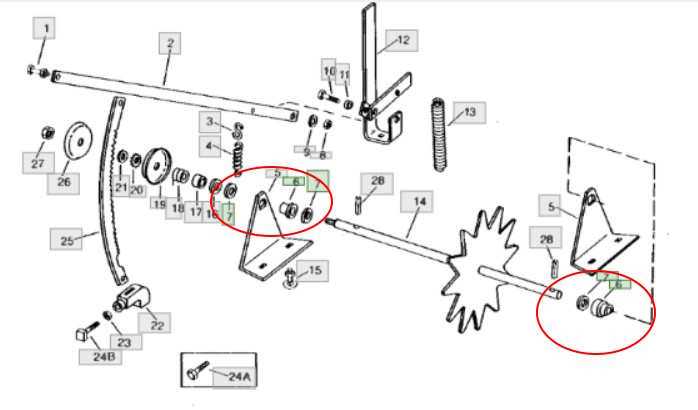

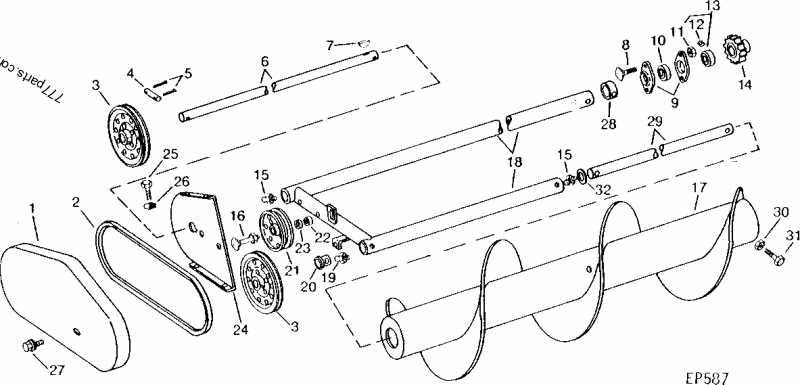

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations serve as valuable guides, helping users identify individual elements and their relationships within a complex assembly. Mastering the interpretation of these visuals can significantly enhance your troubleshooting and replacement efforts.

Key Elements to Look For

- Labels: Each element typically has annotations indicating its name or part number, allowing for easy identification.

- Reference Numbers: Items are often numbered in the illustration, which corresponds to a list that provides further details.

- Connections: Lines or arrows may indicate how components interact or fit together, clarifying assembly sequences.

Steps to Effectively Interpret Visuals

- Begin by familiarizing yourself with the overall layout, noting the major sections of the assembly.

- Identify the components that are most critical to your task, using the labels and reference numbers for guidance.

- Cross-reference the visual with accompanying documentation to gather additional details about each element’s function and specifications.

- Take notes on any specific configurations or arrangements that may impact installation or troubleshooting.

Comparative Analysis with Other Models

This section delves into the distinctions and similarities among various machinery models, focusing on design, functionality, and user experience. By evaluating these aspects, users can better understand which equipment best suits their operational needs and preferences.

Design and Build Quality

When comparing the structural integrity and craftsmanship of different models, certain designs stand out for their durability and ease of maintenance. While some machines emphasize lightweight construction for mobility, others prioritize robust materials to withstand harsh working conditions. This balance between weight and strength is crucial in selecting the right equipment for specific agricultural tasks.

Performance and Efficiency

Performance metrics vary significantly among machinery types, influencing operational efficiency. Some models are designed for high throughput, allowing for greater productivity during peak seasons. In contrast, others may focus on fuel efficiency or lower maintenance costs, appealing to users seeking long-term savings. Analyzing these performance attributes can help determine which model offers the best return on investment for specific farming operations.

Where to Find Genuine Parts

Finding authentic components for your machinery is crucial to ensure optimal performance and longevity. Sourcing high-quality replacements can help maintain efficiency and reliability, minimizing downtime during operation. Here are some recommended avenues for obtaining these essential items.

Authorized Dealers

One of the most reliable sources for original components is through authorized dealers. These establishments often have extensive inventories and provide expert advice on the correct items needed for specific models.

Online Retailers

Numerous online platforms specialize in selling genuine components for agricultural machinery. These websites often feature detailed descriptions and compatibility information, allowing users to select the right items conveniently from the comfort of their homes.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Expert advice, assurance of quality | Potentially higher prices |

| Online Retailers | Convenience, often competitive pricing | Need to verify authenticity |

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and repair of agricultural machinery. Understanding the key components and their functions can significantly enhance the efficiency of operations.

What are the main components of this agricultural implement?

The machinery consists of several essential elements, including the feeding mechanism, cutting system, and collection unit. Each plays a vital role in ensuring optimal performance.

How can I identify worn or damaged components?

Regular inspection is crucial. Look for signs of wear such as cracks, rust, or unusual noises during operation. These indicators can help pinpoint parts that may need replacement or repair.

Where can I find replacement components?

Replacement elements can be sourced from authorized dealers, online marketplaces, or specialized suppliers. Ensure that the components meet the required specifications for compatibility.

How often should maintenance be performed?

Routine maintenance should be conducted based on usage frequency. Typically, it is advisable to perform checks before and after the harvesting season to ensure all mechanisms function smoothly.

Can I perform repairs myself?

Many repairs can be conducted by individuals with basic mechanical skills. However, for complex issues, it is recommended to consult a professional technician to avoid further complications.