In the realm of agricultural machinery, having a clear grasp of the various components is crucial for efficient operation and maintenance. This knowledge not only aids in the seamless performance of the equipment but also enhances the longevity of its use.

Familiarity with individual elements allows operators to quickly identify issues and implement effective solutions. Such understanding empowers farmers to maximize their productivity while minimizing downtime and repair costs.

Moreover, a detailed exploration of these elements can reveal insights into optimal usage practices and necessary precautions, ensuring that the machinery operates at its ultimate efficiency. Engaging with these insights ultimately leads to a more effective and sustainable farming experience.

Overview of John Deere 37 Sickle Mower

This segment provides an insight into a particular agricultural implement known for its efficiency in cutting grass and crops. Designed to enhance productivity on farms, this machine plays a vital role in various harvesting processes.

The key features of this equipment include:

- Robust construction for durability and longevity.

- Easy maneuverability in diverse terrains.

- Efficient cutting mechanism ensuring a clean finish.

- Compatibility with various tractors for versatile use.

Understanding the components and functionality of this implement is crucial for farmers seeking to maximize their operational efficiency. Proper maintenance and care will not only extend its lifespan but also improve performance.

In conclusion, this implement is an essential asset for those in the agricultural sector, simplifying the process of cutting and harvesting with its innovative design and reliable operation.

Importance of Mower Parts Diagram

Understanding the components of agricultural equipment is essential for effective maintenance and repair. A visual representation of these elements facilitates easier identification and troubleshooting, ultimately leading to more efficient operation.

Clear Communication: A well-structured illustration enhances communication among technicians and operators, reducing the chances of misunderstandings.

Streamlined Repairs: When individuals can quickly locate and understand the various components, it simplifies the repair process and minimizes downtime.

Comprehensive Knowledge: Familiarity with the equipment’s structure not only aids in immediate repairs but also fosters a deeper understanding of its functionality and performance.

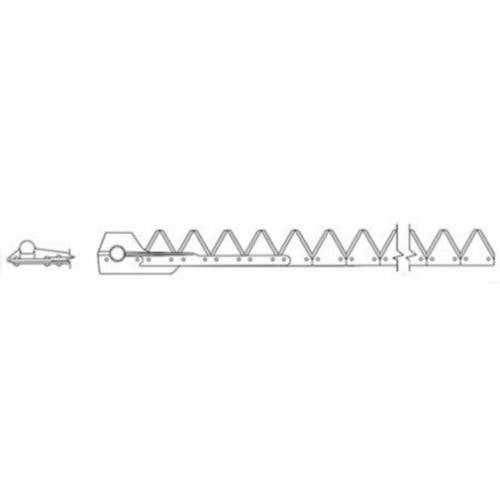

Key Components of the Sickle Mower

The efficient operation of a grass-cutting machine relies on several crucial elements that work together harmoniously. Understanding these components can enhance maintenance and improve performance, ultimately leading to more effective agricultural practices.

Cutting Mechanism

The cutting mechanism is the heart of the machine, designed to deliver precision and speed. This assembly typically includes blades that oscillate to ensure a clean cut, minimizing damage to the vegetation and promoting healthier regrowth.

Drive System

The drive system transfers power from the engine to the cutting assembly, allowing for seamless operation. This includes belts, gears, and other components that ensure reliability and efficiency, making it essential for achieving optimal results in the field.

How to Read Parts Diagrams

Understanding the intricacies of visual schematics is essential for effective maintenance and repair tasks. These illustrations serve as a roadmap, highlighting each component’s placement and functionality within a larger system.

Start by familiarizing yourself with the legend or key, which typically outlines symbols and abbreviations. This will provide clarity on what each element represents. Pay close attention to the numbering system, as it often correlates with a list of items or specifications, aiding in identifying necessary components.

Next, trace the connections between parts to comprehend how they interact. This can reveal potential areas of wear or malfunction. By delving into the details, you can gain insight into both the assembly and disassembly processes, ensuring that you can address issues effectively.

Finally, keep the original manual handy for reference. It often contains additional context that enhances understanding, ultimately leading to more successful repairs and maintenance.

Identifying Common Replacement Parts

Understanding the essential components of agricultural equipment is crucial for maintenance and efficient operation. Recognizing which elements may require replacement can enhance performance and prolong the lifespan of the machinery.

Key Components to Monitor

Several critical elements should be regularly inspected to ensure optimal functionality. These components often wear out and need to be replaced to maintain effective performance.

| Component | Description |

|---|---|

| Blades | Critical for cutting efficiency, these can dull over time and require regular checks. |

| Drive Belts | Essential for power transmission, they may wear and need periodic replacement. |

| Bearings | Facilitate smooth movement; wear can lead to decreased efficiency and noise. |

Maintenance Tips

Regular maintenance and timely replacement of these components can prevent unexpected downtime and ensure the equipment operates at its ultimate potential. Keeping an eye on wear indicators can facilitate proactive care and reduce long-term costs.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your agricultural equipment. By following a few straightforward practices, you can enhance functionality and reduce the risk of unexpected breakdowns. Consistent attention to details can lead to significant improvements in performance and reliability.

Here are some key maintenance tips:

| Tip | Description |

|---|---|

| Clean Components | Regularly remove debris and residue to prevent wear and tear. |

| Inspect for Wear | Check parts for signs of damage or excessive wear and replace as needed. |

| Lubricate Moving Parts | Ensure all moving components are adequately lubricated to reduce friction. |

| Check Adjustments | Regularly verify settings and alignments for optimal operation. |

| Store Properly | Keep equipment in a dry, sheltered place to protect it from the elements. |

Finding Genuine John Deere Parts

When it comes to maintaining your machinery, sourcing authentic components is crucial for optimal performance and longevity. Utilizing original elements ensures that your equipment operates efficiently, reducing the risk of breakdowns and enhancing overall productivity.

Benefits of Authentic Components

Choosing original items not only guarantees compatibility but also supports the integrity of your machinery. Quality materials and precise manufacturing standards contribute to the reliability and safety of your equipment. Additionally, utilizing genuine components often leads to better resale value and fewer maintenance issues in the long run.

Where to Find Genuine Components

Authorized dealers and reputable online retailers are excellent sources for acquiring authentic items. Look for vendors that offer a comprehensive inventory and have a solid reputation within the industry. Customer reviews and recommendations can also guide you in identifying trustworthy sources.

Assembly Process for Sickle Mower

The assembly of a cutting implement requires careful attention to detail and a systematic approach to ensure optimal functionality. Each component plays a crucial role in the overall performance, and understanding the sequence of assembly is essential for a successful setup. This process not only enhances the efficiency of the implement but also prolongs its lifespan with proper maintenance and alignment.

Preparation and Organization

Before commencing the assembly, it is vital to gather all necessary tools and components. Organizing parts in a logical manner can significantly streamline the workflow. Reviewing the assembly instructions and having a clear understanding of each component’s function will aid in avoiding common pitfalls. Ensuring a clean workspace will also facilitate a smoother assembly process.

Step-by-Step Assembly

The assembly should start with the base frame, followed by the installation of the drive mechanism. After securing these primary components, attention should shift to the attachment of cutting blades and adjusting mechanisms. Careful calibration of the settings will ensure that the cutting edge remains effective. Finally, conducting a thorough inspection of all connections and fittings is crucial to guarantee safety and efficiency during operation.

Understanding Mower Adjustment Mechanisms

Effective cutting requires a deep understanding of the various mechanisms that facilitate adjustments in equipment. These systems play a crucial role in achieving optimal performance, ensuring precision in operation, and adapting to different conditions. Grasping how these components work together is essential for maintaining efficiency and prolonging the lifespan of the machine.

Key Components of Adjustment Mechanisms

- Height Control: Regulates the cutting height to suit various terrains.

- Angle Settings: Allows for changes in the angle of the cutting blade for different tasks.

- Tension Adjustment: Ensures the appropriate tension in belts and cables for smooth operation.

Importance of Regular Maintenance

Regular inspection and maintenance of adjustment systems are vital for performance. Neglecting these components can lead to uneven cuts and increased wear. Ensure to check:

- For signs of wear and tear.

- That all settings are correctly calibrated.

- The responsiveness of adjustment levers and mechanisms.

Troubleshooting Common Issues

Maintaining agricultural machinery can often present challenges that require keen observation and problem-solving skills. Identifying and addressing common malfunctions is essential for ensuring optimal performance and longevity of the equipment. This section will outline some frequent issues and their potential solutions to keep your machinery running smoothly.

1. Uneven Cutting Performance

If the cutting mechanism is not providing consistent results, check for any wear or damage to the cutting edges. Inspect the alignment of the blades, as misalignment can lead to uneven results. Ensure that the tension on the cutting mechanism is properly adjusted; insufficient tension may cause the blades to lag, while excessive tension can lead to rapid wear.

2. Excessive Vibration

Excessive vibration during operation can indicate underlying issues that need attention. First, examine the balance of the components. Imbalances may arise from damaged or worn parts, necessitating replacement. Additionally, ensure that all fasteners are securely tightened, as loose connections can exacerbate vibration issues.

Regular maintenance and prompt troubleshooting are key to preventing larger problems and ensuring efficient operation.

Benefits of Regular Equipment Checkups

Conducting frequent evaluations of machinery is essential for maintaining optimal performance and longevity. These assessments not only prevent unexpected breakdowns but also enhance operational efficiency, ensuring that equipment runs smoothly during crucial tasks.

Improved Reliability

Regular inspections significantly increase the dependability of your machinery. By identifying potential issues early, you can address them before they escalate into costly repairs, leading to less downtime and greater productivity.

Cost-Effectiveness

Investing time in routine checkups can lead to substantial savings in the long run. Early detection of wear and tear allows for timely replacements and adjustments, reducing the risk of expensive replacements and ensuring that your equipment operates at its ultimate capacity.

Resources for Additional Mower Information

For those seeking comprehensive guidance on their agricultural equipment, a variety of sources can enhance your understanding and provide valuable insights. Whether you need repair instructions, maintenance tips, or detailed specifications, exploring different materials can help ensure optimal performance and longevity of your machinery.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Manuals | Official documentation containing detailed instructions and maintenance guidelines. | Visit here |

| Online Forums | Community platforms where users share experiences and troubleshooting advice. | Join the discussion |

| Video Tutorials | Visual guides that demonstrate repair techniques and operational tips. | Watch tutorials |

| Parts Suppliers | Websites that offer replacement components and accessories for various models. | Find suppliers |