Agricultural machinery relies on various critical systems to perform its essential functions efficiently. Among these systems, one of the most pivotal is the mechanism responsible for connecting and operating external tools. This section will provide an in-depth look at the fundamental aspects of this connection setup, shedding light on the crucial components that ensure smooth operation in the field.

Understanding the arrangement and interaction of these elements is vital for maintaining functionality and addressing any mechanical issues that may arise. Whether you’re performing routine maintenance or troubleshooting, familiarity with the structure of these systems will help streamline repairs and ensure optimal performance.

In the following paragraphs, we will explore the layout and the role of each segment in this essential configuration, ensuring clarity and precision in every step of the maintenance process.

Overview of John Deere 4020 3-Point Hitch

The lifting system on this model of agricultural machinery is designed for efficient handling of various implements, enhancing the machine’s versatility in the field. It offers a reliable solution for attaching tools and equipment, ensuring smooth operation during tasks like plowing, tilling, and other soil management activities.

- The system is known for its robust construction, allowing it to support heavy-duty farming equipment.

- Its adaptability makes it suitable for a wide range of tasks, helping operators easily switch between different tools.

-

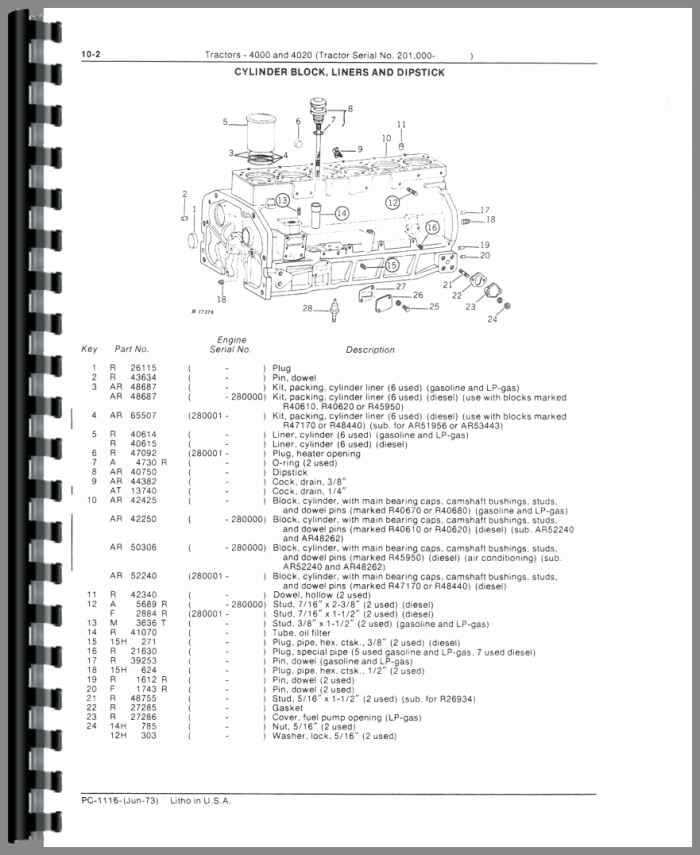

Main Components of the 3-Point Hitch System

The lifting mechanism in agricultural equipment plays a vital role in attaching and handling a wide range of implements. This system consists of various interconnected parts designed to distribute weight evenly and ensure smooth operation during field tasks. By understanding its core elements, operators can maintain equipment efficiency and prevent potential issues.

Lifting Arms and Stabilizers

At the heart of the system are the lifting arms, which connect to different attachments. These components are responsible for raising and lowering the tools. Stabilizers ensure that the attachments remain steady and secure during movement, reducing lateral sway and providing better control in uneven terrains.

Hydraulic Cylinders and Controls

The hydraulic cylinders are key elements that power the vertical motion of the system. Operated through a control panel, they allow precise adjustment of equipment height, ensuring that the attached implements work effectively under various conditions. These controls also enable quick responses to changes

Understanding the Lift Arms and Their Function

The lift arms play a crucial role in the operation of agricultural machinery, enabling the smooth and efficient movement of various implements. These components are designed to handle a wide range of tasks by providing controlled elevation and lowering mechanisms. The ability to adjust and manage heavy equipment with precision is essential for enhancing productivity in farming operations.

Below, we explore the key features and purpose of these essential components:

- Stability: The arms ensure proper balance when handling attachments, maintaining even distribution of weight.

- Flexibility: Their adjustable nature allows operators to raise or lower equipment based on field requirements.

- Durability: Built to withstand significant forces, they contribute to the machine’s overall robustness.

By understanding how the lift arms operate, users can better utilize their equipment, ensuring efficient

Connecting the Top Link to the Tractor

When securing the upper link to your machine, it’s important to ensure that the connection is stable and properly aligned. This component is essential for maintaining the balance and smooth operation of your equipment, especially during fieldwork or when handling heavy implements. The top link helps to adjust the angle of the attached tool, contributing to optimal performance and safety during use.

First, locate the mounting point on the rear of the machine. Make sure it is clean and free from debris before attempting to secure the link. Insert the top link into the designated slot and align it carefully. Once in position, secure it firmly with a locking pin or similar fastener, ensuring that the connection is tight and won’t shift during use.

After securing the top link, check the stability by gently moving it to confirm there is no excessive play. Adjust as

Lower Linkage Mechanism and Adjustments

The lower linkage system is crucial for ensuring effective connections between the tractor and various implements. Proper adjustments and understanding of this mechanism enhance the performance and functionality of the equipment, allowing for optimal operation in various agricultural tasks.

This section explores the components and adjustment techniques associated with the lower linkage mechanism. A well-maintained system improves efficiency and extends the lifespan of both the tractor and the attachments.

- Components of the Lower Linkage:

- Lower arms

- Draft arms

- Connecting pins

- Adjustable links

- Adjustment Procedures:

- Ensure the tractor is on a level surface before making adjustments.

- Check the condition of all components for wear or damage.

- Adjust the length of the lower arms to achieve the desired implement height.

- Verify the alignment of the linkage to ensure smooth operation.

- Maintenance Tips:

- Regularly lubricate all moving parts to prevent wear.

- Inspect for loose connections and tighten as necessary.

- Replace worn components promptly to maintain efficiency.

By following these guidelines, operators can ensure that the lower linkage mechanism functions effectively, contributing to the overall productivity of their agricultural practices.

Hydraulic System’s Role in Hitch Operation

The hydraulic mechanism plays a crucial role in the functionality of attachment systems used in agricultural machinery. By converting fluid pressure into mechanical movement, it facilitates the lifting, lowering, and positioning of various implements. This efficiency not only enhances productivity but also provides operators with greater control over their equipment, allowing for precise adjustments in the field.

Components of the Hydraulic System

Understanding the key elements of the hydraulic system is essential for effective operation and maintenance. Each component works in unison to ensure smooth functionality. Below is a summary of the main parts involved:

Component Function Hydraulic Pump Generates pressure needed to move the fluid Fluid Reservoir Stores hydraulic fluid and maintains system pressure Control Valve Regulates the flow and direction of the hydraulic fluid Cylinders Convert hydraulic pressure into mechanical force Hydraulic Lines Transport fluid between components Benefits of an Efficient Hydraulic System

An efficient hydraulic setup provides several advantages in equipment operation. Enhanced lifting capability, reduced operator effort, and improved versatility are key benefits that contribute to overall agricultural efficiency. Regular maintenance of the hydraulic components ensures longevity and optimal performance, preventing costly downtime and repairs.

Pins and Fasteners: Ensuring Proper Assembly

In any mechanical system, the significance of securing components with appropriate connectors cannot be overstated. Reliable assembly relies on selecting the correct types of pins and fasteners to achieve stability and functionality.

When assembling machinery, it is crucial to utilize the right fasteners to prevent loosening over time. This involves selecting components made from durable materials capable of withstanding operational stresses. Additionally, using the correct size and type of fastener ensures that parts fit together snugly, minimizing wear and enhancing performance.

Routine inspections are essential to maintain the integrity of these connections. Regular checks can help identify any signs of wear or damage, allowing for timely replacements. Proper assembly techniques, including applying the correct torque specifications, further contribute to the longevity and safety of the equipment.

Inspection and Maintenance of Hitch Parts

Regular examination and upkeep of coupling mechanisms are essential for ensuring optimal functionality and longevity. Proper care prevents potential issues, enhances performance, and maintains safety during operation. Adopting a systematic approach to these tasks can help identify wear or damage early, leading to timely interventions.

Routine Inspection Procedures

Conducting routine checks is vital for maintaining the integrity of attachment systems. The following steps are recommended:

- Examine the structural components for signs of rust, cracks, or other damages.

- Check all connections to ensure they are secure and free from excessive play.

- Inspect pivot points and joints for proper lubrication and any signs of wear.

- Assess hydraulic lines for leaks or deterioration.

Maintenance Recommendations

Implementing regular maintenance practices will extend the life of the coupling equipment:

- Lubricate moving components regularly to prevent friction and wear.

- Replace any worn or damaged items promptly to avoid more extensive repairs.

- Keep the area around the coupling clean and free from debris.

- Follow manufacturer guidelines for specific maintenance schedules and recommended products.

Replacing Worn-Out Parts on the 3-Point Hitch

Over time, components in agricultural machinery can experience wear and tear, leading to decreased performance and efficiency. Identifying and replacing these degraded elements is crucial for maintaining optimal functionality and ensuring smooth operations. This section outlines key considerations and steps for effectively swapping out old components with new ones.

Identifying Worn Components

Regular inspections play a vital role in detecting damaged or worn components. Look for signs such as rust, cracks, or excessive play in the joints. Pay attention to any unusual noises during operation, as these can indicate underlying issues. By promptly identifying these problems, you can prevent further damage and costly repairs.

Steps for Replacement

Once you have determined which elements need replacement, gather the necessary tools and replacement components. Begin by safely lifting the equipment and securing it to avoid accidents. Remove the old components, taking note of how they are installed for proper reassembly. Install the new elements in reverse order, ensuring everything is tightened to the manufacturer’s specifications. Finally, conduct a thorough check to confirm that all connections are secure before putting the machinery back into operation.

Troubleshooting Common Hitch Issues

When dealing with attachment systems on agricultural machinery, several challenges may arise that affect performance and usability. Understanding the typical problems and their solutions can enhance the functionality and efficiency of the equipment. Here are some common concerns and recommended approaches to address them.

Issue Symptoms Possible Solutions Misalignment Difficulty connecting attachments, uneven operation Check alignment of the connecting components, adjust as necessary Wear and Tear Excessive play, noisy operation Inspect for worn parts, replace any damaged components Hydraulic Issues Inconsistent movement, slow response Examine hydraulic fluid levels, check for leaks or blockages Control Problems Unresponsive controls, erratic behavior Ensure controls are functioning properly, inspect wiring and connections