The efficiency of agricultural machinery relies heavily on the quality and functionality of its components. Understanding how these elements work together is crucial for optimal performance and maintenance. A comprehensive look at the individual sections of a particular model can enhance one’s knowledge and ensure that each part is functioning as intended.

In this section, we will explore the intricate arrangement of elements that contribute to the overall effectiveness of a specific agricultural machine. By examining the relationships and configurations of various components, users can gain insights into maintenance routines and potential upgrades, leading to improved productivity in the field.

Having a clear visual representation of how these sections interconnect can aid operators and technicians in diagnosing issues more efficiently. Moreover, it fosters a deeper understanding of the machinery’s operational principles, ultimately enhancing its longevity and reliability.

The 4400 model is renowned for its robust construction and innovative design, which combine to deliver exceptional performance in various agricultural settings. This machine integrates advanced technologies that enhance efficiency and productivity, making it a vital asset for farmers looking to optimize their harvesting processes.

| Feature | Description |

|---|---|

| Engine Power | The model is equipped with a high-performance engine that provides substantial horsepower, ensuring the ability to handle demanding tasks with ease. |

| Cutting Width | A wide cutting header allows for increased coverage in each pass, significantly reducing harvesting time and enhancing overall efficiency. |

| Grain Handling System | Featuring a reliable grain handling system, this machine ensures efficient transportation of harvested crops, minimizing loss and maximizing yield. |

| Operator Comfort | The operator’s cabin is designed for maximum comfort and visibility, allowing for better maneuverability and less fatigue during long working hours. |

| Maintenance Accessibility | Engineered for easy access to critical components, the design simplifies routine maintenance tasks, contributing to prolonged machine life and reliability. |

Importance of Parts Identification

Recognizing the components of machinery is crucial for effective maintenance and repair. Accurate identification not only ensures proper functioning but also minimizes downtime, enhancing productivity. Understanding the specific elements of equipment allows operators and technicians to address issues efficiently, leading to improved performance and longevity.

Benefits of Proper Identification

- Enhanced Efficiency: Knowing the exact components enables quick troubleshooting and repair, reducing operational delays.

- Cost Savings: Accurate identification helps prevent unnecessary purchases of incorrect or redundant items.

- Safety Assurance: Familiarity with individual elements ensures safe handling and operation, reducing the risk of accidents.

- Effective Inventory Management: Recognizing components aids in maintaining optimal stock levels and ordering practices.

Impact on Maintenance Practices

- Streamlined Repairs: Identifying the right components allows for targeted maintenance efforts.

- Informed Upgrades: Understanding existing elements helps in making informed decisions when upgrading or replacing equipment.

- Knowledge Transfer: Familiarity with components supports training efforts for new operators and technicians.

Common Replacement Parts for the Combine

Regular maintenance of agricultural machinery is essential for optimal performance and longevity. Understanding which components are prone to wear can help operators prepare for timely replacements, ensuring that the equipment remains efficient and effective in the field. Below are some commonly replaced elements that contribute to the overall functionality of harvesting machinery.

Essential Components

- Header Assembly

- Auger System

- Threshing Cylinder

- Drive Belts

- Feed Chain

- Grain Elevator

Wear Items

- Worn Blades

- Chain Sprockets

- Roller Bearings

- Seals and Gaskets

- Filters (Oil, Air, Fuel)

By being aware of these key components and their maintenance needs, operators can enhance the reliability and performance of their harvesting equipment. Regular inspections and proactive replacements can lead to a smoother operation during harvest seasons.

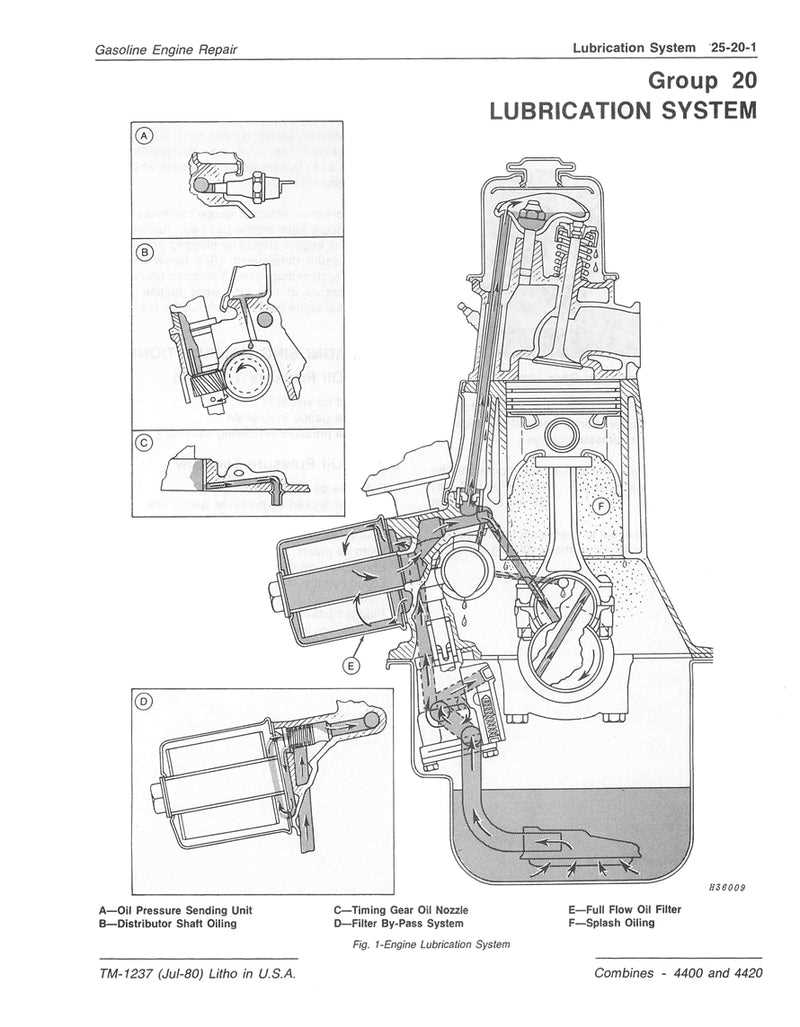

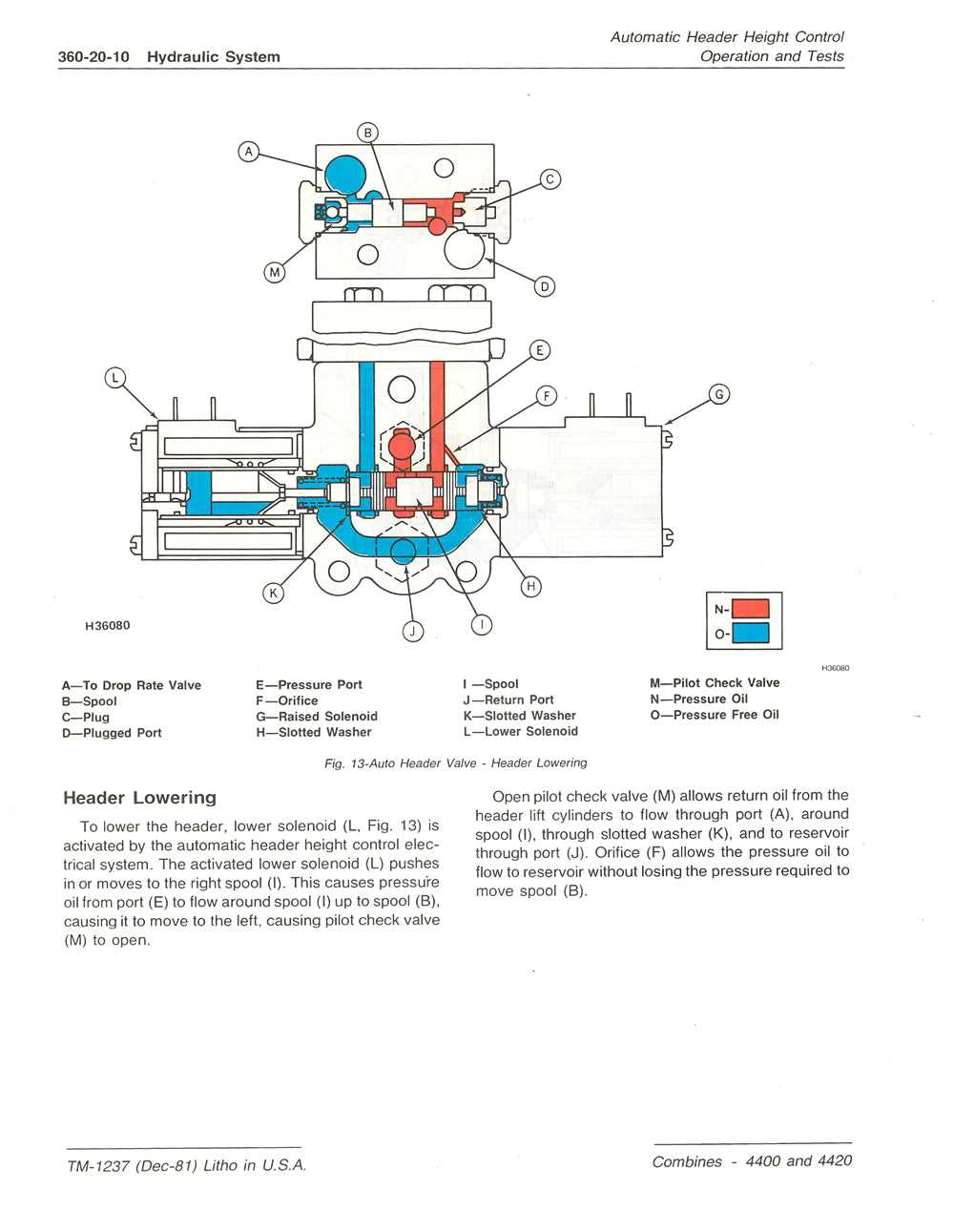

How to Read the Parts Diagram

Understanding an illustration that showcases the components of machinery is essential for effective maintenance and repairs. These visual guides help users identify individual elements, facilitating easier sourcing and replacement. By familiarizing yourself with the layout and notations, you can ensure that you are well-prepared for any mechanical tasks.

Familiarize Yourself with the Layout

Begin by examining the overall structure of the illustration. Take note of how components are grouped and labeled. Each section may represent different areas of the machinery, providing a logical organization that simplifies navigation. Understanding this arrangement can save time when locating specific items.

Deciphering Symbols and Labels

Every illustration utilizes specific symbols and numerical codes to represent individual components. Familiarize yourself with the legend, if available, which explains these notations. This knowledge will empower you to quickly identify each element’s function and its corresponding identifier in the illustration.

Maintenance Tips for the 4400

Proper upkeep is essential to ensure optimal performance and longevity of agricultural machinery. Regular attention to key components can help prevent breakdowns and maintain efficiency during peak operational periods.

- Regular Inspections: Conduct routine checks on all major systems, including the engine, transmission, and hydraulic components, to identify any wear or damage.

- Fluid Levels: Monitor and maintain appropriate levels of oil, coolant, and hydraulic fluid to ensure smooth operation.

- Cleaning: Keep the machine clean from debris, dust, and crop residues. Regular washing can prevent corrosion and maintain visibility for operators.

- Belts and Hoses: Inspect belts for signs of wear and check hoses for leaks or cracks. Replace any damaged parts immediately to avoid further complications.

- Sharpening Blades: Ensure that cutting blades are sharp and properly adjusted for efficient operation. Dull blades can strain the engine and reduce cutting efficiency.

Following these guidelines will contribute to the reliability and efficiency of your agricultural equipment, ultimately enhancing productivity during critical harvesting periods.

Where to Find Genuine Parts

Locating authentic components for your agricultural machinery is essential for maintaining optimal performance and longevity. Genuine replacements ensure that your equipment operates efficiently and safely, adhering to manufacturer specifications. Here are some reliable avenues to explore when searching for these essential items.

Authorized Dealers

One of the best ways to obtain original components is through authorized distributors. These vendors specialize in equipment and offer a wide range of products that meet the strict quality standards set by the manufacturer. Engaging with these retailers guarantees that you receive authentic items, complete with proper warranty coverage.

Online Marketplaces

Additionally, several reputable online platforms provide a selection of genuine components. When using these websites, it is crucial to verify the seller’s credibility and check customer reviews. This practice helps ensure that you are purchasing high-quality items rather than imitations. Always look for listings that explicitly state the authenticity of the products.

Tools Needed for Repairs

Having the right tools is essential for conducting effective maintenance and repairs on agricultural machinery. A well-equipped workshop ensures that tasks can be completed efficiently and safely, minimizing downtime and improving productivity. This section outlines the key instruments required to handle repairs with precision and ease.

Basic Hand Tools

Basic hand tools are fundamental for any repair job. Items such as wrenches, pliers, and screwdrivers should be readily available. These tools allow for the disassembly and reassembly of various components, ensuring that everything is securely fitted and functioning correctly. It is also advisable to have a good set of sockets to reach fasteners in tighter spaces.

Specialized Equipment

In addition to standard hand tools, specialized equipment may be necessary for more complex repairs. This includes torque wrenches for ensuring proper tightness, hydraulic jacks for lifting heavy parts, and diagnostic tools for troubleshooting electronic systems. Investing in these tools can greatly enhance the effectiveness of maintenance procedures and extend the lifespan of machinery.

Typical Issues with the Combine

In the realm of agricultural machinery, several common challenges can arise during operation, impacting efficiency and productivity. Recognizing these issues is essential for timely maintenance and effective troubleshooting.

One frequent problem is clogging, which can occur in various sections due to the accumulation of material. This issue may hinder the flow of crops, leading to reduced performance and potential damage if not addressed promptly. Operators should regularly inspect and clear any blockages to ensure smooth functioning.

Another concern involves the wear and tear of components, particularly those subjected to constant movement and friction. Regular checks for signs of fatigue or damage can prevent breakdowns and extend the lifespan of critical machinery parts.

Additionally, misalignment of the machine’s settings can result in inefficient harvesting. Operators need to verify that all adjustments are properly calibrated for optimal performance, ensuring that the equipment operates under the best possible conditions.

Lastly, electrical issues, such as faulty connections or malfunctioning sensors, can disrupt operations. Conducting routine inspections of the electrical systems can help identify potential problems before they escalate, maintaining the reliability of the equipment.

Enhancing Performance Through Upgrades

Improving efficiency and productivity in agricultural machinery often relies on strategic enhancements. By investing in quality modifications, operators can achieve significant gains in functionality, reliability, and overall effectiveness. Upgrades not only extend the lifespan of the equipment but also optimize its operational capabilities, making tasks easier and more efficient.

Key Areas for Upgrading

- Engine Performance: Upgrading components such as fuel injectors or air filters can lead to better fuel efficiency and increased power output.

- Transmission Systems: Enhancements in the transmission can improve speed control and responsiveness, ensuring smoother operations.

- Hydraulic Components: Optimizing hydraulic systems can enhance lifting capabilities and responsiveness, crucial for various agricultural tasks.

Benefits of Upgrades

- Increased Efficiency: Upgraded machinery typically performs tasks faster and with greater precision.

- Cost Savings: Improved fuel efficiency and reduced downtime can lead to significant savings over time.

- Enhanced Comfort: Modern upgrades often include ergonomic features that improve operator comfort during extended use.

Owner Testimonials and Experiences

Hearing from those who have used a specific agricultural machine can provide invaluable insights for potential buyers. Owners often share their real-world experiences, highlighting the strengths and weaknesses of their machinery, which helps others make informed decisions. This section collects a variety of testimonials that showcase satisfaction levels, operational challenges, and overall performance.

Positive Experiences

Many users have expressed their contentment with the efficiency and reliability of their machinery. Below are some common themes from positive testimonials:

- High Productivity: Owners frequently mention how their equipment has significantly increased their harvesting efficiency, allowing them to cover more ground in less time.

- Ease of Use: Many testimonials emphasize the intuitive controls and user-friendly features, making it accessible even for those new to operating such machines.

- Durability: Users often praise the robust construction, highlighting that their machines endure tough conditions without frequent breakdowns.

Challenges Faced

While the majority of feedback is positive, some owners have shared challenges they encountered:

- Maintenance Requirements: A few users noted that regular upkeep is essential for optimal performance, which can be time-consuming.

- Part Availability: Some owners mentioned difficulties in sourcing replacement components, emphasizing the importance of knowing local suppliers.

- Initial Investment: A common concern is the upfront cost, with some users feeling that it took time to see a return on their investment.

Overall, these testimonials paint a comprehensive picture of ownership experiences, providing a valuable resource for prospective buyers in their decision-making process.

Resources for Further Information

Accessing reliable resources is essential for anyone seeking detailed insights into machinery components and maintenance. A variety of platforms can provide in-depth knowledge, technical documentation, and community support for enthusiasts and professionals alike.

- Manufacturer’s Website: Official sites often offer manuals, schematics, and specifications for various machinery models.

- Online Forums: Community-driven platforms allow users to share experiences, troubleshooting tips, and modifications, fostering a collaborative environment.

- YouTube Channels: Video tutorials and walkthroughs can visually guide users through repairs and maintenance procedures, enhancing understanding.

- Technical Publications: Books and journals dedicated to agricultural machinery provide scholarly insights and historical context.

- Local Dealers: Authorized dealers can provide expert advice, genuine parts, and maintenance services tailored to specific models.

Utilizing these resources can enhance knowledge and skills, ensuring effective maintenance and operation of agricultural machinery.