The intricate assembly of heavy machinery plays a crucial role in the efficiency and effectiveness of construction and excavation projects. A comprehensive overview of these elements allows operators and technicians to understand the relationships between various components, ensuring optimal performance and longevity. By exploring the various features of such equipment, one can gain insights into their functionality and maintenance requirements.

Each unit within the machinery is designed to perform specific tasks, contributing to the overall operation of the system. Knowledge of these individual components, along with their configurations, facilitates informed decision-making during repairs and replacements. This understanding is essential not only for those working directly with the equipment but also for those involved in its design and manufacturing processes.

Additionally, familiarizing oneself with the layout of these components enhances troubleshooting skills and helps identify potential issues before they escalate. By analyzing the arrangement and interaction of each element, users can effectively manage upkeep and ensure the reliability of their machines over time.

This section offers a comprehensive look into the machinery known for its durability and efficiency. It serves as a crucial tool in various construction and agricultural applications, combining strength with advanced engineering. Understanding the components that make up this equipment is essential for effective maintenance and operation.

| Component | Description | Function |

|---|---|---|

| Engine | Power source that drives the entire system. | Provides the necessary horsepower for operation. |

| Transmission | System that transfers power from the engine to the tracks. | Facilitates movement and speed control. |

| Hydraulic System | Network of pumps and cylinders. | Enables lifting and tilting functions. |

| Track Assembly | Understructure that supports the vehicle. | Provides stability and traction on various terrains. |

| Cab | Operator’s control area. | Offers visibility and comfort during operation. |

Recognizing the significance of each component not only aids in better operational understanding but also enhances maintenance practices, ensuring longevity and optimal performance.

Key Features of the Dozer

This machinery stands out in the field of earth-moving equipment due to its robust construction and efficient design. Its primary function revolves around moving large quantities of material swiftly, making it indispensable for various construction and landscaping projects. A blend of power and versatility characterizes its operation, allowing for seamless execution of numerous tasks.

Powerful Engine

The heart of this equipment lies in its powerful engine, which provides the necessary torque to handle heavy loads with ease. This capability enables it to perform demanding tasks while maintaining high levels of productivity. Coupled with advanced transmission systems, the engine ensures smooth operation across different terrains.

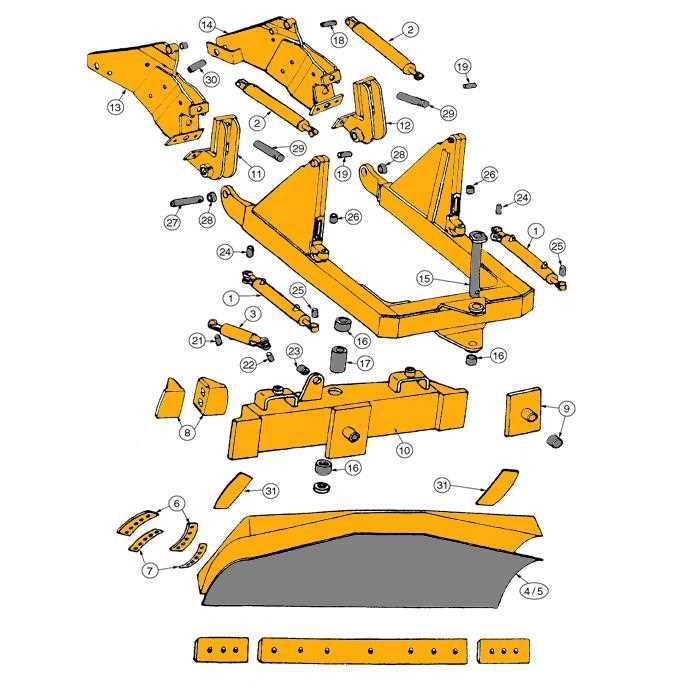

Durable Blade Design

Equipped with a heavy-duty blade, this machine excels in cutting and pushing materials efficiently. The blade’s design is optimized for various applications, allowing it to adapt to different job requirements. Durability and performance are at the forefront, ensuring longevity and reliability in challenging environments.

Importance of Parts Identification

Recognizing the components of heavy machinery is crucial for effective maintenance and repair. A comprehensive understanding of each element contributes to the overall functionality and longevity of the equipment.

Accurate identification of individual elements enables operators to promptly address issues, ensuring minimal downtime. This knowledge allows for informed decisions regarding replacement and upgrades, leading to enhanced performance.

Moreover, having a clear grasp of each component aids in streamlining maintenance routines. Technicians can efficiently diagnose problems and procure the necessary components, avoiding delays caused by miscommunication or incorrect orders.

In addition, awareness of compatibility between different components is essential. Understanding how various elements interact can prevent potential damage and ensure that repairs are completed correctly, safeguarding the investment in the equipment.

Common Components in Dozer Design

The construction machinery industry relies on various elements to ensure efficiency and effectiveness in heavy-duty tasks. Understanding these fundamental parts is essential for optimizing performance and maintaining durability in earth-moving applications. This section delves into the essential features that contribute to the functionality and reliability of such machines.

Key Structural Elements

Several structural components play a crucial role in the overall design and operation of these machines. Their interdependence ensures that the equipment can withstand significant stress while performing various tasks.

| Component | Function |

|---|---|

| Frame | Provides the foundation for the entire machine, supporting all other components. |

| Track System | Facilitates movement over various terrains, enhancing stability and traction. |

| Blade | Used for pushing material and shaping landscapes, crucial for earth-moving tasks. |

| Engine | Powers the machinery, converting fuel into mechanical energy for operation. |

Operational Systems

In addition to structural components, specific operational systems ensure that the machinery functions effectively in various conditions. These systems enhance control, maneuverability, and overall efficiency.

| System | Role |

|---|---|

| Hydraulic System | Controls the movement of the blade and other attachments, providing precision and power. |

| Cooling System | Maintains optimal operating temperatures for the engine and hydraulic fluids. |

| Electrical System | Powers lights, control systems, and other electrical components, ensuring functionality. |

| Transmission | Transfers power from the engine to the tracks, enabling movement and speed adjustments. |

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages for machinery maintenance and performance. These elements are designed to meet specific engineering standards, ensuring compatibility and optimal functioning. This section outlines the key benefits of opting for these quality replacements over generic alternatives.

Enhanced Reliability

OEM components provide superior reliability due to their precise manufacturing processes. Here are some reasons for their dependability:

- Strict quality control measures are enforced during production.

- Components are made from high-grade materials, leading to increased durability.

- Original designs replicate the specifications of the original unit, ensuring perfect fit and function.

Long-Term Cost Efficiency

Investing in original components can lead to long-term savings. Consider the following points:

- Reduced risk of failure, minimizing repair costs over time.

- Less frequent replacements due to higher durability.

- Improved resale value of machinery, as using OEM parts enhances overall performance.

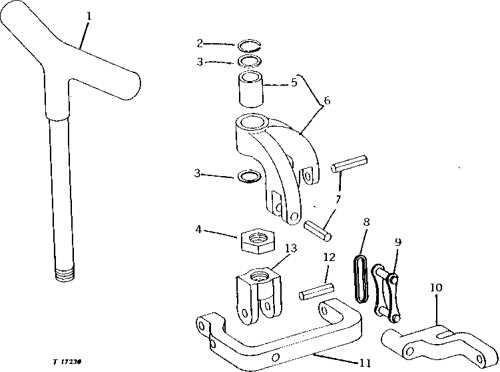

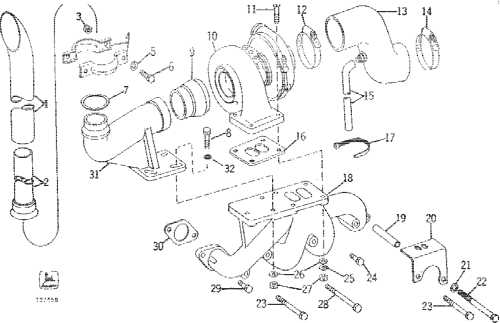

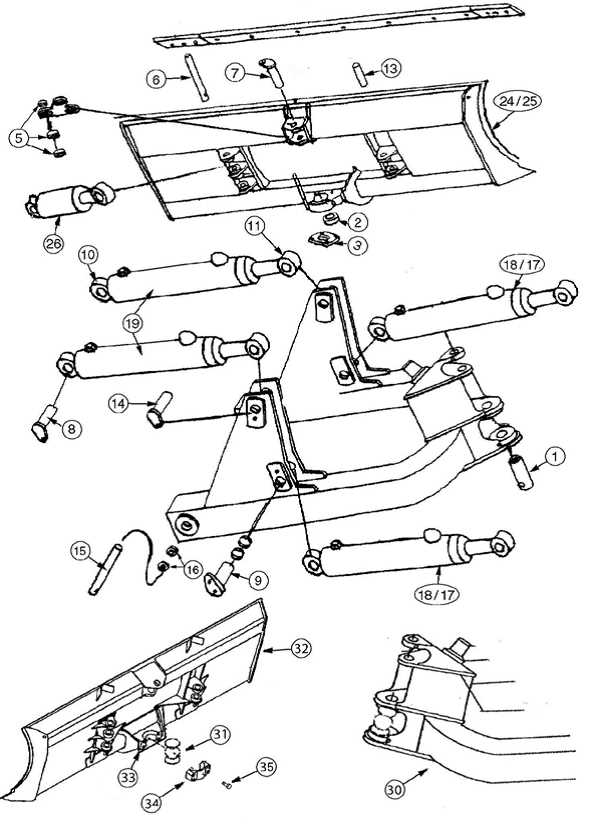

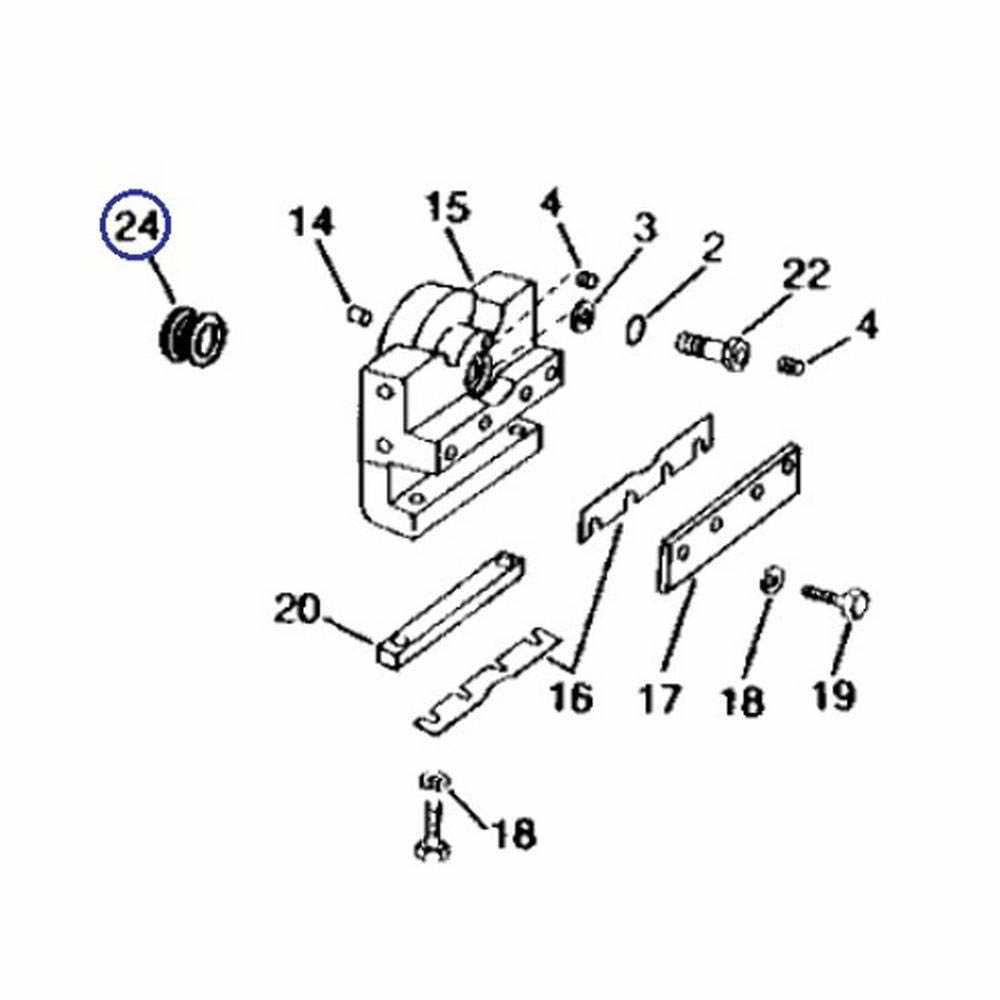

Visual Aids for Parts Understanding

Utilizing visual resources can significantly enhance comprehension of machinery components and their functions. Diagrams, illustrations, and photographs serve as effective tools to facilitate a clearer understanding of various elements, their arrangements, and operational relationships within equipment.

Annotated visuals can pinpoint specific components, showcasing their locations and interactions. These aids not only simplify the learning process but also assist in troubleshooting and maintenance tasks, making them invaluable for both novice users and experienced operators. By incorporating such resources, individuals can gain a more thorough grasp of the machinery’s inner workings and improve their proficiency in handling equipment.

Moreover, visual representations can bridge the gap between theoretical knowledge and practical application. They allow for quicker identification and recognition of different sections, thereby promoting a more intuitive approach to managing and operating the machine effectively. Overall, integrating visual aids into the learning experience fosters a deeper insight into machinery and enhances overall efficiency.

Maintenance Tips for Dozer Components

Regular upkeep of essential machinery elements ensures optimal functionality and extends the lifespan of the equipment. Implementing a systematic maintenance routine can help prevent costly repairs and downtime. This section outlines key practices to keep various components in top condition.

Lubrication and Inspection

Frequent lubrication of moving parts is crucial for reducing friction and wear. Inspecting components for signs of damage or excessive wear can help identify issues before they become serious problems. A well-lubricated system operates more efficiently and contributes to overall performance.

| Component | Maintenance Frequency | Tips |

|---|---|---|

| Hydraulic System | Every 250 hours | Check fluid levels and replace filters regularly. |

| Tracks | Monthly | Inspect for wear and adjust tension as needed. |

| Engine | Every 100 hours | Change oil and filters, and check cooling systems. |

Cleaning and Storage

Maintaining cleanliness is vital for machinery longevity. Dirt and debris can accumulate in critical areas, leading to overheating and malfunction. Proper storage practices, such as covering the equipment when not in use, can also protect it from the elements and prolong its service life.

How to Read Parts Diagrams

Understanding technical illustrations can be essential for effective maintenance and repairs. These visual representations provide detailed information about components, their arrangements, and how they interact within a larger system. Mastering the ability to interpret these illustrations allows for efficient identification of necessary elements and aids in troubleshooting issues.

Familiarizing Yourself with Symbols and Notations

Most visual aids utilize specific symbols and notations to convey information clearly. Take time to study the legend or key, which explains what each symbol represents. Pay attention to various indicators, such as arrows that show movement or connections, as well as color codes that may signify different materials or functions. Recognizing these symbols will enhance your ability to comprehend the overall layout.

Identifying Components and Their Relationships

After understanding the symbols, focus on the individual elements depicted. Trace each part and note how it connects to others. Look for outlines, numbers, or labels that indicate specific items. Analyzing these connections helps to build a mental map of the system, making it easier to identify replacement options when necessary. Remember that the arrangement often reflects the assembly order, which can be invaluable during reassembly or repairs.

Common Issues and Solutions

When operating heavy machinery, various challenges may arise, affecting performance and efficiency. Understanding these common problems and their respective solutions can significantly enhance operational reliability and longevity of the equipment.

| Issue | Description | Solution |

|---|---|---|

| Hydraulic Failure | Loss of power or slow response in hydraulic functions. | Check fluid levels and inspect for leaks. Replace damaged hoses or seals. |

| Engine Overheating | Excessive temperature leading to potential engine damage. | Ensure proper coolant levels and clean the radiator. Check for blockages in airflow. |

| Track Misalignment | Uneven wear or misalignment of tracks causing instability. | Regularly adjust track tension and inspect for wear. Replace worn components as needed. |

| Electrical Malfunctions | Failures in starting or electrical components. | Inspect wiring and connections for corrosion. Test batteries and replace faulty components. |

| Wear and Tear | General degradation of components affecting performance. | Conduct regular maintenance checks and replace worn parts according to the service schedule. |

Where to Find Replacement Parts

Locating suitable components for heavy machinery can be a daunting task, yet it is essential for maintaining optimal performance and longevity. Numerous avenues exist for acquiring high-quality alternatives that align with specific needs.

Authorized Dealers are often the most reliable source. They typically carry a comprehensive inventory of original components, ensuring compatibility and adherence to manufacturer standards. Visiting a local dealer can also provide access to knowledgeable staff who can assist with inquiries and offer tailored recommendations.

Online Retailers present a vast selection of options, making it easier to compare prices and availability. Websites specializing in machinery components often feature user reviews, which can guide purchasers in making informed decisions. Furthermore, online marketplaces can yield both new and used alternatives, catering to various budget constraints.

Salvage Yards can be a treasure trove for those seeking cost-effective solutions. These facilities often stock a wide range of salvaged machinery, allowing individuals to find hard-to-get items at a fraction of the cost of new ones. It’s essential to inspect the condition of the components carefully before making a purchase.

Forums and Community Groups dedicated to machinery enthusiasts can also be invaluable resources. Engaging with fellow owners can provide insights into where to find specific components and recommendations based on personal experiences. These communities may also facilitate trades or sales among members.

By exploring these diverse channels, individuals can effectively secure the necessary replacements, ensuring their machinery remains functional and efficient.

Comparative Analysis with Other Models

This section delves into the distinctions and similarities among various heavy machinery models, focusing on their structural components and operational efficiency. By examining different machinery in the same category, it becomes evident how specific designs can influence performance and durability in challenging environments.

Structural Features: When comparing models, one key aspect is the configuration of their structural elements. While some machines prioritize a compact design for enhanced maneuverability, others boast robust frames that offer greater stability and support. Analyzing these differences can help users select the most suitable option for their specific applications.

Operational Efficiency: Another significant area of comparison lies in the efficiency of operation. Variances in engine specifications, hydraulic systems, and power transmission can result in notable differences in performance. Understanding how these factors interplay across models allows for a better appreciation of each machine’s strengths and limitations.

Ultimately, a thorough examination of these factors provides valuable insights into selecting equipment that aligns with user needs, ensuring optimal performance and longevity in various tasks.

Expert Recommendations for Owners

Maintaining heavy machinery requires attention to detail and a proactive approach. Owners should prioritize regular inspections and adhere to manufacturer guidelines to ensure optimal performance and longevity of their equipment. Understanding the essential components and their functions is key to identifying potential issues before they escalate.

Regular Maintenance Checks

Consistent maintenance is crucial for avoiding costly repairs. Schedule routine evaluations of hydraulic systems, engines, and tracks to identify wear and tear. Consider keeping a detailed log of all service activities to track the condition of each component effectively.

Utilizing Quality Replacement Components

When replacement is necessary, always opt for high-quality alternatives. Investing in superior components not only enhances performance but also extends the lifespan of your machinery. Research reputable suppliers to ensure you are acquiring reliable materials that meet industry standards.

Future Upgrades for the Dozer

As technology advances, there are numerous enhancements that can significantly improve the functionality and efficiency of heavy machinery. Implementing these upgrades can lead to increased productivity, reduced operational costs, and enhanced safety features. Embracing modern innovations ensures that the equipment remains competitive and capable of meeting evolving industry demands.

Potential enhancements include advanced hydraulic systems, improved engine performance, and upgraded control mechanisms. These modifications can optimize power distribution, enhance maneuverability, and provide better operator feedback, ultimately leading to superior performance on job sites.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Hydraulic System | Implementing a closed-center hydraulic system for more efficient fluid management. | Improved responsiveness and reduced fuel consumption. |

| Engine Optimization | Upgrading to a more fuel-efficient engine with better torque characteristics. | Increased power output and lower emissions. |

| Control System | Integrating advanced electronic control systems for enhanced precision. | Better operator control and reduced fatigue. |

| Safety Features | Adding advanced monitoring and alert systems for real-time diagnostics. | Increased operator safety and reduced risk of accidents. |

Incorporating these advancements not only modernizes the equipment but also positions operators for greater success in their projects. By staying current with technological trends, operators can maximize their investment and ensure longevity in their operations.