The intricate mechanisms of agricultural machinery are vital for efficient operation. Understanding the layout and functionality of these elements enhances maintenance and repair efforts, ensuring optimal performance.

In this section, we will explore the various components that contribute to the seamless operation of this particular model. By familiarizing oneself with the arrangement and interconnections, operators can make informed decisions regarding upkeep and troubleshooting.

Through detailed illustrations and descriptions, we aim to provide clarity on the assembly of essential parts. This knowledge is crucial for both seasoned professionals and newcomers looking to deepen their understanding of heavy machinery.

Overview of John Deere 5085M

This section provides a comprehensive look at a popular agricultural machine designed for versatility and efficiency. Renowned for its reliability, this model caters to various farming needs, enhancing productivity in numerous tasks.

Key Features

Equipped with advanced technology, this equipment offers exceptional performance. Its powerful engine ensures ample torque, while the user-friendly controls enhance operator comfort during prolonged use.

Applications

Ideal for diverse agricultural activities, this machine excels in both fieldwork and transport tasks. Its adaptability makes it a preferred choice for farmers seeking a robust solution for their operations.

Essential Components and Their Functions

This section explores key elements that play a vital role in the functionality of agricultural machinery. Understanding these components helps in maintaining efficiency and ensuring optimal performance.

- Engine: The heart of the machine, responsible for converting fuel into mechanical energy.

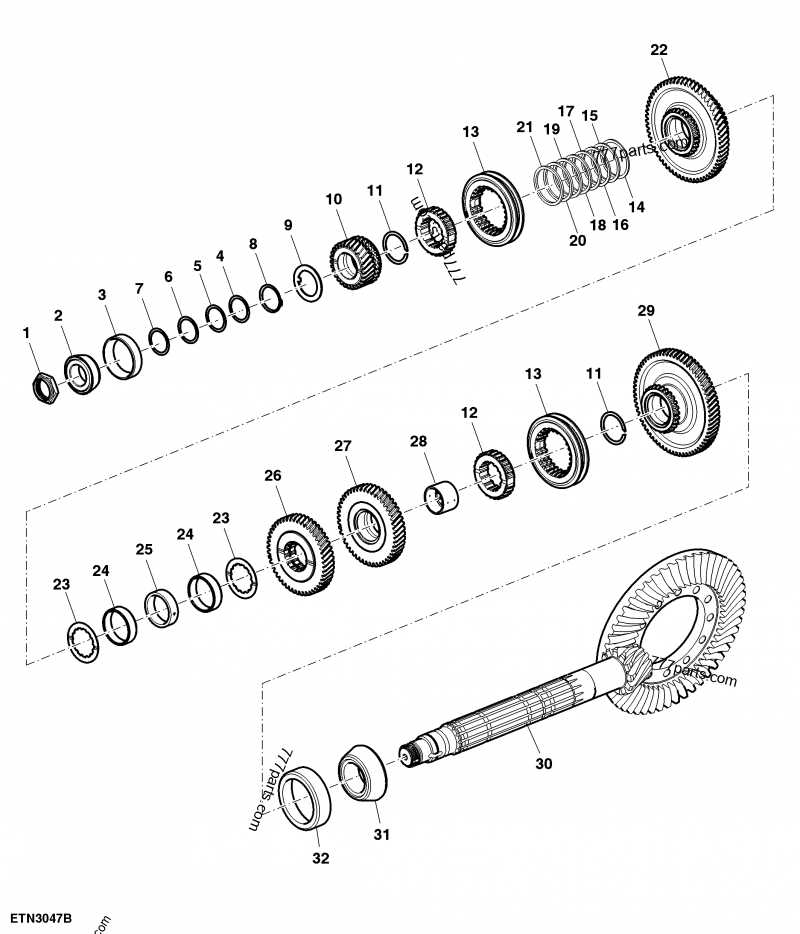

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for movement.

- Hydraulic System: Powers various attachments and implements, enabling tasks such as lifting and lowering.

- Electrical System: Supports the ignition, lighting, and other electrical components essential for operation.

- Chassis: The frame that supports all components, providing stability and strength during use.

Each of these elements contributes to the overall functionality and effectiveness of the machinery, ensuring it meets the demands of various agricultural tasks.

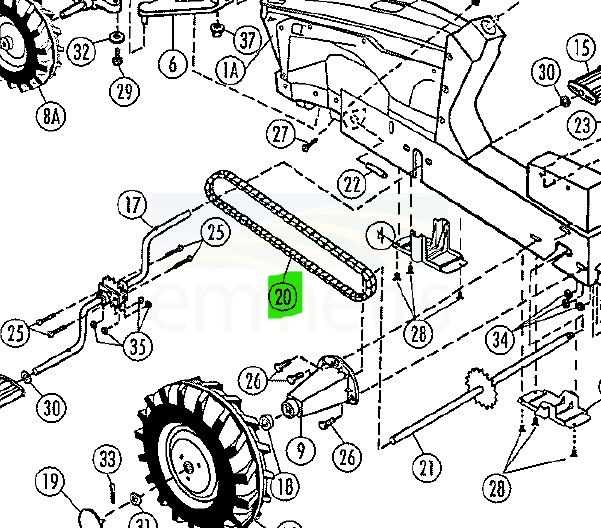

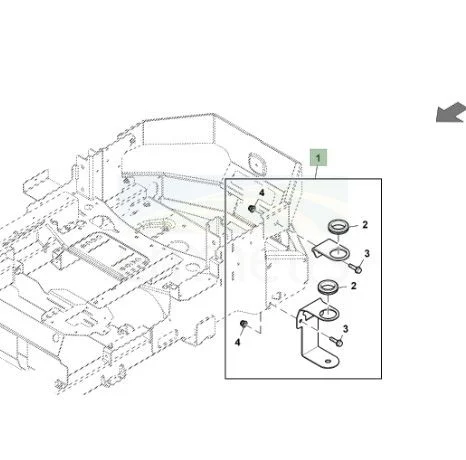

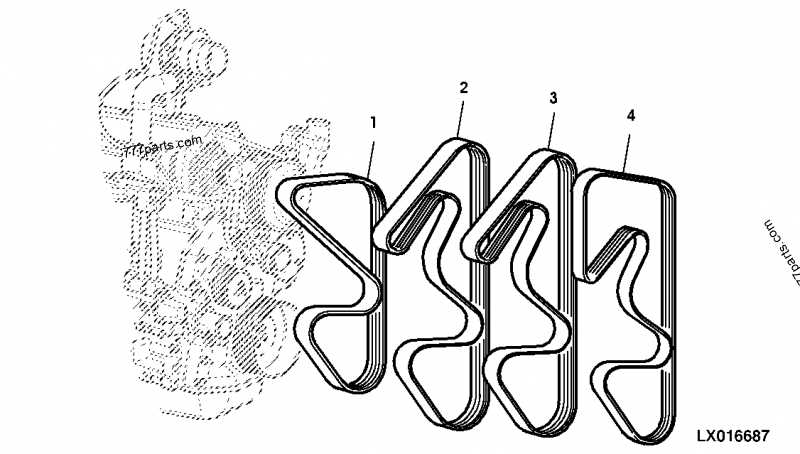

Understanding the Parts Diagram

Comprehending the layout of components in machinery is essential for efficient maintenance and repair. A visual representation serves as a guide, illustrating how each element interacts within the system.

This illustration aids technicians in identifying individual elements and their respective functions, ensuring accurate diagnostics and troubleshooting. Familiarity with this visual tool enhances overall operational efficiency.

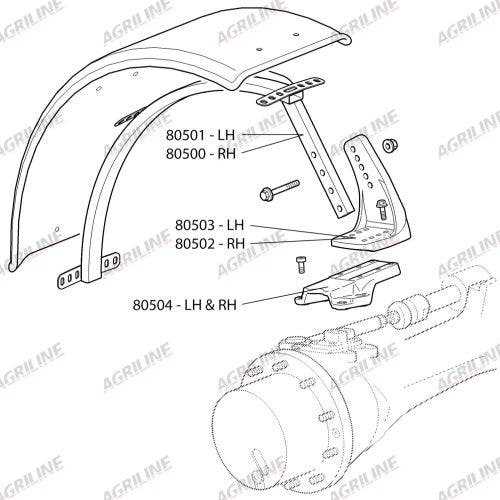

Key Replacement Parts Availability

The availability of essential components is crucial for maintaining the functionality of agricultural machinery. Ensuring that operators have easy access to these elements can significantly reduce downtime and enhance operational efficiency.

Manufacturers often provide a comprehensive range of replacements for key components. Genuine options are typically recommended, as they guarantee compatibility and durability. However, aftermarket alternatives may also be available, offering cost-effective solutions for operators seeking budget-friendly choices.

To facilitate the procurement process, various suppliers and dealers stock these essential components, making them readily accessible. It is advisable to consult with authorized distributors to confirm the availability of specific items.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your machinery requires regular upkeep and attention. Following a consistent maintenance routine can greatly extend the lifespan and reliability of your equipment.

- Perform routine inspections to identify wear and tear early.

- Change lubricants and fluids according to the manufacturer’s recommendations.

- Keep filters clean and replace them as needed to maintain optimal performance.

- Check and tighten bolts and fasteners to prevent loose components.

- Regularly clean the exterior to avoid buildup of dirt and debris.

Implementing these practices will not only improve efficiency but also enhance safety during operation. Prioritizing maintenance is essential for a long-lasting and reliable machine.

Common Issues and Solutions

This section addresses frequent challenges encountered with machinery operations and their effective resolutions. Understanding these issues can enhance performance and reduce downtime.

Typical Problems

- Engine starting difficulties

- Overheating issues

- Unusual noises during operation

- Hydraulic system malfunctions

Suggested Solutions

- Check battery connections and charge levels for starting issues.

- Inspect coolant levels and radiator for overheating.

- Examine belts and gears to identify noise sources.

- Ensure hydraulic fluid is at proper levels and free of contaminants.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance significantly enhances performance and longevity. These original elements are specifically designed to fit and operate seamlessly with your equipment, ensuring optimal functionality and reliability.

Enhanced Performance

Genuine components contribute to the overall efficiency of your machine, reducing the likelihood of malfunctions and ensuring smooth operation. They provide the perfect fit and compatibility, which translates to better performance in various tasks.

Long-Term Cost Savings

While authentic components may have a higher upfront cost, they often lead to savings in the long run. Reduced wear and tear, fewer breakdowns, and decreased need for replacements can result in significant financial benefits over time.

Parts Identification Guide

This section aims to assist users in recognizing and locating essential components for their machinery. A comprehensive understanding of each element’s function and placement enhances maintenance and operational efficiency.

Familiarizing yourself with the different sections of the equipment is crucial. Each area contains specific components that contribute to overall performance. Utilizing manuals or reference materials can facilitate easier identification, ensuring that necessary replacements or adjustments are made promptly.

Additionally, consulting visual aids can be beneficial. Diagrams and illustrations often provide clarity, making it simpler to pinpoint where each element resides. This proactive approach minimizes downtime and improves productivity.

Cost Considerations for Repairs

When planning maintenance or restoration of machinery, it’s essential to assess the financial implications involved. Various factors influence the overall expenses, including labor rates, material costs, and the complexity of the required work.

Labor Costs: Skilled technicians may charge differing rates based on their expertise and the region. It’s advisable to obtain quotes from multiple service providers to ensure competitive pricing.

Replacement Components: Sourcing quality parts is crucial, as cheaper options might lead to increased future expenses due to frequent replacements. Consider the balance between initial costs and long-term reliability.

Overall Budgeting: Setting aside a budget that accounts for unexpected repairs can prevent financial strain. Regular maintenance can also help minimize large expenses over time, ensuring optimal performance and longevity of the equipment.

Upgrading Components for Better Performance

Enhancing machinery efficiency often requires a focus on key elements that contribute to overall functionality. By upgrading specific components, operators can experience improved productivity, reduced downtime, and extended equipment lifespan. This section will explore various enhancements that can be made to optimize performance.

Key Areas for Upgrades

Prioritizing certain parts for enhancement can lead to significant gains. The following table highlights critical components that can benefit from upgrades:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Transmission | High-performance gear systems | Smoother operation, increased torque |

| Engine | Turbocharger installations | Enhanced power output, improved fuel efficiency |

| Hydraulics | Advanced pump systems | Faster response times, higher lifting capacity |

Considerations for Upgrading

Before proceeding with enhancements, it is essential to assess compatibility and overall impact on the machinery. Consulting with experts and reviewing performance data can ensure that upgrades align with operational goals.