The effective operation of farming equipment relies heavily on understanding how each element works in unison. By exploring the various mechanisms and configurations, one can grasp the significance of each component’s role in maintaining functionality and efficiency. This section aims to provide clarity on the layout and integration of different mechanical systems within such machines.

Each part contributes to the overall performance, from the smallest detail to the largest framework. Proper knowledge of these elements helps in both everyday use and during maintenance or repairs. Familiarizing oneself with the arrangement of these components is crucial for anyone involved in agricultural operations, ensuring smooth functioning and prolonged equipment life.

Whether you’re troubleshooting issues or simply aiming to understand your machinery better, having a clear reference of its internal systems is invaluable. By focusing on how these elements connect and support one another, you can ensure that the equipment operates at peak performance.

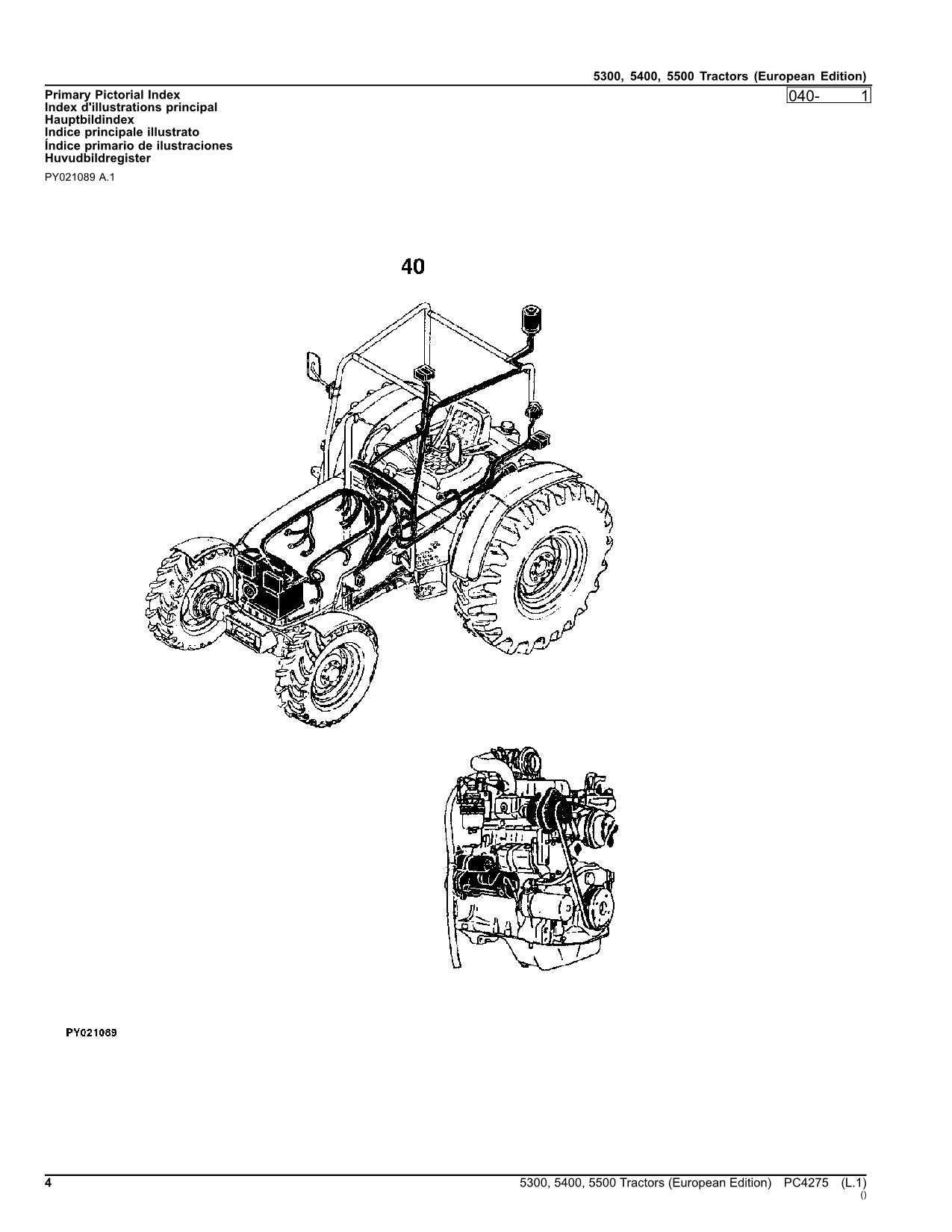

John Deere 5300 Parts Overview

Understanding the key components of agricultural machinery is essential for ensuring its proper functioning and longevity. Each section of this equipment is designed to fulfill a specific role, contributing to the overall performance and efficiency. Familiarity with these components can aid in maintaining the machine, preventing potential issues before they arise.

From the core of the engine to the transmission and hydraulic systems, every part works in harmony to deliver reliable service in various field conditions. Recognizing the importance of each piece is critical for timely repairs and upkeep, helping operators get the most out of their machinery during planting, harvesting, and other farming tasks.

Engine Components and Layout

The internal structure of the engine is crucial for its performance and durability. Understanding the key components and how they are arranged helps ensure proper maintenance and troubleshooting. In this section, we explore the basic elements of the engine and their spatial arrangement, offering insight into the essential functions of each part.

Main Elements of the Engine

The engine consists of several primary components such as the cylinder block, pistons, and crankshaft, all of which work in unison to generate power. These parts are meticulously arranged to maximize efficiency and ensure smooth operation. The proper functioning of these elements is vital for the overall health of the engine.

Layout and Design

The layout of these components is designed to optimize performance, with attention given to balance and energy distribution. The positioning of the pistons

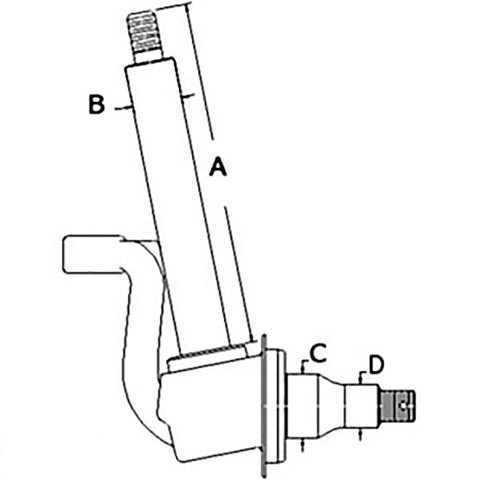

Hydraulic System Breakdown

The hydraulic system is a crucial component that powers various mechanisms, enabling smooth and efficient operation of machinery. This section provides an overview of how this system works, detailing the primary elements involved and how they interact to maintain functionality. Understanding these key components is essential for ensuring optimal performance and timely troubleshooting.

- Pump: This element is responsible for generating the necessary pressure to drive the hydraulic fluid through the system.

- Valves: These are used to control the flow and pressure of the fluid, directing it to the appropriate parts of the machinery.

- Cylinders: Hydraulic cylinders convert the fluid pressure into mechanical force, enabling movement of parts.

- Reservoir: The fluid storage tank ensures a steady supply of hydraulic fluid for consistent operation.

Regular maintenance of these components is key to preventing system failures and ensuring longevity. Proper inspection and timely

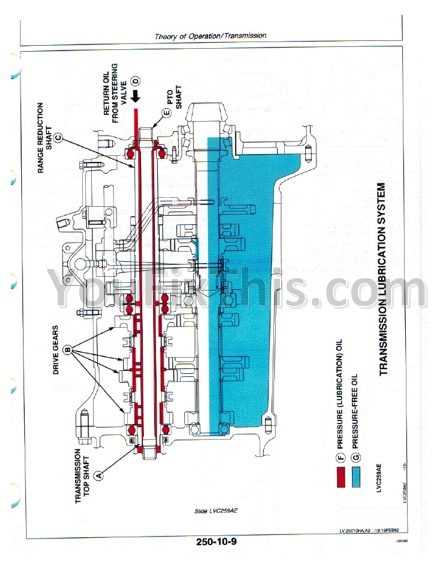

Transmission Assembly Guide

Assembling a transmission system requires attention to detail and a clear understanding of the overall structure. Ensuring all components are correctly aligned and secured is key to maintaining optimal performance. This guide will walk through the essential steps for assembling the transmission, highlighting the primary areas to focus on during the process.

The transmission consists of multiple interconnected parts that work in harmony to transfer power efficiently. Proper assembly involves careful placement of gears, shafts, and bearings, ensuring each element is positioned and tightened correctly.

| Step | Description | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Position the main housing and inspect for any debris or irregularities that could impact assembly. | ||||||||||||||||||||||||

| 2 | Carefully align the input and output shafts, ensuring they are seated firmly within the designated slots. |

| Component | Description |

|---|---|

| Fuel Tank | The storage unit that holds the fuel before it is sent to the engine. |

| Fuel Pump | Responsible for transporting fuel from the tank to the engine at the correct pressure. |

| Fuel Filter | Removes impurities and contaminants from the fuel before it reaches the engine. |

| Fuel Injector | Atomizes the fuel and delivers it directly into the combustion chamber for efficient combustion. |

| Fuel Lines | Hoses that connect the various components of the fuel system, allowing for the flow of fuel. |

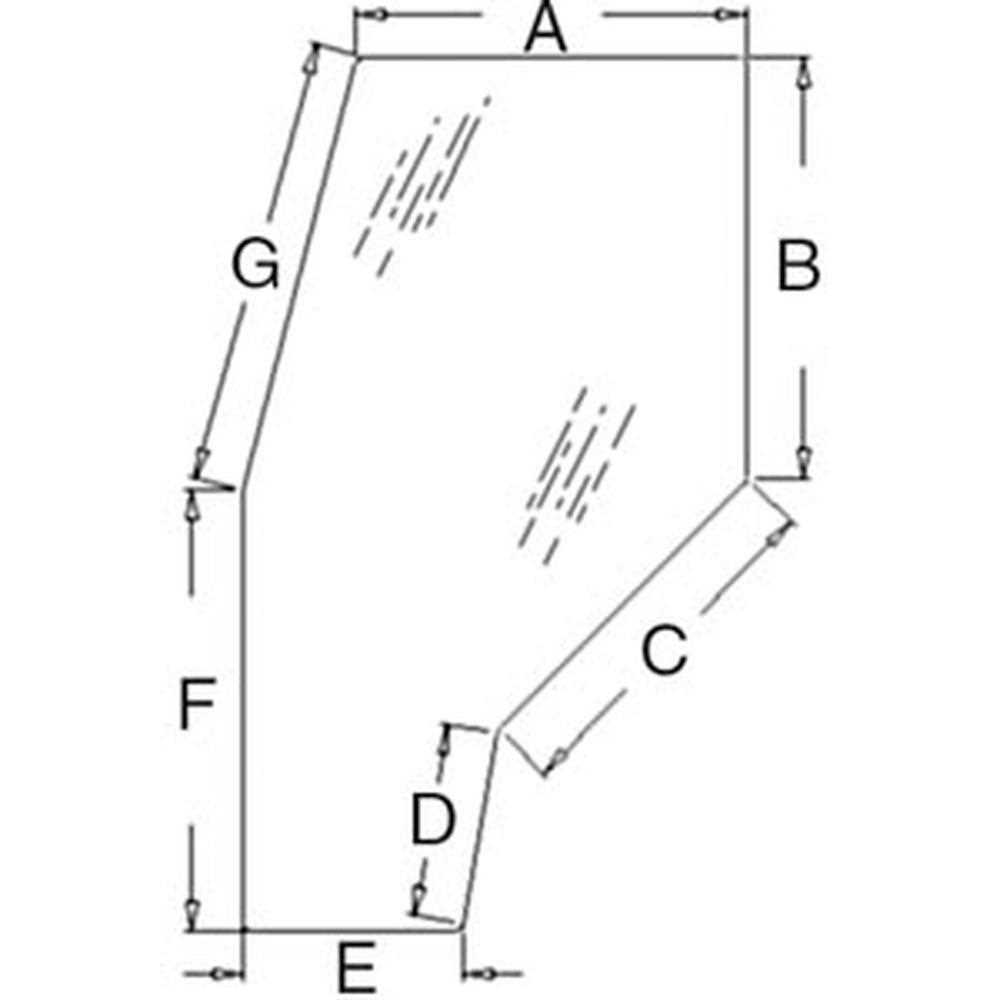

Front Axle and Suspension Parts

The front axle and suspension system play a crucial role in ensuring stability and handling in agricultural machinery. These components are designed to support the weight of the vehicle while providing a smooth ride over various terrains. A well-functioning front axle and suspension system contribute to the overall performance and longevity of the equipment.

Key elements of the front axle and suspension assembly include:

- Axle Housing: The main structure that supports the wheel assembly and connects to the chassis.

- Spindles: Components that allow for the rotation of the wheels, providing steering capabilities.

- Leaf Springs: Elastic elements that absorb shocks and maintain vehicle stability during operation.

- Shock Absorbers: Devices that dampen vibrations and enhance ride comfort by controlling the rebound of the suspension.

- Ball Joints: Pivot points that connect the axle to the steering mechanism, allowing for smooth movement.

Maintaining these components is essential for optimal performance. Regular inspections can help identify wear and tear, ensuring safe and efficient operation. Addressing issues promptly will extend the lifespan of the assembly and improve overall functionality.

Cabin Controls and Instruments

The cabin of a utility vehicle is equipped with a range of controls and instruments that enhance the operator’s experience and efficiency. These components are strategically positioned to ensure ease of access and functionality, enabling seamless operation during various tasks. Understanding the layout and purpose of each control is essential for effective vehicle management.

Control Layout

The arrangement of controls in the cabin plays a crucial role in the overall usability of the machine. Each control is designed to perform specific functions, allowing operators to manage the vehicle’s systems effectively. Below is a brief overview of typical controls found within the cabin:

| Control Type | Description |

|---|---|

| Steering Wheel | Used to direct the vehicle’s movement. |

| Throttle Control | Regulates engine power and speed. |

| Brake Pedal | Activates the braking system for stopping. |

| Gear Selector | Allows the operator to change gears as needed. |

| Instrument Panel | Displays vital information such as speed, fuel level, and engine temperature. |

Instruments Overview

The instruments in the cabin provide essential feedback to the operator, ensuring informed decision-making during operation. Common instruments include gauges and warning lights, each serving a specific purpose to enhance operational safety and efficiency. Familiarity with these instruments is vital for optimal vehicle performance.

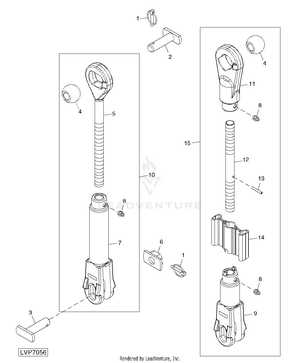

Rear PTO and Hitch System

The rear power take-off and towing mechanism play a crucial role in enhancing the functionality of agricultural machinery. These components are designed to facilitate the connection of various implements, allowing for efficient operation and versatility in different farming tasks.

One of the primary features of this system is its ability to provide a reliable power source for attachments such as mowers, tillers, and other essential tools. This allows users to maximize productivity while minimizing downtime during operations. The design ensures seamless integration with the tractor, enabling quick attachment and detachment of implements.

Moreover, the hitch system is engineered to support heavy loads, ensuring stability and safety during operation. Its adjustable nature allows for compatibility with a wide range of equipment, making it an indispensable aspect of modern agricultural practices. Regular maintenance of these components is vital to ensure optimal performance and longevity.