Maintaining a lawn care machine requires a clear comprehension of its individual elements. Each component plays a crucial role in ensuring optimal performance, making it essential for users to familiarize themselves with these intricate systems. A visual representation of these parts can greatly enhance one’s ability to troubleshoot and perform maintenance effectively.

For those looking to dive deeper into the inner workings of their machinery, exploring an organized layout of its various sections can be incredibly beneficial. This detailed view allows operators to identify specific pieces, understand their functions, and recognize when replacements or repairs are necessary. Knowledge of these components is the ultimate key to longevity and efficiency in lawn maintenance.

By examining a structured outline of these elements, users can develop a more intuitive grasp of their equipment. This understanding not only simplifies maintenance tasks but also empowers users to make informed decisions when it comes to repairs and upgrades. With the right insights, managing your lawn equipment becomes a straightforward endeavor.

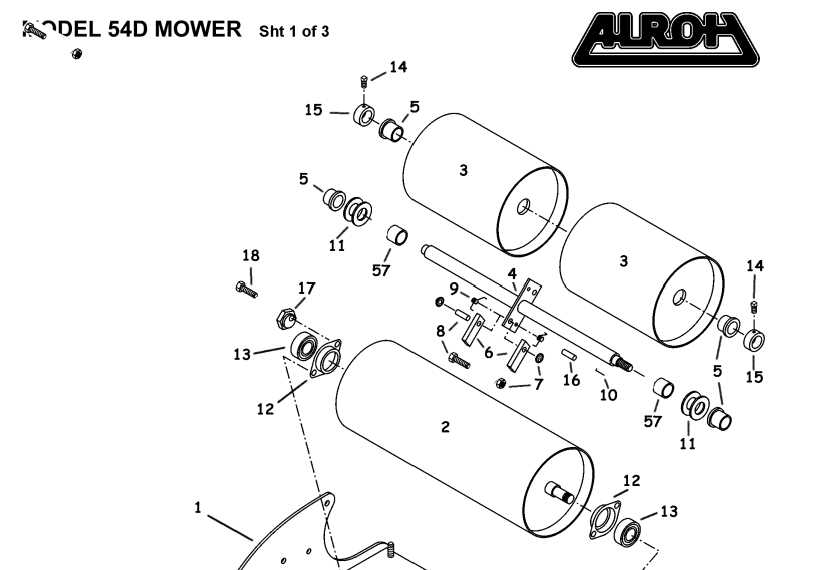

Understanding John Deere 54D Parts

Grasping the components of lawn maintenance machinery is essential for efficient operation and maintenance. Familiarity with the intricate elements ensures longevity and optimal performance. This section aims to illuminate the various elements involved in such equipment, emphasizing their roles and importance.

Components play a vital role in the functionality of any machine. Each section is designed to fulfill specific tasks, contributing to the overall efficiency. Understanding these sections allows operators to troubleshoot issues effectively and perform necessary maintenance.

For instance, the cutting mechanism is crucial for achieving a clean, precise cut. Its design and configuration influence the quality of work performed. Additionally, other parts like the drive system and frame structure are equally important, as they ensure stability and power transfer.

By delving into these elements, operators can identify potential problems early and implement solutions, ultimately enhancing the performance of their machinery.

Overview of the 54D Model

The 54D model is a significant component in the realm of outdoor power equipment, known for its durability and efficiency. Designed for various landscaping tasks, it stands out for its robust construction and versatility, catering to both residential and commercial needs. Understanding the features and functionality of this model can greatly enhance the user experience and maintenance practices.

Key Features

- Durable materials that withstand tough conditions

- Efficient cutting performance for a pristine finish

- Compatibility with various attachments for enhanced functionality

- User-friendly design for easy operation and maintenance

Applications

- Residential lawn care and landscaping

- Commercial grounds maintenance

- Seasonal snow removal

- Versatile gardening tasks

Key Components Explained

Understanding the essential elements of a machinery model is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring the equipment functions efficiently and effectively. This section will delve into the primary features and their functions, providing insights into their importance in the overall system.

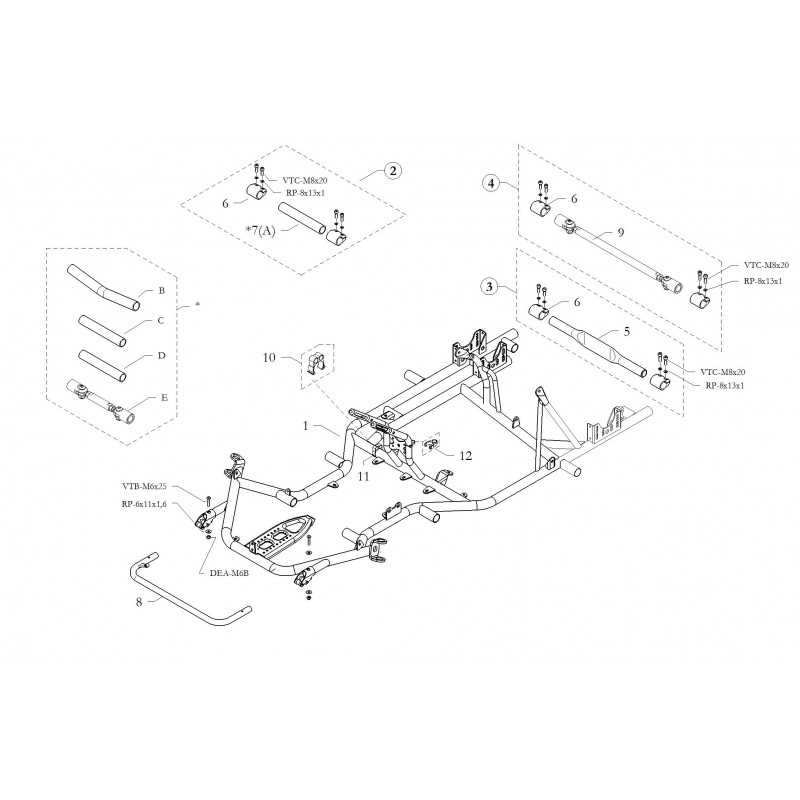

- Frame: The structural backbone that supports all other components, providing stability and strength.

- Engine: The powerhouse that drives the machinery, converting fuel into mechanical energy.

- Transmission: This component transmits power from the engine to the wheels or blades, allowing for smooth operation and control.

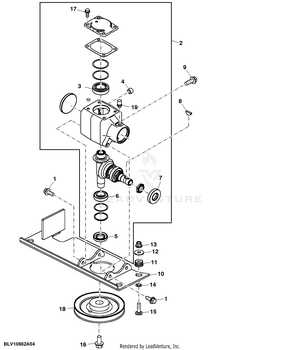

- Hydraulic System: Responsible for transferring power through fluid movement, enabling lifting and steering functionalities.

- Control Panel: The interface where operators can manage and monitor the machinery, adjusting settings as necessary.

Each of these elements contributes to the overall functionality and efficiency, making it essential to understand their roles for proper maintenance and troubleshooting.

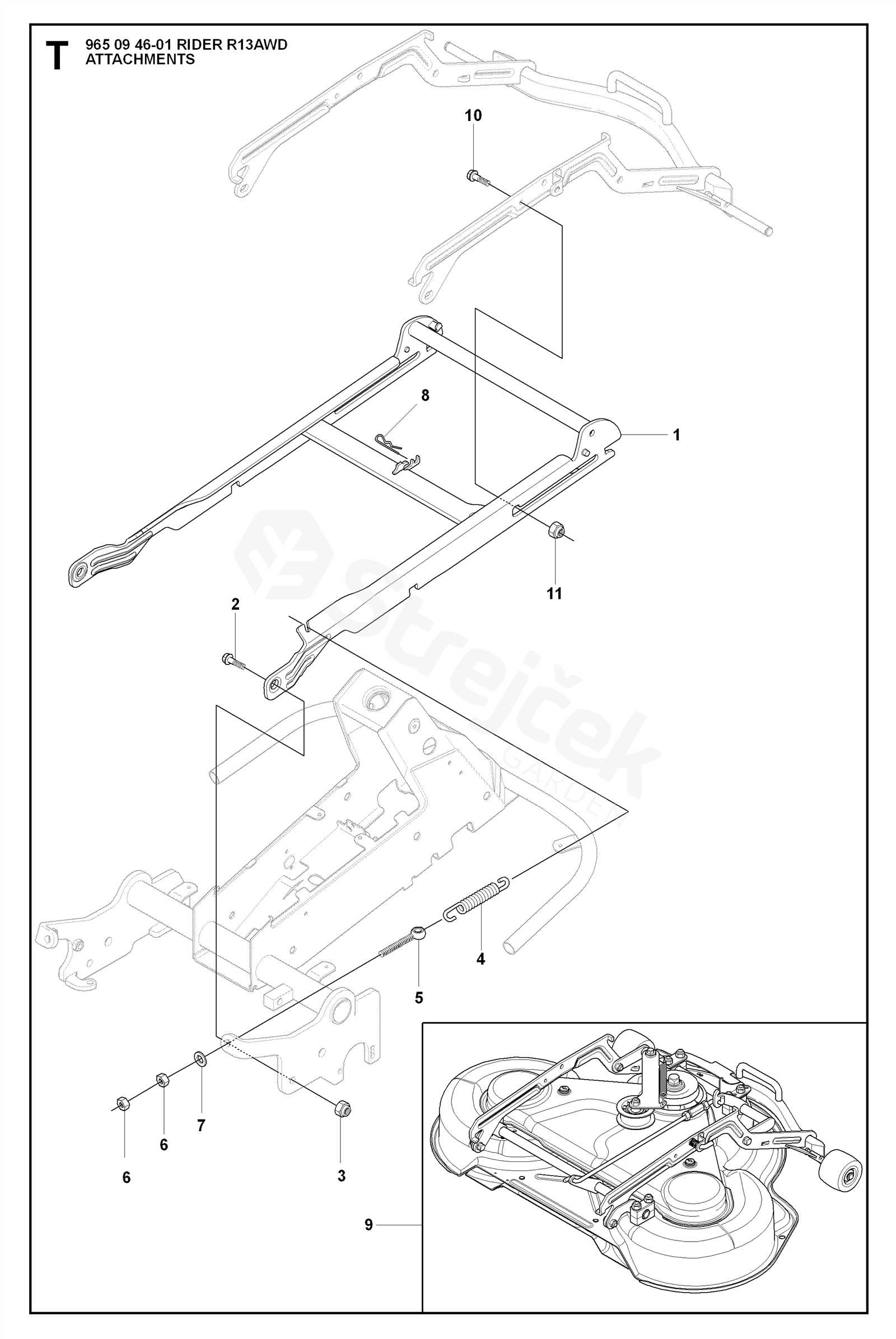

Importance of Parts Diagrams

Visual representations of components are essential for understanding the assembly and functionality of machinery. They serve as a guide, allowing users to identify individual elements and their relationships within a system. This clarity can significantly enhance maintenance, repairs, and overall equipment longevity.

Facilitating Repairs and Maintenance

Having access to accurate illustrations simplifies the troubleshooting process. Technicians can quickly locate faulty components and determine the necessary steps for replacement or repair. This not only saves time but also minimizes the risk of errors during service interventions.

Enhancing User Knowledge

Visual aids contribute to a deeper understanding of how systems operate. By studying these illustrations, users can gain insights into the machinery’s design and functionality, fostering better decision-making when it comes to operation and care. As a result, this knowledge empowers individuals to maintain their equipment more effectively.

Finding the Right Replacement Parts

Ensuring optimal performance of your equipment often hinges on selecting the correct components. When it comes to maintenance and repairs, understanding how to identify and source the appropriate items is essential for longevity and efficiency. A methodical approach to finding the right replacements can save time and money while enhancing the overall functionality of your machinery.

Understanding Component Compatibility

Before purchasing any replacements, it’s crucial to grasp the compatibility of the items with your specific model. Different machines can have unique specifications, so consulting the manufacturer’s documentation or online resources can provide valuable insights. Cross-referencing part numbers and utilizing visual aids can help you ensure that the replacements will fit seamlessly.

Where to Source Quality Components

There are several reliable sources for obtaining high-quality replacements. Authorized dealers often carry genuine components, ensuring that you receive parts that meet original specifications. Additionally, reputable online retailers and local suppliers can provide a wide selection at competitive prices. Always look for reviews and ratings to gauge the reliability of a supplier. Investing in quality components will ultimately contribute to the durability and performance of your equipment.

Common Issues with 54D Components

When dealing with various components of mowing equipment, several recurring problems can emerge that affect performance and longevity. Understanding these issues can help in maintaining efficiency and reducing downtime.

One frequent concern is the wear and tear on blades, which can lead to uneven cutting and increased fuel consumption. Regular inspection and timely replacement are essential to mitigate this issue.

Another common problem involves the drive belt, which may become frayed or loose over time. This can result in slippage or complete failure, impacting the overall operation of the machine.

Additionally, components related to the hydraulic system can develop leaks or clogs, causing reduced power and responsiveness. Regular maintenance checks are crucial to ensure these systems function optimally.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular care and attention. Implementing a systematic approach to maintenance can significantly enhance performance and reduce the likelihood of unexpected breakdowns. Here are essential practices to consider for optimal durability.

- Regular Cleaning: Keep your machine free from debris and dirt. Regularly clean the exterior and interior components to prevent corrosion and wear.

- Fluid Checks: Monitor and replace fluids as recommended. This includes oil, fuel, and coolant, which are vital for smooth operation.

- Inspect Components: Frequently check for signs of wear or damage. Pay special attention to belts, filters, and other critical parts.

- Sharpen Blades: For cutting equipment, ensure blades are sharp to improve efficiency and reduce strain on the motor.

- Storage Conditions: Store equipment in a dry, sheltered area to protect it from harsh weather conditions and prolong its life.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided in the user manual for best results.

By implementing these strategies, you can help ensure your machinery remains in excellent condition for many years to come.

Where to Buy Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. There are several reliable avenues to explore when seeking high-quality replacements that ensure compatibility and durability.

Authorized dealers often provide the most trusted options, as they typically stock items directly from the manufacturer. This ensures that every piece meets the required specifications and quality standards.

Additionally, online retailers can be a convenient choice. Many established platforms specialize in equipment components, offering a wide selection with competitive pricing. Always verify the credibility of the seller to ensure you are receiving genuine products.

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official retailers recognized by the manufacturer. | Guaranteed authenticity, expert advice, and warranty support. |

| Online Marketplaces | Websites that specialize in selling equipment components. | Convenience, variety, and often lower prices. |

| Local Repair Shops | Shops that service equipment and may sell components. | Personalized service and local support. |

In conclusion, whether you choose a physical store or an online platform, ensure that the components you purchase are genuine to keep your machinery running smoothly.

Step-by-Step Repair Guide

This section provides a comprehensive approach to maintaining and fixing your equipment efficiently. By following a structured method, you can identify issues, gather necessary components, and execute repairs effectively. Each step is designed to simplify the process and ensure that you can return your machinery to optimal working condition.

Step 1: Assess the Situation

Begin by carefully inspecting the equipment to determine the nature of the problem. Look for any visible signs of wear, damage, or malfunction. Take note of any unusual sounds or behaviors that might indicate underlying issues.

Step 2: Gather Required Tools and Components

Before starting the repair, collect all necessary tools and replacement items. Having everything on hand will streamline the process and prevent unnecessary interruptions. Refer to manuals or online resources to ensure you have the correct specifications.

Step 3: Disassemble as Needed

With a clear understanding of the problem, carefully disassemble the affected areas. Keep track of screws and parts to avoid losing anything. Organize components in a way that makes reassembly straightforward.

Step 4: Execute the Repair

Replace or repair the identified faulty components based on your assessment. Follow manufacturer guidelines or repair manuals for precise instructions. Pay attention to detail to ensure that all parts fit securely and function properly.

Step 5: Reassemble and Test

Once the repair is complete, reassemble the equipment with care. Make sure everything is correctly aligned and fastened. After reassembly, perform a thorough test to confirm that the repairs have resolved the issues and that the machinery operates smoothly.

Step 6: Regular Maintenance

To prevent future problems, establish a routine maintenance schedule. Regular checks and upkeep will prolong the lifespan of your equipment and enhance its performance. Document any repairs and maintenance tasks to track the history of your machinery.

Tools Needed for Repairs

When tackling maintenance or restoration tasks, having the right equipment is essential for efficiency and effectiveness. Proper tools not only streamline the process but also ensure safety and accuracy during repairs. Whether you are a seasoned technician or a DIY enthusiast, equipping yourself with the necessary instruments will make a significant difference in the outcome of your work.

Basic Hand Tools are fundamental for any repair job. These include wrenches, screwdrivers, and pliers, which are essential for disassembling and reassembling components. Investing in high-quality hand tools can prevent damage to parts and enhance the overall experience.

Power Tools also play a crucial role in speeding up the repair process. Drills, grinders, and impact wrenches can handle tougher tasks that require more power than manual tools. However, it’s important to use them with caution and proper technique to avoid accidents.

Safety Gear should never be overlooked. Items such as gloves, goggles, and masks protect you from potential hazards while working. Ensuring your safety allows you to focus on the task at hand without unnecessary distractions.

Diagnostic Equipment is invaluable for identifying issues accurately. Tools like multimeters and pressure gauges help in diagnosing problems effectively, allowing for more precise repairs.

In summary, having a comprehensive set of tools not only makes the repair process smoother but also enhances the quality of the work performed. Preparing adequately with the right equipment is key to successful maintenance tasks.

Upgrading Components for Performance

Enhancing the efficiency of machinery often involves the strategic improvement of various elements. By focusing on specific components, one can significantly boost overall functionality and longevity. This approach not only maximizes productivity but also reduces maintenance costs over time.

Identifying key areas for enhancement is essential. Components such as the drive system, cutting mechanisms, and engine parts can greatly influence performance. Upgrading to higher-quality materials or more advanced designs can yield substantial benefits.

Regular assessments of existing elements are vital to determine which upgrades will provide the ultimate advantage. Investing in superior components can transform standard equipment into high-performing assets, ensuring better results in all applications.

Resources for Further Information

Exploring available resources can significantly enhance your understanding of machinery components and their configurations. Whether you seek technical specifications, maintenance tips, or installation guidelines, various platforms offer valuable insights and assistance.

Online Forums and Communities

Joining online communities dedicated to machinery enthusiasts can provide firsthand experiences and solutions. Platforms like Reddit and specialized forums allow users to share advice, troubleshoot issues, and discuss modifications. Engaging with fellow users can lead to a deeper comprehension of your equipment.

Official Manufacturer Websites

Manufacturer websites often serve as a reliable source for documentation and manuals. Here, you can find detailed guides, safety instructions, and updates on new features. Utilizing these resources ensures you have access to the most accurate and relevant information for optimal performance.