Understanding the intricate workings of agricultural machinery is essential for optimal performance and longevity. A well-organized visual representation of the various elements of a specific piece of equipment can greatly assist operators and technicians in maintaining efficiency and addressing potential issues effectively.

By familiarizing oneself with the essential components and their arrangements, users can ensure that their machinery operates at peak capacity. This knowledge aids in identifying wear and tear, facilitating timely replacements, and enhancing overall productivity in agricultural tasks.

Such illustrative resources serve as valuable guides for both seasoned professionals and newcomers alike, promoting a deeper comprehension of the operational aspects and maintenance requirements of the equipment. Utilizing these references leads to informed decisions that contribute to the machinery’s extended service life.

This section outlines a structured approach to exploring the components of a specific agricultural implement. Each heading serves to highlight different aspects and functions of the machinery, ensuring a comprehensive understanding for users and operators. The following headings will cover various features, maintenance tips, and essential parts relevant to the implement.

- Essential Components of the Machinery

- Maintenance Tips for Optimal Performance

- Common Issues and Troubleshooting Guide

- Upgrading Parts for Enhanced Efficiency

- Identifying Wear and Tear Signs

- Comparative Analysis of Similar Models

- Best Practices for Safe Operation

- Recommended Tools for Repairs

- Understanding the Operating Manual

- Historical Development of Agricultural Implements

- Impact of Technology on Performance

- Future Trends in Agricultural Equipment

Key Features of Rotary Cutters

Rotary cutting implements are essential tools in agricultural and landscaping applications, designed to efficiently manage vegetation. These implements provide versatility and adaptability, making them suitable for various terrains and tasks.

Durability: Crafted from robust materials, these devices withstand the rigors of frequent use. Their construction ensures longevity, even in challenging environments.

Adjustable Cutting Heights: Many models offer the ability to modify the cutting height, allowing users to achieve desired results based on the type of vegetation and the specific requirements of the job.

Wide Cutting Width: With a broader cutting area, these implements enhance productivity, reducing the time needed for larger tasks. This feature makes them ideal for expansive fields and properties.

Efficient Power Use: Designed for optimal performance, these tools utilize power effectively, ensuring that energy consumption is minimized while still achieving high levels of output.

Easy Maintenance: Many models are designed with user-friendly features that facilitate maintenance, ensuring that routine care is straightforward and can be performed quickly.

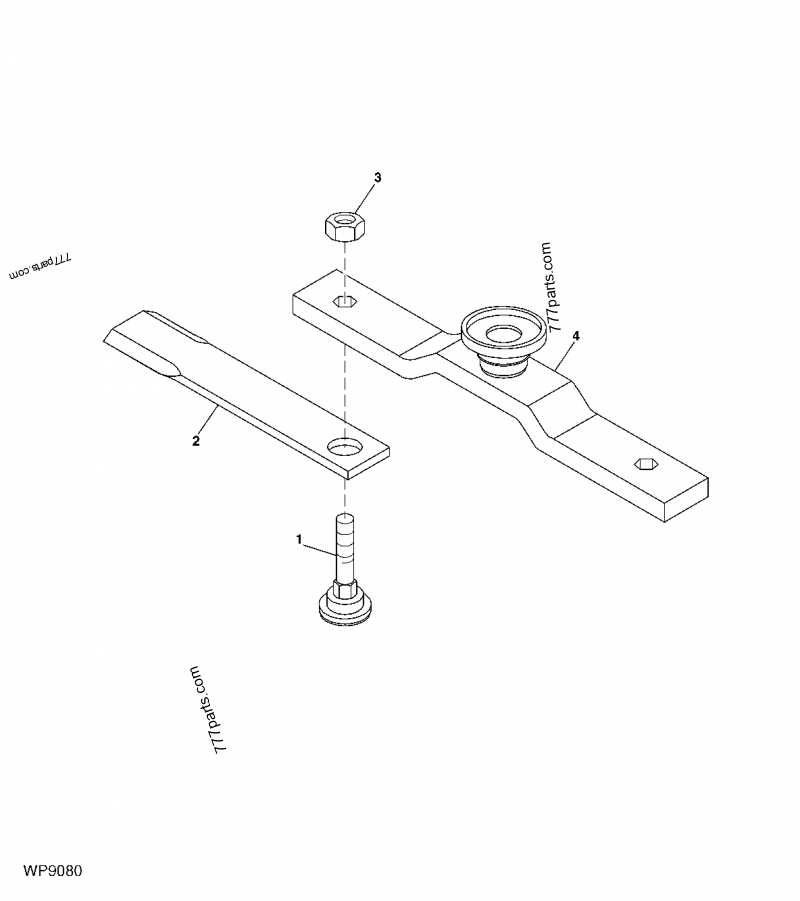

Understanding Parts and Components

This section aims to provide insight into the various elements that constitute a specific agricultural implement. By grasping the functionality and interrelation of these components, users can enhance their maintenance skills and operational knowledge.

Key Components Overview

- Frame: The foundational structure that supports all other elements.

- Blades: Essential for cutting through vegetation effectively.

- Gearbox: Transmits power from the engine to the blades, enabling efficient operation.

- Wheels: Facilitate mobility across different terrains.

- Hitch: Connects the implement to the tractor, ensuring stability during use.

Importance of Regular Maintenance

Routine inspection and care of each component are crucial for optimal performance. Neglecting any part can lead to decreased efficiency and potential damage. Here are some maintenance tips:

- Check for wear and tear regularly.

- Lubricate moving parts to reduce friction.

- Ensure all connections are secure and functional.

Maintenance Tips for Optimal Performance

To ensure the best functionality of your equipment, regular upkeep is essential. Proper maintenance not only extends the lifespan of your machine but also enhances its efficiency. Implementing a systematic approach can lead to significant improvements in performance and reliability.

Routine Inspections

- Check fluid levels regularly, including oil and hydraulic fluid.

- Inspect belts and chains for wear and tension, adjusting as necessary.

- Examine blades for sharpness and damage; sharpen or replace as needed.

- Ensure all bolts and fasteners are secure to prevent loose components.

Seasonal Maintenance Tasks

- Clean the equipment thoroughly after each use to remove debris and prevent corrosion.

- Change oil and filters as per the manufacturer’s recommendations.

- Lubricate all moving parts to minimize friction and wear.

- Store the machinery in a dry, sheltered location to protect it from the elements.

Identifying Common Issues with Cutters

Understanding typical challenges that can arise with cutting equipment is essential for maintaining optimal performance. Regularly identifying these issues can prevent more significant complications, ensuring that the machinery operates smoothly and efficiently.

One common problem is dull blades, which can lead to uneven cutting and increased strain on the motor. Regular sharpening and timely replacement of blades are crucial to avoid this issue. Another frequent concern is misalignment of the cutting mechanism, which may result in inefficient operation and unnecessary wear on components. Ensuring proper alignment during maintenance checks can help mitigate this risk.

Additionally, unusual vibrations during operation may indicate loose components or wear on bearings. It’s vital to inspect and tighten all fittings to maintain stability. Clogs caused by debris accumulation can hinder performance, making it necessary to clean the equipment regularly. By being aware of these potential issues, operators can take proactive measures to enhance the lifespan and effectiveness of their machinery.

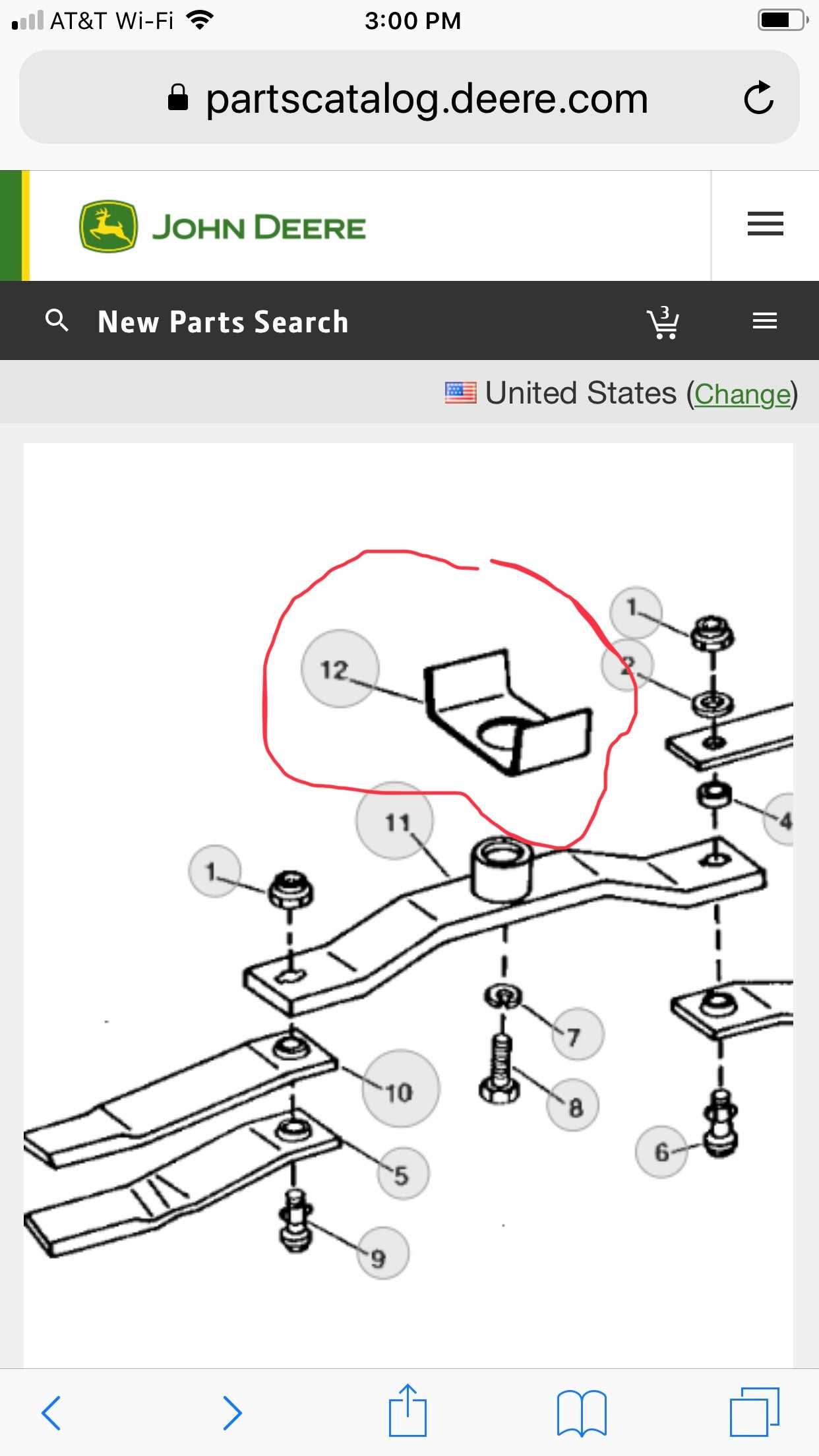

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repairs. These visual aids provide detailed information about each element of the machinery, facilitating identification and replacement. Familiarizing yourself with the layout and symbols used in these graphics will enhance your ability to manage equipment efficiently.

Familiarize Yourself with Symbols

Each illustration includes specific icons that represent various components. Take the time to learn these symbols, as they are crucial for interpreting the information correctly. Most manuals will include a legend to help you decipher the meanings of these signs.

Follow the Numbering System

Typically, parts are numbered sequentially in the illustration. This system allows you to cross-reference the visual representation with the corresponding list of components. Ensuring you understand this numbering will streamline the process of locating and ordering replacements.

Ordering Replacement Parts Effectively

When it comes to acquiring new components for your equipment, efficiency is key. Understanding the process and utilizing the right resources can streamline your experience, ensuring you receive the correct items without unnecessary delays.

Follow these essential steps for effective ordering:

- Identify the Required Components: Before placing an order, make sure to accurately determine which elements you need. Check the equipment’s manual or consult a knowledgeable source.

- Research Suppliers: Look for reputable vendors that specialize in equipment components. Consider factors such as customer reviews, availability, and pricing.

- Verify Compatibility: Ensure that the selected components are suitable for your specific model. This reduces the likelihood of returns or exchanges.

- Utilize Online Resources: Many suppliers offer online catalogs and diagrams. Use these tools to cross-reference and confirm the correct items.

- Check for Discounts: Look for promotional offers or bulk purchase discounts that could save you money.

- Place Your Order: Once you’ve confirmed the components, proceed with the order. Provide all necessary details to avoid delays in processing.

By following these guidelines, you can enhance your ordering experience and ensure your machinery remains in optimal condition.

Benefits of Genuine John Deere Parts

Using authentic components for machinery ensures optimal performance and longevity. These parts are specifically designed to fit perfectly and function seamlessly, which contributes to the overall efficiency of the equipment. Relying on high-quality components can lead to improved productivity and reduced downtime.

Quality Assurance: Genuine components undergo rigorous testing to meet industry standards. This guarantees reliability and durability, minimizing the risk of failure during operation.

Compatibility: Authentic parts are engineered to work with specific models, ensuring that all mechanisms operate harmoniously. This compatibility leads to better performance and extends the life of the machinery.

Support and Warranty: Using original components often comes with the backing of a warranty. This provides peace of mind, knowing that any issues will be addressed by the manufacturer.

Resale Value: Maintaining equipment with genuine components can enhance its resale value. Prospective buyers are more likely to invest in well-maintained machinery that features original parts.

Overall Efficiency: Genuine components contribute to the smooth operation of machinery, reducing wear and tear. This efficiency not only saves on repair costs but also enhances productivity in the long run.

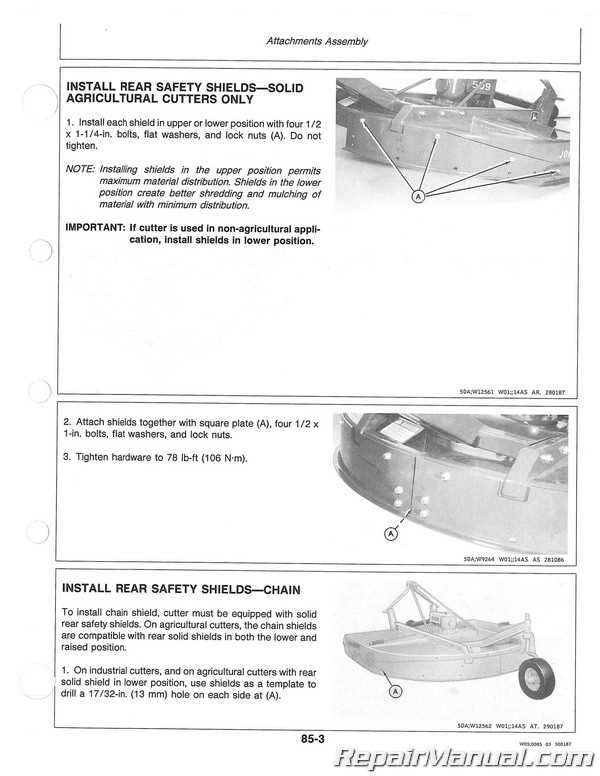

Installation Guide for New Components

This section provides a comprehensive overview of the process for integrating new components into your equipment. Proper installation is crucial for ensuring optimal performance and longevity. Following the correct procedures will help in achieving efficient operation and prevent potential issues.

Preparation Steps

Before beginning the installation, ensure you have all necessary tools and replacement components on hand. Carefully read the accompanying instructions that come with the new parts. Check for compatibility with existing machinery and verify that all items are in good condition.

Installation Procedure

Start by safely securing the equipment and disconnecting any power sources. Remove the old components as per the manufacturer’s guidelines. Place the new parts in position, ensuring they align correctly with the existing framework. Tighten all fittings securely and recheck connections. Once everything is installed, reconnect power and conduct a thorough test to ensure everything functions properly.

Tip: Regular maintenance checks after installation will help to identify any potential issues early and extend the life of your machinery.

Safety Precautions While Operating

Ensuring safety during operation is crucial to prevent accidents and injuries. Adhering to specific guidelines and practices can significantly enhance the protection of the operator and those nearby. Proper knowledge of equipment use, maintenance, and safety measures is essential for a secure working environment.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Conduct a thorough inspection of the machinery before each use to identify any potential issues.

- Keep the operating area clear of obstacles and debris to ensure safe maneuverability.

- Follow the manufacturer’s instructions for operation and maintenance to minimize risks.

- Never allow unauthorized individuals to operate the equipment.

Operational Best Practices

- Maintain a safe distance from bystanders while the machinery is in operation.

- Be cautious of uneven terrain and adjust the speed accordingly to maintain control.

- Do not exceed the recommended load limits to avoid equipment failure.

- Keep hands and feet away from moving parts to prevent injuries.

- Stop the machine and allow it to come to a complete halt before performing maintenance or adjustments.

Comparative Analysis of Similar Models

This section provides a detailed examination of various comparable models within the same equipment category. By evaluating their features, functionalities, and overall performance, users can make informed decisions regarding their investment.

Several key factors are essential for a thorough comparison:

- Design and Build Quality: Assessing the durability and materials used in construction.

- Performance Metrics: Evaluating power output, cutting efficiency, and operational speed.

- Ease of Maintenance: Analyzing accessibility to components for routine servicing.

- Compatibility with Accessories: Checking available attachments and enhancements that can improve usability.

When selecting a model, users should consider the following:

- Intended Use: Determine whether the equipment is suited for heavy-duty tasks or lighter applications.

- Cost of Ownership: Factor in purchase price alongside maintenance and operational costs.

- Manufacturer Support: Evaluate warranty options and availability of replacement parts.

In conclusion, a comprehensive analysis of similar models allows potential buyers to weigh their options effectively and select the most appropriate equipment for their needs.

Customer Reviews on Performance

Customer feedback plays a vital role in understanding the effectiveness of agricultural machinery. Users often share their experiences regarding the performance and reliability of their equipment, providing valuable insights for potential buyers. Evaluating these reviews can help in making informed decisions about purchasing and utilizing such machinery.

Overall Satisfaction

Many users express high levels of satisfaction with their machinery, noting its robust build and efficiency in handling various tasks. The consistent performance across different terrains and conditions is frequently highlighted, with many reviewers emphasizing the equipment’s durability and low maintenance needs.

Efficiency and Versatility

Feedback regarding efficiency often points to the machinery’s ability to perform tasks swiftly without compromising on quality. Users appreciate its versatility, allowing them to tackle different jobs effectively. The adaptability to various field conditions has been particularly praised, enhancing productivity for farmers and landowners alike.

| Feature | Customer Rating |

|---|---|

| Durability | 4.8/5 |

| Efficiency | 4.7/5 |

| Ease of Use | 4.6/5 |

| Maintenance | 4.5/5 |

Where to Find Technical Support

Accessing reliable technical support is crucial for effective maintenance and operation of your equipment. Whether you require assistance with troubleshooting or need guidance on specific components, several resources can provide valuable information.

Manufacturer Support

Most manufacturers offer dedicated support services for their products. This can include:

- Customer service hotlines for immediate inquiries.

- Online portals with extensive resources, including FAQs and troubleshooting guides.

- Authorized service centers for in-person assistance.

Online Forums and Communities

Engaging with online communities can also be beneficial. Consider exploring:

- Dedicated forums where users share experiences and solutions.

- Social media groups focused on specific equipment types.

- Video tutorials on platforms like YouTube that offer practical advice and demonstrations.