In the world of farming, understanding the intricate elements of machinery is essential for maintaining optimal performance. Each piece plays a vital role in ensuring efficiency and productivity on the field.

Familiarity with the layout of these components can significantly enhance the ability to troubleshoot issues and carry out effective repairs. This knowledge not only saves time but also minimizes potential downtime during critical seasons.

Furthermore, having a detailed overview allows operators to delve into the functionality of each part, fostering a deeper appreciation for the technology that supports modern agriculture. Ultimately, a comprehensive understanding equips users to make informed decisions regarding maintenance and upgrades.

Understanding John Deere 630 Disc Parts

In the realm of agricultural machinery, having a thorough comprehension of the various components is essential for optimal functionality. Each element plays a pivotal role in ensuring that the equipment operates smoothly and effectively, enabling users to achieve the best results in their farming activities.

To gain insight into the essential components, consider the following key aspects:

- Frame: The backbone of the machinery, providing stability and support for all attached elements.

- Blades: Crucial for soil preparation, these sharp instruments cut through the earth, promoting better cultivation.

- Bearings: Ensuring smooth rotation, these elements reduce friction and wear, extending the lifespan of the machine.

- Hitch: This connection point allows the equipment to be towed by tractors, ensuring versatility in operation.

- Gang Assembly: A collection of blades arranged in a specific manner to optimize performance during use.

Understanding each of these components allows operators to maintain their equipment effectively and troubleshoot any issues that may arise. Regular inspections and knowledge of each part’s function will lead to improved efficiency and longevity of the machinery.

Overview of Disc Harrow Functionality

The implementation of tillage implements plays a crucial role in soil management and preparation for crop production. These machines are designed to break up the soil, incorporate organic matter, and create a suitable seedbed for various types of crops.

These tools utilize a series of rotating blades that slice through the earth, providing several key benefits:

- Soil aeration, which enhances root development.

- Weed control by disrupting their growth patterns.

- Incorporation of residues, which contributes to improved soil fertility.

- Moisture retention, critical for seed germination and growth.

Effective utilization of these implements depends on various factors, including:

- Soil type and condition.

- Desired depth of tillage.

- Operating speed and field conditions.

Understanding the functionality and mechanics behind these implements allows for optimal performance and enhanced agricultural productivity.

Key Components of the 630 Model

This section explores the essential elements that contribute to the functionality and performance of the specific agricultural implement model. Each component plays a crucial role in ensuring optimal operation and efficiency, allowing users to maximize their productivity in various farming tasks.

The frame serves as the backbone, providing stability and support for all attached elements. Additionally, the cutting blades are designed for precision, enabling effective soil management. The axle system enhances maneuverability, ensuring smooth navigation across different terrains.

Moreover, the hydraulic system allows for adjustable settings, facilitating customized operations based on specific field conditions. Lastly, the wheels are engineered for durability, providing reliable traction and stability during usage.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of agricultural machinery requires consistent care and attention. Proper maintenance not only extends the lifespan of equipment but also enhances performance, leading to better productivity. Below are some essential practices to keep your machinery in optimal condition.

Regular Inspections

Frequent assessments can help identify wear and tear before they escalate into significant issues. Here are key components to inspect:

- Blades and cutting edges

- Hydraulic systems

- Wheels and axles

- Frames and supports

Routine Cleaning

Accumulated dirt and debris can affect performance. Implement these cleaning routines:

- Wash the exterior to remove mud and residues.

- Clear debris from moving parts and ventilation areas.

- Lubricate joints and hinges to prevent rust and corrosion.

By following these guidelines, operators can significantly enhance the reliability and longevity of their equipment, ensuring it remains a valuable asset for years to come.

Common Issues with Disc Parts

When operating agricultural equipment, several typical challenges may arise related to the components responsible for tilling. Understanding these issues can lead to more efficient maintenance and improved performance.

- Wear and Tear: Components may degrade over time, leading to decreased effectiveness.

- Alignment Problems: Improper alignment can result in uneven operation and increased strain on parts.

- Jamming: Accumulation of debris can cause components to seize or operate inefficiently.

- Corrosion: Exposure to moisture and soil can lead to rust and other forms of deterioration.

Addressing these common issues promptly can enhance the longevity and functionality of the equipment, ultimately ensuring optimal performance in the field.

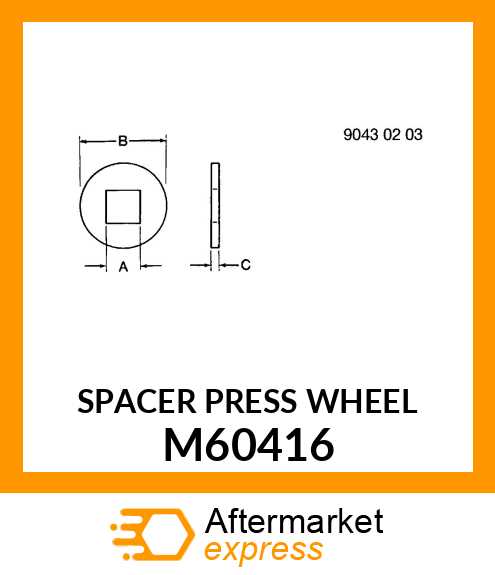

Identifying Replacement Parts Easily

Locating the right components for agricultural machinery can be a daunting task, yet it is essential for maintaining optimal performance. A systematic approach can simplify this process, ensuring you find exactly what you need without unnecessary delays.

Start by familiarizing yourself with the various elements of your equipment. Understanding each component’s function allows for quicker identification when searching for substitutes. Utilize resources such as manuals or online databases to gain insight into specifications and compatibility.

Visual aids like schematics can also be invaluable. They provide a clear overview of the entire assembly, helping to pinpoint the exact items requiring replacement. Additionally, leveraging online forums or community groups can offer guidance and tips from experienced users who have navigated similar challenges.

Lastly, keeping an organized inventory of your current components can save time in the long run. Regularly updating this list will ensure that you have quick access to necessary details, making future replacements straightforward.

Comparative Analysis with Other Models

This section aims to explore the similarities and differences between a specific agricultural implement and its counterparts in the market. By examining various models, we can identify key features, performance metrics, and user preferences that influence equipment choice among farmers.

One significant aspect is the build quality, which often dictates longevity and effectiveness in field operations. While some models prioritize lightweight materials for ease of transport, others focus on durability, offering a more robust construction that can withstand challenging conditions.

Performance capabilities also vary widely. Certain alternatives may provide superior cutting efficiency or better adaptability to diverse soil types, giving them an edge in specific farming scenarios. Assessing these attributes helps users make informed decisions based on their unique operational needs.

Finally, cost-effectiveness plays a critical role in model comparison. Analyzing initial purchase prices alongside long-term maintenance and operational costs allows farmers to evaluate the ultimate value of each implement, ensuring they choose the best option for their investment.

Benefits of Genuine John Deere Parts

Using authentic components for agricultural machinery ensures optimal performance and longevity. These high-quality items are specifically designed to fit and function seamlessly with your equipment, enhancing its efficiency and reliability.

One significant advantage of utilizing genuine components is the assurance of quality. Each piece undergoes rigorous testing to meet industry standards, reducing the likelihood of breakdowns and costly repairs. Furthermore, these items often come with manufacturer warranties, providing additional peace of mind.

Additionally, original components contribute to maintaining the resale value of machinery. Prospective buyers often seek equipment that features authentic parts, as they are associated with superior durability and performance. This aspect can make a substantial difference in the market value when it’s time to sell or trade.

Moreover, using certified components can lead to enhanced efficiency. These parts are engineered to work harmoniously with other machinery elements, promoting smoother operation and reducing fuel consumption. This efficiency not only saves money in the long run but also supports sustainable agricultural practices.

In conclusion, investing in authentic components is a wise choice for any operator. It maximizes equipment performance, prolongs lifespan, and supports overall operational efficiency.

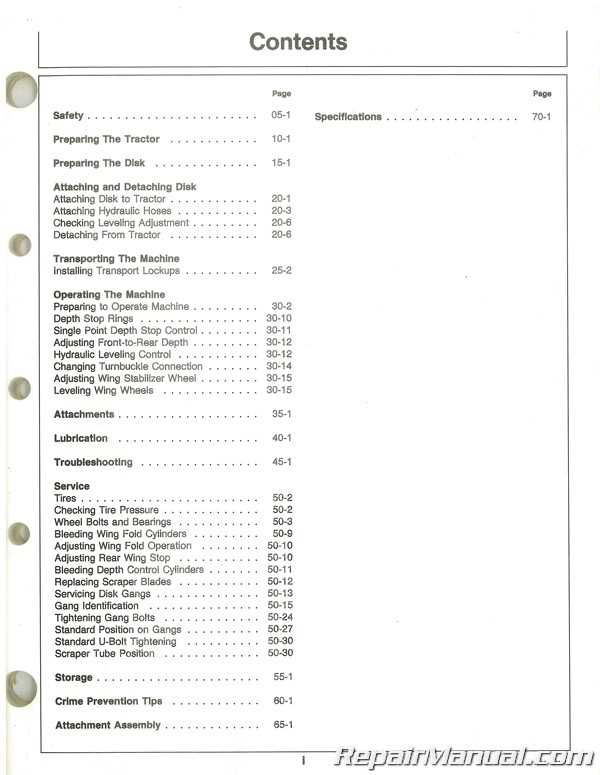

Installation Guide for New Parts

Replacing components in your agricultural machinery can significantly enhance performance and extend the lifespan of your equipment. This guide outlines the essential steps and considerations for successfully installing new components, ensuring optimal functionality and safety during operation.

Preparation Steps

Before beginning the installation, it is crucial to gather all necessary tools and components. Ensure that the equipment is powered down and secure to prevent accidents. A clean workspace will facilitate a smoother installation process. Review the manufacturer’s specifications for the new components to understand any specific requirements or adjustments needed during installation.

Installation Process

Follow these steps to ensure a successful installation:

| Step | Description |

|---|---|

| 1 | Remove the existing component carefully, taking note of how it is attached. |

| 2 | Clean the mounting area to remove debris and old materials. |

| 3 | Position the new component and align it with the mounting points. |

| 4 | Secure the new component using the appropriate fasteners, ensuring they are tightened to the specified torque. |

| 5 | Perform a visual inspection to confirm that the installation is correct. |

| 6 | Repower the equipment and test the new component in operation. |

Following these guidelines will help ensure that your new components are installed correctly, promoting efficient and reliable performance in your machinery.

Cost Considerations for Repairs

When it comes to maintaining and restoring agricultural machinery, understanding the financial implications is crucial. Repair expenses can vary significantly based on several factors, including the complexity of the issues, availability of components, and labor rates. Planning ahead and budgeting effectively can lead to more manageable costs and prevent unexpected financial burdens.

Factors Influencing Repair Costs

Several elements play a role in determining the overall expenses associated with repairs. Age and condition of the machinery often dictate the extent of maintenance required. Older equipment may need more frequent interventions, while newer models might only require standard servicing. Additionally, the availability of components can impact costs; rare or outdated parts often come with higher price tags. Labor costs also vary widely, depending on local market rates and the expertise of the technicians involved.

Budgeting for Unexpected Expenses

It is wise to set aside a contingency fund for unforeseen repairs. Machinery can break down unexpectedly, and having financial resources available can mitigate stress during such situations. Regular inspections and maintenance can help identify potential issues early, allowing for more controlled spending over time. By being proactive, owners can extend the lifespan of their equipment while keeping repair costs within reasonable limits.

Where to Buy Replacement Components

Finding reliable sources for replacement components is essential for maintaining the efficiency of your agricultural equipment. Whether you’re looking for specific items or general supplies, numerous options are available to ensure you can keep your machinery running smoothly.

Online Retailers are among the most convenient choices, offering a wide range of components at competitive prices. Websites dedicated to agricultural machinery often provide detailed descriptions and customer reviews, helping you make informed decisions.

Local Dealers can be a valuable resource as well. They not only stock essential items but also have the expertise to assist with compatibility and installation. Building a relationship with your local supplier can lead to better service and support in the long run.

Salvage Yards are another option worth considering. These facilities often have used components that can be purchased at a fraction of the cost of new ones. While it requires a bit more effort to find the right fit, the savings can be significant.

Lastly, online marketplaces provide a platform for both new and second-hand components. Always check the seller’s ratings and reviews to ensure reliability. By exploring these various avenues, you can find the right components to keep your machinery in top condition.

Expert Recommendations and Resources

When it comes to maintaining and optimizing agricultural machinery, having access to reliable insights and comprehensive resources is crucial. Experts in the field often highlight the importance of understanding the intricacies of equipment components to ensure longevity and efficiency. Below are some valuable recommendations and resources that can enhance your knowledge and aid in effective maintenance practices.

Key Considerations for Maintenance

Regular upkeep not only prolongs the life of your machinery but also maximizes productivity. Here are some essential factors to keep in mind:

| Consideration | Description |

|---|---|

| Routine Inspections | Conduct frequent evaluations to identify wear and tear before it leads to major issues. |

| Quality Replacement Parts | Use high-grade components to ensure compatibility and reliability in performance. |

| Expert Guidance | Consult with professionals for tailored advice and troubleshooting techniques. |

| Proper Lubrication | Ensure all moving parts are adequately lubricated to reduce friction and wear. |

Recommended Resources

Utilizing credible sources can significantly enhance your understanding of machinery maintenance. Consider the following resources:

| Resource | Description |

|---|---|

| Manufacturer’s Manual | A comprehensive guide detailing specifications, maintenance schedules, and troubleshooting steps. |

| Online Forums | Community platforms where users share experiences, tips, and solutions to common challenges. |

| Industry Workshops | Hands-on training sessions conducted by experts, focusing on best practices and innovations. |

| Instructional Videos | Visual aids that demonstrate maintenance techniques and repair procedures step-by-step. |