In the realm of modern agriculture, the efficiency and reliability of machinery play a crucial role in ensuring optimal crop production. A comprehensive grasp of the various elements that constitute these machines enables operators to maintain performance and extend longevity. Each component, from the engine to the harvesting mechanisms, contributes to the overall functionality, making knowledge of these parts essential for effective management.

Familiarity with machinery schematics is vital for troubleshooting and repairs. These detailed illustrations provide insights into the arrangement and interaction of different parts, allowing users to identify potential issues swiftly. By understanding how each piece fits into the larger system, operators can enhance their problem-solving capabilities and make informed decisions regarding maintenance and upgrades.

Moreover, a thorough examination of the specific components can lead to improved operational efficiency. Knowing the role and performance metrics of each part aids in optimizing settings and workflows, ultimately resulting in better yield outcomes. Investing time in learning about these mechanical assemblies not only benefits individual operators but also contributes to the overall advancement of agricultural practices.

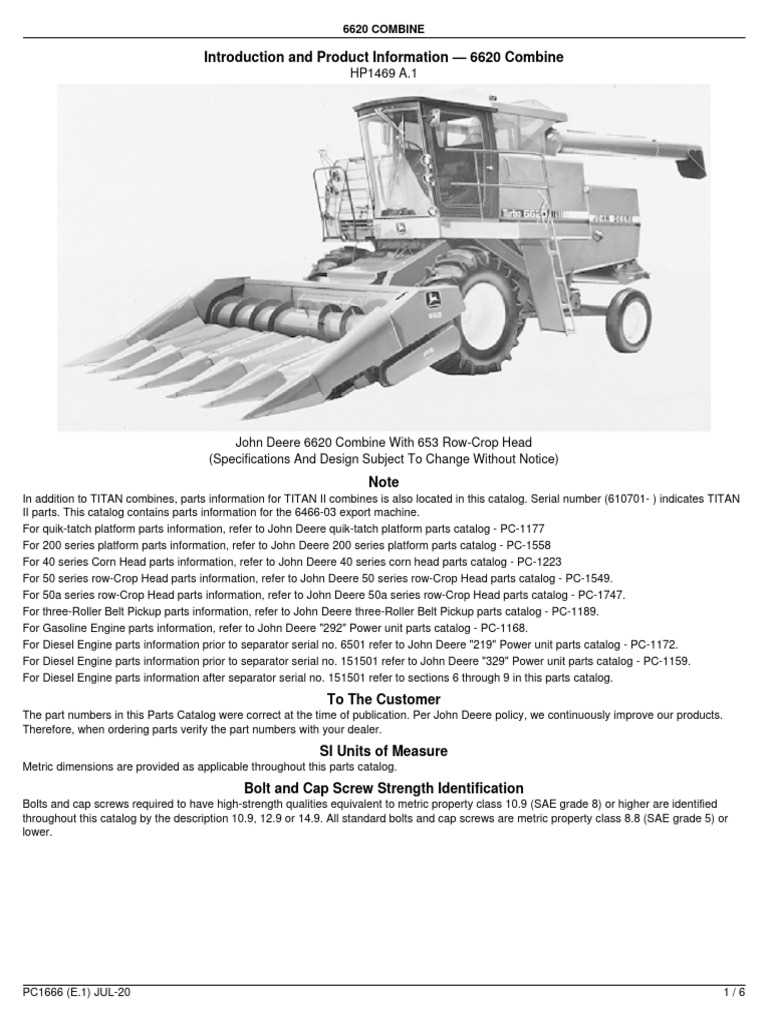

Understanding the John Deere 6620 Combine

This section explores the essential components and functionalities of a prominent agricultural harvesting machine. By examining its design and operational mechanisms, we aim to enhance comprehension of its role in modern farming practices.

Key Features of the Machine

The machinery is equipped with various features that contribute to its efficiency and effectiveness. Some of the notable attributes include advanced harvesting technology, robust engine performance, and user-friendly controls, all designed to maximize productivity during the harvest season.

Maintenance and Upkeep

Regular maintenance is crucial for ensuring the longevity and optimal performance of the equipment. Understanding the essential components and their functions can aid in identifying potential issues early on, thus facilitating timely repairs and replacements.

| Component | Description |

|---|---|

| Engine | Powers the machine and drives various systems. |

| Header | Collects and cuts the crop efficiently. |

| Separator | Separates grains from the harvested material. |

| Grain Tank | Stores the collected grains before unloading. |

| Cab | Provides a comfortable working environment for the operator. |

Key Components of the Combine

Understanding the essential elements of agricultural harvesting machinery is crucial for efficient operation and maintenance. These components work in harmony to ensure the effective processing of crops, enhancing productivity on the field.

Harvesting Mechanism

The harvesting mechanism is at the heart of the machine’s functionality. It is responsible for cutting and gathering crops from the field. This system typically includes cutting blades and augers, which help in efficiently transporting the harvested material to the threshing area.

Separation and Threshing Systems

Once the crops are gathered, they enter the separation and threshing systems. These mechanisms play a vital role in separating the grain from the chaff. Utilizing a combination of drum rotations and screen systems, they ensure that the grains are clean and ready for storage. Regular maintenance of these systems is essential to avoid breakdowns and ensure optimal performance.

In conclusion, familiarity with these key components can greatly enhance the operator’s understanding and efficiency, leading to a more productive harvest season.

Benefits of Using Original Parts

Utilizing authentic components in agricultural machinery ensures optimal performance and longevity. These specialized elements are designed specifically for your equipment, providing a seamless fit and reliable functionality. By choosing original over generic alternatives, operators can maintain the integrity of their machinery while enhancing efficiency and productivity.

One significant advantage is the assurance of quality. Authentic components undergo rigorous testing and adhere to strict manufacturing standards, which generic options often lack. This reliability translates into reduced downtime and fewer repairs, ultimately leading to cost savings in the long run.

Another key benefit is the enhanced compatibility with existing systems. Original elements are engineered to work harmoniously with the machinery, ensuring that every function operates as intended. This compatibility minimizes the risk of malfunctions or the need for frequent adjustments, which can disrupt workflow.

| Benefits | Description |

|---|---|

| Quality Assurance | Undergoes rigorous testing and meets strict standards. |

| Reliability | Reduces downtime and need for repairs. |

| Compatibility | Engineered for seamless integration with machinery. |

| Performance | Enhances overall efficiency and productivity. |

In conclusion, opting for authentic components significantly benefits users by ensuring superior quality, reliability, and compatibility, all of which contribute to the optimal operation of agricultural equipment.

Common Issues and Troubleshooting Tips

In the world of agricultural machinery, encountering challenges is not uncommon. Understanding frequent problems and their solutions can greatly enhance efficiency and minimize downtime. This section provides valuable insights into typical malfunctions and practical advice for resolving them.

1. Engine Performance Issues: If the engine struggles to start or runs unevenly, check the fuel supply, air filters, and spark plugs. Regular maintenance can prevent these issues.

2. Unusual Noises: Strange sounds during operation may indicate loose components or worn parts. Inspect belts, chains, and bearings for wear and ensure they are properly tightened.

3. Hydraulic Problems: Inadequate lifting power or sluggish movement often points to hydraulic fluid levels or leaks. Regularly check fluid levels and inspect hoses for signs of wear.

4. Electrical Failures: Flickering lights or malfunctioning controls can be traced back to electrical connections. Ensure that all wiring is intact and free from corrosion.

5. Cleaning and Maintenance: Clogged filters and dirty components can lead to decreased performance. Regularly clean and replace filters to maintain optimal functioning.

Maintenance Tips for Optimal Performance

Regular upkeep is crucial for ensuring machinery operates at its best. By following essential care practices, users can enhance longevity and efficiency, ultimately leading to a more productive experience.

Routine Inspections

Conduct frequent checks on critical components to identify wear and tear. Timely replacements can prevent larger issues and reduce downtime.

Proper Lubrication

Ensure all moving parts are adequately lubricated to minimize friction. Using the right type of lubricant not only promotes smooth operation but also extends the life of the equipment.

Finding Replacement Parts Online

In today’s digital age, sourcing components for agricultural machinery has never been easier. With just a few clicks, operators can explore numerous online platforms dedicated to providing the necessary items for maintenance and repair. This section outlines the best practices for efficiently locating the right components for your equipment through online resources.

Utilizing Reputable Online Retailers

Start your search with established e-commerce sites that specialize in agricultural equipment. These platforms often feature extensive inventories, detailed descriptions, and user reviews that can help guide your selection. Always ensure that the site offers secure payment options and a clear return policy to protect your investment.

Consulting Community Forums and Resources

Engaging with online communities can also yield valuable insights. Many enthusiasts and professionals share their experiences regarding sourcing and maintaining equipment. Participating in discussions on dedicated forums can lead you to trusted sellers and unique offers that may not be widely advertised.

In summary, leveraging the internet to find necessary components can save time and money, making it essential for anyone involved in machinery upkeep. With the right approach, the search for reliable items becomes a straightforward process.

Comparing Aftermarket vs. OEM Parts

The choice between alternative and original components is a crucial consideration for many equipment owners. Each option presents its own set of advantages and challenges, influencing overall performance, reliability, and cost-effectiveness. Understanding the key differences can help in making informed decisions that suit individual needs and preferences.

Advantages of Aftermarket Components

- Cost Savings: Often, alternative components are priced more competitively, making them an attractive choice for budget-conscious buyers.

- Variety: A wide range of options is available, allowing for more customization to meet specific requirements.

- Accessibility: Many suppliers provide easier access to alternative components, often with shorter lead times.

Benefits of Original Components

- Quality Assurance: Original components typically undergo rigorous testing to ensure they meet the manufacturer’s standards for performance and durability.

- Compatibility: Designed specifically for the equipment, they often guarantee a better fit and functionality.

- Warranty Protection: Purchasing original components can come with warranties that offer additional peace of mind and coverage for potential defects.

In conclusion, the decision between alternative and original components ultimately hinges on individual priorities, including budget, performance expectations, and long-term reliability. Careful evaluation of each option is essential to make the best choice for your equipment needs.

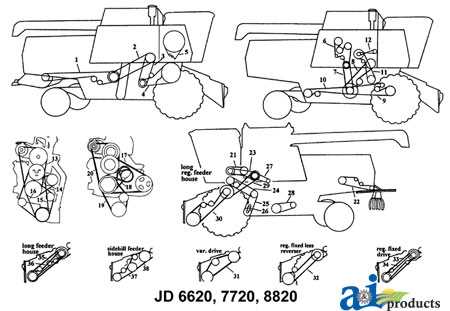

How to Read Parts Diagrams

Understanding technical illustrations is essential for efficient maintenance and repair of machinery. These visual representations provide detailed insights into the components and their relationships within a system, allowing for effective troubleshooting and assembly.

Key Elements of Illustrations

When examining these visuals, focus on the labels and the legends that clarify the components. Pay attention to the numbering system used, as it often corresponds with a list of items that may include specifications and part numbers.

Interpreting Relationships

Analyzing how components are connected can reveal crucial information regarding assembly and disassembly processes. Look for lines or arrows that indicate connections or functions.

| Element | Description |

|---|---|

| Labels | Identify specific components or sections. |

| Legend | Explains symbols or abbreviations used. |

| Numbers | Correspond to a list of components with details. |

Importance of Regular Inspections

Consistent evaluations of machinery play a crucial role in maintaining optimal performance and extending the lifespan of equipment. These assessments not only identify potential issues before they escalate but also enhance operational efficiency and safety.

Benefits of Regular Checks

- Early detection of wear and tear

- Reduction in costly repairs

- Improved safety for operators

- Enhanced efficiency and productivity

Best Practices for Inspections

- Establish a regular inspection schedule.

- Document findings and repairs.

- Utilize checklists for thorough evaluations.

- Engage qualified personnel for detailed assessments.

Upgrades for Enhanced Efficiency

Improving agricultural machinery can significantly boost performance and productivity. Upgrades often lead to better fuel efficiency, increased operational speed, and reduced downtime, ultimately enhancing overall output. By focusing on key areas, operators can achieve remarkable improvements in their equipment’s functionality.

Powertrain Enhancements

Investing in advanced powertrain components can lead to smoother operation and increased torque. Upgrading the engine or transmission system ensures better handling of various field conditions, enhancing the machine’s responsiveness and reducing wear and tear.

Precision Technology Integration

Incorporating precision agriculture technology allows for data-driven decision-making. This includes systems for monitoring crop health and optimizing inputs, leading to more efficient resource utilization and ultimately maximizing yields.

Customer Reviews on John Deere Parts

This section explores feedback from users regarding components used in agricultural machinery. Insights from customers highlight performance, durability, and service quality, helping others make informed decisions when purchasing replacements or upgrades.

Performance Insights

Many users praise the efficiency and reliability of the equipment. Positive reviews often emphasize how these components enhance overall productivity and reduce downtime during critical harvesting periods.

Durability and Longevity

Feedback frequently points to the robustness of these items, with customers noting that well-constructed components stand up to rigorous use. Such durability contributes to lower maintenance costs and extended machinery life.

| Review | Rating |

|---|---|

| Excellent performance in the field | 5 stars |

| Lasts much longer than expected | 4 stars |

| Some issues with fitment | 3 stars |