In modern agriculture, the efficiency of planting equipment plays a crucial role in maximizing yield and minimizing soil disturbance. A specific type of seeding implement is designed to operate effectively in various soil conditions, ensuring optimal seed placement while preserving soil structure. Understanding the intricate components of such machinery is essential for farmers seeking to enhance their cultivation practices.

Exploring the different elements of this specialized equipment reveals a complex interplay between technology and agricultural techniques. Each component serves a unique purpose, contributing to the overall functionality and reliability of the machine. Familiarity with these parts not only aids in maintenance and repair but also empowers operators to make informed decisions about their usage and care.

By delving into the layout and functions of each piece, users can better appreciate the engineering behind efficient planting solutions. Whether for troubleshooting or optimization, grasping the configuration of this essential agricultural tool can lead to improved performance in the field.

Understanding the John Deere 750 Drill

This section explores the key features and components of a specific agricultural implement designed for efficient planting. By examining its construction and functionality, users can better appreciate how it contributes to modern farming practices.

Key Features

The implement is renowned for its durability and precision, allowing for optimal seed placement in various soil conditions. Its design minimizes soil disturbance, promoting healthy crop growth and maximizing yields.

Components and Maintenance

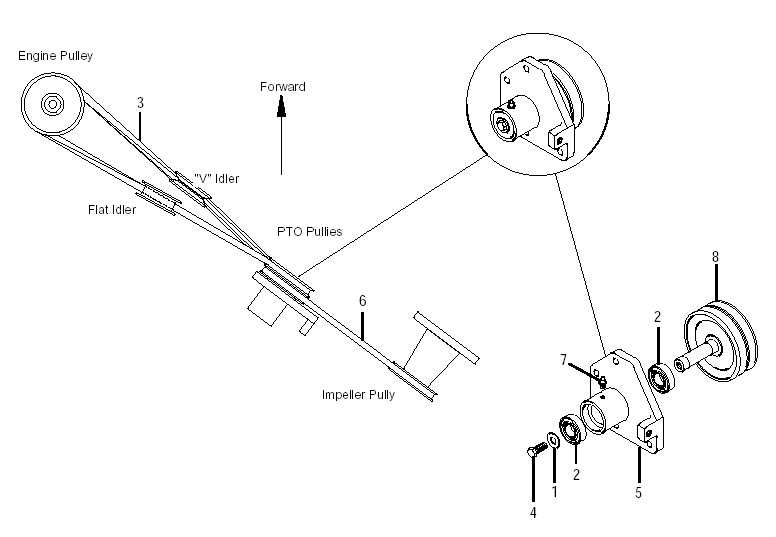

Components of No-Till Drills

No-till equipment plays a crucial role in modern agriculture, allowing for efficient planting while minimizing soil disturbance. Understanding the various elements that comprise these machines is essential for optimizing their use and ensuring effective seed placement.

- Frame: The structural foundation that supports all other components.

- Seed Hoppers: Containers that hold and distribute seeds evenly during planting.

- Openers: Specialized tools designed to penetrate the soil and create furrows for seed placement.

- Press Wheels: Mechanisms that compact the soil over the seeds, ensuring good seed-to-soil contact.

- Fertilizer Attachments: Systems that allow for simultaneous application of nutrients during planting.

Each of these components contributes to the ultimate efficiency and effectiveness of no-till practices, helping farmers achieve better yields with less environmental impact.

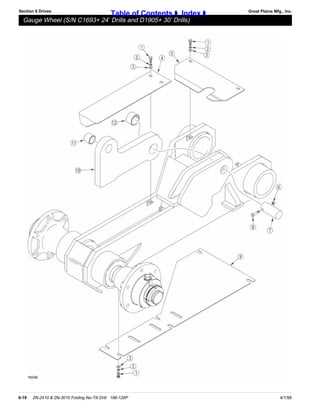

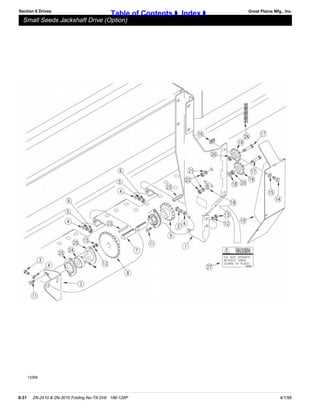

Importance of Parts Diagrams

Understanding the intricacies of machinery requires a clear visual representation of its components. These illustrations serve as essential tools for maintenance, troubleshooting, and assembly. By offering a detailed view, users can easily identify each element, ensuring that repairs and upgrades are performed accurately.

Enhanced Maintenance Efficiency

Accessing a comprehensive visual guide significantly improves maintenance efficiency. It allows technicians to quickly locate specific components, reducing downtime and enhancing overall productivity. With clear indications of how parts fit together, the process becomes more streamlined and intuitive.

Facilitating Troubleshooting

In the event of a malfunction, having a visual reference can be invaluable. It enables users to pinpoint issues swiftly, leading to quicker resolutions. By understanding the layout and function of each component, operators can delve into problem-solving with confidence, ultimately minimizing operational disruptions.

Identifying Key Parts and Functions

Understanding the essential components of agricultural equipment is crucial for effective operation and maintenance. Each element plays a significant role in ensuring optimal performance and achieving desired results in fieldwork. This section will delve into the primary sections of the machinery, outlining their specific functions and importance in the overall process.

Main Components

- Seed Boxes: These containers hold the seeds and are designed to ensure even distribution during planting.

- Openers: These mechanisms create furrows in the soil, allowing seeds to be placed at the correct depth.

- Press Wheels: They follow behind the seed placement to compact the soil, ensuring good seed-to-soil contact.

- Hitch: This component connects the implement to the tractor, providing stability and control during operation.

Supporting Elements

- Frame: The backbone of the equipment, providing structure and support for all components.

- Transport Wheels: These allow for easy movement of the implement from one location to another.

- Depth Control Mechanism: This feature allows operators to adjust the planting depth according to crop requirements.

- Adjustment Levers: These are used for fine-tuning various settings to optimize performance in different field conditions.

By familiarizing oneself with these key components and their respective roles, operators can enhance both the effectiveness and efficiency of their agricultural practices.

Maintenance Tips for Longevity

Ensuring the durability of agricultural equipment requires consistent attention and care. By implementing a series of straightforward maintenance practices, operators can enhance the lifespan and efficiency of their machinery, minimizing unexpected repairs and downtime.

Regular Inspections

Conducting frequent evaluations of your equipment is crucial. Look for signs of wear and tear, and address any issues promptly. Focus on key components such as bearings, blades, and hydraulic systems. Early detection of potential problems can save both time and money in the long run.

Proper Cleaning and Storage

After each use, ensure that the machinery is thoroughly cleaned to remove soil, debris, and residues. This practice prevents corrosion and other damage caused by accumulated materials. Additionally, store the equipment in a sheltered area when not in use to protect it from harsh weather conditions. Consistent upkeep of both cleaning and storage practices significantly contributes to maintaining functionality over time.

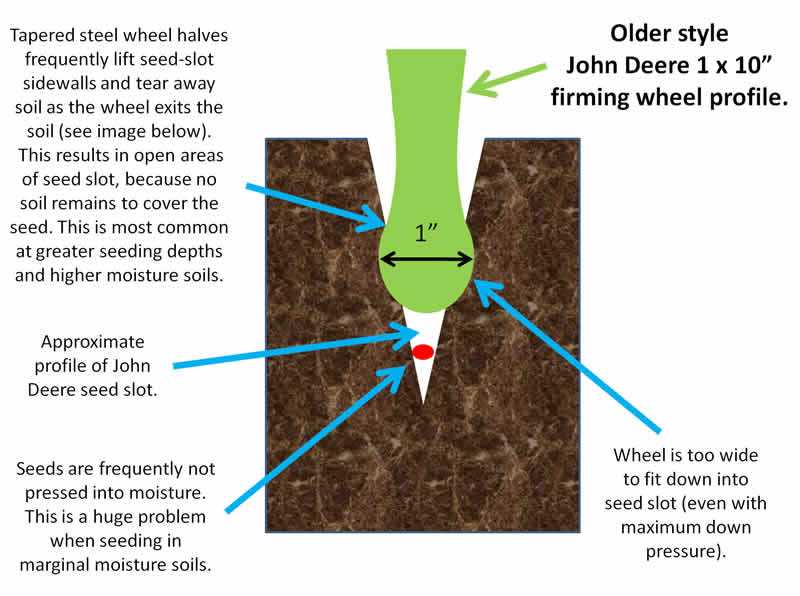

Common Issues with No-Till Drills

No-till planting equipment is designed to minimize soil disturbance while ensuring effective seed placement. However, users often encounter several challenges that can impact performance and efficiency. Understanding these issues can enhance operational success and crop yield.

One prevalent problem is the buildup of residue, which can obstruct seed placement and negatively affect germination rates. Proper maintenance and regular cleaning can help mitigate this issue. Another concern involves uneven seed depth, leading to inconsistent crop emergence. Adjustments to the equipment’s settings or calibration may be necessary to achieve optimal planting results.

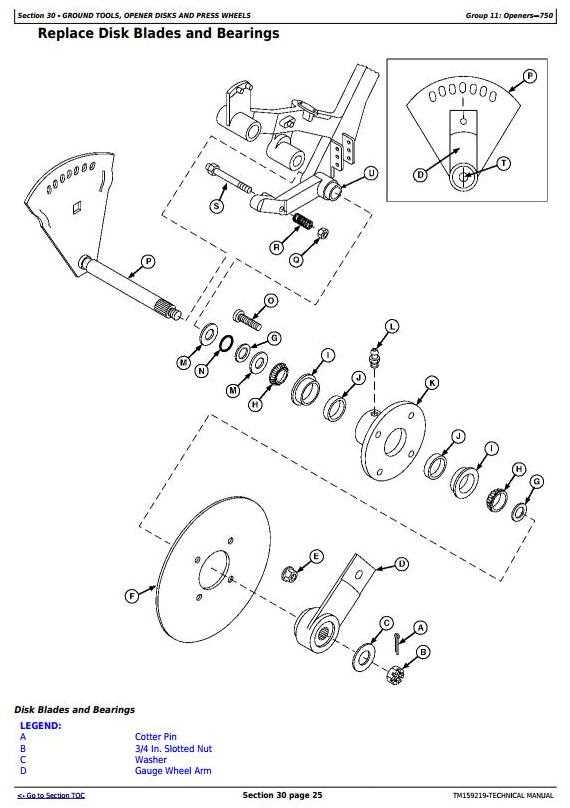

Wear and tear on components, such as openers and bearings, can also cause inefficiencies. Regular inspections and timely replacements are crucial to maintain the functionality of the machinery. Additionally, soil conditions play a significant role; overly wet or dry soils can hinder the equipment’s effectiveness, making it essential to assess soil moisture before planting.

Lastly, the equipment’s ability to adapt to different crop types can pose challenges. Ensuring that the machinery is versatile enough to handle various seeds can improve overall performance. Addressing these common issues will ultimately lead to a more successful planting experience.

How to Replace Worn Parts

Maintaining agricultural equipment is crucial for optimal performance and longevity. Over time, certain components may wear out and require replacement to ensure smooth operation. Understanding the process for swapping these items can enhance efficiency and save costs.

Identifying Worn Components

Regular inspections are essential to detect wear and tear. Look for signs such as unusual noises, reduced efficiency, or visible damage. Marking the areas that need attention will streamline the replacement process.

Replacement Process

Once you’ve identified the faulty components, gather the necessary tools and new items. Begin by disconnecting the equipment from any power source to ensure safety. Follow the manufacturer’s instructions to remove the old components carefully. Install the new parts, ensuring they fit securely and function properly. After reassembly, conduct a test run to confirm everything operates smoothly.

Comparing Models: 750 vs Others

This section explores the distinctions between the featured model and its contemporaries in the agricultural machinery landscape. Understanding these variations helps users identify the most suitable equipment for their specific needs.

Key Features

- Design efficiency

- Depth control mechanisms

- Seed placement accuracy

- Durability of components

Performance Comparison

- Operational speed and ease of use

- Maintenance requirements

- Compatibility with different soil types

- Yield performance under various conditions

Evaluating these aspects provides insight into the ultimate choice for modern farming practices.

Benefits of No-Till Agriculture

No-tillage practices have gained prominence in modern farming due to their numerous advantages. This method minimizes soil disturbance, promoting healthier ecosystems and enhancing sustainability.

Soil Health: By reducing disruption, this approach maintains soil structure and improves its organic matter content. This leads to better moisture retention and nutrient availability for crops.

Erosion Control: With less soil exposure, the risk of erosion decreases significantly. Vegetative cover helps protect the soil from wind and water damage.

Cost Efficiency: Lower fuel and labor costs are achieved as fewer passes over the field are required. This method can also reduce the need for chemical inputs, leading to overall savings.

Biodiversity: Encouraging a diverse range of organisms in the soil enhances its health. Beneficial insects and microbes thrive in less disturbed environments, contributing to a balanced ecosystem.

Carbon Sequestration: This practice aids in capturing carbon dioxide, contributing to climate change mitigation. Healthier soils can store more carbon, benefiting the environment.

In conclusion, adopting practices that limit soil disturbance not only fosters agricultural efficiency but also promotes ecological balance, making it an ultimate choice for sustainable farming.

Finding Replacement Parts Easily

Locating the right components for agricultural machinery can be a daunting task. With numerous options available, having a strategic approach can simplify the process and ensure you find what you need efficiently.

Utilizing Online Resources

- Search manufacturer websites for catalogs.

- Explore online marketplaces specializing in agricultural equipment.

- Join forums or communities dedicated to farming equipment for advice.

Consulting Local Dealers

- Visit nearby dealerships for expert guidance.

- Ask about compatibility with your existing machinery.

- Request quotes for any specific components you need.

Upgrading Your John Deere Equipment

Enhancing agricultural machinery is crucial for improving efficiency and productivity on the farm. Modernizing your equipment can lead to significant advancements in performance, precision, and ease of use. Whether you’re looking to replace outdated components or integrate new technologies, there are numerous options available to boost your operation.

Benefits of Modernization

- Increased productivity through improved technology.

- Enhanced fuel efficiency leading to cost savings.

- Better compatibility with precision farming tools.

- Improved reliability and reduced maintenance issues.

Key Areas for Upgrades

- Hydraulic Systems

- Upgrade pumps for better flow rates.

- Install advanced controls for precision handling.

- Seeding Equipment

- Consider variable rate technology for seed application.

- Opt for better seed placement systems for improved germination.

- Monitoring Systems

- Implement GPS technology for accurate field mapping.

- Use sensors for real-time data collection.

Investing in upgrades not only enhances current capabilities but also prepares your equipment for future advancements in the agricultural sector. Assess your needs and explore options that align with your operational goals to maximize your investment.

Resources for Further Research

This section provides a collection of valuable materials aimed at enhancing understanding and knowledge regarding agricultural equipment maintenance and optimization. Exploring these resources will allow enthusiasts and professionals to delve deeper into effective practices and innovations.

Online Forums: Participating in discussion boards can yield insights from experienced users and experts. Websites dedicated to agricultural machinery often host lively conversations where tips and advice are shared.

Manufacturer Websites: Official websites usually offer extensive documentation, including user manuals and maintenance guides, which serve as ultimate references for proper usage and care.

Trade Publications: Subscribing to industry magazines and journals provides access to articles, case studies, and reviews that highlight advancements and best practices in agricultural technology.

Workshops and Seminars: Attending events can facilitate networking opportunities and provide hands-on experience, making them an excellent way to stay updated on the latest trends.