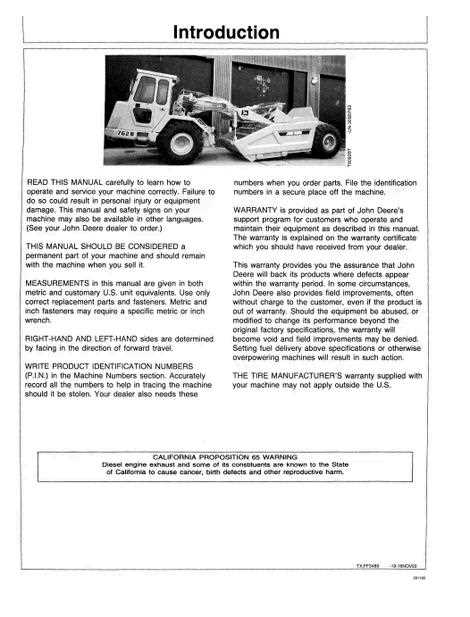

When it comes to maintaining or repairing agricultural machinery, having a clear understanding of the different elements is crucial. Each component plays a vital role in ensuring the smooth operation of the entire system. Knowing the precise layout and connections of these elements can help in diagnosing potential issues and keeping the equipment in optimal working condition.

Identifying essential mechanisms can sometimes be challenging without a visual reference. However, with the correct approach, you can easily navigate through the various parts and connections. This understanding can greatly enhance your ability to efficiently maintain or repair any issues that arise, ensuring longevity and performance.

In this guide, we will explore the arrangement of different sections, offering insights into how they work together. Whether you’re a seasoned mechanic or a new user, understanding the inner workings will help you handle routine tasks with greater confidence and precision.

Understanding the Layout of Essential Components

To maintain and repair complex machinery effectively, it’s important to grasp how its various elements are arranged. A clear understanding of the spatial arrangement helps streamline troubleshooting and ensures that replacements are done with precision. Knowing where each component fits within the broader system is key to efficient maintenance.

- Engine structure: The central power unit is typically surrounded by key elements that support its operation, such as the cooling system and exhaust.

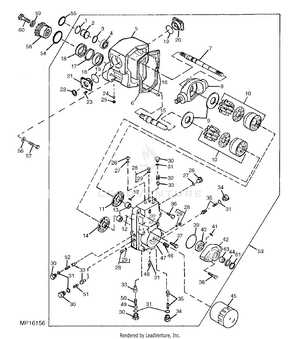

- Transmission components: These elements are strategically positioned to optimize power transfer, enhancing the overall performance of the machine.

- Hydraulic systems: Placed in accessible areas, these systems control important functions and are often linked to other vital components.

- Chassis elements: The framework holds everything together, providing structural integrity while supporting the weight and movement of all interconnected parts.

Understanding this layout can significantly reduce downtime during repairs and increase the longevity of the equipment.

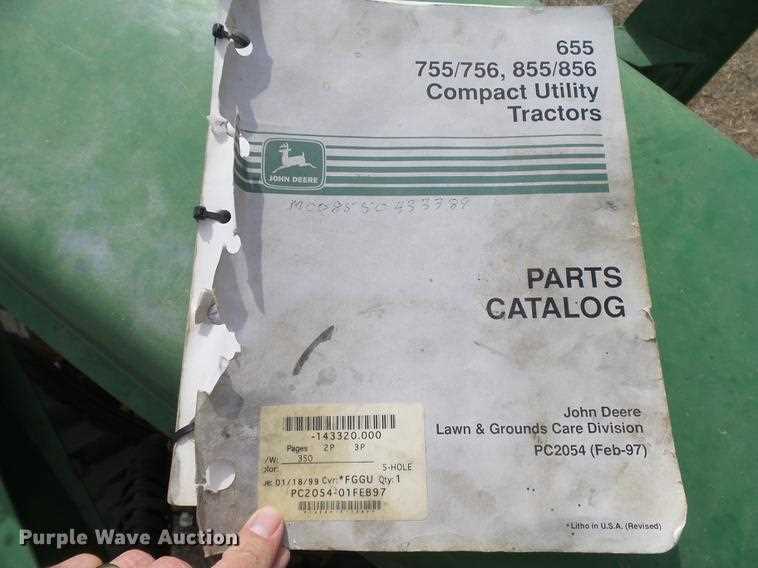

Key Components of the John Deere 855

The machine is built with various crucial elements that work together to ensure its optimal performance in demanding tasks. Understanding the primary systems and their individual roles helps in maintaining and operating the equipment effectively, ensuring long-lasting durability and reliable operation in different conditions.

| Component | Function | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Powers the entire system, delivering the necessary force for all operations. | |||||||||||||||||||||||||

| Hydraulic System | Manages lifting and other hydraulic operations, enabling smooth and powerful movement of attachments. | |||||||||||||||||||||||||

| Transmission | Transfers power from the engine to the wheels, providing adjustable speed and torque control. | |||||||||||||||||||||||||

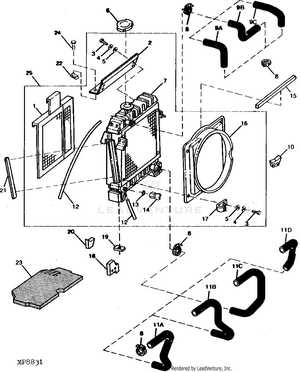

| Cooling System | Prevents overheating by managing the temperature of the engine and other essential parts. | |||||||||||||||||||||||||

| Steering Mechanism | Ensures precise and easy maneuverability, allowing accurate control even in tight spaces. |

| Component | Function | Connection Points | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Starter Relay | Engages the starter motor by allowing current flow | Battery, Ignition Switch, Starter Motor | ||||||||||

| Ignition Switch | Controls the activation of the electrical system | Battery, Starter Relay, Fuse Box | ||||||||||

| Alternator | Generates electrical power and recharges the battery | Battery, Voltage Regulator, Main Wiring Harness | ||||||||||

| Fuse Box | Protects circuits from

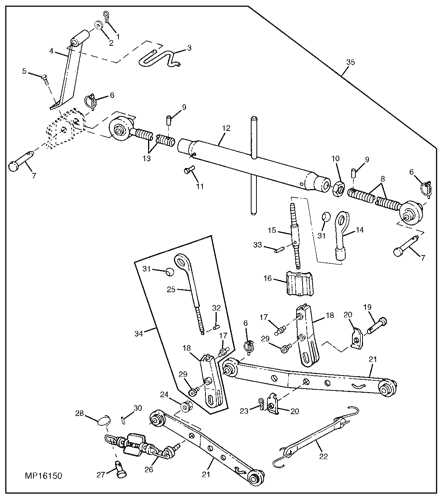

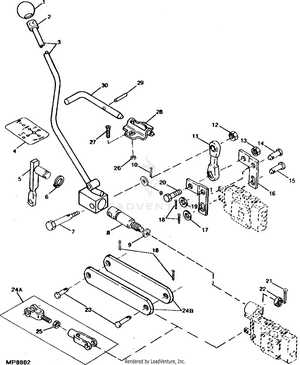

Steering System Components

The steering mechanism plays a crucial role in providing precise control and maneuverability. Understanding the individual components that work together in this system is essential for maintaining smooth and responsive handling. These elements are designed to ensure efficient movement, allowing for accurate directional changes and enhanced stability during operation. Main Steering MechanismThe primary part of the steering system is the steering gearbox, which converts rotational motion from the wheel into lateral movement, guiding the front assembly. It connects to various linkage elements, transmitting the input smoothly while reducing strain on the operator. Linkages and Connectors

Supporting the main mechanism are several linkages, such as tie rods and drag links, which ensure that the control is evenly distributed across both sides. These parts provide stability and allow synchronized movement of the front wheels, contributing to balanced steering performance. Fuel System Structure and Function

The internal combustion engine relies on a complex assembly designed to supply and regulate the flow of energy sources to its core components. This system ensures efficient fuel delivery, proper mixture with air, and seamless combustion processes, which are crucial for optimal engine performance. The design integrates multiple interconnected elements working in harmony to maintain consistent and precise fuel distribution throughout various operational stages. Core Components include the delivery mechanisms responsible for moving fuel from the storage unit to the combustion chamber. Valves and injectors play a pivotal role in controlling the flow and maintaining the required pressure for smooth engine operations. These components work together to ensure the right balance of fuel and air is introduced, maximizing efficiency and power output. System functions extend beyond simple fuel transfer. Integrated filters protect the engine by preventing contaminants from entering critical areas, while pressure regulators and pumps maintain a consistent flow rate. Additionally, the layout is designed to adjust fuel supply dynamically based on demand, ensuring efficient operation across different load conditions. Cooling System Parts Identification

The cooling mechanism in any equipment plays a critical role in maintaining optimal operating temperatures. Understanding the various components within this system is essential for ensuring proper maintenance and addressing potential issues. Each element works together to regulate heat, preventing overheating and ensuring efficient functionality.

|