In the realm of machinery maintenance, a clear visual representation of the various elements involved is essential for both novice and experienced users. Having access to a comprehensive layout allows individuals to quickly identify specific components, facilitating repairs and upgrades. This kind of reference is invaluable, especially for those engaged in hands-on work.

Visual aids serve as a bridge between technical jargon and practical application. They transform complex information into easily digestible formats, enabling users to comprehend the intricacies of their machinery without overwhelming them. By examining these illustrations, users can enhance their understanding of how different parts interact within the overall system.

Moreover, utilizing detailed visuals can significantly streamline the troubleshooting process. Recognizing the correct components enables faster identification of issues, saving both time and resources. This approach not only improves efficiency but also fosters a deeper appreciation for the engineering behind the equipment.

Understanding John Deere 955 Parts

When it comes to the machinery used in agriculture, comprehending the various components and their functions is essential for optimal performance and maintenance. This section delves into the key elements of a specific model, providing insights that enhance the user’s experience and ensure effective operation.

Familiarity with the different segments of this equipment allows for better troubleshooting and repairs. Here are some critical aspects to consider:

- Functionality: Each component plays a vital role in the overall operation, impacting efficiency and productivity.

- Compatibility: Understanding which elements work together helps in making informed decisions when replacements are needed.

- Maintenance: Regular checks and upkeep of individual parts can significantly prolong the lifespan of the entire machine.

To effectively manage these tools, users should focus on the following categories of components:

- Engine assembly

- Transmission system

- Hydraulic components

- Electrical systems

- Chassis and frame

By gaining knowledge in these areas, operators can ensure their machinery remains in peak condition, ultimately enhancing productivity and reducing downtime.

Overview of John Deere 955 Components

This section provides a comprehensive look at the essential elements that contribute to the functionality and performance of a particular agricultural machine. Understanding these components is vital for maintenance, repairs, and overall efficiency in operation.

Key Functional Elements

The machinery consists of various integral parts, each playing a crucial role in its operation. From the engine to the transmission, every component is designed to work in harmony, ensuring optimal performance during agricultural tasks.

Maintenance and Replacement

Regular upkeep and timely replacement of these essential elements are paramount for longevity and reliability. Familiarity with the structure and function of each part enables users to make informed decisions regarding service and replacement, ultimately enhancing the efficiency of the equipment.

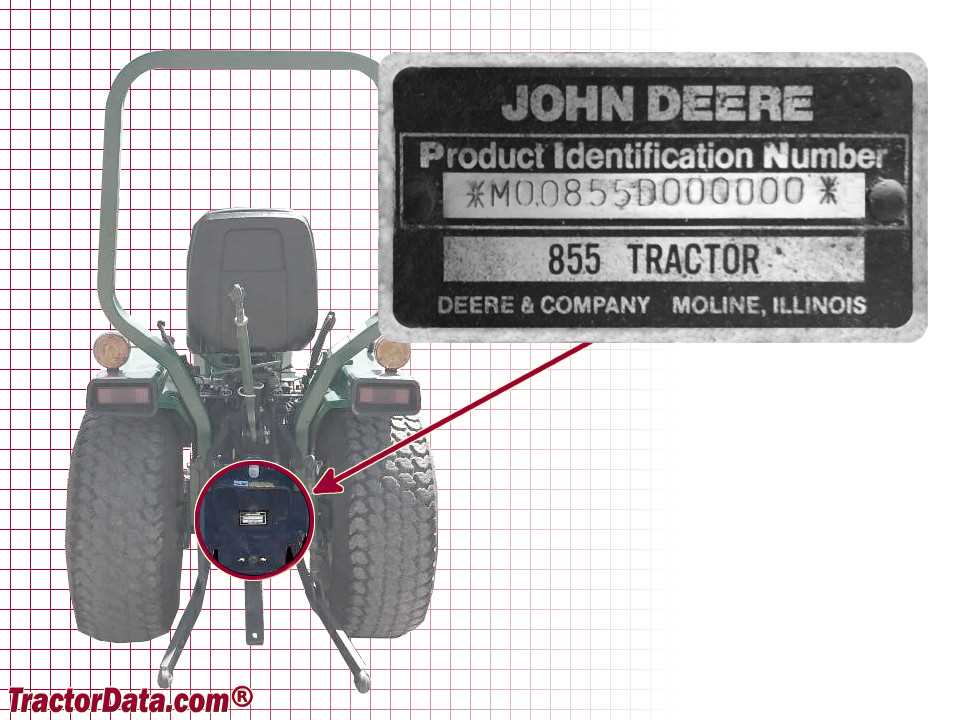

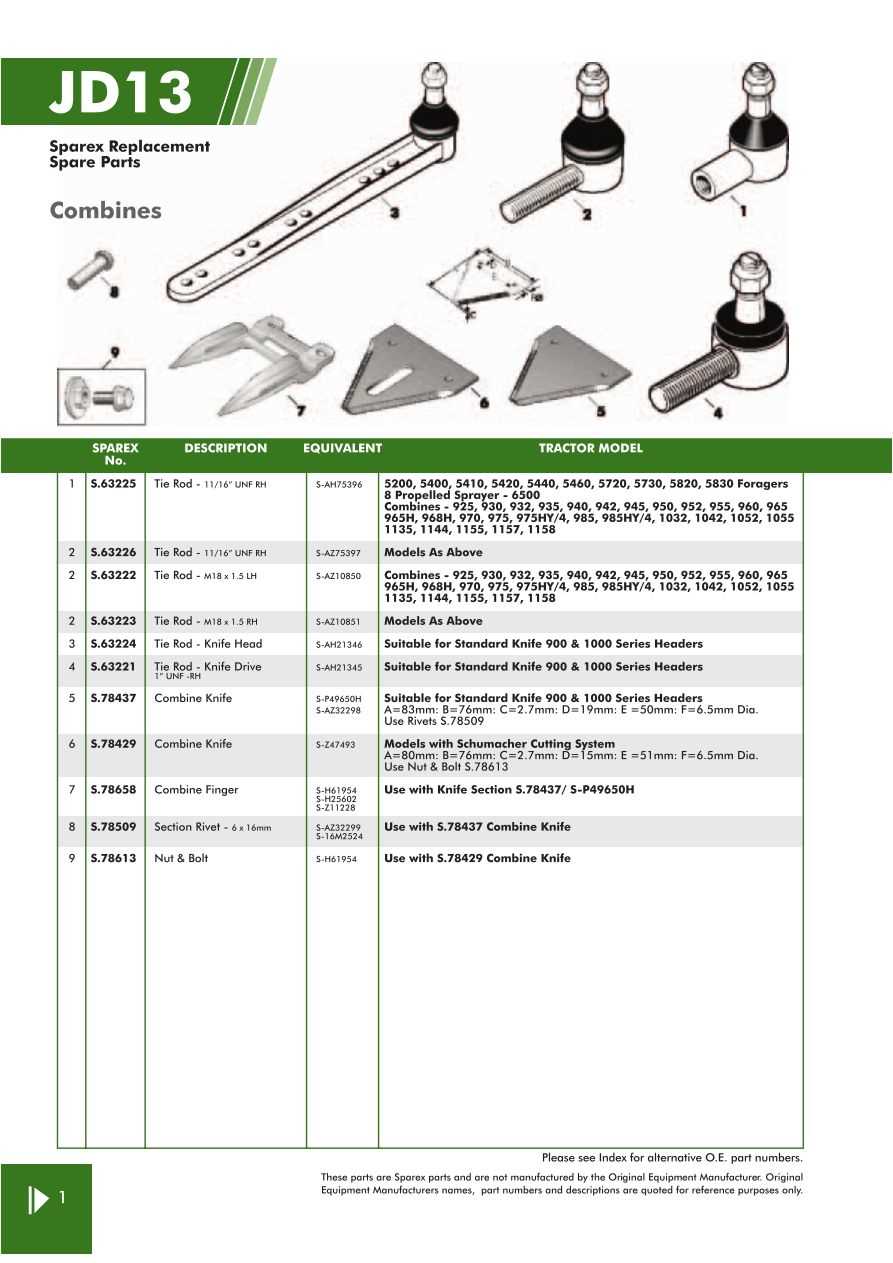

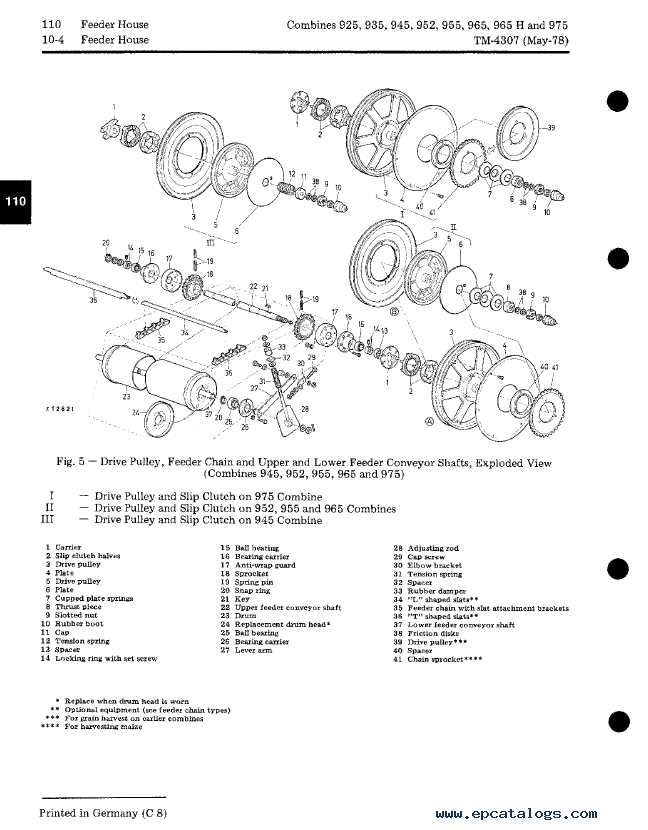

Importance of Accurate Parts Diagram

Having a precise illustration of components is crucial for effective maintenance and repair of machinery. Such visual representations help technicians identify each element accurately, ensuring that the right replacements are used during servicing. A clear depiction not only enhances understanding but also minimizes the chances of errors, which can lead to significant downtime and increased costs.

Moreover, detailed schematics facilitate better communication among team members, allowing everyone involved in repairs to reference the same visual aids. This shared understanding is vital, especially when working on complex systems where each piece plays a critical role in overall functionality.

Additionally, a comprehensive outline of the various elements aids in inventory management. By knowing exactly what is needed, operators can efficiently stock necessary items, reducing delays during repair operations. This practice ultimately leads to improved operational efficiency and longevity of the equipment.

| Benefit | Description |

|---|---|

| Improved Accuracy | Reduces the likelihood of errors in identifying and replacing components. |

| Enhanced Communication | Creates a common reference point for all team members involved in repairs. |

| Efficient Inventory Management | Helps in stocking the right items, minimizing repair delays. |

Key Features of John Deere 955

This section explores the notable characteristics and advantages of a specific agricultural machinery model, emphasizing its capabilities and user-friendly design. Understanding these features can assist potential users in making informed decisions when considering this equipment for their farming needs.

Performance and Efficiency

The machinery is designed to deliver exceptional performance while maintaining fuel efficiency. Its powerful engine and advanced transmission system allow for seamless operation across various terrains. Key highlights include:

- High horsepower output for demanding tasks

- Optimal torque for improved pulling power

- Advanced cooling system for prolonged use

User-Friendly Design

Incorporating ergonomics and accessibility, this model ensures ease of use for operators. The thoughtful layout and intuitive controls enhance the overall experience. Notable aspects include:

- Comfortable seating with adjustable options

- Clear visibility from the operator’s station

- Simple maintenance access for routine checks

How to Interpret Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visuals provide a clear representation of components, their relationships, and how they function together within a system. Grasping the information presented in these graphics can significantly enhance troubleshooting efficiency and streamline the replacement process.

Key Elements of Technical Illustrations

When analyzing these visuals, pay attention to several critical aspects:

| Element | Description |

|---|---|

| Labels | Identifying markings that denote specific components or assemblies. |

| Numbers | Reference numerals that correlate with a list or index, aiding in locating items. |

| Lines | Connecting lines that illustrate how parts interact and fit together. |

| Shading | Visual cues indicating different materials or functionalities. |

Steps for Effective Interpretation

To navigate these visuals successfully, follow these steps:

- Begin by reviewing the legend or key, which explains symbols and notations.

- Identify the main assembly or unit being depicted, focusing on its overall layout.

- Trace the connections between elements, ensuring clarity on how they fit into the system.

- Cross-reference with a corresponding parts list to identify any required replacements.

Common Issues with John Deere 955

When operating agricultural machinery, users often encounter various challenges that can impact performance and efficiency. Understanding these common problems is crucial for timely maintenance and effective resolution.

One frequent issue involves the engine, where symptoms such as poor starting or stalling can arise. These problems may be linked to fuel delivery systems, ignition components, or air intake restrictions.

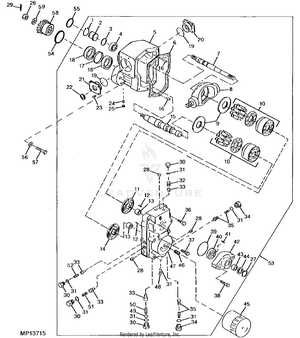

Another prevalent concern pertains to hydraulic systems, which may exhibit leaks or reduced pressure. Such malfunctions can lead to decreased lifting capabilities and overall performance. Regular inspections of hoses and seals can help prevent these issues.

Additionally, electrical failures, including malfunctioning lights or starter problems, can disrupt operations. Checking battery connections and fuses should be part of routine checks to avoid these complications.

Finally, wear and tear on tires and belts can result in compromised traction and functionality. Maintaining proper tire pressure and timely replacement of worn components is essential for optimal operation.

Finding Replacement Parts Easily

Locating suitable components for your machinery can seem daunting at first, but it doesn’t have to be. With the right approach, you can streamline the process and ensure your equipment remains in optimal working condition. Below are several strategies to simplify your search for necessary items.

- Utilize Online Resources: Numerous websites specialize in aftermarket and original equipment offerings. You can search by model or specific features to find what you need.

- Consult User Manuals: Reference materials often contain helpful information regarding compatible items and maintenance guidelines. This can guide you toward the correct selections.

- Join Community Forums: Engaging with fellow enthusiasts and professionals can provide insights into sourcing hard-to-find components. Discussions often reveal tips and reliable suppliers.

- Visit Local Dealers: Establishing a relationship with local vendors can lead to quicker access to components. They may also offer expert advice tailored to your equipment.

- Consider Salvage Yards: These places can be treasure troves for those seeking affordable alternatives. Often, you can find gently used items that are still in excellent condition.

By following these strategies, you can effectively enhance your search for necessary components and maintain your machinery efficiently.

Maintenance Tips for John Deere 955

Ensuring the longevity and optimal performance of your equipment requires regular upkeep. This section offers essential guidelines to help you maintain your machinery effectively, promoting efficiency and preventing costly repairs.

Routine Checks

- Inspect fluids regularly, including engine oil, coolant, and hydraulic fluids.

- Check filters and replace them as needed to maintain airflow and performance.

- Examine belts and hoses for signs of wear and replace them promptly.

Seasonal Maintenance

- Before winter, ensure that the fuel system is treated and the battery is fully charged.

- In spring, check the tires for proper inflation and tread wear.

- Clean and lubricate moving parts to prevent rust and ensure smooth operation.

By adhering to these maintenance practices, you can extend the lifespan of your machinery and enhance its overall performance, ensuring reliable operation for years to come.

Where to Buy Quality Parts

Finding high-quality components for your equipment is essential for ensuring optimal performance and longevity. There are several reliable sources where you can obtain these essential elements, each with its unique advantages. Below are some recommended places to explore when searching for superior items.

- Authorized Dealers: Official representatives often provide genuine items tailored specifically for your model. This option guarantees compatibility and adherence to manufacturer standards.

- Online Retailers: Numerous websites specialize in offering a wide variety of components. Look for reputable e-commerce platforms that provide customer reviews and return policies.

- Local Repair Shops: Many repair facilities maintain an inventory of commonly needed components. Visiting a nearby shop may also provide the opportunity for expert advice on your specific needs.

- Salvage Yards: Salvage yards can be a treasure trove for finding used components at a fraction of the cost. While it may take some digging, this option can yield valuable finds.

- Manufacturer’s Website: The official website often features a parts section where you can directly order components. This is typically a reliable source for high-quality items.

When purchasing, always consider factors such as quality, warranty, and the reputation of the seller. Investing in high-grade elements will enhance your equipment’s efficiency and extend its operational lifespan.

OEM vs. Aftermarket Parts Comparison

When considering components for machinery, users often face the choice between original equipment manufacturer (OEM) options and aftermarket alternatives. Each type has its unique benefits and drawbacks, influencing performance, durability, and cost. Understanding these differences is crucial for making an informed decision.

| Feature | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Quality Assurance | Manufactured to meet specific standards set by the original maker. | Quality may vary; depends on the manufacturer. |

| Cost | Generally more expensive due to brand and warranty. | Often more affordable, providing budget-friendly options. |

| Warranty | Usually comes with a comprehensive warranty. | Warranty terms vary widely; some may not offer any. |

| Availability | Readily available through authorized dealers. | Available from various retailers, including online. |

| Compatibility | Designed specifically for the machinery model. | May fit multiple models but can lead to inconsistencies. |

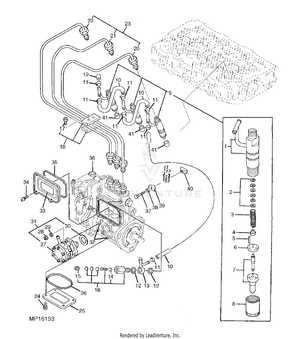

Understanding the Engine Components

The engine is a crucial element of any machinery, playing a vital role in its overall performance and efficiency. Each component within this complex system works in harmony to convert fuel into mechanical energy, enabling the equipment to operate effectively.

Key elements of an engine include the cylinder, piston, crankshaft, and camshaft, among others. Each part has a specific function that contributes to the engine’s operation. For example, the cylinder houses the piston, which moves up and down to create the necessary power. The crankshaft then transforms this linear motion into rotational energy, which ultimately drives the machinery.

Furthermore, understanding how these components interact is essential for maintenance and troubleshooting. Regular checks and timely replacements of worn-out parts can prevent costly repairs and ensure optimal performance. Knowledge of these fundamental elements empowers operators to manage their equipment more effectively.

Tools Needed for Parts Replacement

When it comes to replacing components in your equipment, having the right tools on hand is essential for a smooth and efficient process. Proper preparation not only saves time but also ensures that the job is done correctly, minimizing the risk of damage to the machinery.

Essential Tools

- Wrenches: Adjustable wrenches and socket sets are crucial for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help you handle different types of screws.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small parts.

- Torque Wrench: This tool ensures that fasteners are tightened to the correct specifications.

- Utility Knife: Handy for cutting through packaging and other materials.

Safety Equipment

- Gloves: Protect your hands from sharp edges and chemicals.

- Safety Goggles: Shield your eyes from debris during the replacement process.

- Steel-Toed Boots: Prevent foot injuries from heavy components.

By gathering these tools before beginning your project, you will set yourself up for success and ensure a seamless experience when working on your machinery.

Resources for John Deere Enthusiasts

For individuals passionate about agricultural machinery, a variety of valuable resources are available to enhance knowledge and skills. These tools include manuals, forums, and websites that cater specifically to fans of heavy equipment and outdoor power implements.

Online communities play a crucial role in connecting enthusiasts, providing platforms for sharing insights and experiences. These forums enable users to discuss maintenance tips, troubleshooting techniques, and best practices related to various models and equipment types.

Additionally, numerous websites offer comprehensive guides and tutorials, covering everything from basic operation to advanced repair strategies. These resources ensure that operators are well-informed and equipped to handle their machinery effectively, maximizing productivity and efficiency.

Incorporating social media groups can further expand access to knowledge, as they allow for real-time discussions and updates on new developments in the industry. Engaging with fellow machinery lovers can lead to a wealth of information and support.