Understanding the layout and functionality of various mechanical elements is essential for effective maintenance and repairs of utility vehicles. Knowing how different components interact with each other can help extend the lifespan of the equipment and prevent potential breakdowns. For those seeking detailed schematics, visual representations of the components offer a valuable resource for identifying specific parts and their locations.

The schematic illustrations provide clarity on how each element fits within the broader mechanical system. Whether it’s for routine maintenance or troubleshooting an issue, these diagrams play a crucial role in helping users recognize and replace the right components. Learning to navigate these detailed illustrations can significantly enhance one’s ability to service and maintain the vehicle efficiently.

Accurate component schematics serve not only as a guide for repairs but also aid in understanding the design and structure of the vehicle’s mechanical assembly. This knowledge allows for more informed decisions regarding upgrades, replacements, or modifications, ensuring the vehicle remains in optimal working condition.

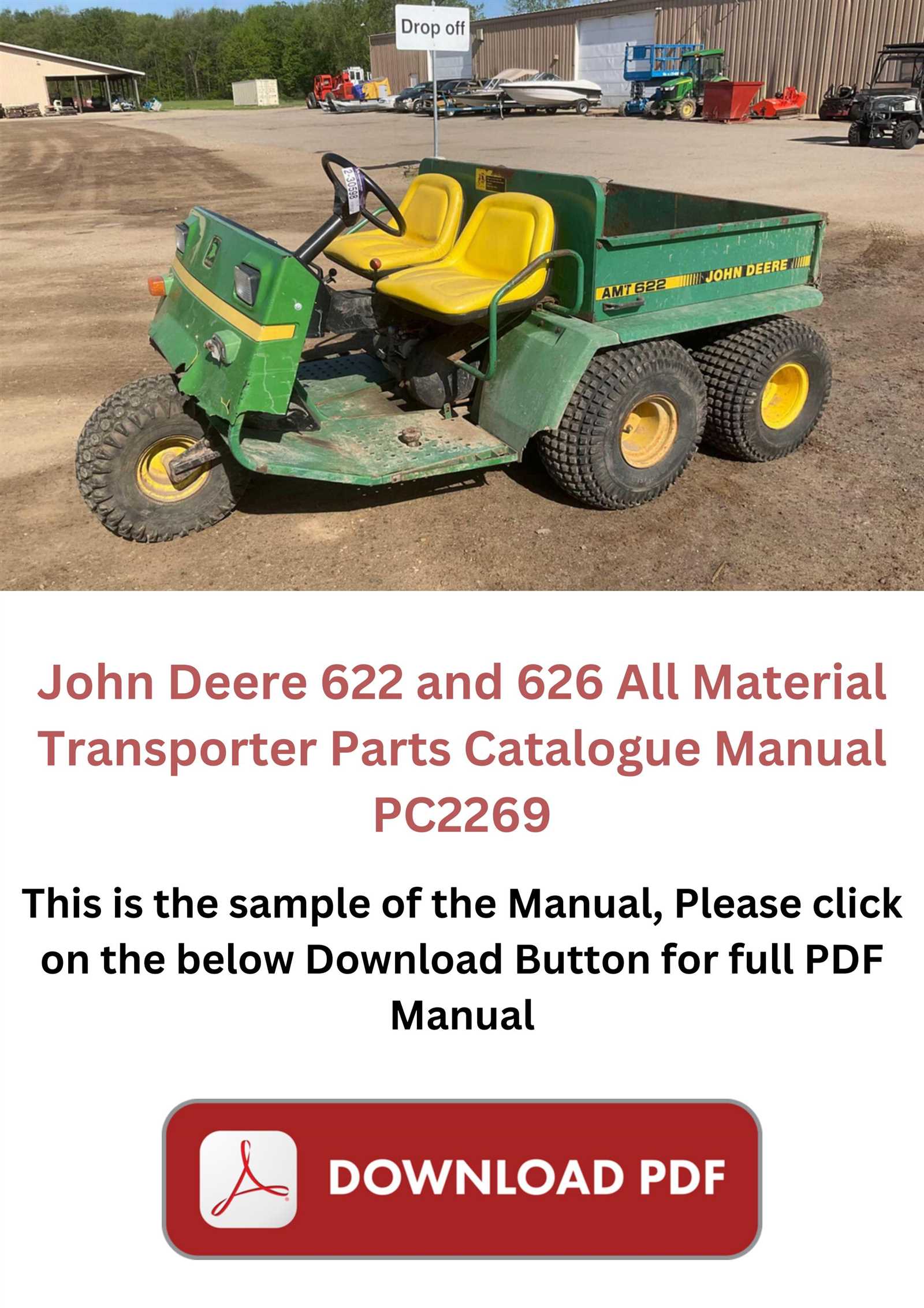

John Deere AMT 622 Parts Diagram

Understanding the layout and configuration of the components in this utility vehicle is essential for effective maintenance and repair. Knowing the arrangement of various elements can help in identifying issues quickly and replacing items accurately. Whether it’s routine upkeep or troubleshooting, having a clear visualization of each element’s placement is invaluable.

Maintenance Efficiency improves significantly when each component’s position is clearly mapped out. This visualization assists users in locating specific items, reducing downtime and simplifying the process of finding the correct replacement.

Enhanced Troubleshooting is achieved by having a clear view of where each element is situated, which makes it easier to pinpoint sources of malfunctions. By understanding the overall structure, repairs can be made more efficiently, ensuring optimal operation and prolonging the machine’s lifespan.

Understanding the AMT 622 Layout

The layout of this versatile utility vehicle is designed to optimize both functionality and ease of use. With its thoughtfully arranged components, every element is placed to facilitate efficient operation and maintenance. The overall structure ensures that essential functions are easily accessible, allowing for quick adjustments and repairs.

Key sections of the layout include areas dedicated to the engine, transmission, and control mechanisms, each strategically positioned for optimal performance. The design emphasizes balance, with weight distributed evenly to enhance stability and handling on various terrains.

Accessibility and organization are central to the layout, making routine inspections straightforward. The arrangement prioritizes user-friendly features, which not only improve operational efficiency but also extend the vehicle’s lifespan through easier upkeep.

Key Components of the AMT 622

The vehicle is composed of several essential elements, each designed to enhance its performance and reliability. Understanding these crucial elements can help in maintaining the machine’s functionality and addressing any potential issues effectively.

Engine and Transmission

The power unit is the core of the machine, providing the necessary energy to drive its various functions. It works in conjunction with the transmission system to ensure smooth and consistent movement across different terrains. This collaboration between the power source and the drivetrain is crucial for delivering both speed and control.

Suspension and Steering

A sturdy suspension setup plays a vital role in absorbing shocks and bumps, allowing for a smoother ride over uneven surfaces. Paired with a responsive steering mechanism, the suspension helps the operator maintain control and maneuverability, especially in challenging environments. Together, they contribute to a balanced and stable driving experience.

Other Essential Elements include the braking system, which ensures safe stopping power, and the frame, providing structural support to handle heavy loads. Each of these components works together, forming a reliable and efficient machine ready for various tasks.

Engine Assembly Breakdown

The engine structure consists of various interconnected components, each playing a crucial role in ensuring smooth operation. Understanding the layout and the relationship between these elements helps in diagnosing potential issues and performing maintenance tasks efficiently. This section provides an overview of the primary units involved, highlighting their functions and interactions within the mechanical system.

Key elements include the combustion chamber, where fuel ignition occurs, and the cooling system, which regulates temperature. Additionally, the lubrication pathways ensure that moving parts remain in optimal condition, minimizing wear. By familiarizing oneself with these segments, one can gain insights into the intricate workings of the machinery and take appropriate measures to enhance performance and longevity.

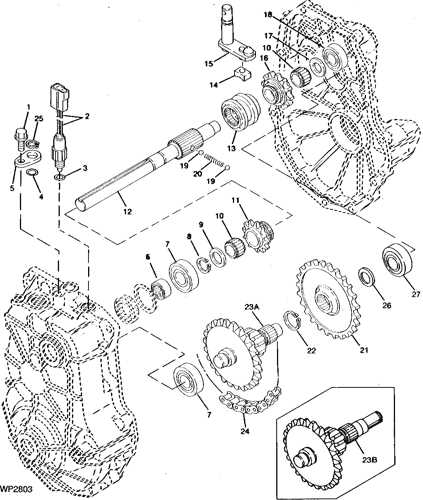

Transmission Parts Identification

Understanding the key elements within the transmission system is crucial for effective maintenance and repair. The various components work together to ensure the proper transfer of power, making the vehicle functional and efficient. Recognizing these elements and their roles can help identify potential issues and facilitate accurate repairs.

- Gear Sets: The gears enable the change of speed and torque. Each set works in synchronization to provide smooth shifting and effective power distribution.

- Shafts: These connect different sections of the transmission, transferring rotational force from one part to another. Proper alignment is essential to avoid wear and damage.

- Bearings: Bearings reduce friction between moving parts, ensuring smoother operation. They need regular inspection to prevent early wear.

- Clutch Mechanism: Responsible for engaging and disengaging the drive, the clutch ensures the vehicle can switch between gears without grinding.

- Seals and Gaskets: These components prevent fluid leaks, maintaining the correct lubrication and pressure inside the system.

Regular checks on these elements can prolong the life of the transmission and ensure its optimal performance. Early detection of any irregularities can significantly reduce repair costs and downtime.

Suspension and Frame Details

The suspension and framework of a utility vehicle play a crucial role in its overall performance, stability, and comfort during operation. These components are designed to absorb shocks and vibrations while providing a solid structure that supports the vehicle’s weight and functionality. Understanding the intricacies of these elements helps in maintaining the vehicle’s efficiency and longevity.

A well-designed suspension system enhances the vehicle’s ability to traverse rough terrain while ensuring a smooth ride for the operator. The frame serves as the backbone, connecting various parts and ensuring durability under various working conditions. Proper maintenance and occasional inspections are essential to ensure these components function optimally.

| Component | Description |

|---|---|

| Shock Absorbers | Elements that dampen the impact of uneven surfaces, enhancing ride quality. |

| Springs | Parts that provide support and flexibility, allowing for adjustments based on load. |

| Chassis | The frame that supports the entire vehicle and houses essential components. |

| Control Arms | Linkages that connect the suspension system to the chassis, allowing for movement. |

| Mounting Brackets | Supports that secure various suspension elements to the frame, ensuring stability. |

Electrical System Diagram Guide

This section aims to provide a comprehensive understanding of the electrical layout utilized in specific machinery. By exploring the intricate components and their interconnections, users can gain valuable insights into the functioning of the electrical network. A clear representation of this system can enhance troubleshooting and maintenance efforts, ensuring optimal performance and reliability.

Key Components Overview

The electrical system comprises various essential elements, including switches, connectors, and power sources. Each part plays a crucial role in the overall operation, contributing to the efficient functioning of the equipment. Understanding how these components interact can help in diagnosing issues and implementing effective solutions.

Importance of Accurate Representation

A precise illustration of the electrical framework serves as a vital reference for technicians and operators. It facilitates the identification of potential problems and streamlines the repair process. By utilizing an accurate representation, users can ensure that any modifications or repairs are carried out effectively, minimizing downtime and enhancing productivity.

Steering Mechanism Overview

The steering system is a crucial component that ensures precise control and maneuverability of the vehicle. It plays a vital role in enabling operators to navigate various terrains effectively, enhancing overall performance and safety.

This mechanism typically comprises several interconnected parts that work in harmony to facilitate smooth directional changes. A key aspect of this system is its ability to transmit the driver’s input into appropriate adjustments in the front wheels, allowing for responsive handling.

Additionally, the design of the steering system can significantly influence the machine’s stability and ease of use. Various configurations exist, each tailored to meet specific operational demands, ensuring optimal functionality in diverse conditions.

Overall, understanding the steering mechanism’s fundamentals is essential for maintenance and troubleshooting, contributing to the longevity and reliability of the equipment.

Brake System Component Analysis

The brake system is a vital component of any vehicle, playing a crucial role in ensuring safety and control during operation. Understanding the various elements that comprise this system is essential for effective maintenance and troubleshooting. Each component works synergistically to provide reliable stopping power and responsiveness, contributing to overall vehicle performance.

Hydraulic System: At the core of the brake system lies the hydraulic mechanism, which transfers force from the brake pedal to the braking components. This system utilizes fluid dynamics to amplify the driver’s input, ensuring that sufficient pressure is applied to achieve effective deceleration.

Brake Pads: These friction materials are critical for generating the necessary stopping force when pressed against the brake rotor. Their composition and condition directly influence braking efficiency and noise levels, making regular inspection essential for optimal performance.

Rotors: Rotors serve as the contact surface for brake pads. Their design and material properties affect heat dissipation and durability. Maintaining the integrity of rotors is vital to prevent warping or uneven wear, which can lead to decreased braking effectiveness.

Calipers: These components house the brake pads and apply pressure to them against the rotors. The caliper’s functionality is paramount in converting hydraulic pressure into mechanical force, making it a key player in the braking process.

Brake Lines: Responsible for transporting hydraulic fluid throughout the system, these lines must be free of leaks or blockages. Regular checks are necessary to ensure that fluid pressure is maintained, allowing for timely and responsive braking action.

In summary, a thorough understanding of each element within the brake system is essential for maintaining vehicle safety and functionality. Regular inspection and maintenance of these components can prevent failures and enhance the overall driving experience.

Fuel System Parts Explained

The fuel system is a crucial component of any engine, responsible for delivering the necessary fuel to ensure optimal performance. Understanding the various elements that make up this system can help in maintaining and troubleshooting any issues that may arise. Each part plays a significant role in the efficiency and functionality of the engine.

The fuel tank serves as the storage reservoir, holding the fuel until it is needed. Fuel pumps are essential for transferring the fuel from the tank to the engine, ensuring a steady flow under pressure. Fuel filters are employed to remove impurities from the fuel, protecting the engine from potential damage and maintaining smooth operation.

Injectors or carburetors play a vital role in mixing the fuel with air, allowing for proper combustion. Additionally, fuel lines connect the various components, facilitating the movement of fuel throughout the system. Understanding the function of each element is key to ensuring the longevity and reliability of the engine.

Interior and Control Layout

The arrangement of components within the operator’s compartment plays a crucial role in enhancing functionality and comfort. A well-designed interface ensures that controls are easily accessible and intuitive, promoting efficient operation during various tasks.

Key aspects of the interior layout include:

- Ergonomic positioning of controls for optimal reach and usability

- Strategic placement of displays and indicators to enhance visibility

- Provision for storage of essential tools and personal items

Additionally, the control layout is meticulously organized to streamline operations:

- Primary controls for engine operation and speed management are centrally located.

- Auxiliary functions, such as lighting and auxiliary hydraulics, are positioned for quick access.

- Comfort features, including seat adjustments and climate controls, are conveniently situated.

This thoughtful arrangement contributes significantly to an operator’s overall experience, enabling better focus on tasks and improving productivity.

Maintenance Tips for AMT 622 Parts

Regular upkeep of machinery components is essential for optimal performance and longevity. Implementing effective maintenance strategies can help ensure that your equipment operates smoothly, reducing the likelihood of breakdowns and costly repairs. Below are some key practices to enhance the durability of your machinery’s components.

Routine Inspections

Conducting regular inspections is crucial in identifying potential issues before they escalate. Consider the following:

- Check for signs of wear and tear, including cracks or corrosion.

- Ensure all connections are secure and free from debris.

- Examine moving parts for proper lubrication and functionality.

Proper Cleaning Techniques

Maintaining cleanliness is vital for preserving the functionality of components. Follow these cleaning tips:

- Use a soft brush or cloth to remove dirt and grime.

- Avoid using harsh chemicals that could damage the materials.

- Inspect filters and screens regularly, replacing them as necessary.

By adhering to these maintenance guidelines, you can enhance the efficiency and lifespan of your machinery, ensuring reliable performance in the long run.