The operation of lawn machinery relies heavily on the intricate arrangement of its various elements. Knowing the layout and function of these components can greatly enhance maintenance and repair efforts. This section aims to provide a comprehensive overview of the key elements that make up a specific model of lawn tractor, focusing on their roles and interconnections.

By delving into the individual segments, users can gain insights into how each piece contributes to the overall functionality of the equipment. Familiarity with these components not only aids in troubleshooting issues but also facilitates informed decisions during servicing. Understanding the significance of each part is essential for anyone looking to optimize the performance of their lawn care machinery.

Moreover, having a clear visual representation of these elements can assist in recognizing wear and tear, thus promoting timely replacements and maintenance. This knowledge empowers operators to ensure their equipment remains in peak condition, ultimately leading to more efficient and effective lawn care.

The efficient operation of any machine relies heavily on its crucial elements. This section highlights the significant features that contribute to the functionality and performance of this specific model. Understanding these components is essential for proper maintenance and optimal use.

Essential Features

- Engine: A powerful motor that ensures smooth operation and reliability.

- Transmission: A robust system that provides seamless gear shifting, enhancing control during use.

- Deck: The cutting mechanism designed for precision and efficiency in various mowing conditions.

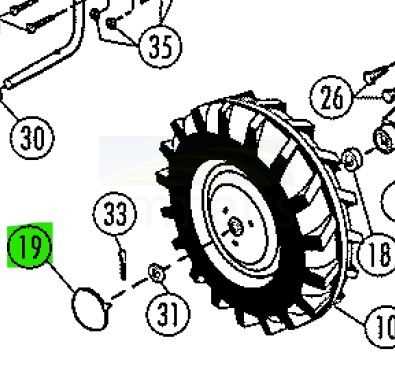

- Wheels: Durable and well-constructed, offering stability and maneuverability on different terrains.

Supportive Systems

- Fuel System: Ensures the engine operates efficiently by providing a consistent fuel supply.

- Electrical System: Powers various components, ensuring reliable starting and operational functionality.

- Cooling System: Maintains optimal engine temperatures, preventing overheating during extended use.

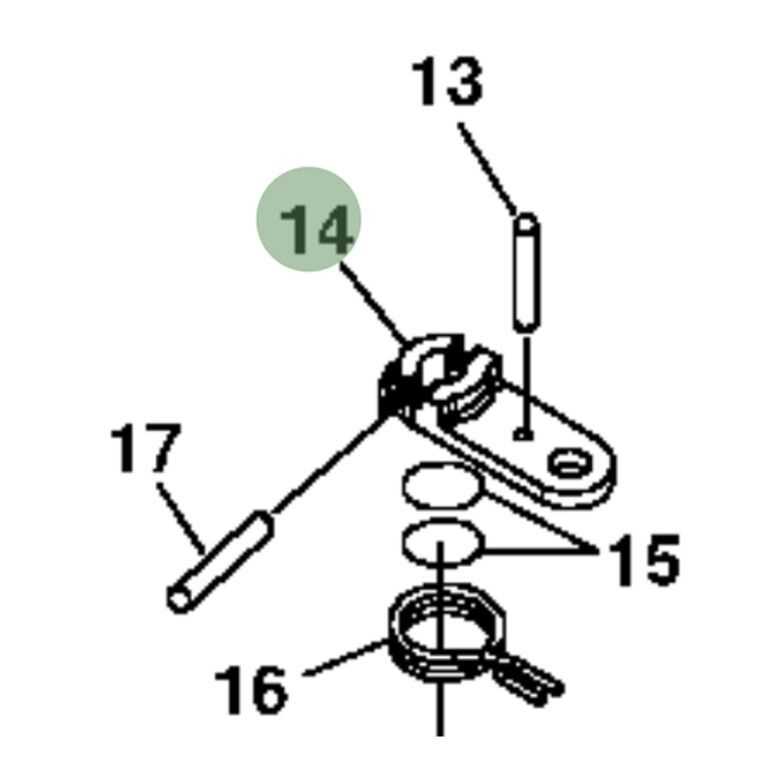

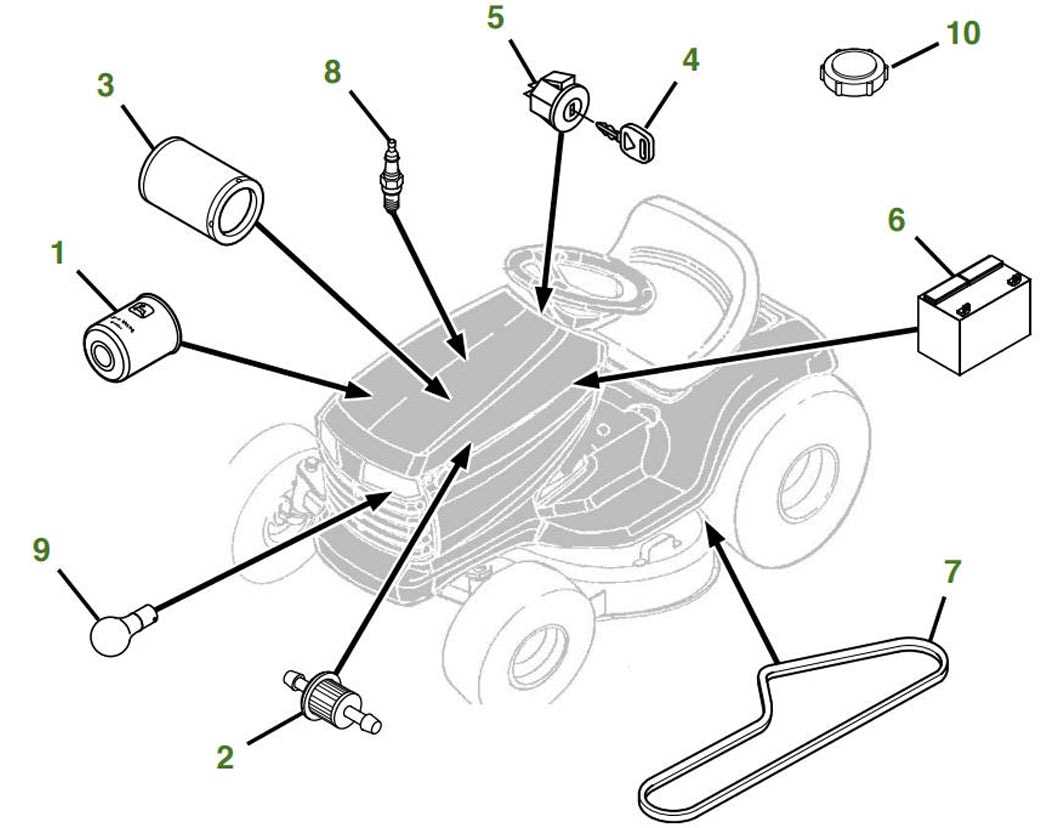

Identifying Essential Replacement Parts

Understanding the key components of your machinery is crucial for effective maintenance and timely repairs. Recognizing which elements require replacement can significantly enhance the longevity and performance of your equipment. This section will guide you through identifying the most critical components that may need attention during servicing.

Common Components to Monitor

Regular inspection of the main assemblies can help prevent unexpected breakdowns. Focus on elements such as the engine, transmission, and cutting system, as these are vital for overall functionality. Ensuring these parts are in optimal condition can lead to improved efficiency and reduced wear over time.

Signs of Wear and Tear

It’s essential to be aware of the indicators that suggest a component may be failing. Unusual noises, reduced performance, or visible damage are common signs that a particular part may need to be replaced. Staying proactive about these issues can save you time and resources in the long run.

Maintenance Tips for E120 Components

Proper upkeep of your machinery is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns. This section offers valuable insights into how to care for various elements of your equipment effectively.

Routine Inspections

Conducting frequent assessments of your machinery can help identify wear and tear early. Check for any signs of damage, loose connections, or unusual sounds during operation. Addressing minor issues promptly can save you from costly repairs later on.

Lubrication and Cleaning

Maintaining cleanliness and proper lubrication of moving parts is vital. Use appropriate lubricants to minimize friction and wear. Regularly clean components to remove debris and dirt, ensuring smooth functionality. Neglecting these practices can lead to accelerated wear and decreased efficiency.

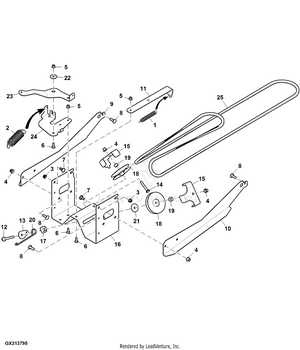

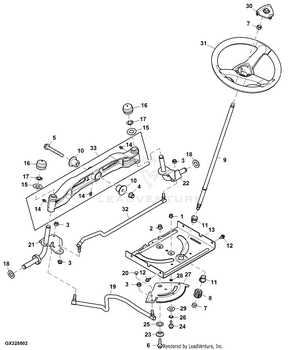

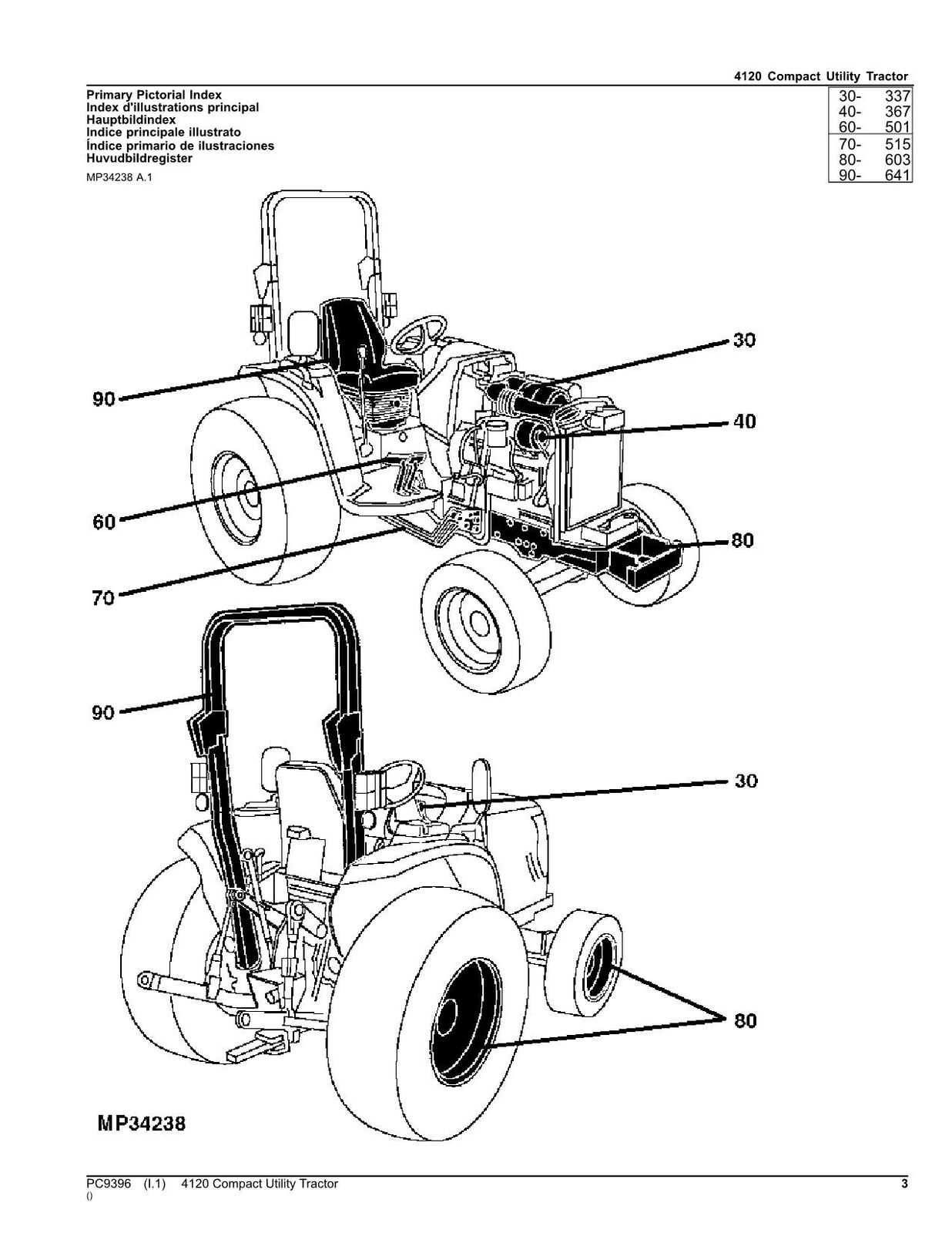

Visual Guide to E120 Parts Layout

This section offers a comprehensive overview of the components found in the specified model. By exploring the layout and arrangement of these essential elements, users can gain a better understanding of the machine’s functionality and maintenance needs. The following table presents a structured view of the various sections and their respective components.

| Component Section | Description |

|---|---|

| Engine | Power unit providing the necessary energy for operation. |

| Transmission | System responsible for power transfer and speed regulation. |

| Chassis | Framework that supports all other components and provides stability. |

| Control Panel | Interface for the operator to manage machine functions. |

| Deck | Cutting area that houses the blades for grass trimming. |

Common Issues and Solutions

In the realm of lawn maintenance equipment, various challenges can arise during operation. Understanding these typical problems and their corresponding solutions can significantly enhance performance and longevity. This section aims to provide insights into frequently encountered difficulties and effective remedies to ensure smooth functioning.

Engine Difficulties

One prevalent issue involves engine performance. If the motor fails to start or runs erratically, it may indicate fuel supply problems or ignition system faults. To resolve this, first check the fuel levels and replace stale fuel. Additionally, inspect the spark plug for wear and replace it if necessary.

Cutting Performance Issues

Another common challenge is unsatisfactory cutting results. This can manifest as uneven grass height or missed patches. To tackle this, ensure the cutting blades are sharp and properly aligned. Regular maintenance, such as cleaning the deck and adjusting the cutting height, can greatly improve efficiency and outcomes.

Parts Availability and Sourcing

Access to essential components is crucial for maintaining optimal performance and longevity of your machinery. Understanding where to find these items can significantly enhance your repair and maintenance processes.

Finding Reliable Suppliers

Identifying trustworthy vendors is vital for sourcing quality components. Here are some recommended sources:

- Authorized dealerships that offer genuine items.

- Reputable online retailers specializing in equipment supplies.

- Local hardware stores that may stock compatible alternatives.

- Aftermarket suppliers providing cost-effective options.

Checking Availability

When searching for necessary components, consider the following tips to ensure availability:

- Visit supplier websites for real-time stock updates.

- Contact local dealers directly to inquire about inventory.

- Join online forums or communities for recommendations on where to find specific items.

- Utilize parts lookup tools that may offer insights into compatible options.

Comparison with Other Models

When selecting a riding lawn tractor, it is crucial to weigh the features and capabilities of different models to find the one that best meets your needs. Understanding how various machines perform in terms of power, maneuverability, and versatility can help you make an informed decision.

Power and Performance

One of the key aspects to consider is the engine power. Some models offer higher horsepower, making them better suited for larger lawns or rougher terrain. Others might be designed for smaller areas but excel in efficiency and fuel economy. It’s important to match the power output with the intended use.

- Higher horsepower for large or hilly areas

- Smaller engines for efficiency and lower fuel consumption

Maneuverability and Features

Another significant factor is the ease of operation. Some models feature a tighter turning radius, making them ideal for navigating complex landscapes, while others offer more

Installation Instructions for Key Parts

Proper assembly of essential components is crucial for ensuring the optimal performance and longevity of any mechanical system. In this section, we will walk through the steps needed to install the core elements efficiently and securely. These instructions will guide you through the process, highlighting the importance of precise alignment and secure connections.

| Component | Installation Steps | ||

|---|---|---|---|

| Drive Belt | Ensure the belt is correctly positioned around the pulleys, maintaining proper tension to avoid slippage during operation. Check alignment before securing the belt. | ||

| Blade | Attach the blade securely using the provided bolts, e

Expert Recommendations for UpgradesFor enthusiasts looking to enhance the performance and longevity of their equipment, selecting the right enhancements is essential. Upgrades can significantly improve efficiency, durability, and functionality. Below are some key areas to consider when evaluating potential improvements for your machine. Performance EnhancementsInvesting in components that boost efficiency and power can make a noticeable difference in your equipment’s output. From optimized engines to advanced transmission systems, these changes not only improve productivity but also reduce operational strain. Consider innovations that promote smoother handling and increase power delivery. Durability ImprovementsChoosing stronger materials and advanced protective features can extend the lifespan of your equipment. Components designed with high endurance and wear resistance ensure that your machine withstands demanding tasks over time. Look for modern options that offer enhanced durability without sacrificing performance.

|