Maintaining and operating a high-performance turf care machine requires a comprehensive understanding of its individual components. Each element plays a crucial role in the overall functionality, contributing to efficient operation and optimal results. This section delves into the essential elements of a specific model, providing insights into how they interact and the importance of each in achieving top-tier performance.

Whether you are a seasoned operator or a newcomer to turf management, grasping the layout and function of various components can enhance your maintenance practices. Knowledge of these elements not only aids in troubleshooting common issues but also empowers users to make informed decisions about repairs and upgrades. By exploring the intricacies of this particular machine, you will gain a deeper appreciation for the engineering and design that drives its efficiency.

In this exploration, we will highlight the key sections and mechanisms, showcasing their roles and how they contribute to the machine’s overall functionality. Understanding these relationships will serve as a valuable resource for effective operation and care, ensuring that your turf care machine remains in peak condition throughout its lifecycle.

This section aims to provide a comprehensive overview of the essential components of a specific agricultural machine. Understanding the configuration and functionality of each part can significantly enhance the efficiency and effectiveness of its operations. By familiarizing oneself with the layout and roles of various elements, users can ensure proper maintenance and troubleshooting, leading to improved performance and longevity of the equipment.

Below is a structured table that outlines key components, their functions, and associated maintenance tips:

| Component | Function | Maintenance Tips |

|---|---|---|

| Engine | Powers the machinery | Regular oil changes and filter replacements |

| Transmission | Transfers power to wheels | Check fluid levels and inspect for leaks |

| Hydraulic System | Controls various attachments | Ensure fluid levels are adequate and check for pressure |

| Chassis | Supports all components | Inspect for rust and structural integrity |

| Control Panel | Manages operations and settings | Keep clean and ensure all indicators function |

Overview of F935 Components

This section provides a comprehensive look at the various elements that make up a specific model of machinery. Understanding these components is essential for effective maintenance and operation. Each part plays a critical role in ensuring the overall functionality and efficiency of the equipment, contributing to its performance in various tasks.

| Component | Description | Function |

|---|---|---|

| Engine | A powerful internal combustion unit. | Drives the entire system and provides necessary power. |

| Transmission | A system that transfers power from the engine. | Enables the adjustment of speed and torque. |

| Hydraulic System | A network of components that uses fluid power. | Operates lifting and steering mechanisms. |

| Chassis | The framework that supports the entire structure. | Provides stability and structural integrity. |

| Electrical System | A network of wiring and components for electrical functions. | Powers lights, controls, and other electronic features. |

Key Features of F935 Parts

The components of this machinery are designed to enhance performance and durability, ensuring optimal functionality in various conditions. Each element is meticulously crafted to provide reliability and efficiency, contributing to the overall productivity of the equipment. Understanding the distinct characteristics of these elements is crucial for maintenance and repair, ultimately prolonging the lifespan of the machine.

Durability and Reliability

High-quality materials are utilized in the construction of each component, allowing them to withstand the rigors of heavy use. This resilience minimizes the need for frequent replacements and repairs, ensuring that operators can rely on their machinery for extended periods.

Enhanced Performance

The design of these elements is aimed at optimizing functionality, improving efficiency in various tasks. From engine components to transmission systems, each part plays a vital role in ensuring smooth operation, ultimately enhancing the overall effectiveness of the machinery.

Common Issues with F935 Parts

When maintaining outdoor equipment, users often encounter various challenges related to their components. Understanding these common issues can help ensure optimal performance and longevity of the machinery.

Frequent Problems

- Wear and Tear: Over time, certain components may degrade due to regular usage, leading to diminished functionality.

- Corrosion: Exposure to moisture can cause rust and corrosion, particularly in metal parts, which can compromise their effectiveness.

- Loose Connections: Vibration during operation can result in loose bolts or fasteners, causing misalignment and operational failures.

Preventive Measures

- Regularly inspect components for signs of damage or wear.

- Keep the machinery clean and dry to minimize rust formation.

- Secure all fasteners and connections to ensure proper alignment and function.

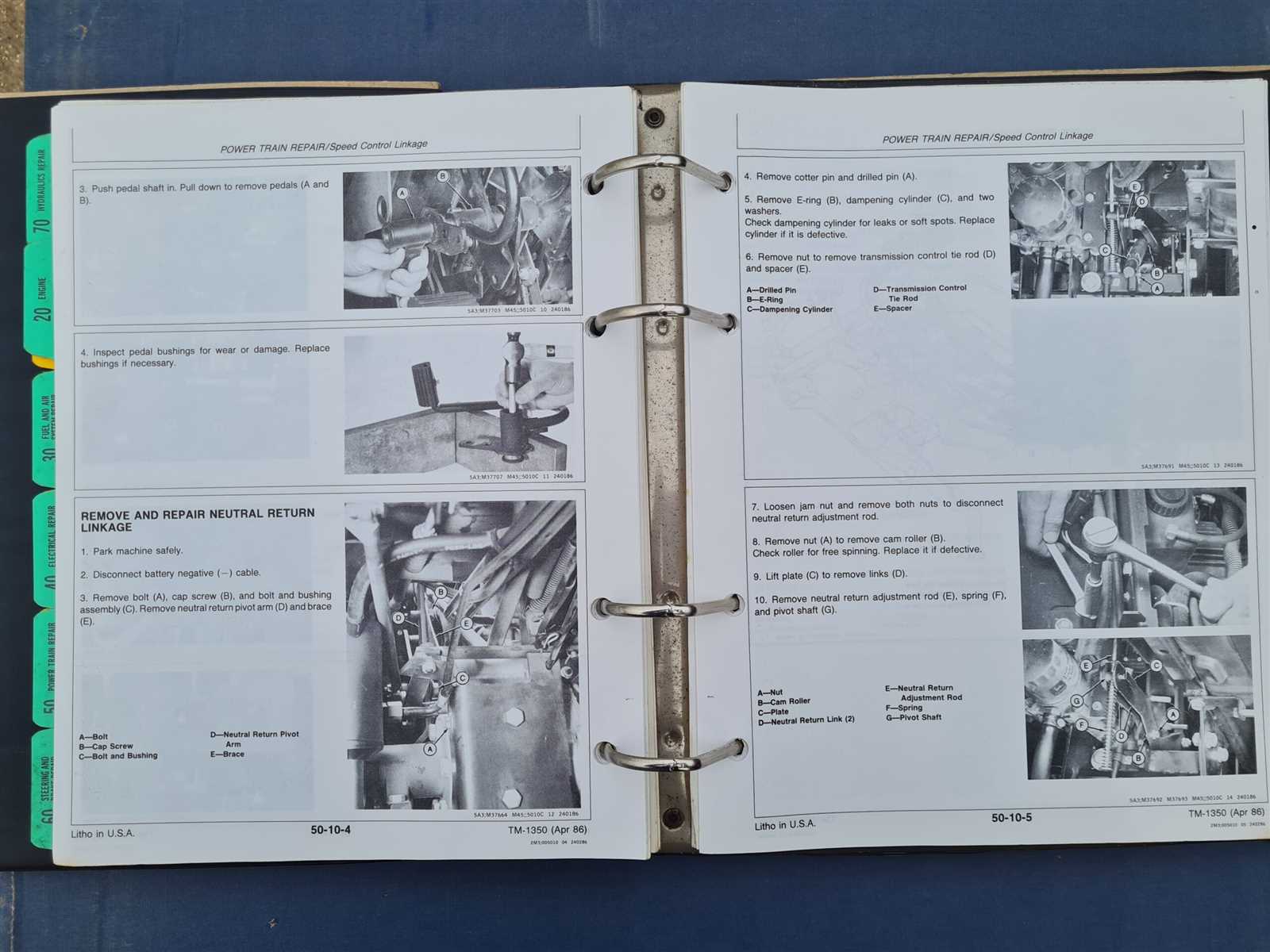

Importance of Accurate Diagrams

Clear and precise illustrations are vital in various fields, serving as essential tools for understanding complex systems. They provide a visual representation that simplifies intricate components, enhancing comprehension and facilitating effective communication.

Accurate visuals play a significant role in numerous applications, including:

- Maintenance and Repair: Detailed illustrations aid technicians in identifying specific components, streamlining repair processes, and minimizing errors.

- Assembly and Installation: Well-crafted visuals guide users through intricate assembly procedures, ensuring correct placement and alignment of parts.

- Training and Education: Effective diagrams serve as teaching aids, helping learners grasp complex concepts through visual aids that complement theoretical knowledge.

- Documentation: Clear illustrations enhance manuals and guides, providing users with a reliable reference that improves usability and reduces confusion.

In conclusion, high-quality representations are indispensable for effective communication, promoting efficiency and accuracy in various technical endeavors. Their importance cannot be overstated, as they bridge the gap between understanding and application.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for anyone involved in maintenance or repair tasks. These illustrations provide a clear overview of the various elements, allowing users to identify and locate specific items easily. By familiarizing yourself with the conventions used in these visuals, you can streamline your repair processes and ensure that you have the correct items for your equipment.

Familiarize Yourself with Symbols and Labels

Each illustration features unique symbols and annotations that indicate specific items. Take the time to study these elements, as they are key to interpreting the visual correctly. Recognizing common abbreviations and symbols will help you quickly understand the layout and relationships between different components.

Follow the Flow of Assembly

Most visuals are designed to represent the assembly sequence or the relationship between items. Pay attention to the flow depicted in the illustration, as it often guides you through the installation or disassembly process. Understanding how components fit together can save time and prevent mistakes during maintenance activities.

Finding OEM Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality original manufacturer components is essential. These authentic items ensure optimal performance and longevity, safeguarding your investment and enhancing reliability. Understanding how to locate these replacements can make a significant difference in the upkeep of your machinery.

Researching Authorized Dealers is one of the most effective methods to obtain genuine components. Authorized retailers often carry a comprehensive inventory of items that meet the manufacturer’s specifications, providing peace of mind that you are purchasing authentic replacements.

Utilizing Online Resources is another excellent approach. Many manufacturers offer online catalogs where you can search for specific components based on model numbers or descriptions. This not only saves time but also provides detailed information about the available items, making it easier to select the right ones for your needs.

Additionally, Networking with Other Owners can be invaluable. Engaging with fellow users through forums or local clubs can yield insights into reliable sources for original components. Shared experiences and recommendations can guide you toward trustworthy suppliers and help you avoid subpar options.

Finally, Consulting the Owner’s Manual is crucial. The manual typically contains valuable information regarding the specifications and compatible components for your equipment. This knowledge is vital for ensuring that you choose the correct replacements and maintain the performance and safety of your machinery.

Tools Required for Maintenance

Proper upkeep of machinery is essential for optimal performance and longevity. Having the right tools on hand is crucial for effective maintenance tasks. The following tools are commonly needed to ensure your equipment remains in top condition and operates smoothly.

- Wrenches: Various sizes of adjustable and fixed wrenches are necessary for loosening and tightening bolts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is essential for accessing different components.

- Socket Set: A comprehensive socket set allows for efficient fastening of nuts and bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Pliers: Needle-nose and regular pliers assist in gripping and manipulating small parts.

In addition to these basic tools, the following items can enhance maintenance efficiency:

- Oil Filter Wrench: Helps in removing and replacing oil filters during routine oil changes.

- Multimeter: Useful for diagnosing electrical issues and ensuring proper function of electrical systems.

- Grease Gun: Essential for lubricating moving parts and ensuring smooth operation.

- Safety Equipment: Gloves, goggles, and ear protection are vital for ensuring personal safety while working on machinery.

Investing in high-quality tools not only facilitates maintenance tasks but also contributes to the overall efficiency and safety of equipment operation.

Maintenance Tips for F935

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. Here are some essential tips to help you keep your machinery in excellent condition.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Check Engine Oil | Every 50 hours | Inspect oil level and condition. Replace if dirty or low. |

| Clean Air Filter | Every 100 hours | Remove dust and debris. Replace if damaged or excessively dirty. |

| Inspect Belts and Hoses | Every 100 hours | Look for wear, cracks, or fraying. Replace if necessary. |

| Sharpen Blades | Every 25 hours | Ensure a clean cut. Dull blades can damage grass and lead to uneven growth. |

| Battery Maintenance | Monthly | Check connections and clean terminals. Test voltage regularly. |

| Grease Moving Parts | Every 50 hours | Lubricate bearings and pivot points to reduce wear and tear. |

Adhering to these guidelines will help you maintain high performance and extend the life of your machine. Always refer to the user manual for specific recommendations related to your model.

Upgrading Your F935 Components

Improving the various elements of your machine can significantly enhance its performance and longevity. Whether you are looking to boost efficiency, increase functionality, or simply replace worn-out components, upgrading is a worthwhile investment. This section will explore the different avenues for enhancement, ensuring that your equipment operates at its best.

When considering upgrades, it’s essential to assess both the current state of your machine and your specific needs. Here are some areas where improvements can be made:

- Engine Performance: Upgrading the engine can lead to better fuel efficiency and increased power. Consider options such as high-performance filters and enhanced exhaust systems.

- Transmission System: Improving the transmission can provide smoother gear shifts and better overall control. Look for updated components that offer improved reliability.

- Suspension: A robust suspension system can improve stability and handling. Upgrading springs and dampers can make a noticeable difference in ride quality.

- Cutting Mechanism: Enhancing the cutting mechanism with new blades or innovative cutting technology can lead to cleaner cuts and reduced maintenance time.

Additionally, consider the following recommendations for effective upgrades:

- Research reliable manufacturers and suppliers to ensure quality components.

- Consult with professionals or experienced users to gain insights into the most effective upgrades.

- Plan for installation, whether you are doing it yourself or hiring a technician.

- Keep records of all upgrades to monitor performance improvements over time.

Investing in upgrades can not only enhance the efficiency of your machinery but also extend its lifespan, making it a valuable endeavor for any operator.

Where to Buy F935 Parts

Finding the right components for your machinery can enhance its performance and longevity. With a variety of sources available, it’s essential to know where to look for high-quality replacements. This section will guide you through the most reliable avenues to obtain the necessary items for your equipment.

Authorized Dealers

One of the most dependable options is to visit authorized dealerships. These locations offer genuine replacements that meet the manufacturer’s specifications. They often provide expert advice and support, ensuring that you select the right item for your needs. Checking the official website for a dealer locator can help you find a nearby establishment.

Online Retailers

The internet offers a vast marketplace for purchasing machinery components. Numerous online platforms specialize in these items, providing a wide range of options at competitive prices. Ensure that you read customer reviews and check return policies before making a purchase. Additionally, websites focusing on used equipment can be valuable for finding more affordable alternatives.

F935 Parts Compatibility Guide

This section aims to assist users in identifying suitable components for their machinery, ensuring optimal performance and longevity. Understanding compatibility between various elements is crucial for maintaining the equipment’s efficiency and functionality.

Understanding Component Compatibility

When selecting replacements or upgrades, it is essential to consider the specifications and requirements of the machinery. Different models may have varying needs, so consulting compatibility charts and manufacturer recommendations can significantly enhance decision-making. This approach minimizes the risk of errors and promotes a smoother operation.

Commonly Used Components

Some frequently sought-after items include engine components, drive mechanisms, and hydraulic systems. Each element must be evaluated for its fit and functionality within the specific framework. Utilizing genuine components or approved alternatives often ensures reliability and durability.

In conclusion, knowing the right alternatives enhances the maintenance process and contributes to the equipment’s overall performance. Always refer to trusted resources to verify the compatibility of your selected components.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in identifying and resolving issues within complex machinery. They provide a clear view of component relationships and functionalities, enabling users to pinpoint potential failures more efficiently. By interpreting these visuals, technicians can systematically approach problems, ensuring that no critical elements are overlooked.

Benefits of Visual Guides

- Enhanced Understanding: Visuals simplify complex systems, making it easier to comprehend how various elements interact.

- Streamlined Diagnostics: With a clear layout, troubleshooting becomes quicker and more organized, allowing for faster identification of faulty components.

- Effective Communication: Visual aids facilitate discussions among team members, ensuring everyone is aligned on the issues at hand.

Best Practices for Using Visual Aids

- Always refer to the most current visual representations to ensure accuracy in your assessments.

- Cross-reference visuals with written documentation for a comprehensive understanding of the system.

- Take notes while reviewing the visual aids to capture important observations and insights.