Ball Joints: These pivot points enable smooth movement of the control arms, ensuring flexibility while maintaining structural integrity

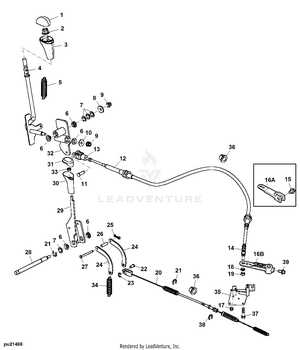

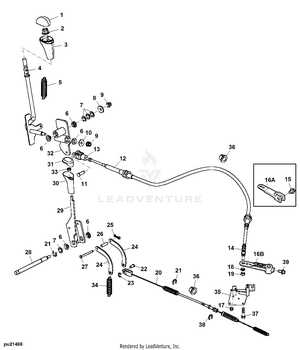

Steering Mechanism and Assembly

The steering system is an essential part of the vehicle, ensuring precise control and maneuverability. This mechanism allows the driver to navigate and direct the wheels with ease, enhancing overall handling and responsiveness. Proper maintenance of these components is vital for safe and smooth operation.

Key Components: The assembly consists of interconnected parts that work in harmony. The steering wheel transmits input to the linkage system, which then controls the movement of the wheels. Every element must be in good condition to avoid steering difficulties and ensure optimal performance.

Regular inspection of the gear system, rods, and connectors helps prevent wear and tear. Lubrication and alignment checks are necessary to maintain the efficiency of the steering assembly. Addressing minor issues early can prevent larger problems and ensure a safer driving experience.

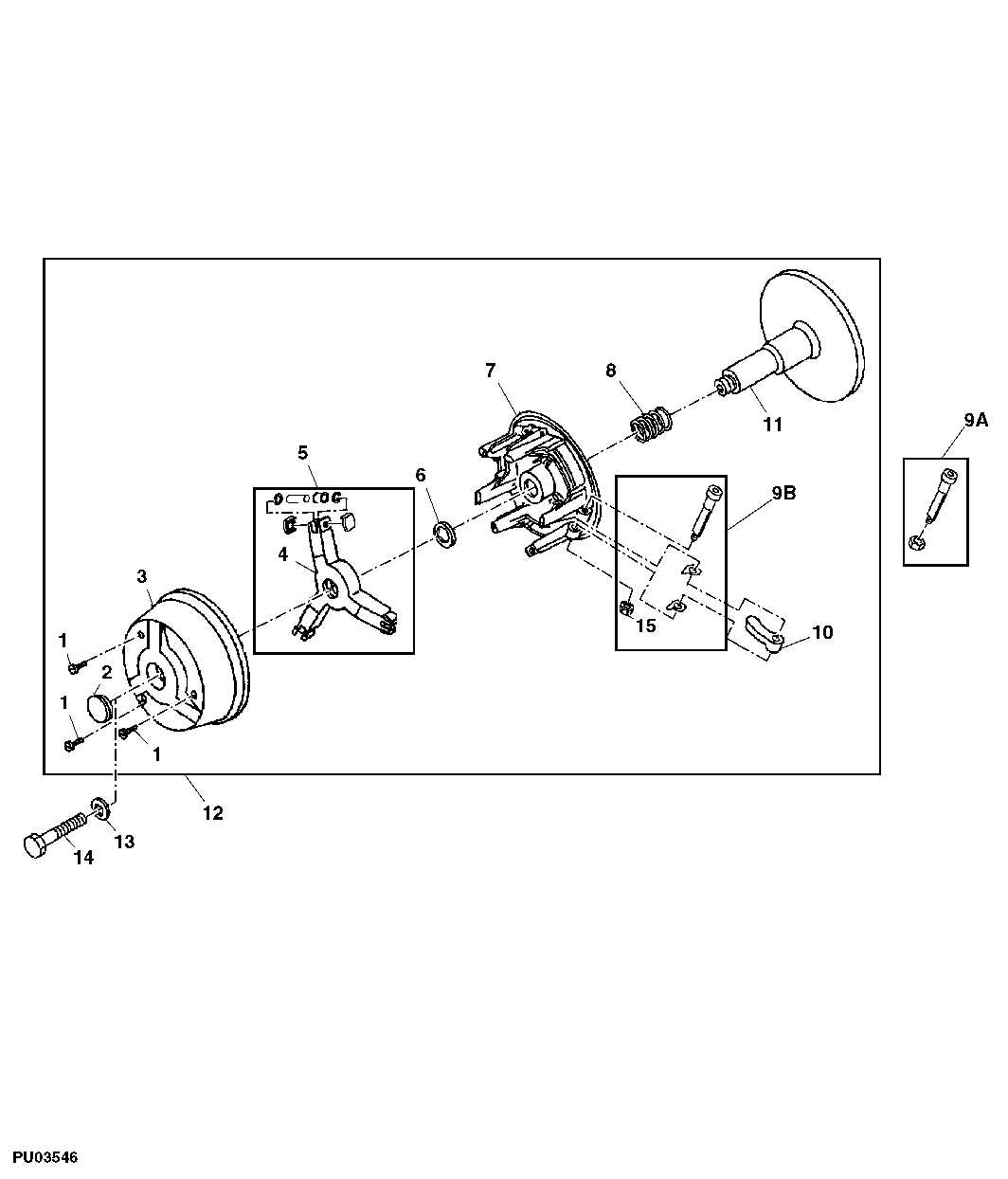

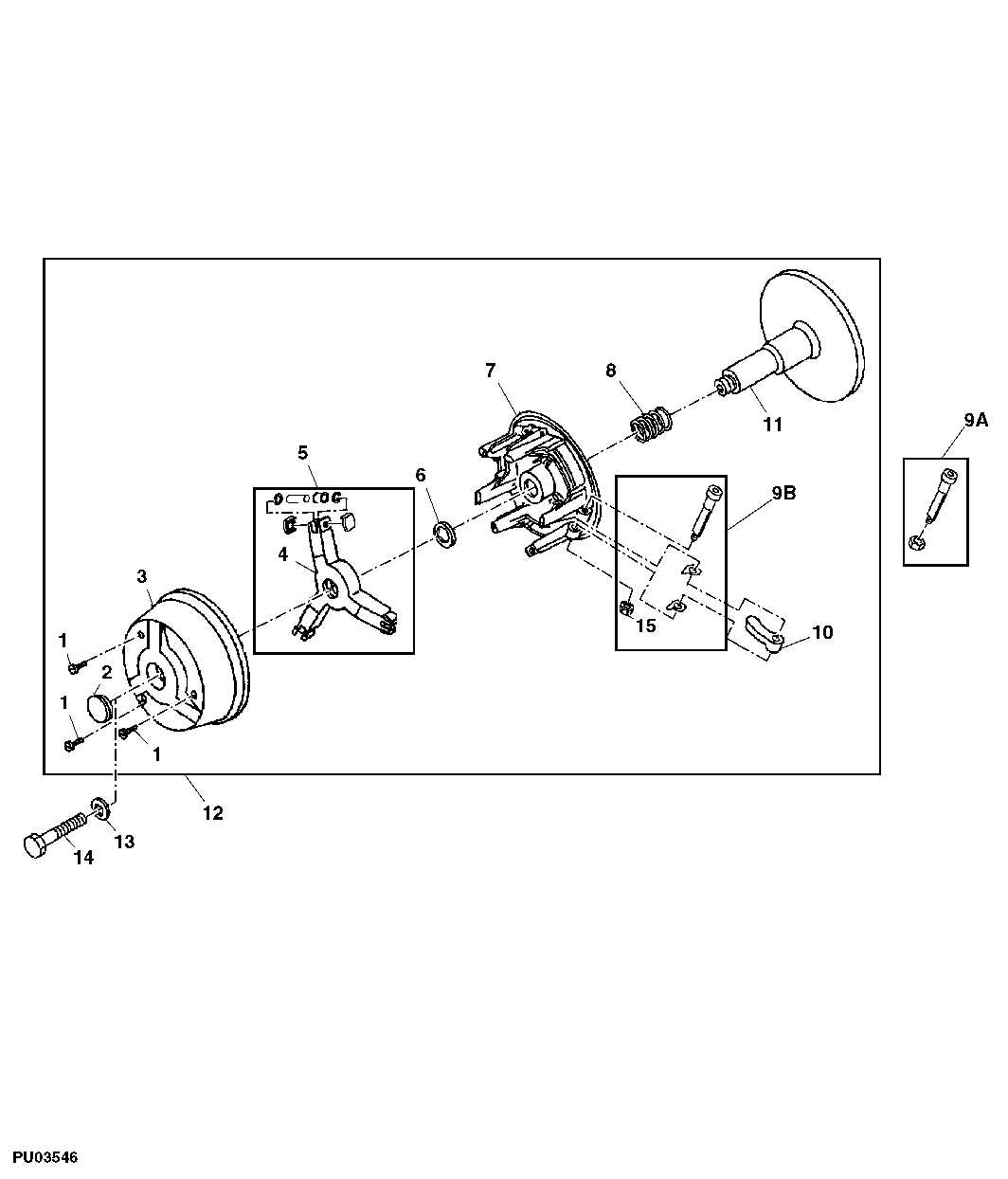

Brake System Components Overview

The braking system is a crucial aspect of any vehicle, ensuring safe and reliable operation. Understanding the different elements involved in this system can help in maintaining optimal performance and addressing potential issues. This section provides an overview of the essential components that make up the braking mechanism.

Key Components

- Brake Pads: These are the friction materials that press against the brake rotors to create the necessary stopping force.

- Brake Rotors: Also known as discs, they are the surfaces against which the brake pads are applied to slow down or stop the vehicle.

- Calipers: The calipers house the brake pads and are responsible for applying pressure to them against the rotors.

- Brake Lines: These tubes transport brake fluid from the master cylinder to the calipers, enabling the system to function effectively.

- Master Cylinder: This component generates hydraulic pressure to actuate the calipers, allowing the vehicle to stop.

Maintenance Tips

- Regularly inspect brake pads for wear and replace them as needed.

- Check the brake fluid level and quality to ensure optimal performance.

- Inspect brake lines for leaks or damage to maintain hydraulic integrity.

- Examine rotors for signs of warping or excessive wear, which can affect braking efficiency.

Electrical Parts and Wiring Diagram

This section provides a comprehensive overview of the electrical components and their interconnections within the vehicle’s system. Understanding these elements is essential for effective troubleshooting and maintenance.

| Component |

Description |

| Battery |

Supplies power to the electrical system and starts the engine. |

| Starter Motor |

Engages the engine to initiate the combustion process. |

| Alternator |

Charges the battery and powers electrical accessories when the engine is running. |

| Fuse Box |

Protects the electrical circuits by breaking the connection in case of overload. |

| Ignition Switch |

Controls the power flow to the ignition system. |

| Wiring Harness |

Connects various electrical components and facilitates communication between them. |

Fuel System and Tank Layout

The fuel system is a vital component of any utility vehicle, playing a crucial role in ensuring efficient operation. This section delves into the configuration and organization of the fuel tank and related elements, providing insights into their functionality and maintenance.

Overview of the Fuel System

The fuel system encompasses various components that work together to store and supply fuel to the engine. Understanding the layout of these elements is essential for proper maintenance and troubleshooting.

- Fuel Tank: The primary storage unit for fuel, typically located at the rear or under the vehicle.

- Fuel Lines: These conduits transport fuel from the tank to the engine, ensuring a continuous supply.

- Fuel Pump: This component draws fuel from the tank and pushes it through the fuel lines, providing the necessary pressure for optimal engine performance.

- Fuel Filter: A crucial element that removes impurities from the fuel before it reaches the engine, protecting it from potential damage.

Maintenance Tips

Regular maintenance of the fuel system is vital for longevity and performance. Consider the following recommendations:

- Inspect the fuel tank for any signs of leaks or damage.

- Check fuel lines for cracks or wear to prevent fuel loss.

- Replace the fuel filter according to the manufacturer’s guidelines to ensure clean fuel supply.

- Monitor the fuel pump’s performance and listen for unusual noises that may indicate a problem.

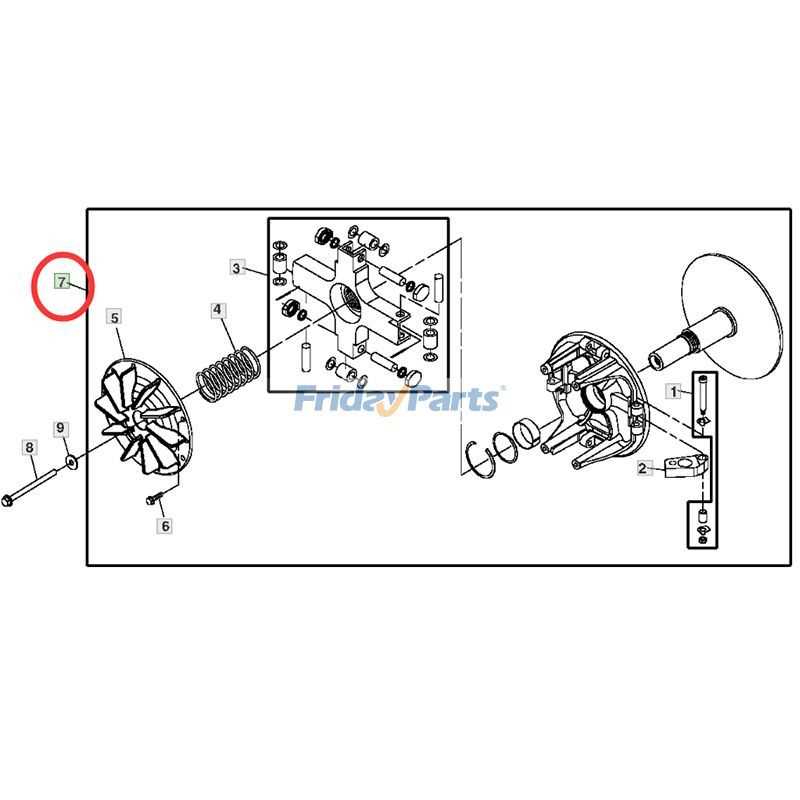

Cooling System Parts Explained

The cooling system plays a vital role in maintaining optimal operating temperatures for various machinery. Understanding its components is essential for effective maintenance and troubleshooting. This section delves into the key elements that contribute to efficient heat management.

Key Components of the Cooling System

- Radiator: This component dissipates heat from the coolant, ensuring the engine stays within a safe temperature range.

- Coolant Reservoir: A container that holds excess coolant and allows for expansion, helping to regulate fluid levels.

- Water Pump: Responsible for circulating coolant throughout the system, maintaining consistent flow.

- Thermostat: A valve that controls coolant flow based on temperature, ensuring efficient operation.

- Hoses: Flexible tubes that transport coolant between different components, providing essential connections.

Importance of Regular Maintenance

Regular upkeep of the cooling system is crucial for preventing overheating and potential damage. Monitoring coolant levels, inspecting hoses for leaks, and ensuring the radiator is clean can significantly enhance the performance and longevity of machinery. By understanding these essential components, operators can better manage their equipment’s cooling efficiency.

Body Panels and Exterior Parts

The exterior components of utility vehicles play a crucial role in both functionality and aesthetics. These elements not only protect the internal mechanisms but also contribute to the overall look and feel of the machine. Understanding the various sections of the outer shell is essential for maintenance and customization.

Fenders are vital for safeguarding the wheels and preventing debris from being thrown while driving. They come in different shapes and sizes, ensuring that the vehicle can navigate various terrains with ease.

Body panels encompass the sides and rear of the vehicle, providing structural integrity and contributing to aerodynamics. These panels can be replaced or upgraded to enhance durability and style.

Grilles and front covers not only give a distinctive look but also serve to protect the engine area from foreign objects. Ensuring these components are in good condition is key for optimal airflow and engine cooling.

Finally, tailgates and access doors offer convenience for loading and unloading cargo. Their design often reflects a balance between strength and accessibility, making them essential for utility and transport.

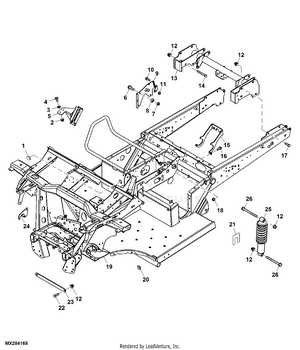

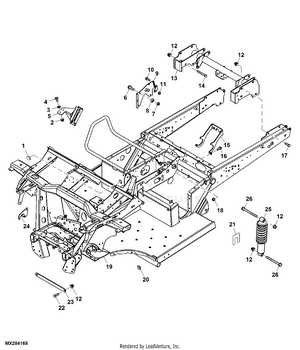

Chassis and Frame Diagram

The structural framework of an off-road vehicle plays a crucial role in its overall functionality and performance. Understanding the configuration and components of this framework is essential for maintenance and upgrades. This section explores the various elements that contribute to the stability and durability of the vehicle’s body.

Key Components of the Structure

Several vital elements form the foundation of the vehicle’s body. These include the main chassis, cross members, and support brackets, which work together to provide strength and stability. Each component is designed to endure the stresses encountered during operation, ensuring longevity and reliability.

Maintenance Considerations

Regular inspection of the structure is necessary to identify any signs of wear or damage. Maintaining the integrity of the framework helps in preventing larger issues that could affect overall performance. Ensuring that all parts are securely attached and free from corrosion is crucial for safe operation.

Tire and Wheel Components

The functionality of a vehicle relies heavily on its wheel and tire assembly. These elements play a crucial role in providing stability, traction, and overall performance, ensuring a smooth ride across various terrains. Understanding the different components involved is essential for maintaining optimal operation and longevity.

Tire Specifications

Tires are designed with specific attributes that cater to diverse environments. Factors such as tread patterns, rubber composition, and size significantly impact performance and safety. Selecting the right tire is vital for enhancing grip and handling capabilities.

Wheel Features

Wheels are not merely structural supports; they are engineered to work harmoniously with tires. Key characteristics, such as diameter, width, and material, contribute to the overall efficiency of the vehicle. A well-chosen wheel can improve responsiveness and reduce wear on the tires.

| Component |

Description |

| Tread Pattern |

Influences traction and water dispersal. |

| Sidewall Height |

Affects ride comfort and handling. |

| Wheel Diameter |

Determines compatibility with tires. |

| Material |

Impacts weight and durability. |

Maintenance Tools and Accessories

Proper upkeep of your utility vehicle is essential for ensuring its longevity and optimal performance. A variety of tools and supplementary items are available to aid in routine checks and repairs. These resources not only facilitate efficient maintenance but also enhance the overall functionality of the vehicle.

Essential Tools for Upkeep

- Wrenches and Sockets: Crucial for tightening and loosening bolts.

- Screwdrivers: Useful for adjusting various components.

- Grease Gun: Essential for applying lubricant to moving parts.

- Tire Pressure Gauge: Important for maintaining correct tire inflation.

Recommended Accessories

- Floor Jack: Facilitates lifting the vehicle for underbody access.

- Toolbox: Keeps all tools organized and easily accessible.

- Protective Gear: Includes gloves and goggles to ensure safety during maintenance tasks.

- Cleaning Supplies: Helps maintain the exterior and interior cleanliness.